Drill bit of hollow drill and manufacturing method thereof

A hollow drill and drill bit technology, which is applied in drilling/drilling equipment, drill repairing, drilling tool accessories, etc., can solve the problems of poor chip removal, easy wear, and small chip space, and achieve the effect of not being easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawings and examples.

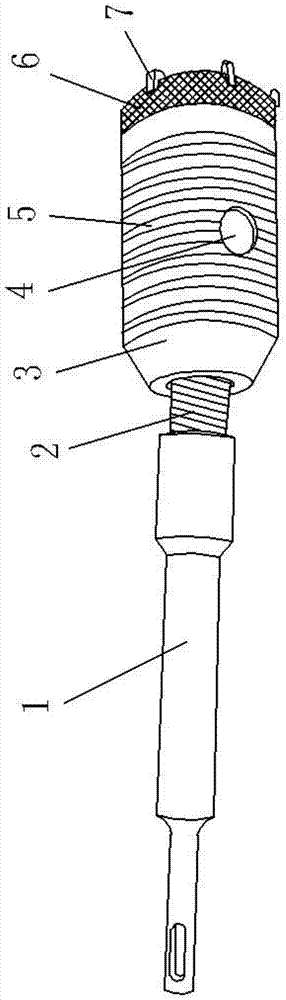

[0026] As shown in the figure, a hollow drill bit includes a drill shank 1 and a cylinder body 3. It is characterized in that: the top end of the cylinder body 1 is provided with a wear-resistant layer 6, and a number of cutting teeth 7 are evenly distributed on the wear-resistant layer 6. , the wear-resistant layer 6 is formed by overlay welding of wear-resistant materials, the cutting teeth 7 are directly welded on the wear-resistant layer 6, the side of the cylinder 3 is provided with chip removal holes 4, and the outer surface of the cylinder 3 is A chip removal groove 5 is provided, the chip removal groove 5 is threaded, the top of the drill shank 1 is provided with an external thread 2, the drill shank 1 is connected with the cylinder 3 through the external thread 2, and the bottom of the cylinder 3 is There are matching internal threads in the mounting hol

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap