Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Vapour deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Physical vapour deposition. Physical vapour deposition (PVD) is a process used to produce a metal vapour that can be deposited on electrically conductive materials as a thin, highly adhered pure metal or alloy coating. The process is carried out in a vacuum chamber at high vacuum (10–6 torr) using a cathodic arc source.

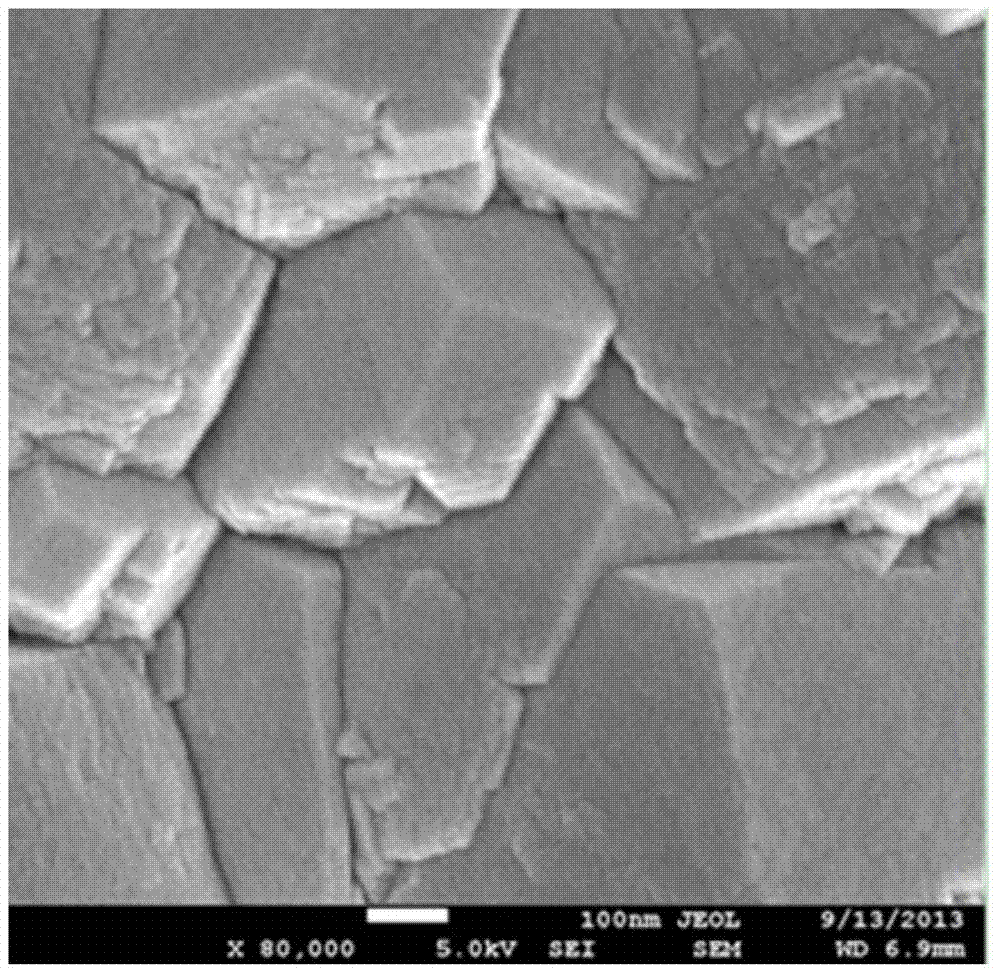

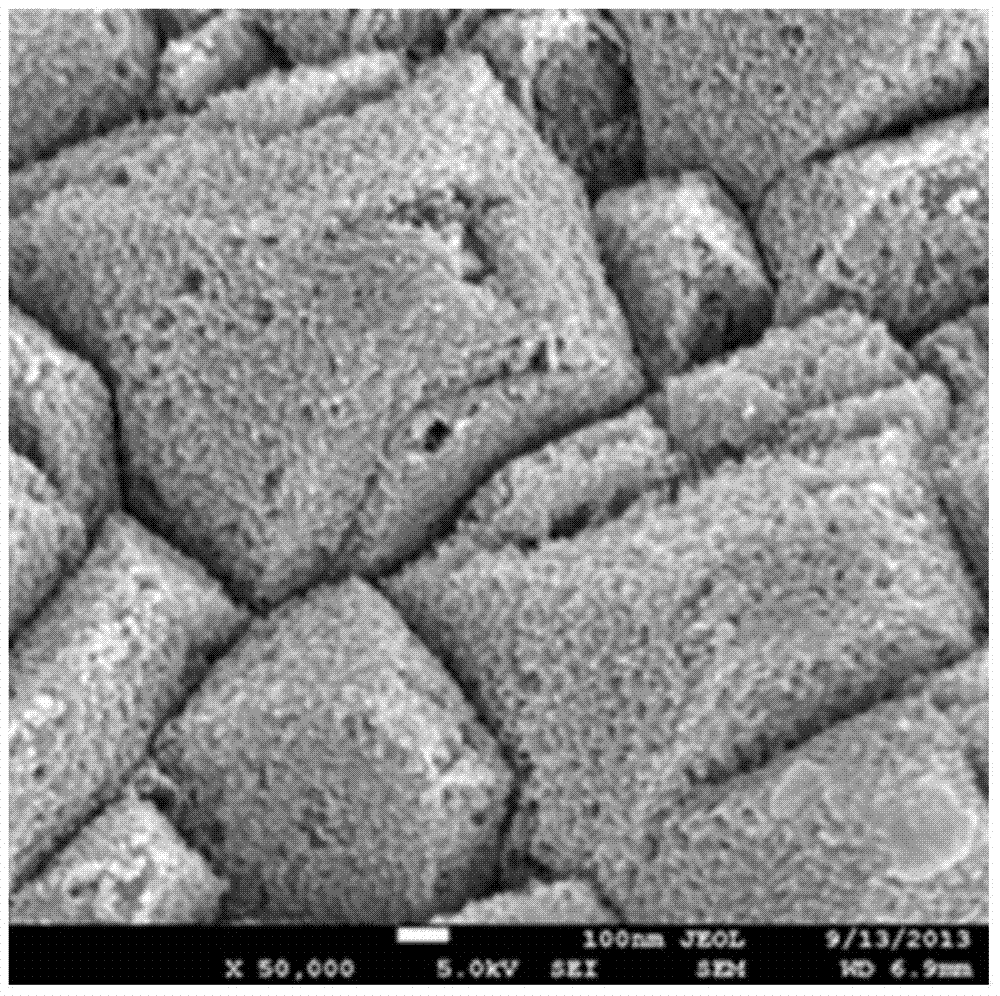

Preparation method of porous diamond film

ActiveCN104498894AImprove hydrophilicityIncrease contentChemical vapor deposition coatingAir atmosphereMicrowave

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

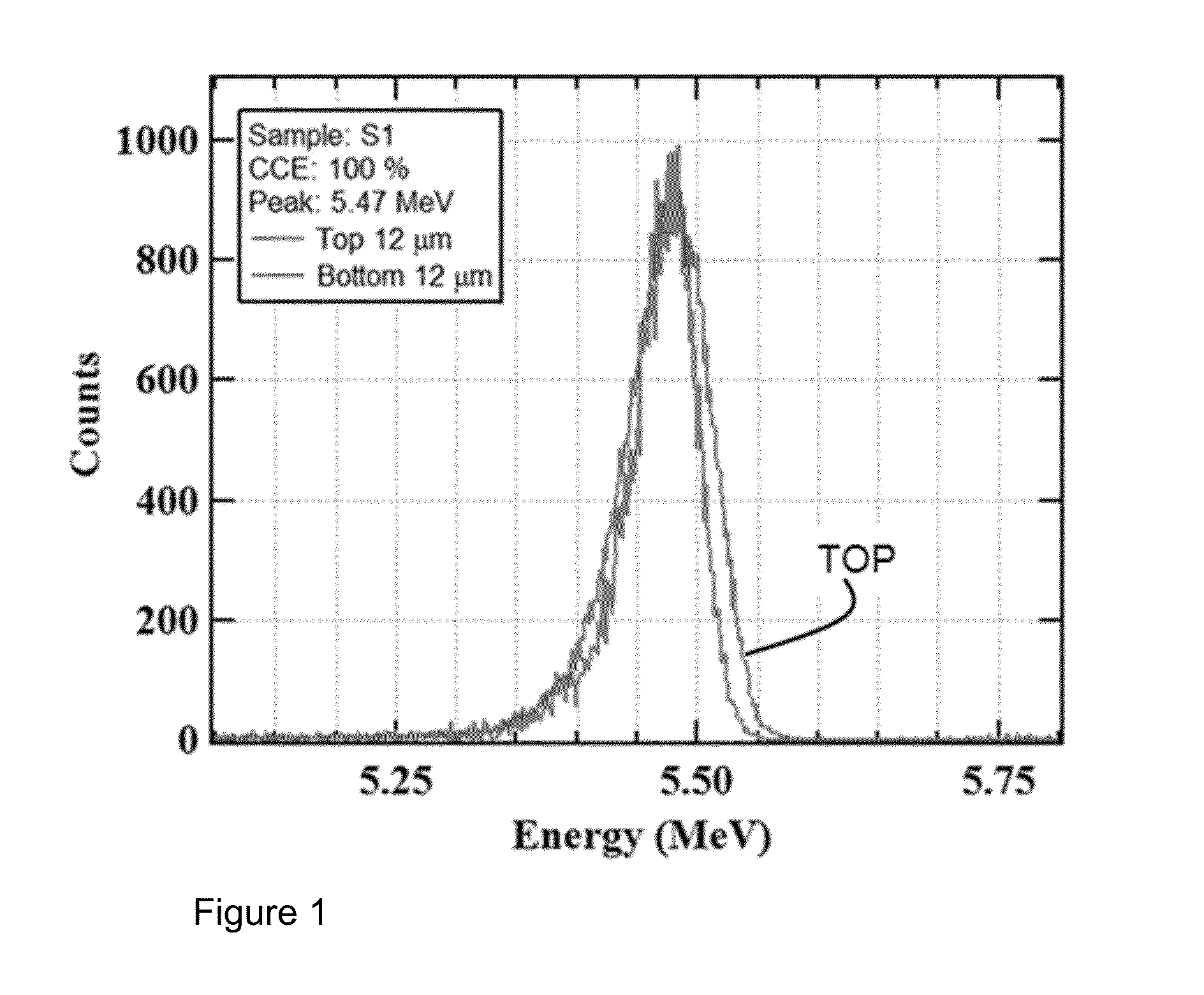

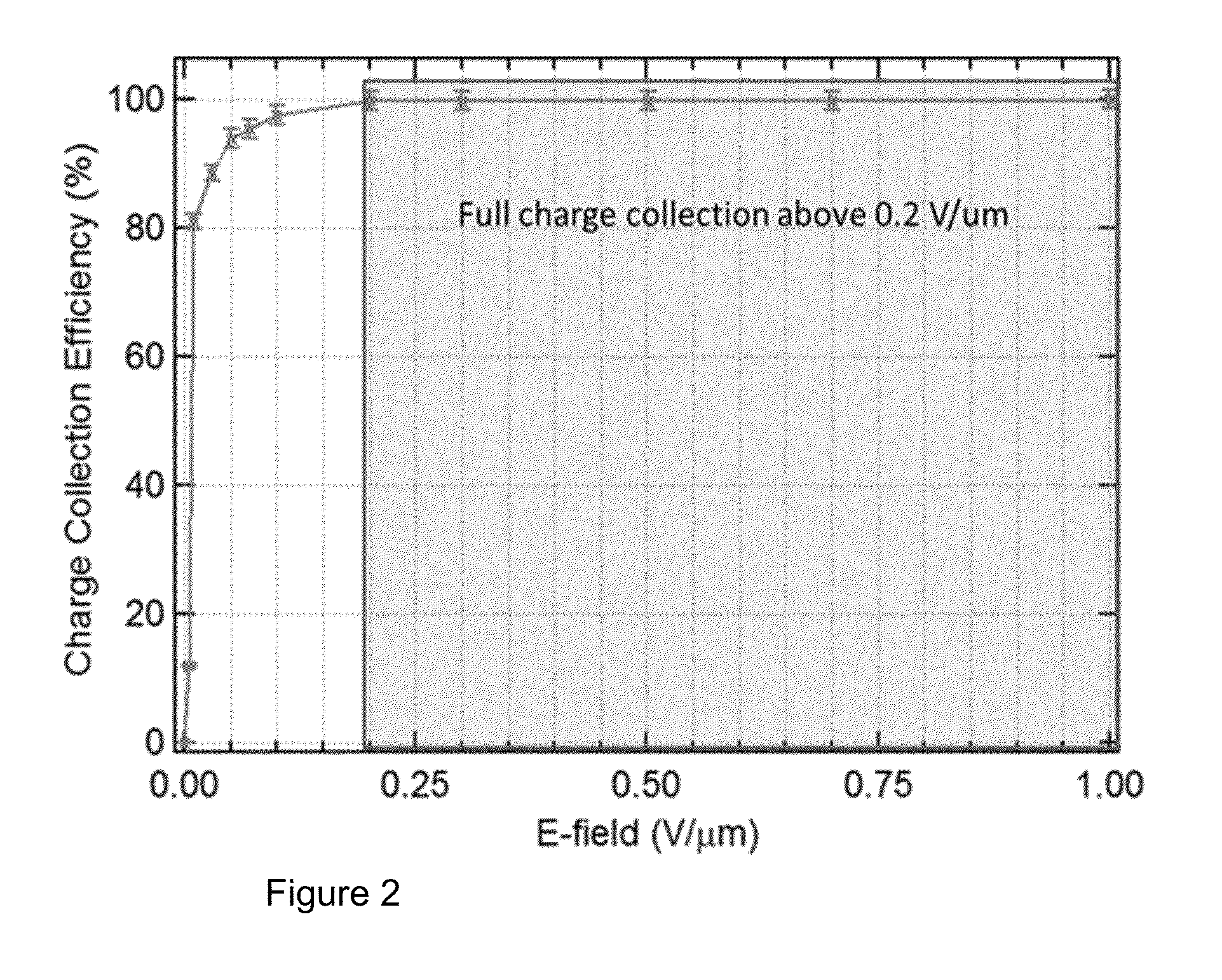

Electronic device grade single crystal diamonds and method of producing the same

ActiveUS20160201221A1Reduce crystal defect densityPolycrystalline material growthUltra-high pressure processesMicrowaveSingle crystal

Owner:IIA TECH

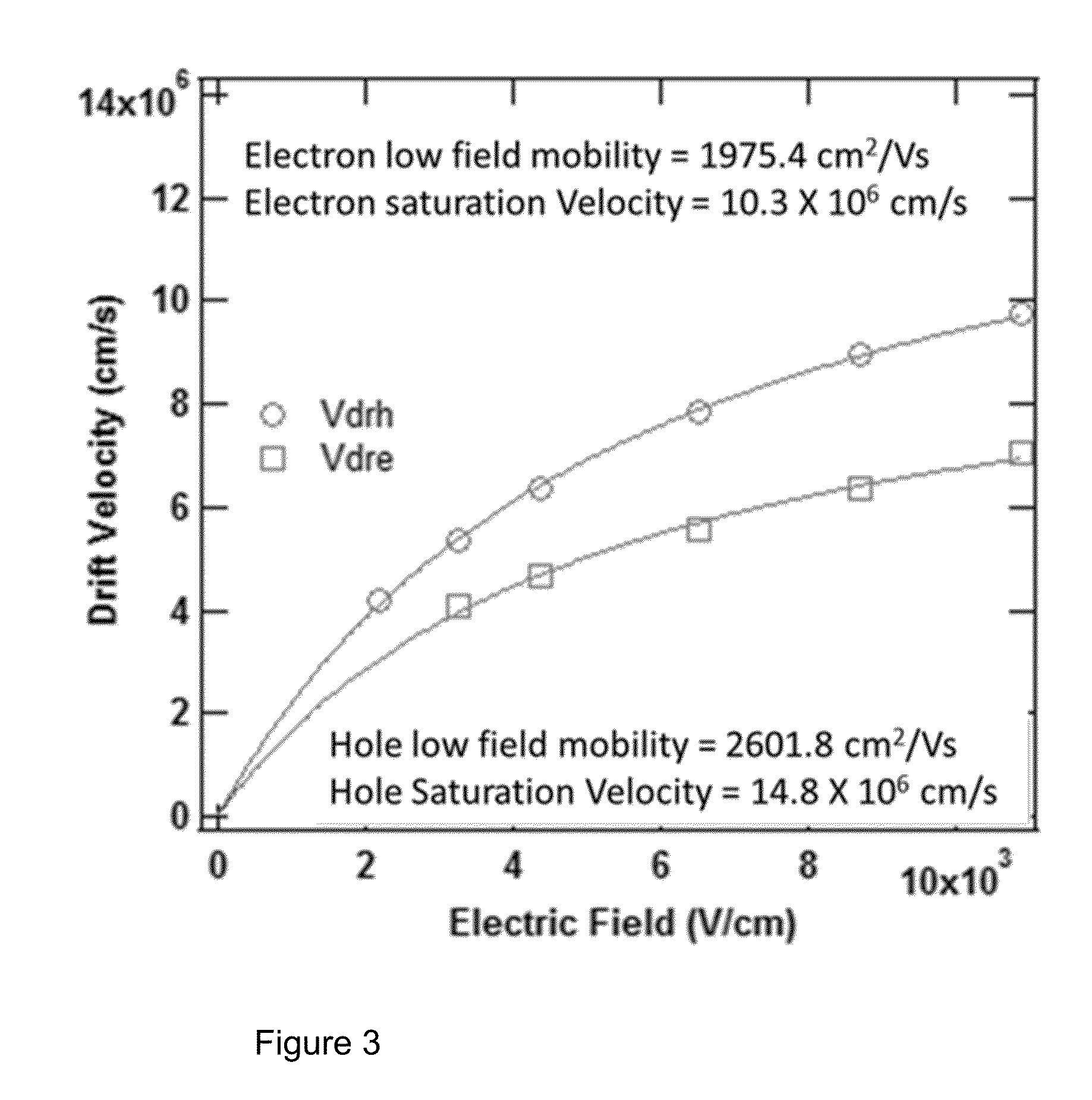

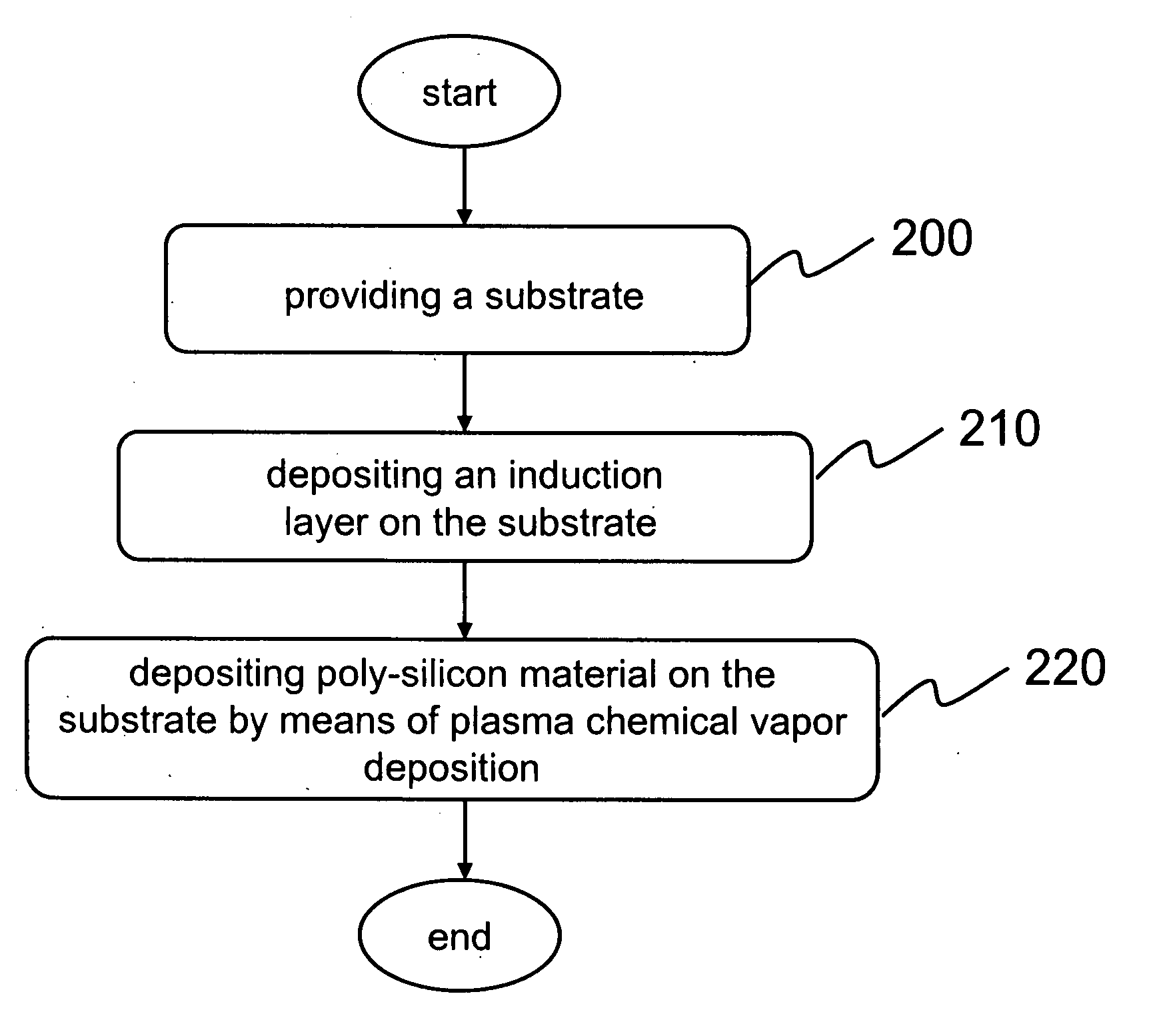

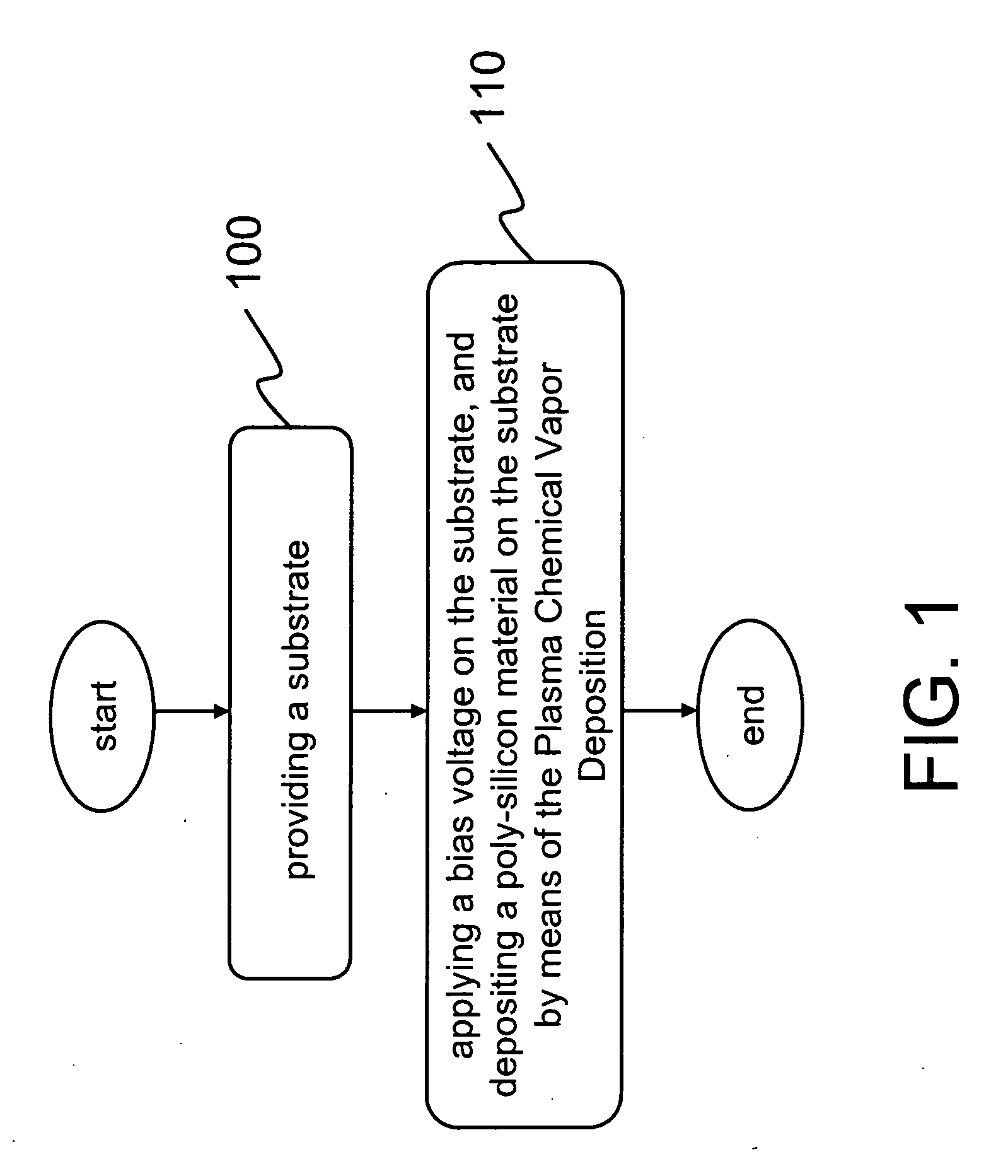

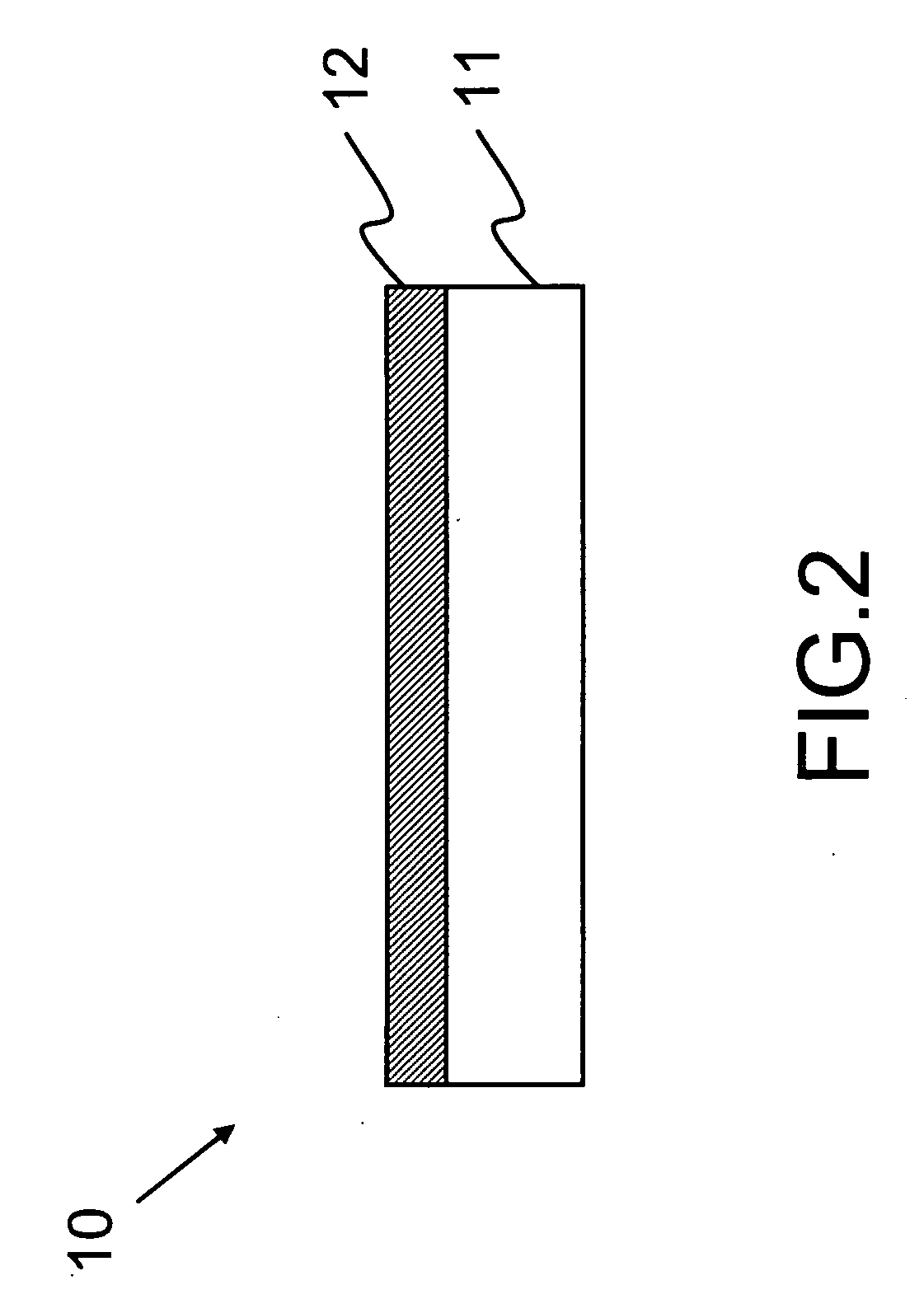

Element of low temperature poly-silicon thin film and method of making poly-silicon thin film by direct deposition at low temperature and inductively-coupled plasma chemical vapor deposition equipment therefor

InactiveUS20070077735A1Quality improvementReduce thicknessPolycrystalline material growthSolid-state devicesInductively coupled plasmaSilicon thin film

Owner:IND TECH RES INST

Semiconductor device with contact etching stop layer and forming method thereof

InactiveCN101740498AAvoid phenomena such as poor reliabilityAvoid damageSemiconductor/solid-state device detailsSolid-state devicesHigh densityGate oxide

The invention discloses a method for forming a semiconductor device with a contact etching stop layer, which comprises the following steps of: providing a substrate on which at least one grid structure is formed; putting the substrate in a settling chamber to carry out the settlement of the contact etching stop layer; oxidizing the contact etching stop layer in situ to form an oxide film on the surface of the contact etching stop layer; taking out the substrate on which the oxide film is formed; and forming an interlayer dielectric layer on the oxide film by high-density plasma chemical vapour deposition equipment. The invention also discloses the semiconductor device with the contact etching stop layer. The semiconductor device with the contact etching stop layer and the forming method thereof of the invention can effectively prevent damages which are caused by using the high-density and large-power plasma in the step of settling the interlayer dielectric layer to a gate oxide layer and voids phenomena of device performance drift, device reliability reduction and the like.

Owner:SEMICON MFG INT (BEIJING) CORP

Method for preparing cubic boron nitride single crystal-film homogeneous P-N junction

InactiveCN101807519AReduce processing difficultyIncrease productivitySemiconductor/solid-state device manufacturingDiffusion methodsSynthesis methods

Owner:JILIN UNIV

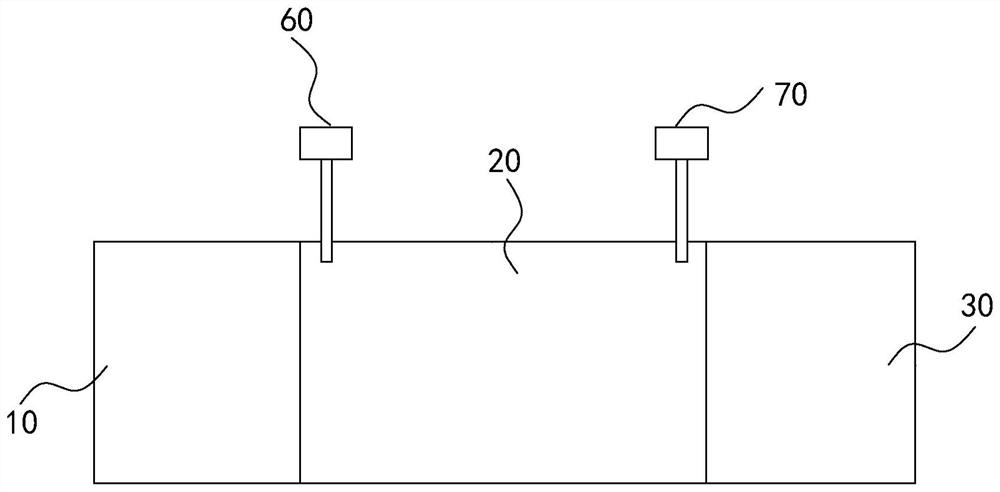

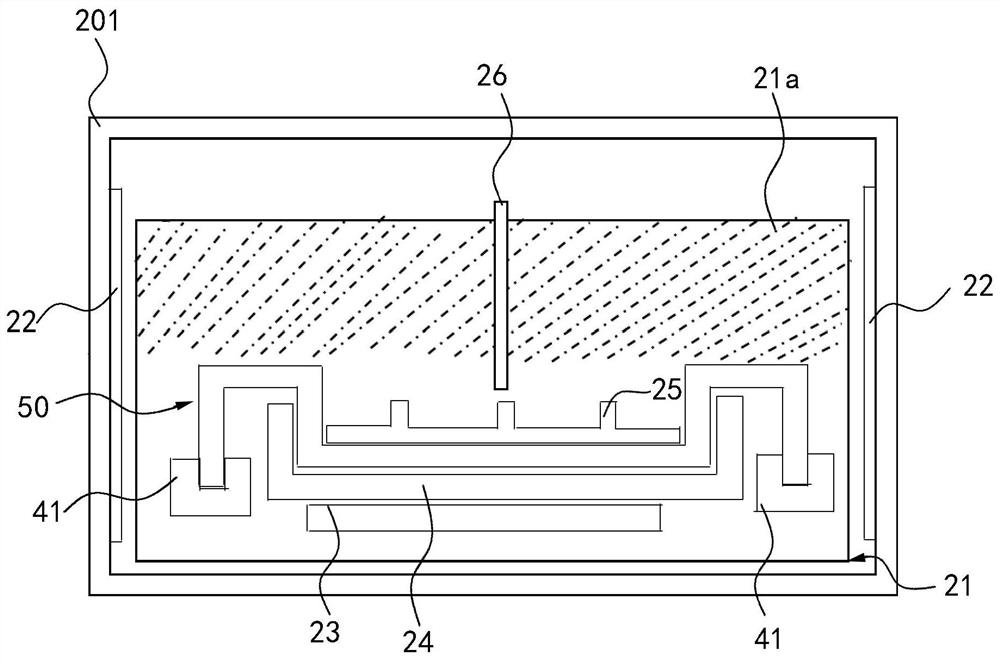

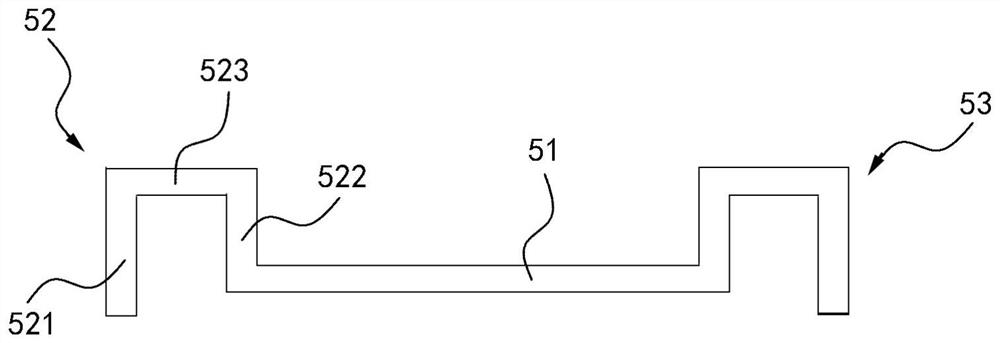

Chemical vapor deposition device

PendingCN113718235ARealize continuous productionChemical vapor deposition coatingPhysical chemistryThin membrane

Owner:BEIJING GRAPHENE INST

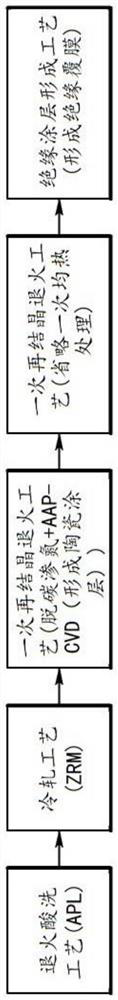

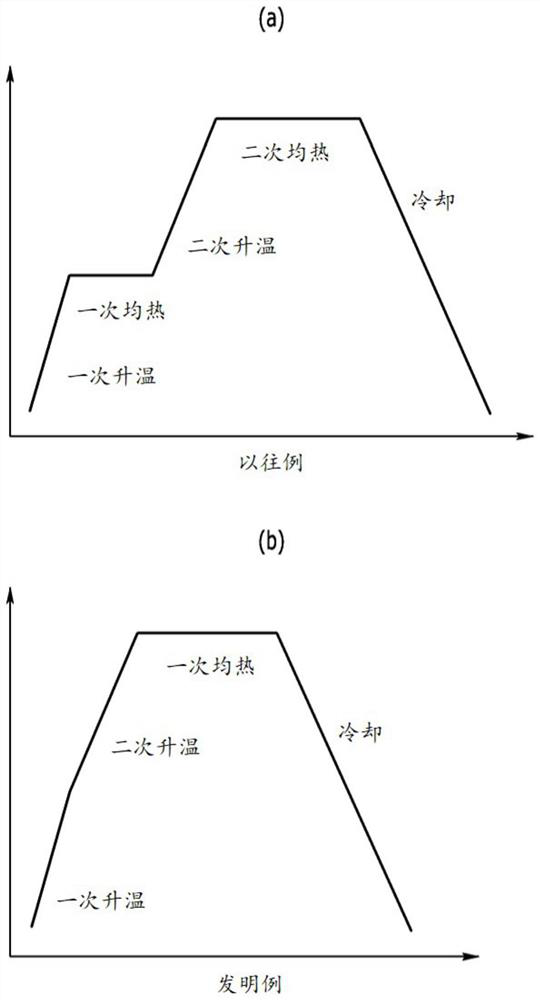

Grain-oriented electrical steel plate and preparation method thereof

PendingCN114867874AReduce iron lossGood insulation propertiesFurnace typesChemical vapor deposition coatingElectrical steelCeramic coating

Owner:POHANG IRON & STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap