Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Chemical vapor deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high quality, high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

Eluting, implantable medical device

Owner:COOK INC

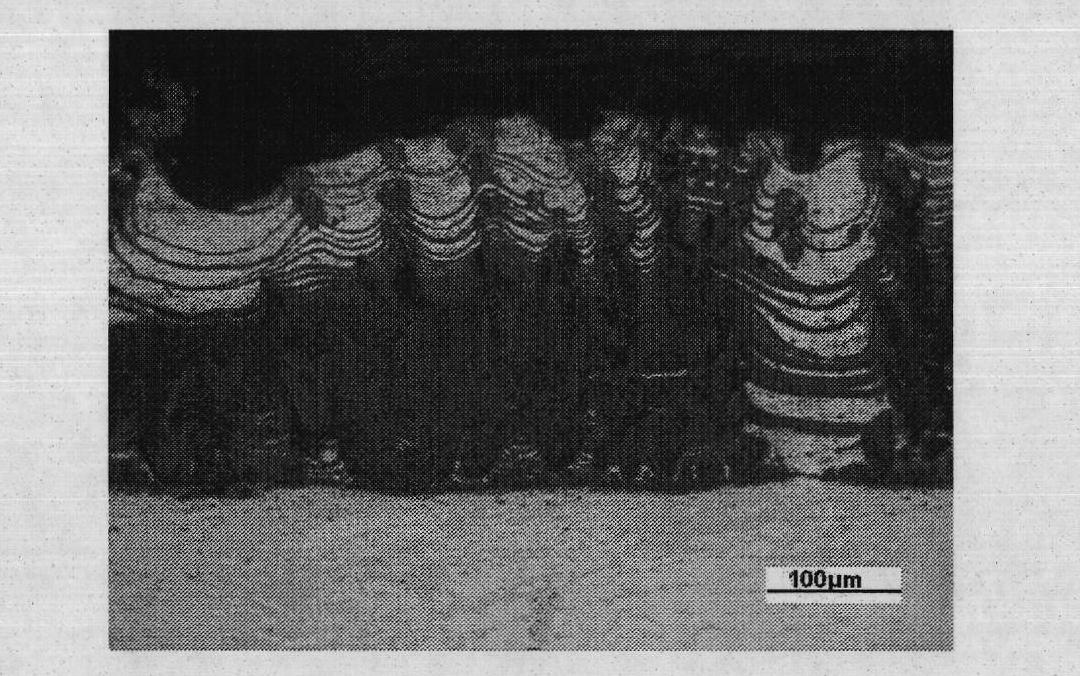

Aluminum and aluminum alloy matrix aluminum nitride reinforced gradient composite surface layer

InactiveCN101880854AImprove wear resistanceSolid state diffusion coatingSurface gradientSurface layer

Owner:JILIN UNIV

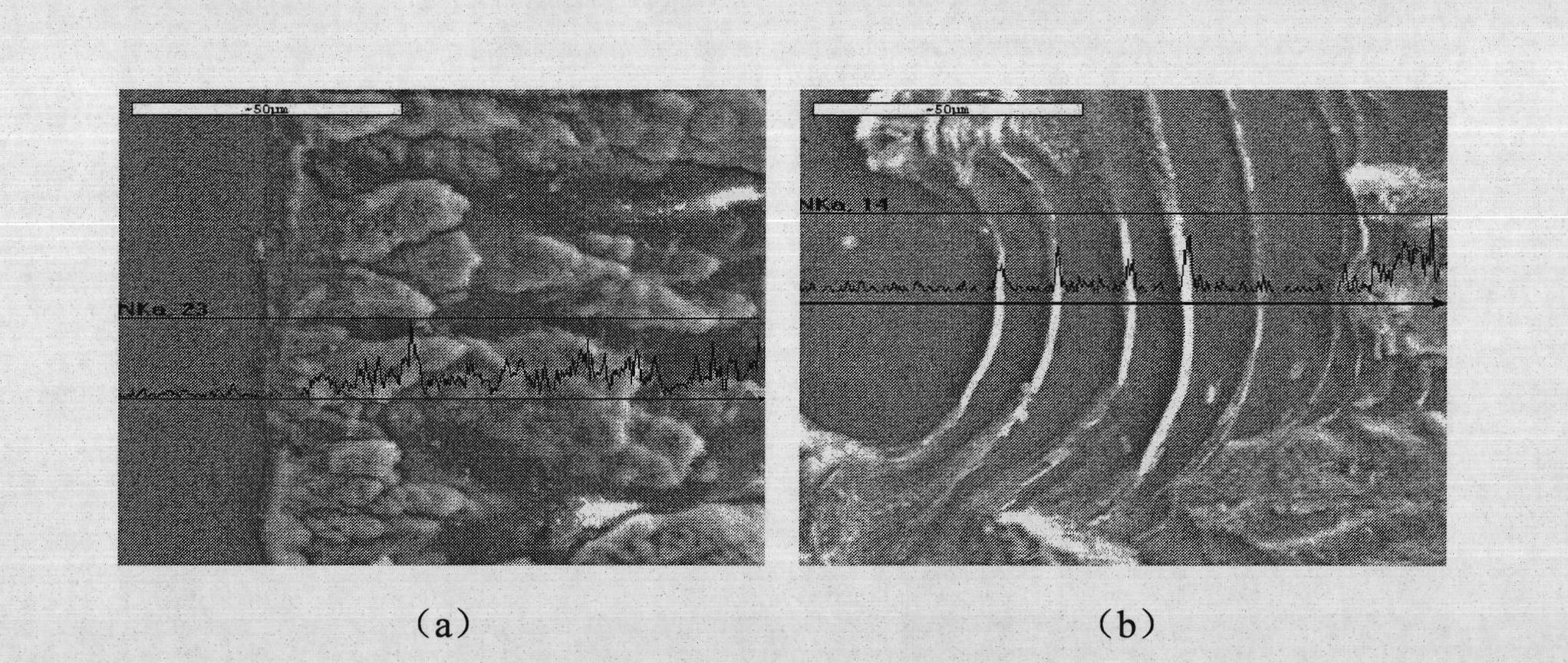

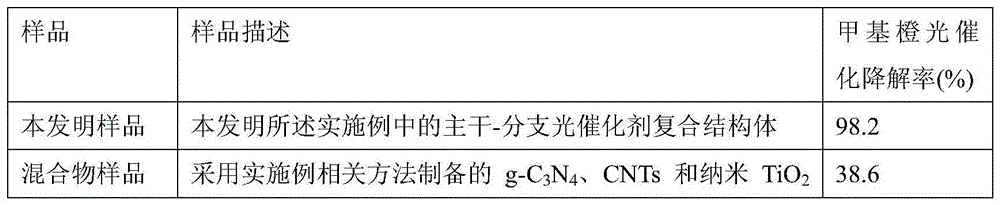

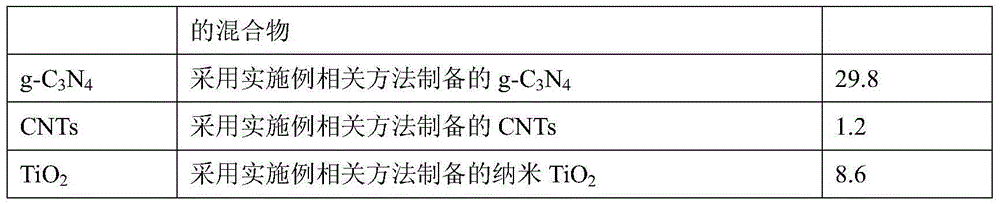

Photocatalyst composite structure and preparation method thereof

InactiveCN104801325AImprove adsorption capacityLarge specific surface areaPhysical/chemical process catalystsHydrogen productionDecompositionCarbon nanotube

Owner:EAST CHINA UNIV OF SCI & TECH +1

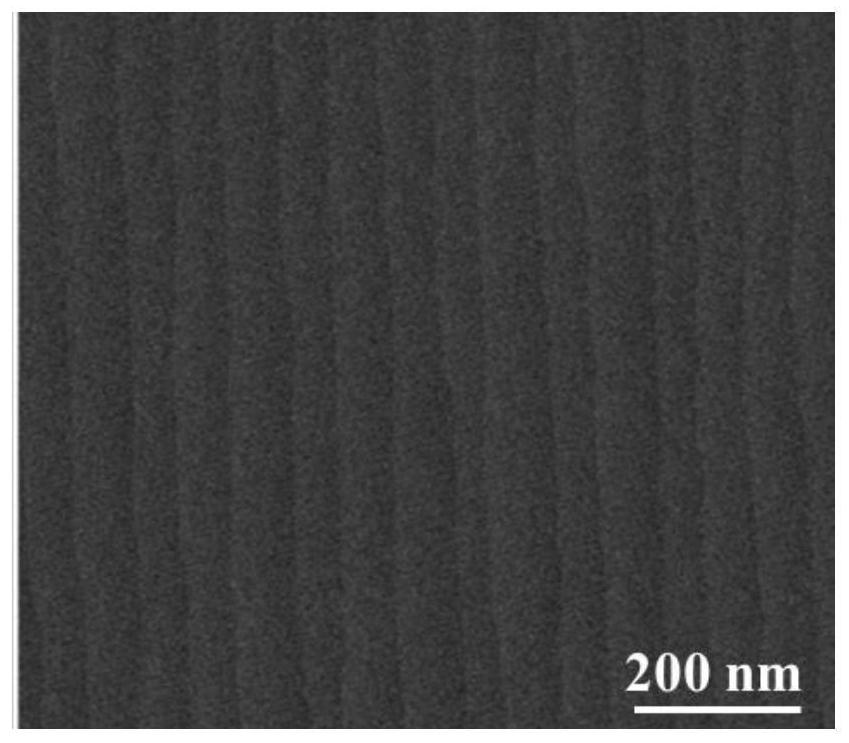

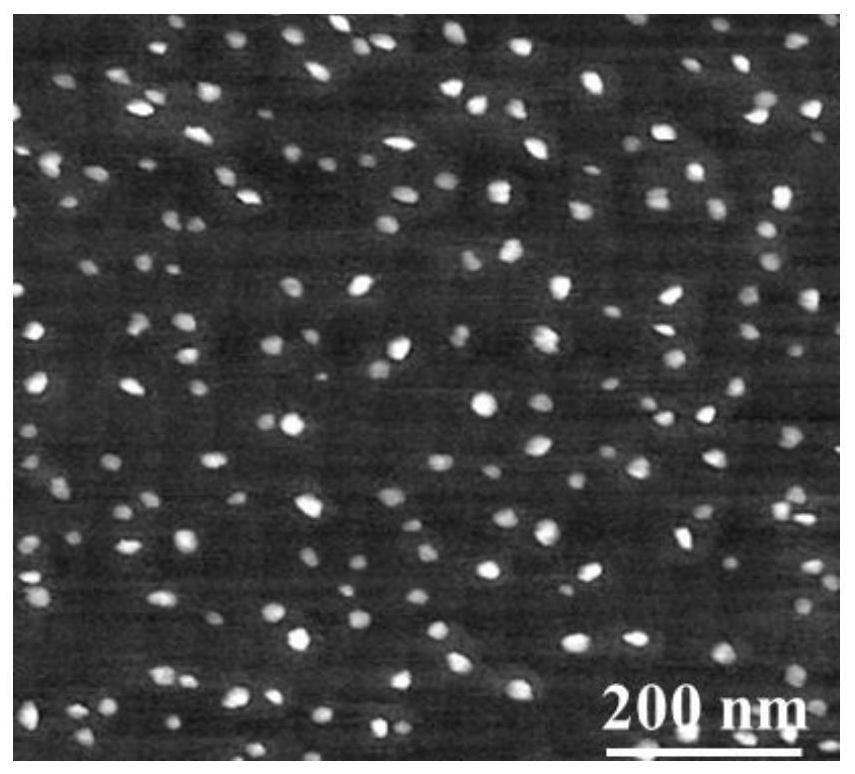

Super-clean graphene and preparation method thereof

The invention discloses super-clean graphene and a preparation method thereof. The preparation method of the super-clean graphene comprises the following steps: putting foam copper on a copper substrate, and attaching; leading carbon source gas and hydrogen to perform chemical vapor deposition; after deposition is completed, obtaining the super-clean graphene at the contact surface of the copper substrate and the foam copper. The preparation method has the advantages that the preparation method is simple and is suitable for large-scale production, the continuous clean area reaches the sub-centimeter level, and the preparation method is suitable for the fields of electronics, optics and the like.

Owner:PEKING UNIV

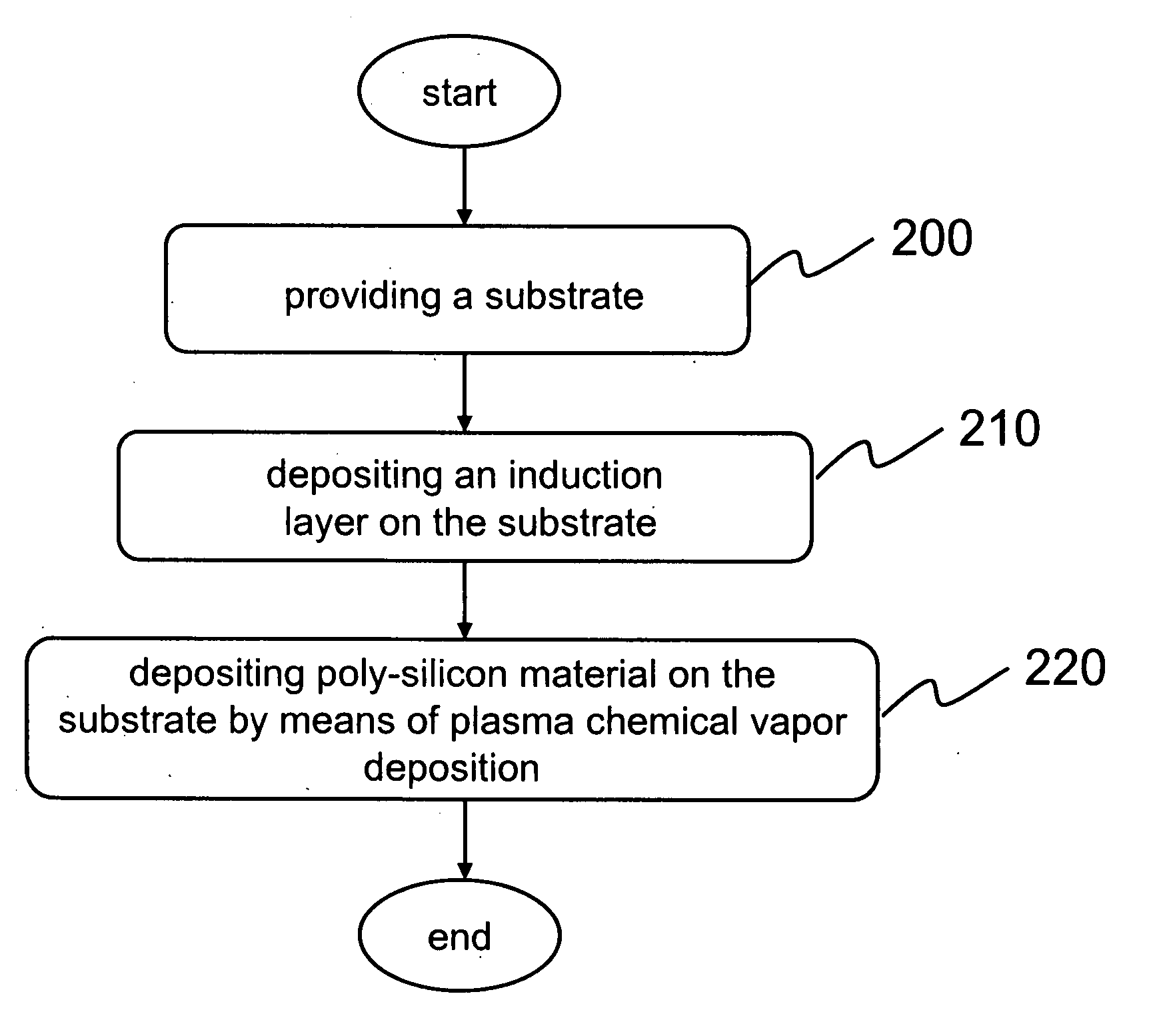

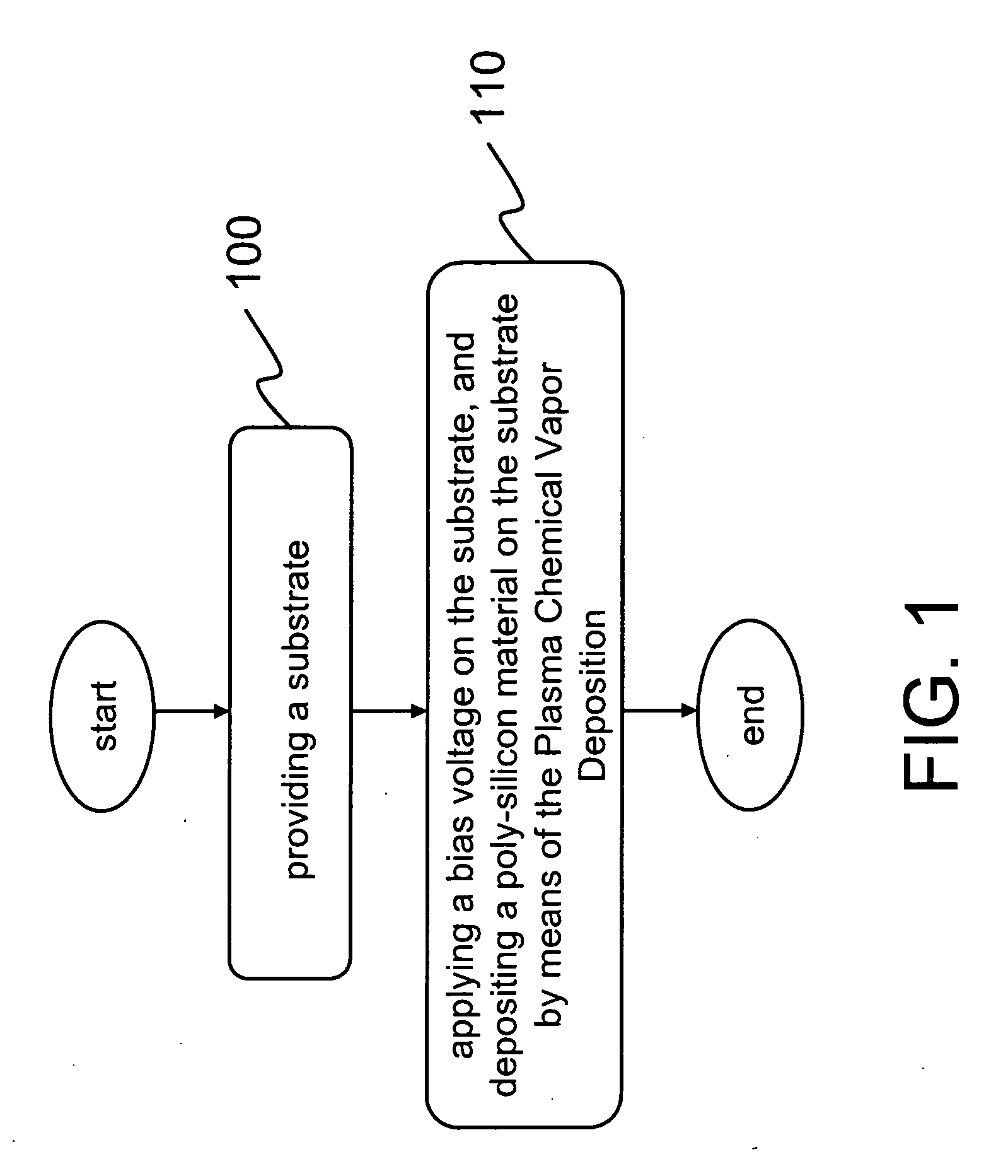

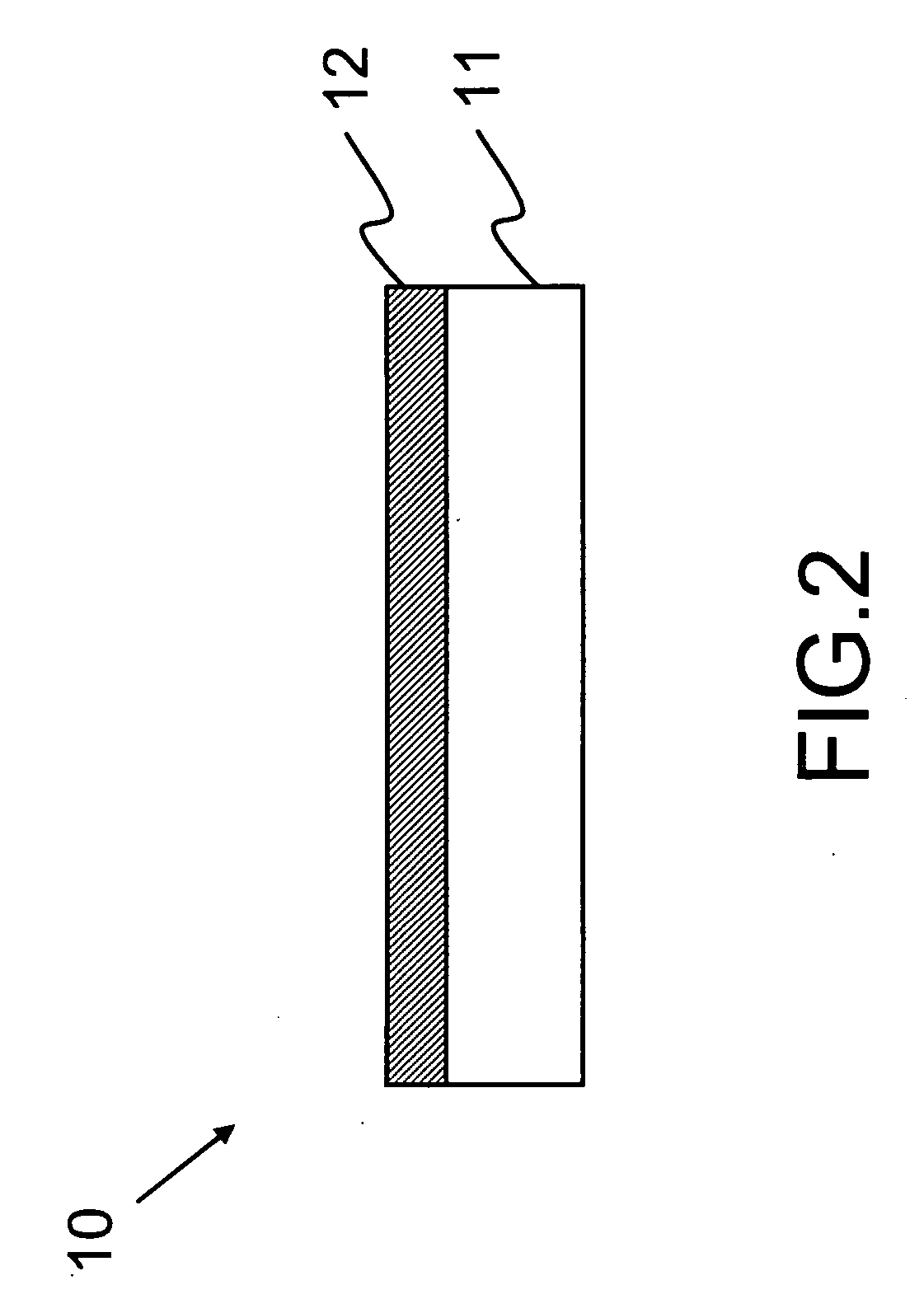

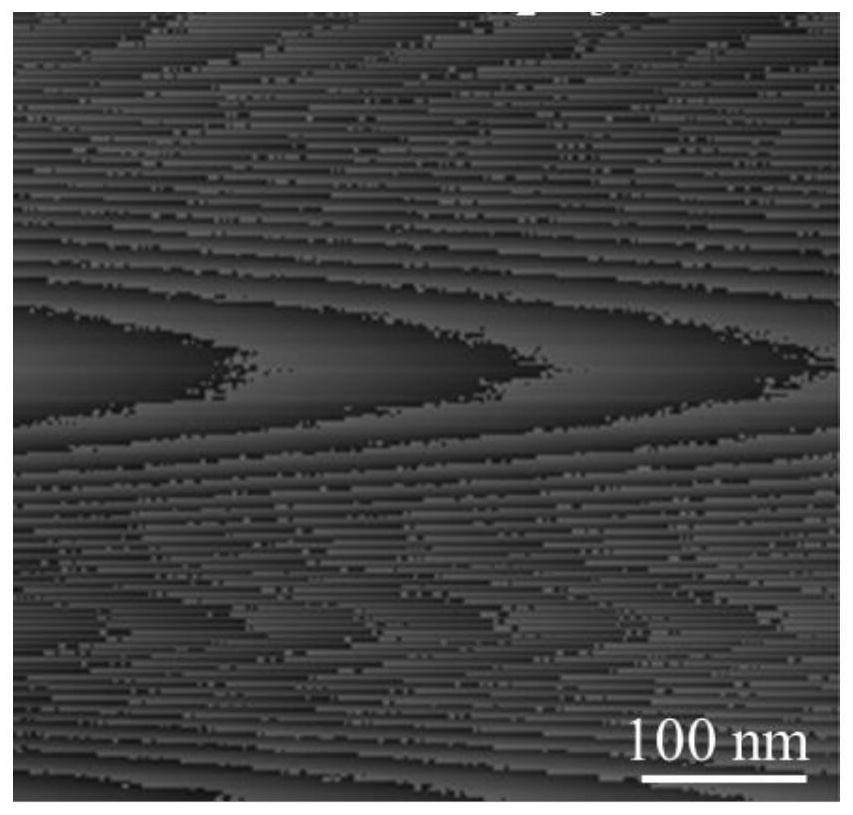

Element of low temperature poly-silicon thin film and method of making poly-silicon thin film by direct deposition at low temperature and inductively-coupled plasma chemical vapor deposition equipment therefor

InactiveUS20070077735A1Quality improvementReduce thicknessPolycrystalline material growthSolid-state devicesInductively coupled plasmaSilicon thin film

Owner:IND TECH RES INST

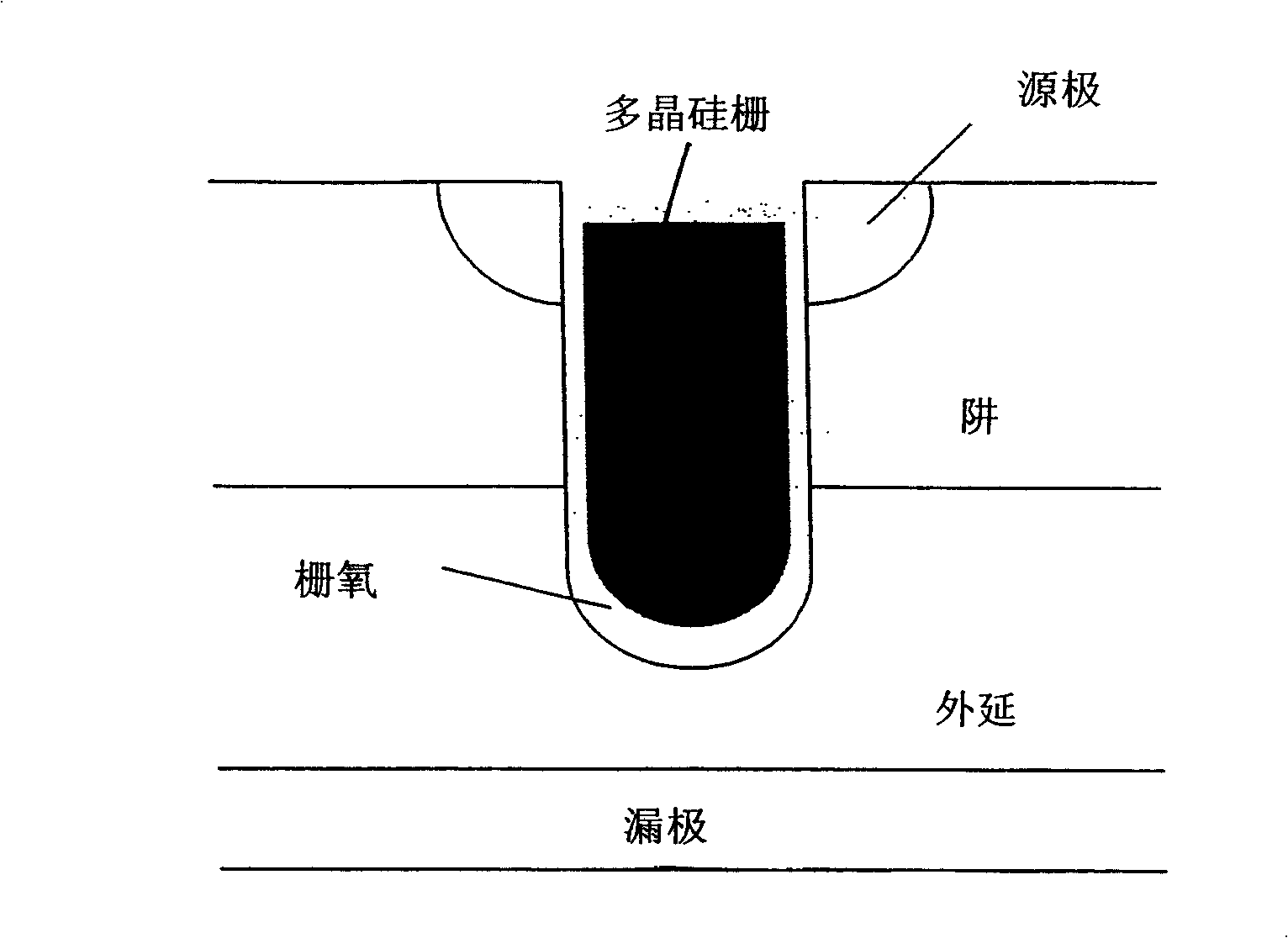

Semiconductor device with contact etching stop layer and forming method thereof

InactiveCN101740498AAvoid phenomena such as poor reliabilityAvoid damageSemiconductor/solid-state device detailsSolid-state devicesHigh densityGate oxide

The invention discloses a method for forming a semiconductor device with a contact etching stop layer, which comprises the following steps of: providing a substrate on which at least one grid structure is formed; putting the substrate in a settling chamber to carry out the settlement of the contact etching stop layer; oxidizing the contact etching stop layer in situ to form an oxide film on the surface of the contact etching stop layer; taking out the substrate on which the oxide film is formed; and forming an interlayer dielectric layer on the oxide film by high-density plasma chemical vapour deposition equipment. The invention also discloses the semiconductor device with the contact etching stop layer. The semiconductor device with the contact etching stop layer and the forming method thereof of the invention can effectively prevent damages which are caused by using the high-density and large-power plasma in the step of settling the interlayer dielectric layer to a gate oxide layer and voids phenomena of device performance drift, device reliability reduction and the like.

Owner:SEMICON MFG INT (BEIJING) CORP

5G-based high-performance electromagnetic shielding material and preparation method thereof

InactiveCN111875921AImprove absorbing performanceLight in massMagnetic/electric field screeningCarbide siliconNanowire

The invention discloses a 5G-based high-performance electromagnetic shielding material, of which the volume density is less than 2.5 g / cm3 and the electromagnetic shielding efficiency is greater than85dB; the high-performance electromagnetic shielding material is composed of foamy carbon, silicon carbide nanowires, graphene and phenolic resin. The preparation method comprises the following steps:taking organic foam as a raw material, carrying out pyrolysis at high temperature to prepare foam carbon, then carrying out in-situ growth of silicon carbide nanowires in the foam carbon by adoptinga chemical vapor deposition (CVI) method and Ni catalysis to obtain a silicon carbide nanowire reinforced foam carbon matrix, and then carrying out vacuum pressure impregnation with graphene modifiedresin, thereby finally obtaining the silicon carbide nanowire reinforced foam carbon material of the graphene modified resin. The material has a good shielding effect on high-frequency electromagneticwaves, the shielding bandwidth is large, the heat dissipation performance is good, and meanwhile structure and function integration is achieved.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

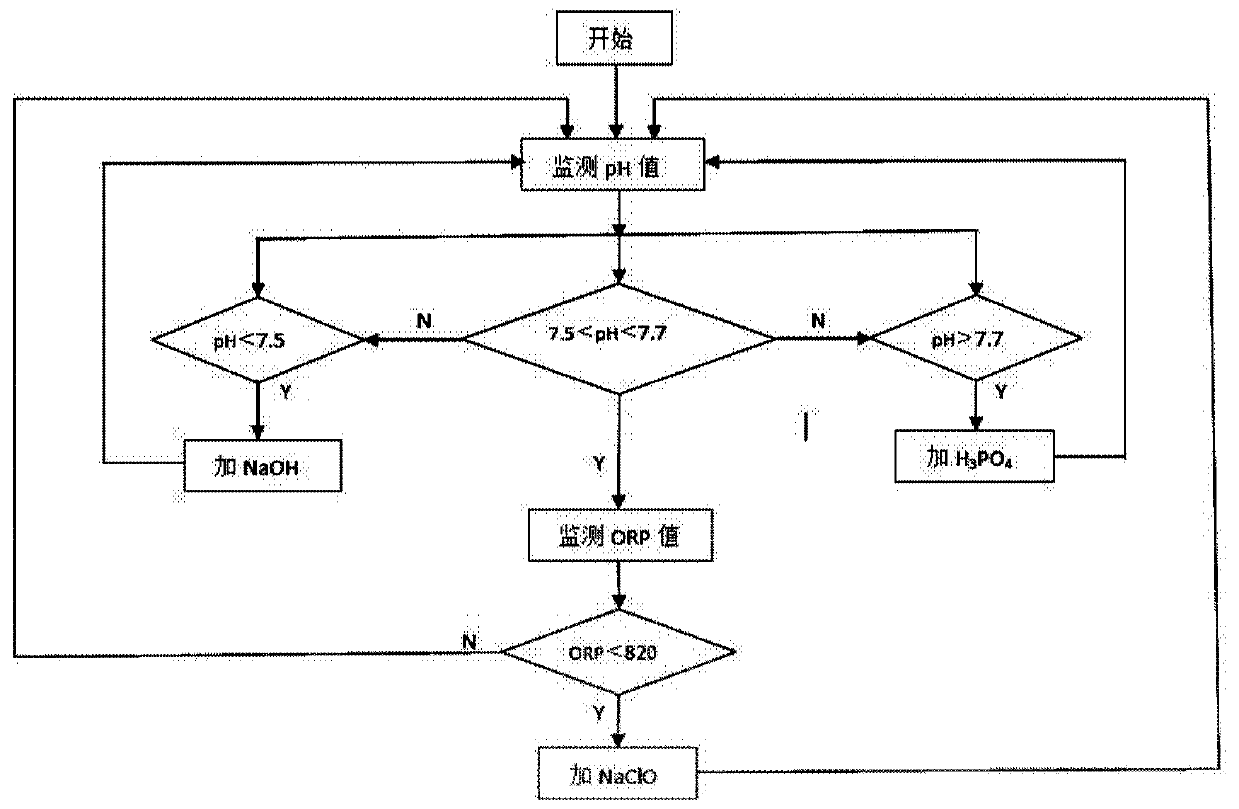

A kind of etching method of diffusion layer of crystalline silicon solar cell

InactiveCN102290491ASimple processLow equipment requirementsAfter-treatment detailsFinal product manufactureEtchingPhosphoric acid

Owner:WUXI SAIJING SOLAR

Preparation method and application of wafer-level absolute single-layer transition metal chalcogenide

ActiveCN113088922AImprove crystal qualityLarge single crystal sizeFinal product manufactureChemical vapor deposition coatingPhysical chemistrySingle crystal

Owner:NORTHWESTERN POLYTECHNICAL UNIV

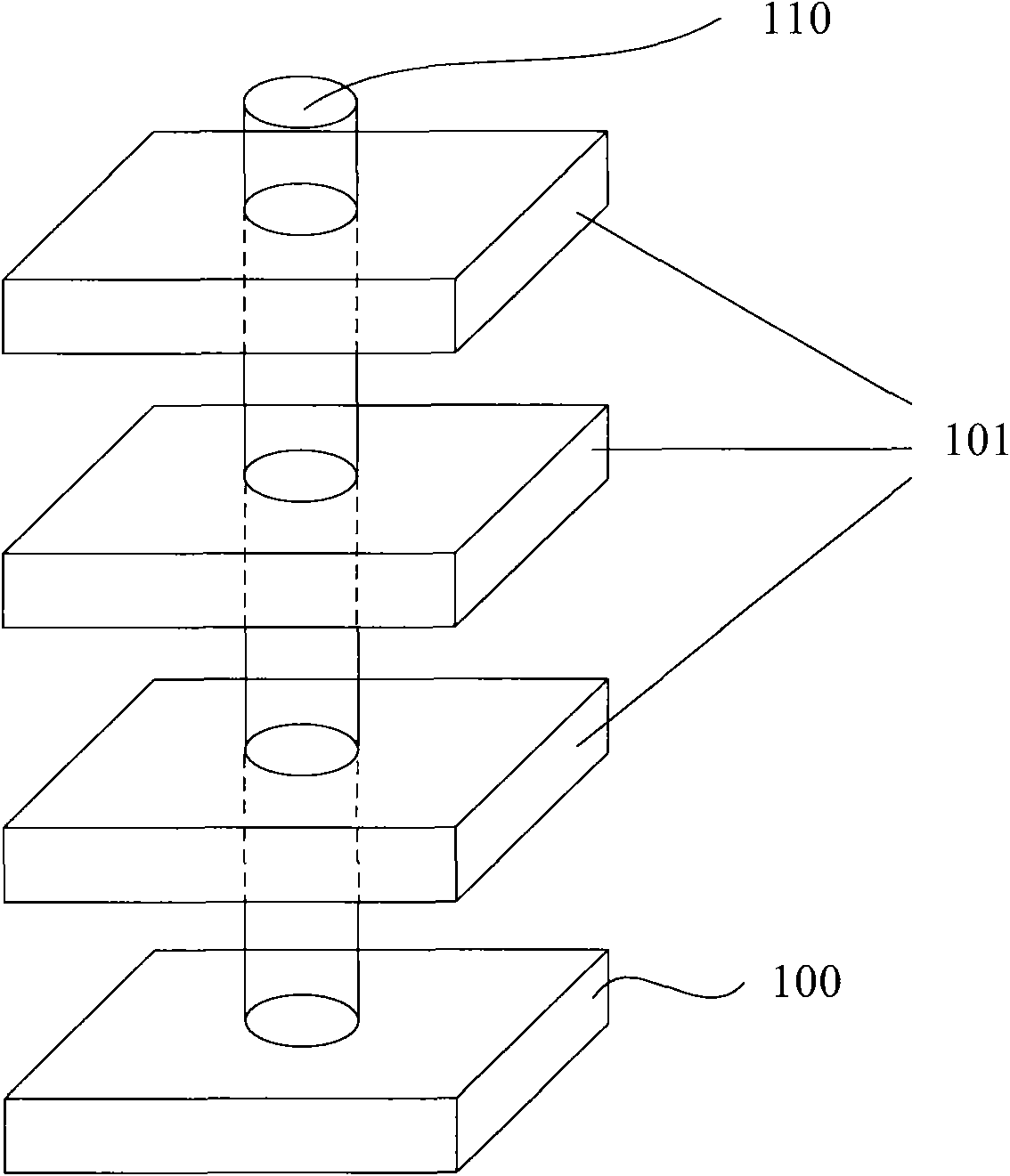

Multilayer body and method for producing same

An object of the invention is to provide a laminate which is good in adhesiveness between a substrate and a thin film laminated thereon by a dry film-forming method such as a chemical vapor growth method or a vacuum evaporation method even if the substrate is a polymer substrate made of a nonpolar polymer; and a process for producing the same. In order to attain the above-mentioned object, the invention provides a laminate comprising a polymer substrate, a primer layer comprising a cyclized rubber which is a conjugated diene polymer cyclized product or a derivative thereof, the layer being formed on the surface of the polymer substrate, and a thin film laminated on the surface of the primer layer by a dry film-forming method; and a process for producing the same. The present invention also provides a laminate comprising a polymer substrate in which a cyclized rubber which is a conjugated diene polymer cyclized product or a derivative thereof is incorporated into a polymer-molding material, and a thin film laminated on the surface of the polymer substrate by a dry film-forming process; and a process for producing the same.

Owner:ZEON CORP

Method for preparing cubic boron nitride single crystal-film homogeneous P-N junction

InactiveCN101807519AReduce processing difficultyIncrease productivitySemiconductor/solid-state device manufacturingDiffusion methodsSynthesis methods

Owner:JILIN UNIV

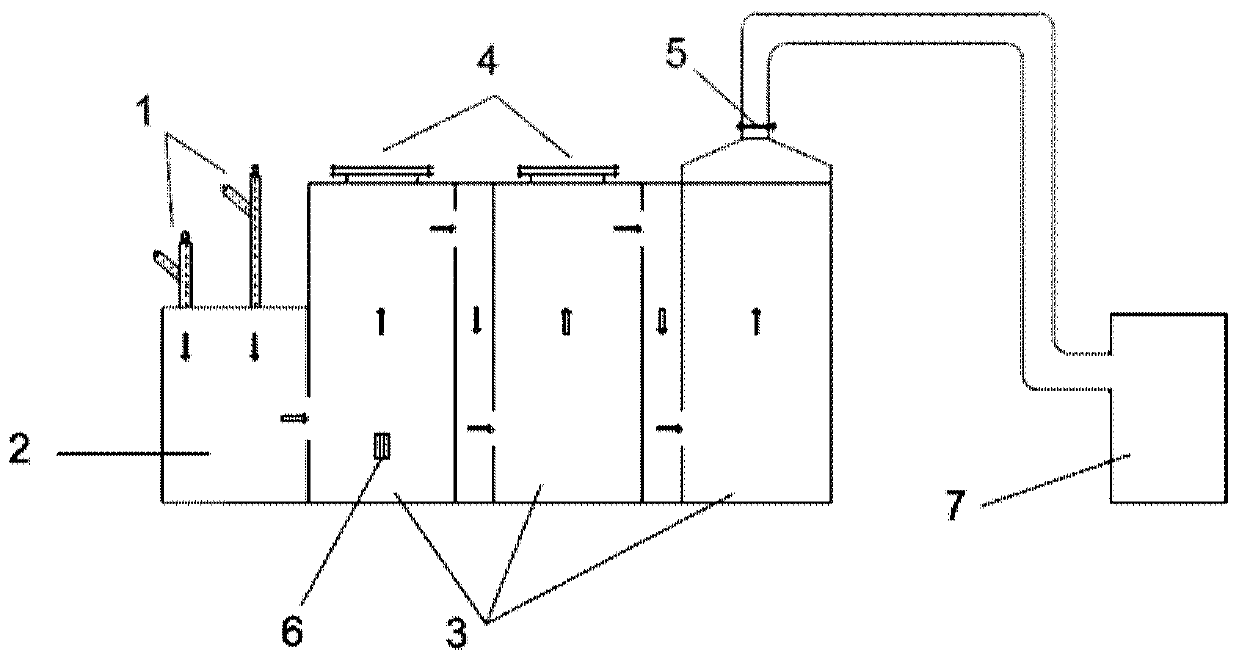

Exhaust gas treatment device of metal organic chemical vapor deposition apparatus and application of exhaust gas treatment device

PendingCN110339673APrevent leakageNo cloggingDispersed particle separationEngineeringChemical vapor deposition

Owner:DR TECH CO LTD YIXING JIANGSU

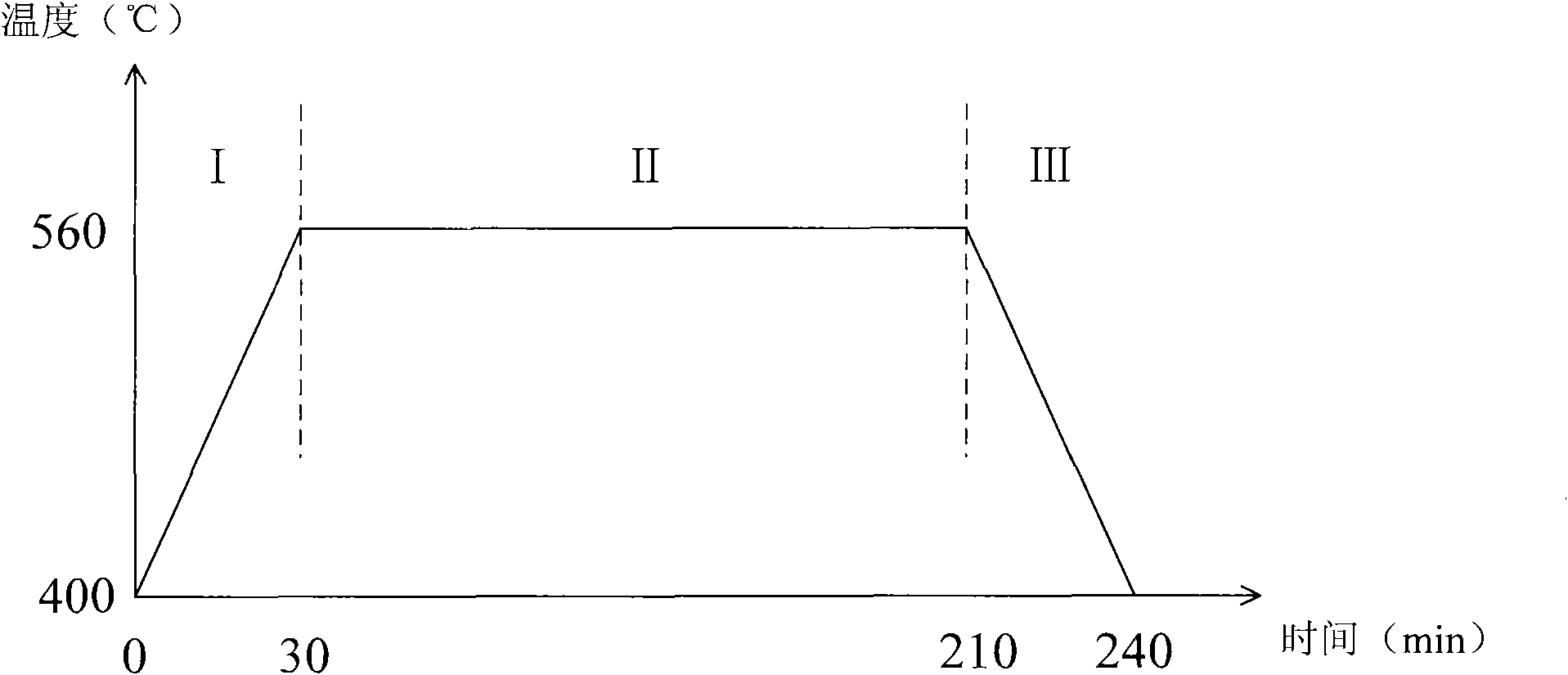

Method for forming amorphous silicon oxide laminated structure

InactiveCN102074470AReduce time consumptionIncrease production capacitySemiconductor/solid-state device manufacturingReaction temperatureAmorphous silicon

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for producing low-temperature polysilicon thin film transistor with crystallized bottom metals

InactiveCN102013400AImproved high leakage characteristicsSemiconductor/solid-state device manufacturingGas phaseEvaporation

The invention relates to a method for producing a low-temperature polysilicon thin film transistor with crystallized bottom metals, which belongs to the field of photoelectricity. The method for producing a low-temperature polysilicon thin film transistor with crystallized bottom metals is provided by the invention. By utilizing the method, the high current leakage characteristic of the low-temperature polysilicon thin film transistor can be improved. The method comprises a step of enhancing the chemical vapor deposition by plasmas or preparing an amorphous silicon thin film layer through chemical vapor deposition, and a step of utilizing Ni atomic units to plate a Ni metal layer by evaporation or sputtering evaporation, wherein the step of utilizing the Ni atomic units to plate a Ni metal layer by evaporation or sputtering evaporation is performed firstly, and then the step of enhancing the chemical vapor deposition by plasmas or preparing the amorphous silicon thin film layer through chemical vapor deposition is performed.

Owner:SICHUAN CCO DISPLAY TECH

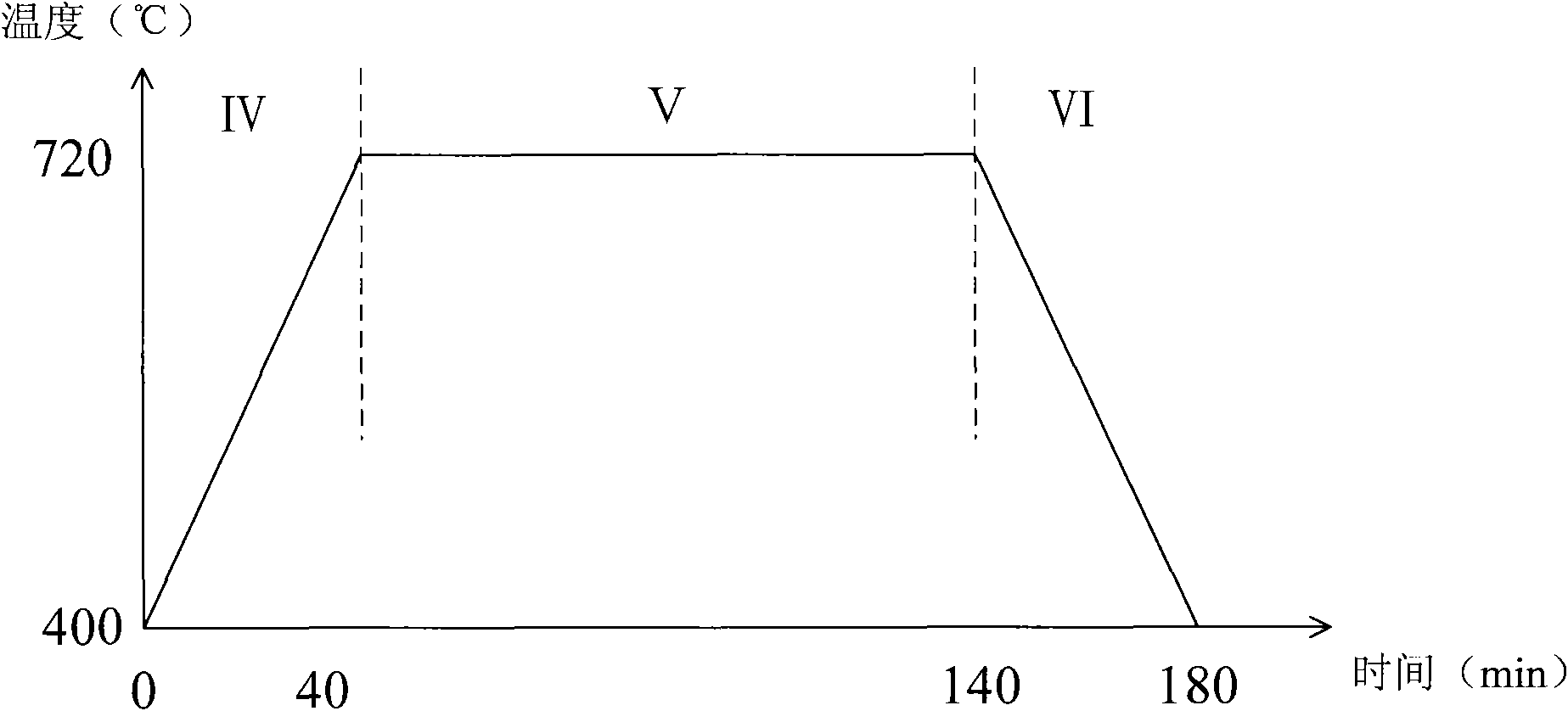

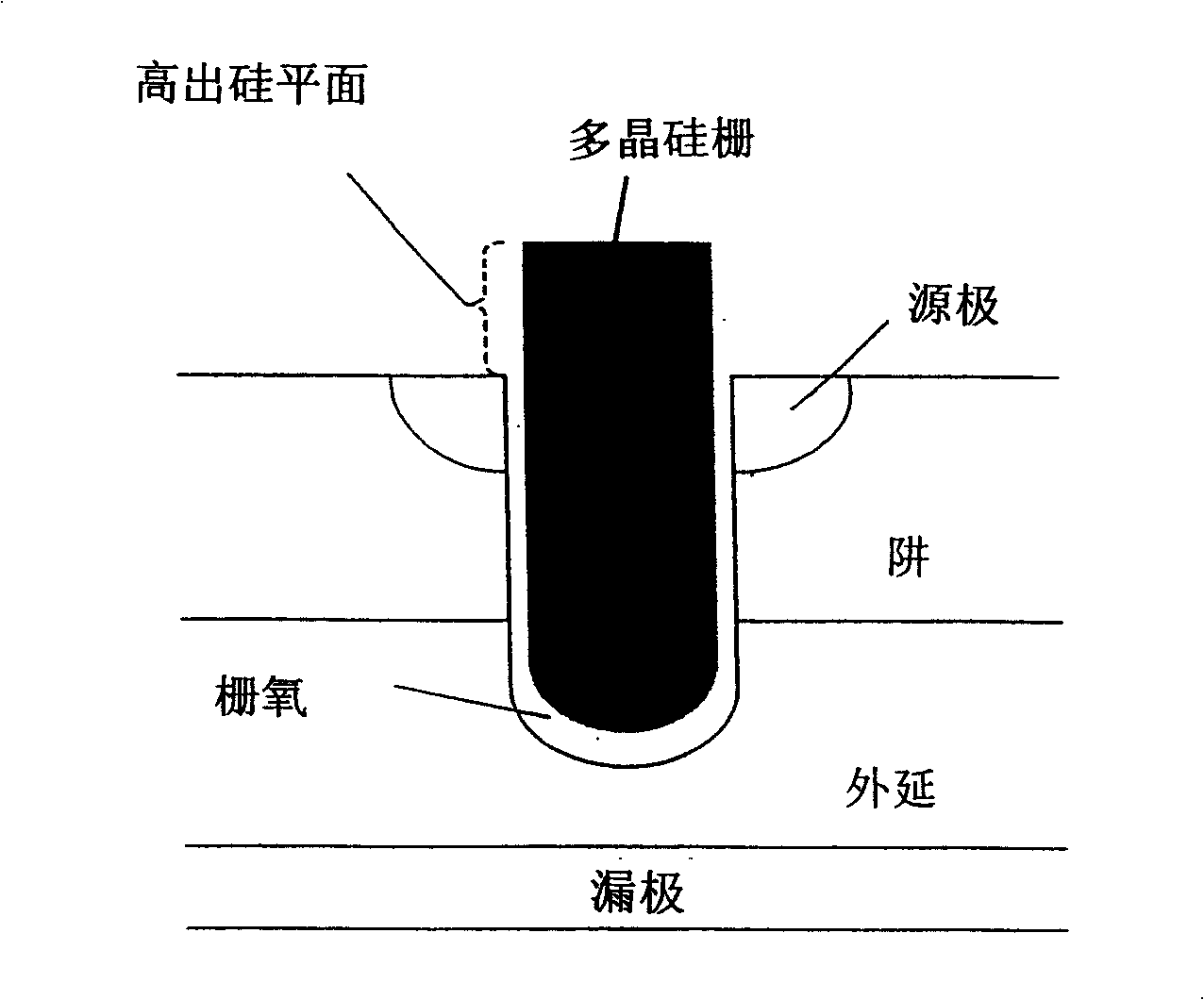

High power MOS transistor manufacturing method

ActiveCN100416856CIncrease the cross-sectional areaImprove frequency characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical resistance and conductanceGrating

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

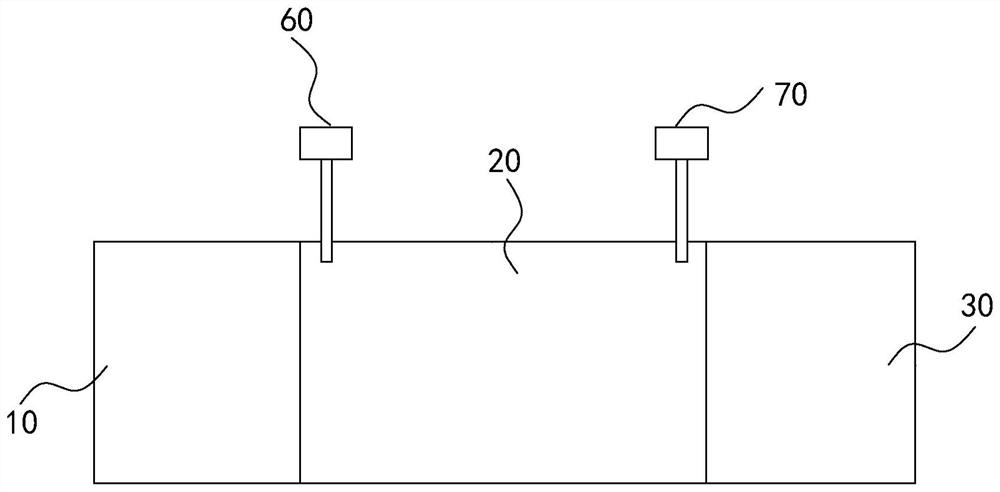

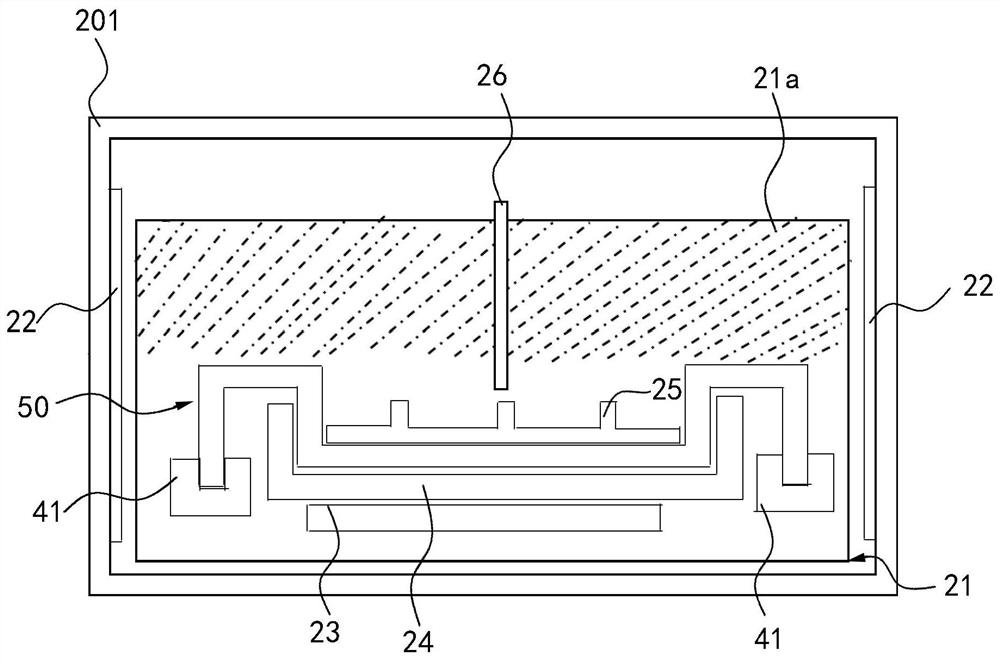

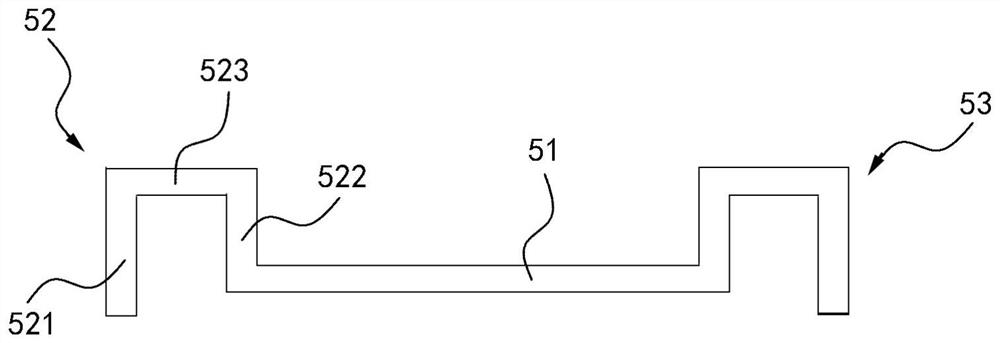

Chemical vapor deposition device

PendingCN113718235ARealize continuous productionChemical vapor deposition coatingPhysical chemistryThin membrane

Owner:BEIJING GRAPHENE INST

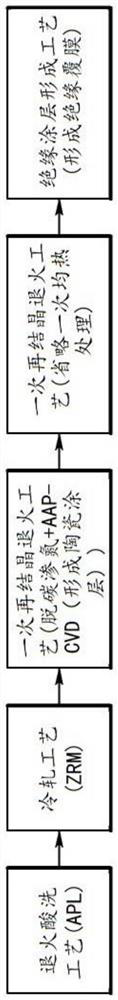

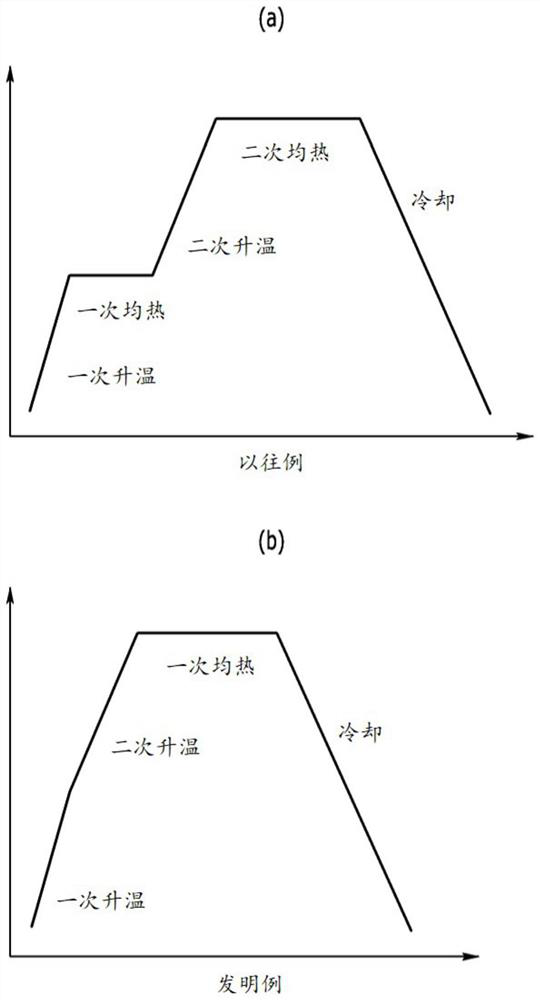

Grain-oriented electrical steel plate and preparation method thereof

PendingCN114867874AReduce iron lossGood insulation propertiesFurnace typesChemical vapor deposition coatingElectrical steelCeramic coating

Owner:POHANG IRON & STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap