Semiconductor structure and forming method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

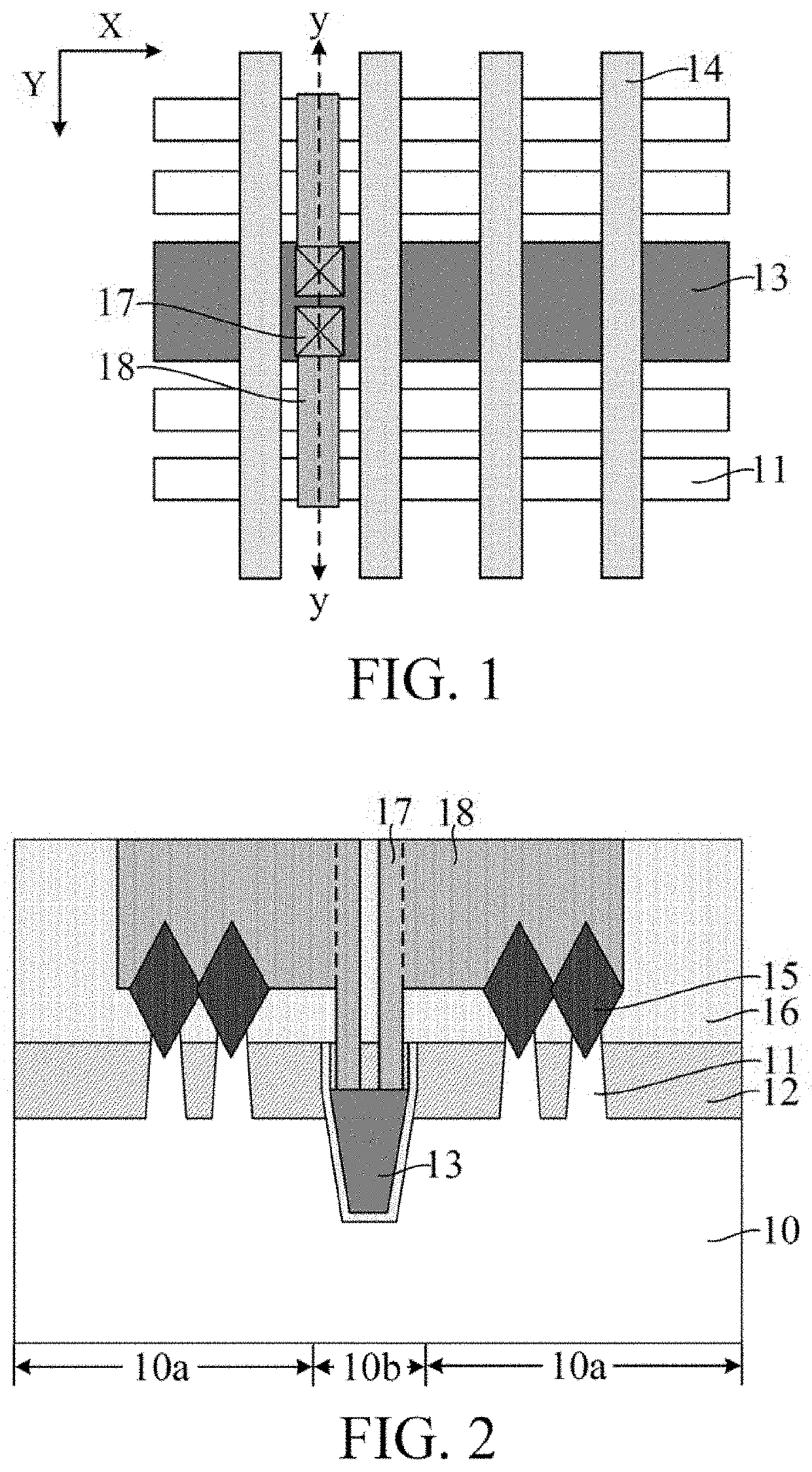

[0020]From the background, one of skill in the art will appreciate that a performance of a semiconductor device can be improved. A semiconductor structure is now combined to analyze the reasons why the performance of the device is still to be improved. FIG. 1 and FIG. 2 are schematic structural diagrams of a semiconductor structure. FIG. 1 is a top view, and FIG. 2 is a cross-sectional view of FIG. 1 in a y-y direction.

[0021]As shown in FIG. 1 and FIG. 2, the semiconductor structure includes: a substrate 10, including device regions 10a and a power rail region 10b; discrete fins 11 on the substrate 10 in the device regions 10a; an isolation structure 12, located on the substrate 10 exposed by the fin 11, where a top surface of the isolation structure 12 is lower than a top surface of the fin 11; a power rail line 13, located in the substrate 10 in the power rail region 10b and the isolation structure 12, where both the power rail line 13 and the fin 11 extend in a transverse direction

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap