Dirty oil blocking device based on marine environmental protection engineering

A technology for interception devices and environmental protection projects, which is applied in water conservancy projects, general water supply conservation, and cleaning of open water surfaces. It can solve problems such as the spread of dirty oil, breakage of interception devices, and time-consuming and labor-intensive problems, so as to enhance adaptability and facilitate collection and treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

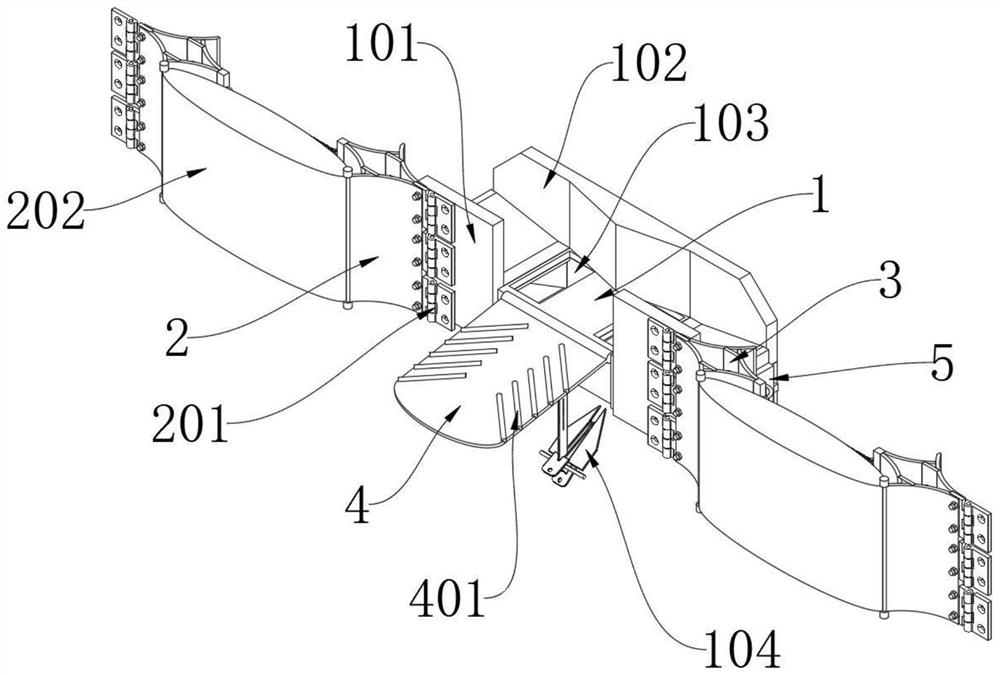

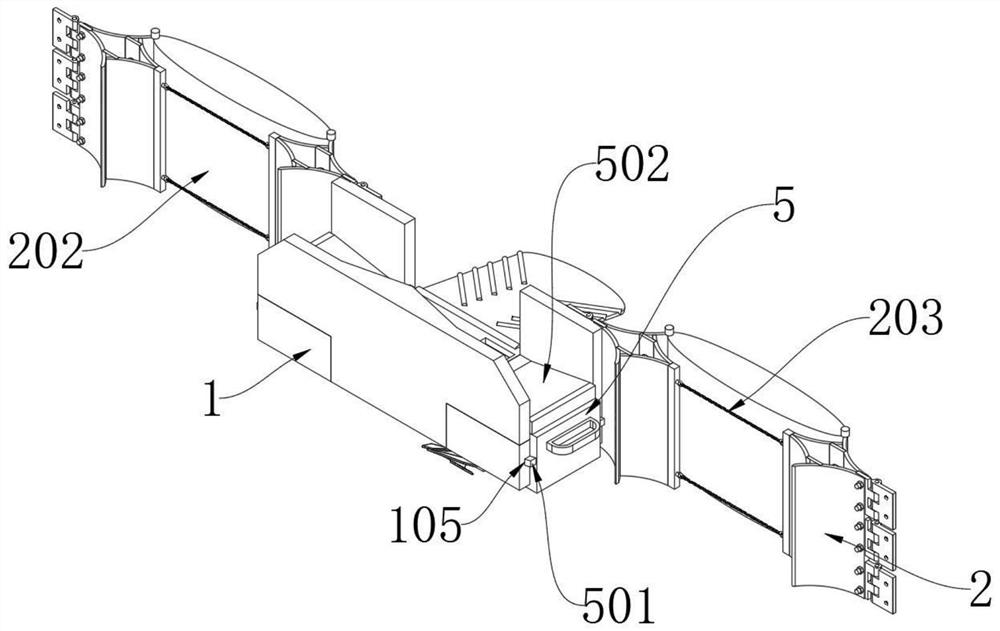

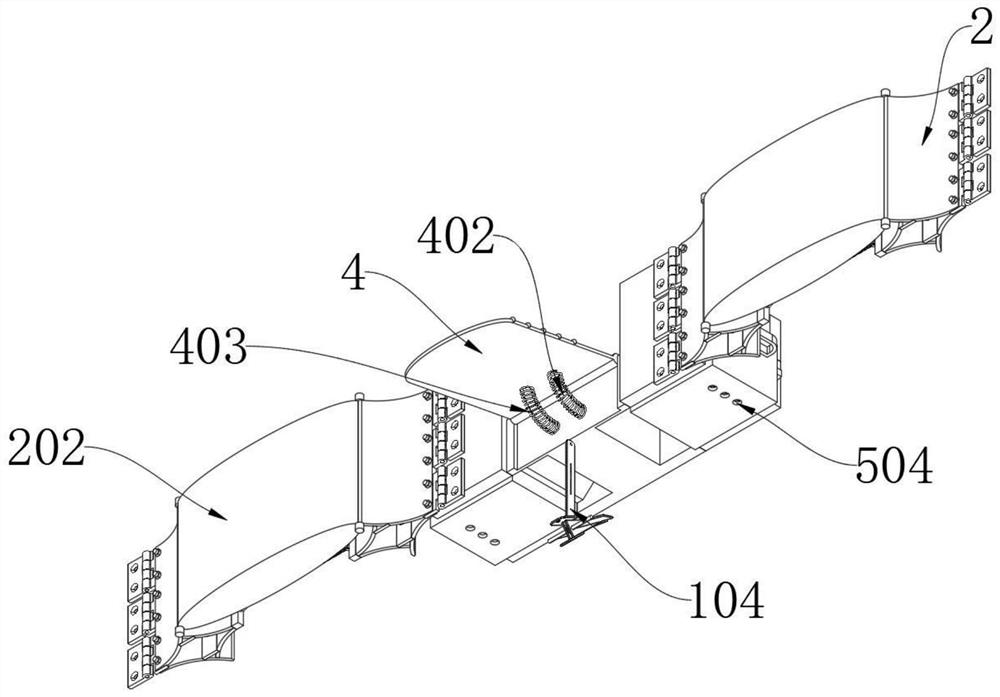

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides a waste oil interception device based on marine environmental protection engineering, which includes an interception module 1; the left edge and the right edge of the front side wall of the interception module 1 are respectively fixed and connected with a horizontal hinged series mechanism 2 by fixing bolts The middle part of the left end and the right end of the hinged series mechanism 2 is fixed with an I-shaped buffer mechanism 3; the middle part of the front edge edge of the top plane of the interception module 1 is horizontally connected with the oil inlet tongue plate 4; the oil inlet tongue plate 4 includes Guide side strips 401, guide bending columns 402 and self-adaptive springs 403, the left end edge and the right end edge of the top plane of the oil inlet flap 4 are respectively fixed with guide side strips 401 that converge toward the rear and middle at longitudinal interva

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap