Composite immobilized enzyme material for repairing polluted water source and its preparing process

A technology for immobilizing enzymes and composite materials, applied in chemical instruments and methods, immobilization on or in inorganic carriers, biological water/sewage treatment, etc. , the problem of high production cost, to achieve the effect of convenient industrial production, high industrial production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Carry out by above-mentioned specific embodiment, the raw material formula weight of immobilized enzyme composite material is: construction waste (3~5mm of particle diameter) 70%, fly ash 20%, rosin soap 0.5%, calcium oxide expansion agent 0.5%, enzyme liquid 9% (enzyme activity 2000u / ml), add an appropriate amount of water, mix and stir the materials, the stirring speed is 10-20 rpm, and the stirring time is 30-60 minutes; stand for nitrification; then mix and stir evenly to make the sludge The moisture content is 22%, and it is left to stand at room temperature for 1 to 2 hours, then sent to a non-burning brick machine for pressing and forming, and naturally air-dried to obtain the product. The model is: P-HST30, Mianshaozhuanji.

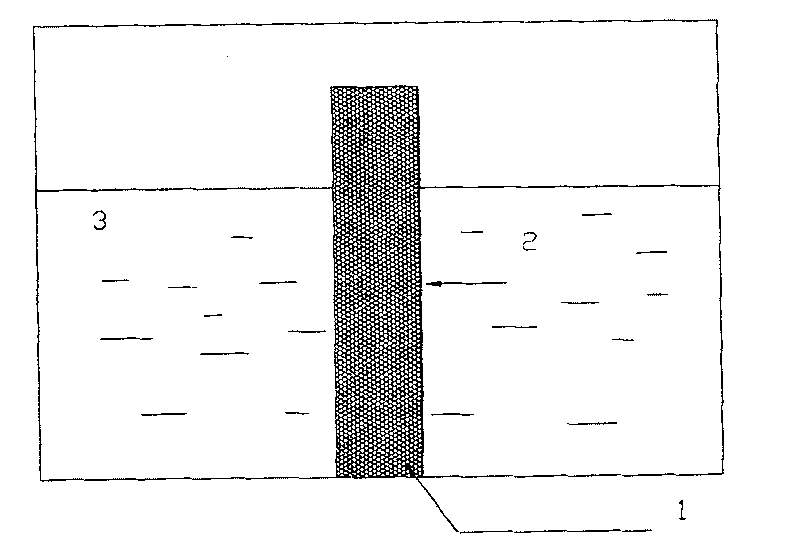

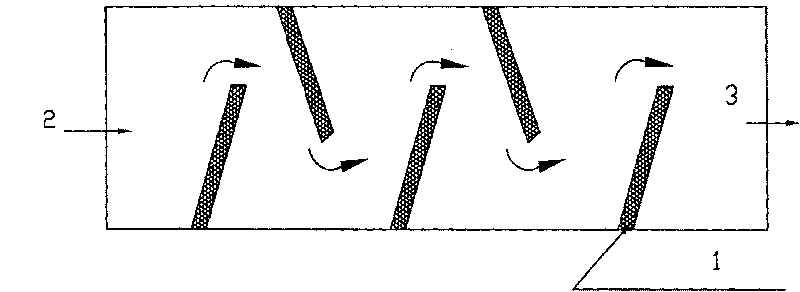

[0025] When the above-mentioned immobilized enzyme composite material is used for printing and dyeing wastewater treatment, firstly, the immobilized enzyme composite material (block material with an outer diameter of 36×24×12cm) is filled in

Embodiment 2

[0028] Carry out by above-mentioned specific embodiment, the raw material formula weight of immobilized enzyme composite material is: ceramic particle (3~5mm of particle diameter) 60%, portland cement 10%, fly ash 20%, rosin soap 0.5%, calcium oxide Expanding agent 0.5%, enzyme preparation (solid state) 9% (enzyme activity 2000u / mg), add appropriate amount of water, mix and stir the materials, stirring speed is 10-20 rpm, stirring time is 30-60 minutes; stand for nitration and then mix and stir evenly, so that the moisture content of the mud is 25%, the pH value of the mud is measured to be 6.5, and stand at room temperature for 2 to 3 hours. The product is obtained by pressing the unburned brick machine model GQC-302 and drying it in a dryer at a temperature of 40°C.

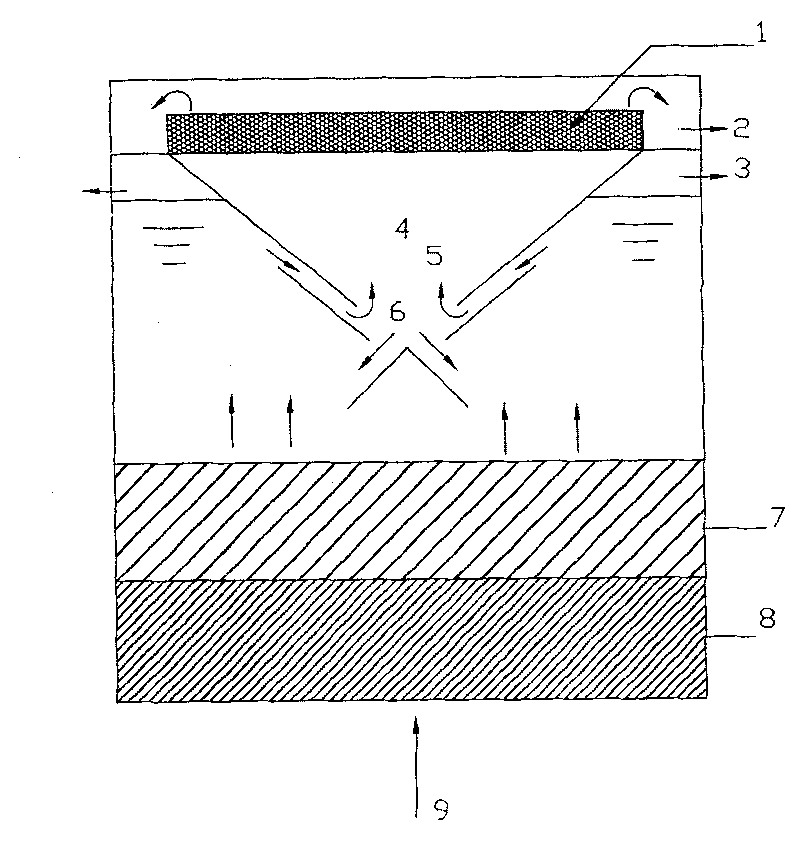

[0029] The above-mentioned immobilized enzyme composite material is filled in an upflow bioreactor, and the papermaking wastewater is treated (assisted physicochemical treatment at the front stage of the reactor

Embodiment 3

[0032]Carry out according to above-mentioned specific embodiment, the raw material formula weight of immobilized enzyme composite material is: pumice 65%, portland cement 18%, fly ash 8%, rosin soap 0.4%, calcium oxide expansion agent 0.4%, enzyme preparation 8.2% % (enzyme activity 2000u / ml), add appropriate amount of water after mixing and stirring the ingredients evenly, adjust the moisture content of the mud to 26%, measure the pH value of the object soaking water to 6.0, stir the speed at 10 to 20 rpm, and stir for a period of time 30 to 60 minutes; stand still for nitrification; mix and stir evenly, and stand at room temperature for 3 hours, then send it into a non-burning brick machine, and press to form, that is, the immobilized enzyme composite material with a square appearance shape is obtained. The material is weak gray in color, odorless, the enzyme activity measured indirectly is ≥18000u / kg, the compressive strength is 6mpa, the porosity is 20%, and the water perm

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap