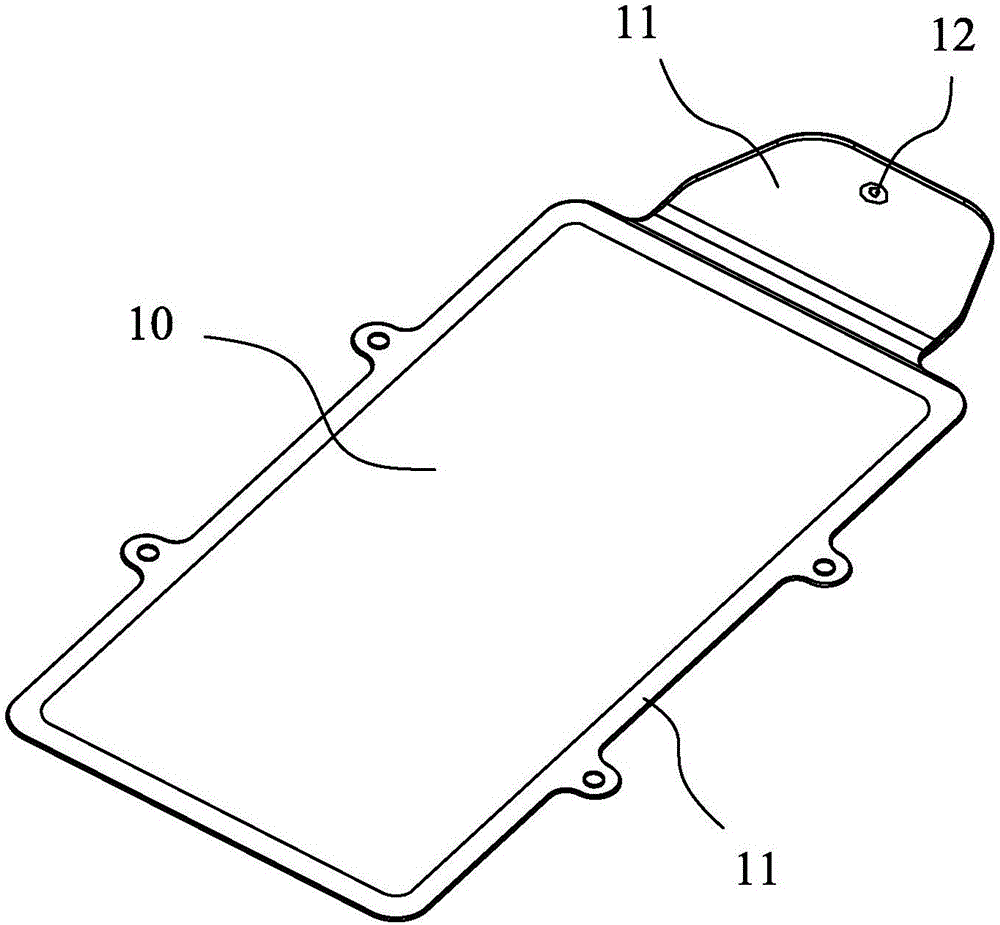

Manufacturing method of high-hardness plastic screen and housing of mobile phone and mobile phone screen and housing manufactured thereby

A production method and mobile phone screen technology, applied in chemical instruments and methods, telephone structure, telephone communication, etc., can solve problems such as increasing user cost, affecting normal use of users, and fragile glass screen, so as to improve clarity , enhance the overall hardness, increase the effect of light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

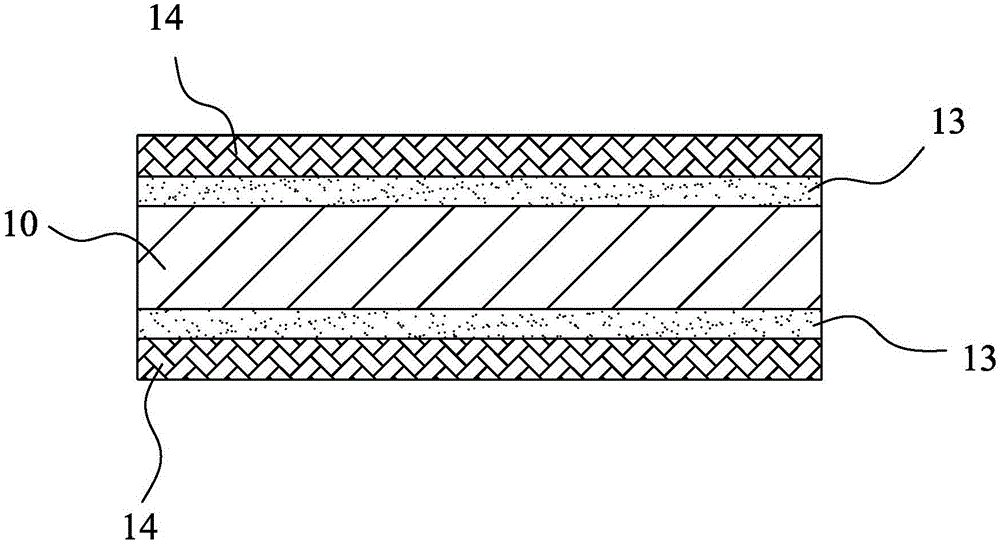

[0028] A method for manufacturing a high-hardness plastic mobile phone screen and case, comprising the following steps:

[0029] (1) Secondary compression molding: First, close the injection mold and lock the first parting surface of the injection mold, and then move the clamping cylinder back by 0.2mm, so that the second parting surface of the injection mold has a certain mold opening. space, and then inject plastic raw materials into the injection mold. The second parting surface is opened by 0.2mm under pressure. After the injection is completed, the clamping cylinder advances and locks the second parting surface. After cooling, the mold is opened to obtain a molded part. plastic substrate;

[0030] (2) The plastic substrate is cleaned and dried for the first time by using the dry air after destaticization, and the dew point of the dry air is -40°C;

[0031] (3) The first soaking: soak the plastic substrate after the first cleaning and drying into the adhesive, so that a laye

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap