Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Steelmaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

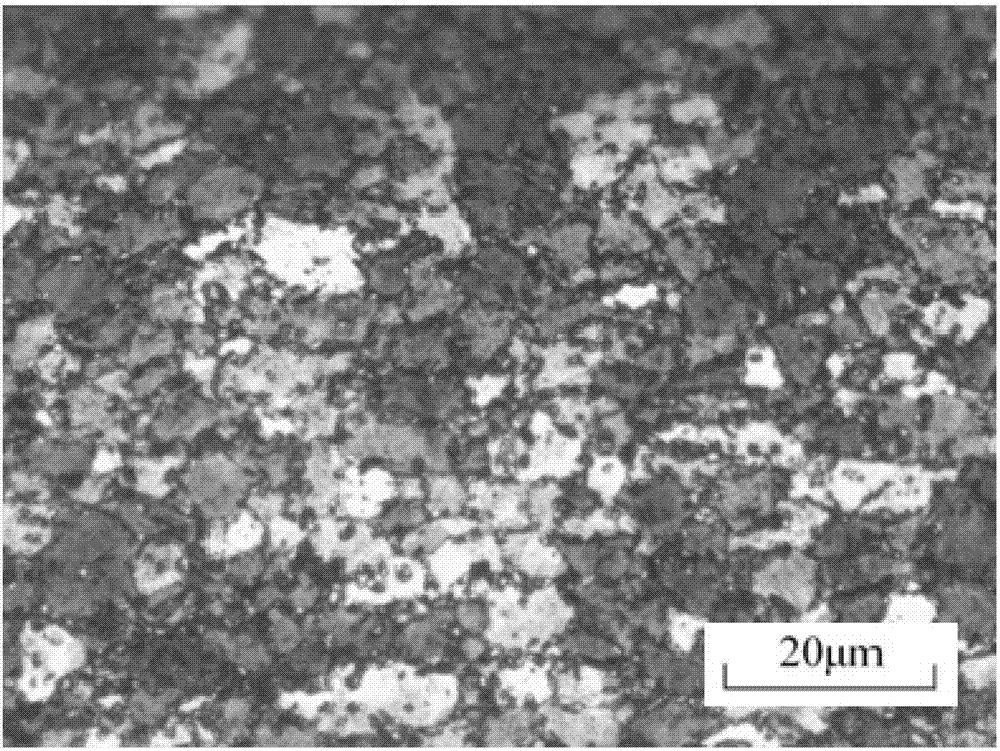

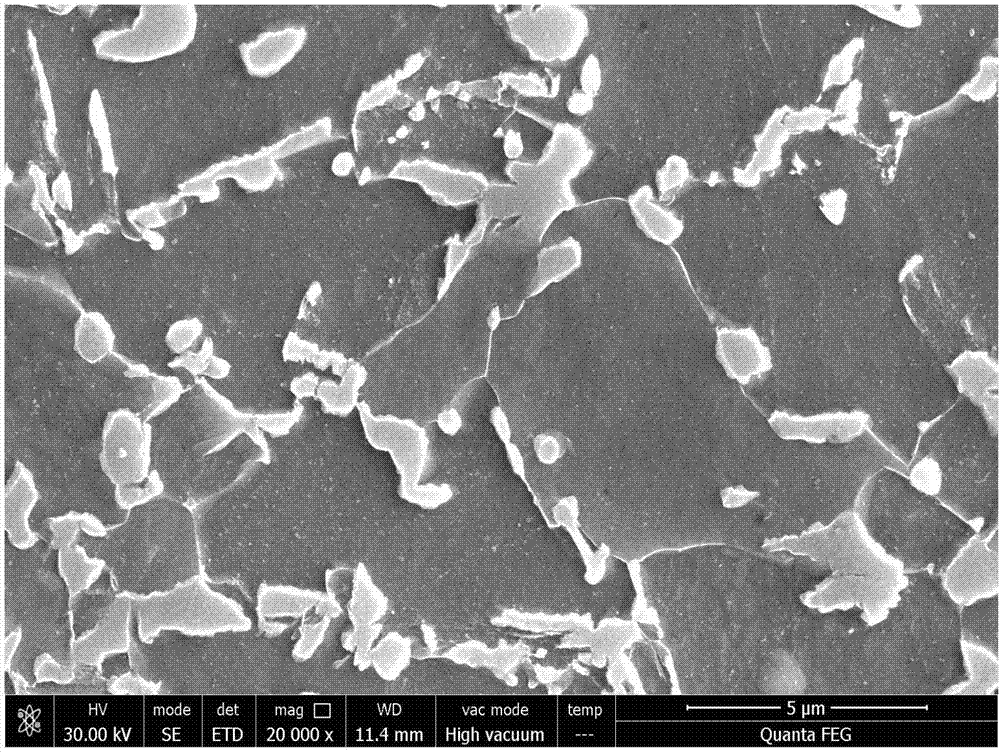

Steelmaking is the process of producing steel from iron ore and/or scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon (most important impurity) are removed from the sourced iron, and alloying elements such as manganese, nickel, chromium, carbon and vanadium are added to produce different grades of steel. Limiting dissolved gases such as nitrogen and oxygen and entrained impurities (termed "inclusions") in the steel is also important to ensure the quality of the products cast from the liquid steel.

High-surface-quality hot-galvanized transformation induced plasticity (TRIP) steel plate and manufacturing method thereof

ActiveCN106868403AImprove performanceGood coating performanceHot-dipping/immersion processesFurnace typesSteelmakingHigh surface

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Production method of ultra-low silicon peritectic steel

Owner:TANGSHAN IRON & STEEL GROUP +1

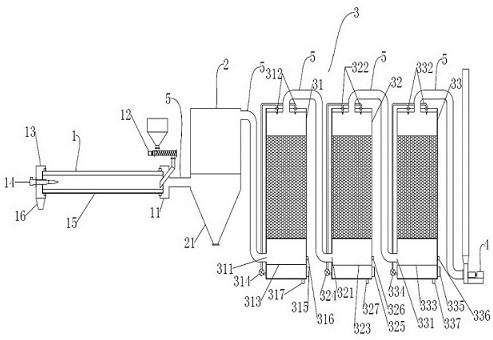

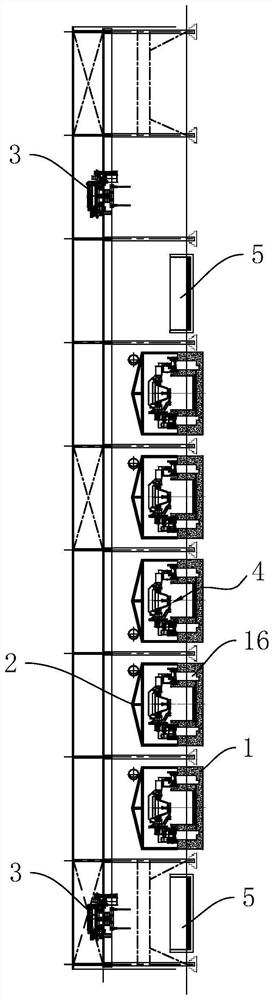

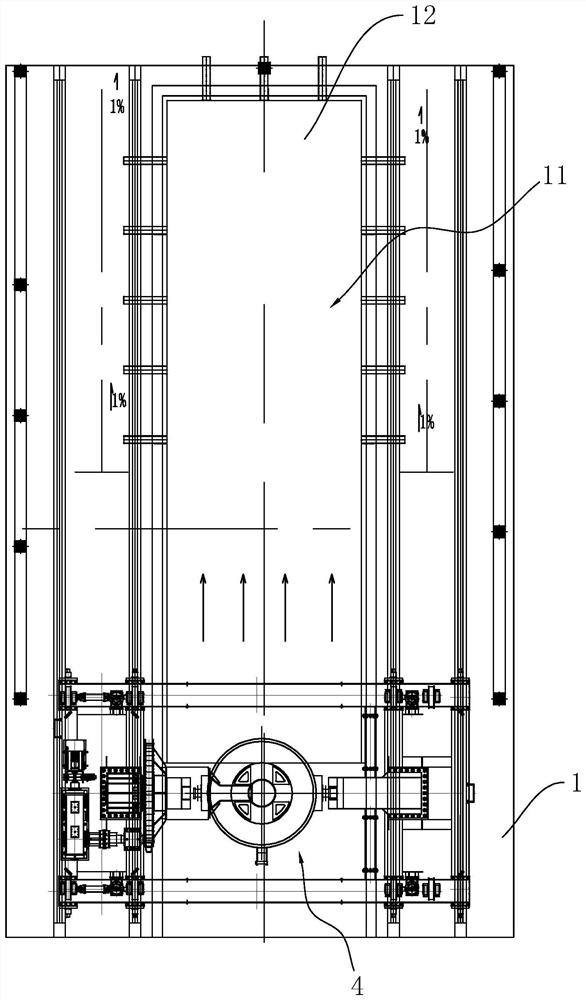

One-key remote ladle car positioning and automatic uncovering and covering control device

ActiveCN110369700AIncrease coverage rateReduce usageMelt-holding vesselsCasting safety devicesLower limitSteelmaking

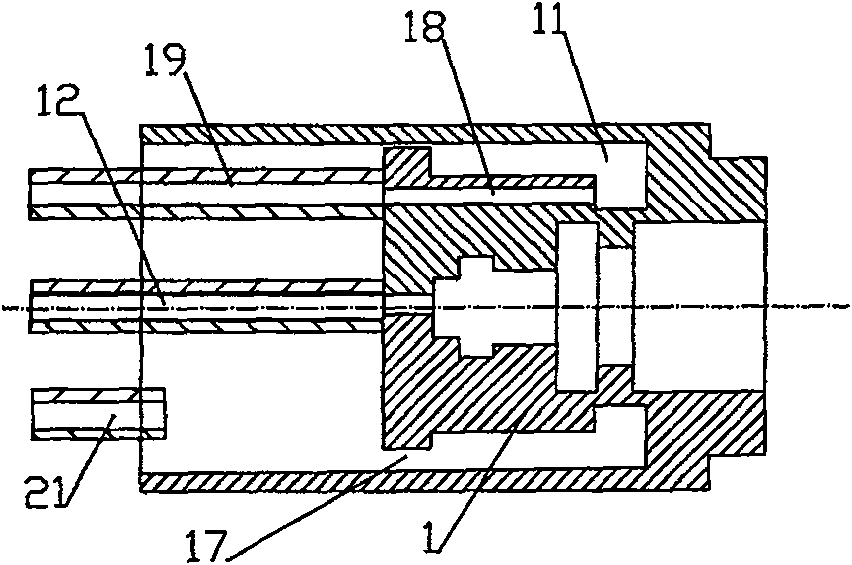

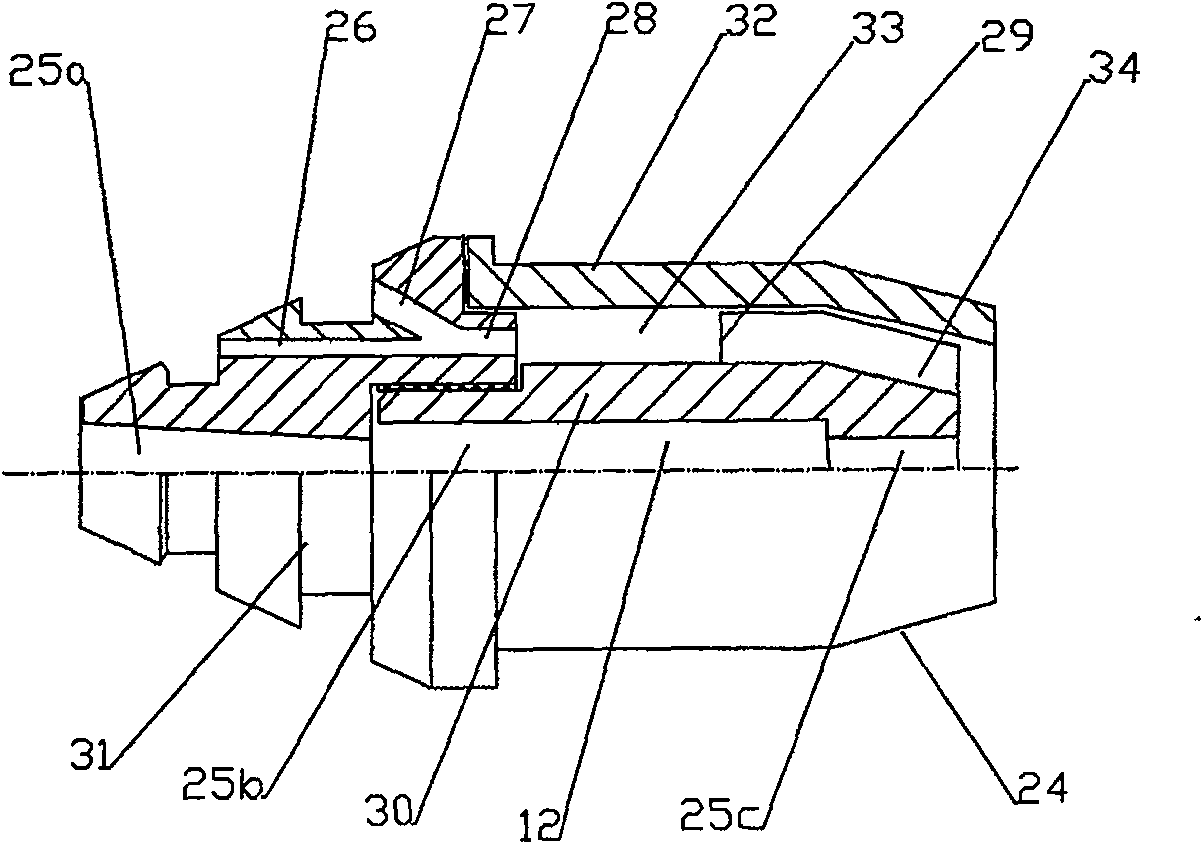

The invention relates to a one-key remote ladle car positioning and automatic uncovering and covering control device which comprises a motor, a coupler, a band brake, a speed reducer, a crank I, a pinshaft, a connecting rod I, a pressure sensor, a pin shaft, a crank II, a gear I, a shaft, a gear II, a main shaft, a fishing hook, a bearing box, a fixing bolt, a connecting rod II, an uncovering andcovering traveling trolley, a ladle cover, an uncovering and covering trolley driving device, a ladle car, a steel ladle, a digital laser positioner I, a digital laser positioner II, a PLC system, anupper limit position, a lower limit position, a laser receiving plate I, a laser receiving plate II, an under-furnace steel car track and an uncovering and covering trolley track. According to the device, various process equipment accidents caused by a large amount of manual operation are reduced, the ladle covering rate is greatly improved, the cost is reduced, the use of human resources is reduced, the production efficiency and the labor efficiency of workers are improved, and deep automatic steelmaking is realized.

Owner:TANGSHAN STAINLESS STEEL +1

Low-aluminum and low-silicon welding wire steel low-sulfur-control smelting method

ActiveCN111979374AReduce sulfur contentPrevent slagSteelmakingSlag (welding)

Owner:NANJING IRON & STEEL CO LTD

Efficient converter protection method for predicting converter final slag viscosity model

ActiveCN110991772AReduce maintenance costsReduce slag splash timeSteel manufacturing process aspectsForecastingSteelmakingData acquisition

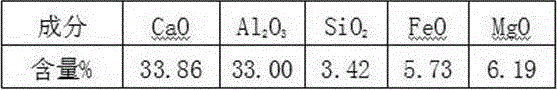

The invention discloses an efficient converter protection method for predicting a converter final slag viscosity model, and belongs to the field of converter steelmaking. The method comprises the following steps: data of a secondary charging system of a steel mill is collected in real time through a data acquisition module and the data is transmitted to a calculation processing module; the data processed by the calculation processing module is classified by the judgment processing module to obtain different output results; and finally, an output module is used for controlling a secondary system, human interference is reduced, the smelting time is shortened, and automatic and efficient furnace protection is achieved. According to a system, the final slag viscosity of the converter can be calculated through the prediction model, whether the characteristics of the final slag meet the requirements of slag splashing furnace protection or not can be obtained in real time, the variety and addition amount of a modifier and a matched slag splashing scheme are given through processing and calculation, and blindness and randomness of modification are reduced. According to the efficient converter protection method, the slag splashing time can be shortened, the slag splashing furnace protection effect is improved, and the converter operation rate is increased.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Application method of aluminum ash

InactiveCN113293256ARealize secondary useReduce pollutionManufacturing convertersProcess efficiency improvementSteelmakingAluminium

The invention discloses an application method of aluminum ash. According to the application method, the aluminum ash is used as a converter steelmaking slag former. The aluminum ash is added in the middle stage of converter blowing, and the adding amount is controlled to be 2-4 kg per ton of steel. The application method has the beneficial effects that secondary use of the aluminum ash is achieved, environmental pollution is reduced, slagging in the converter steelmaking process is improved, the effect of a fluorite cosolvent for converter steelmaking can be replaced, and the steelmaking cost is reduced.

Owner:XINGTAI IRON & STEEL

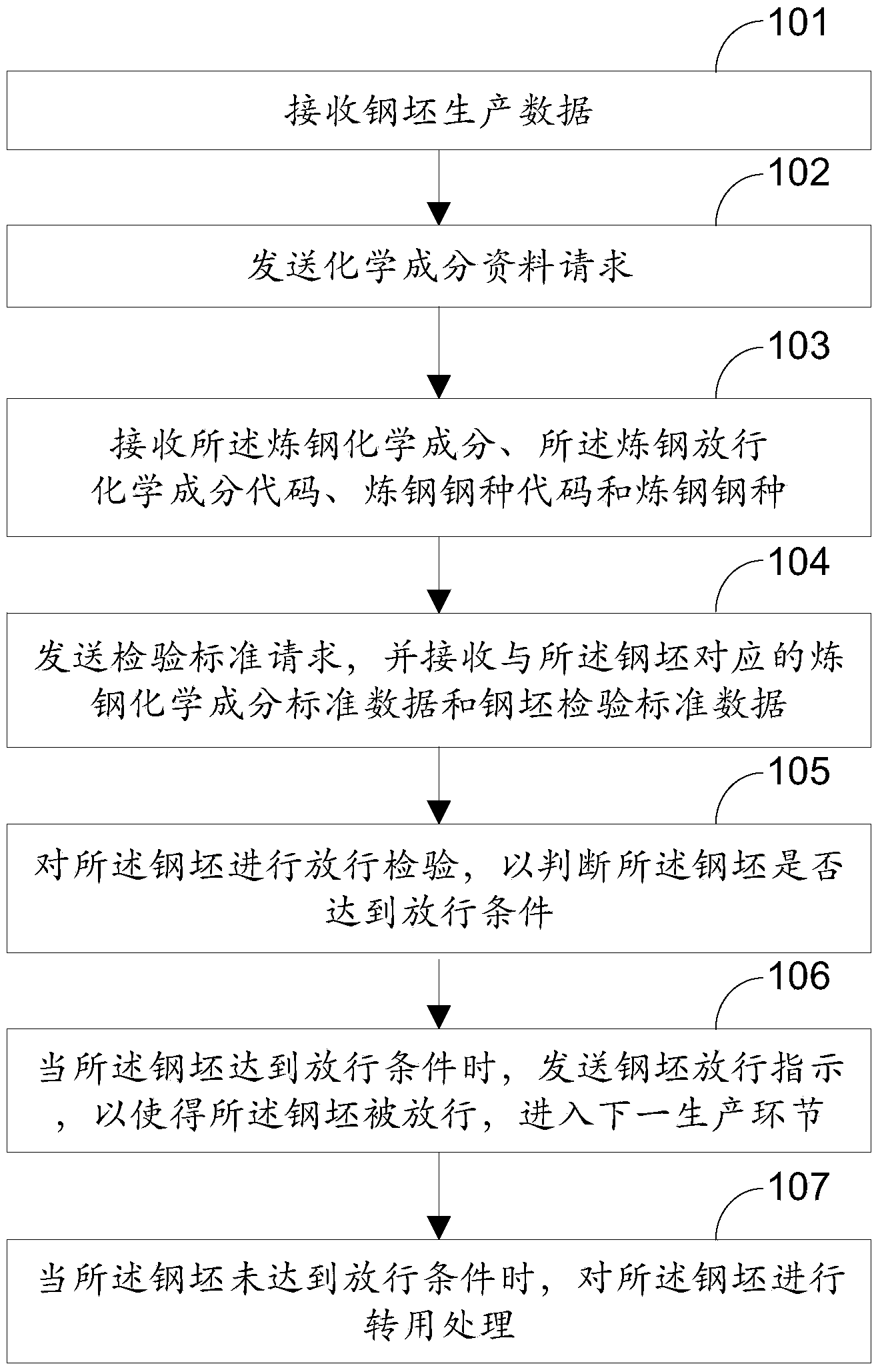

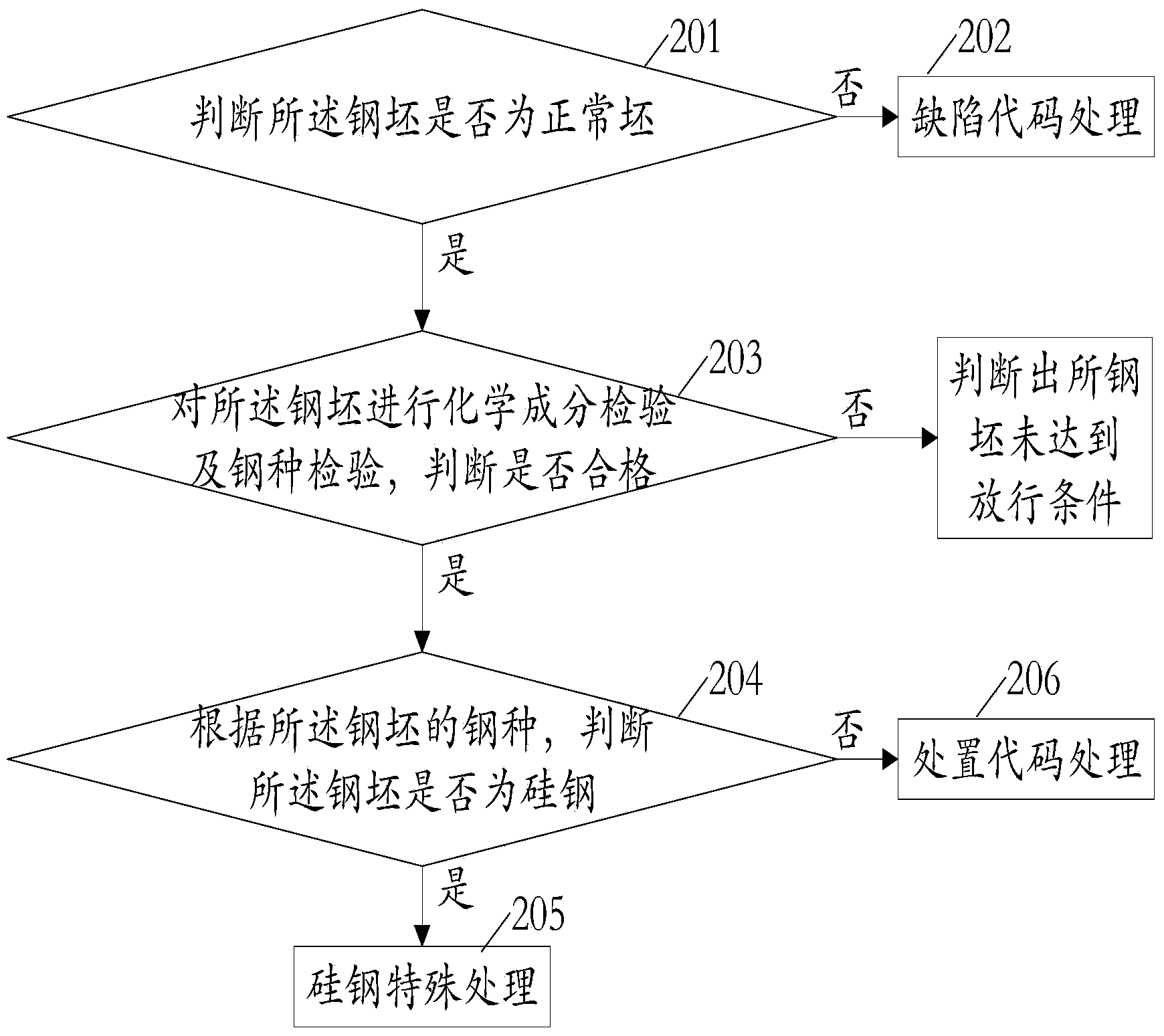

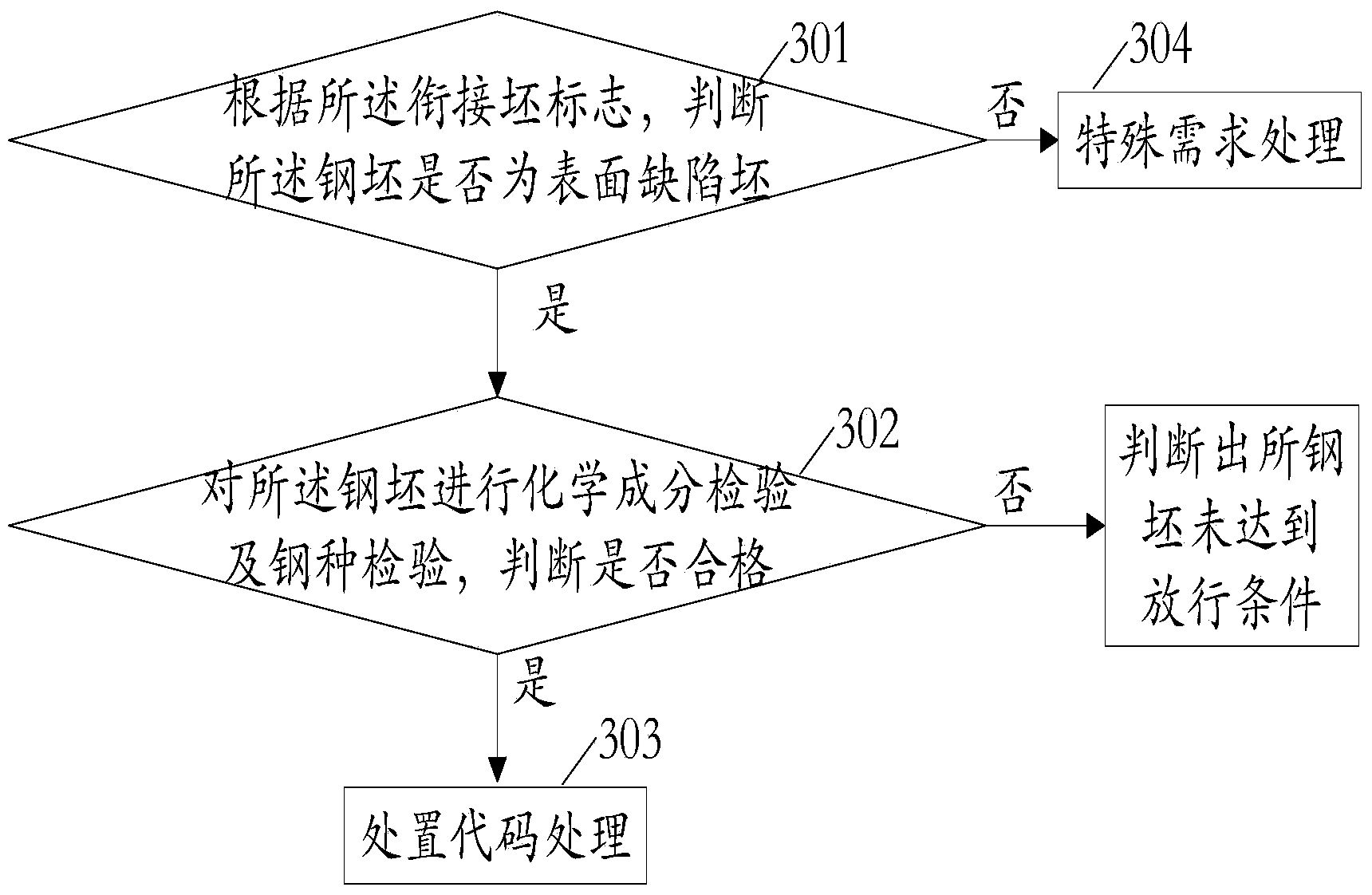

Steel billet testing method, device and system

InactiveCN103729561AAutomate processingImprove inspection efficiencySpecial data processing applicationsSteelmakingChemical composition

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Efficient furnace maintenance method

InactiveCN110835668AShorten the refurbishment timeReduce the cost of refurbishmentManufacturing convertersProcess efficiency improvementSteelmakingDolomite

Owner:盐城市联鑫钢铁有限公司

System and method for preparing sulfuric acid by recycling waste crude ferric sulfate salt in iron and steel industry through pickling

PendingCN113511634ASuppress generationEfficient use of resourcesSulfur compoundsIron sulfateSteelmaking

Owner:佛山市景嘉机电设备有限公司

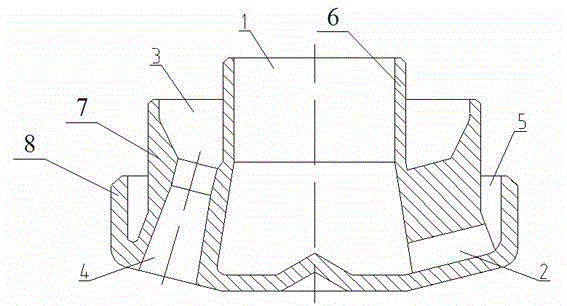

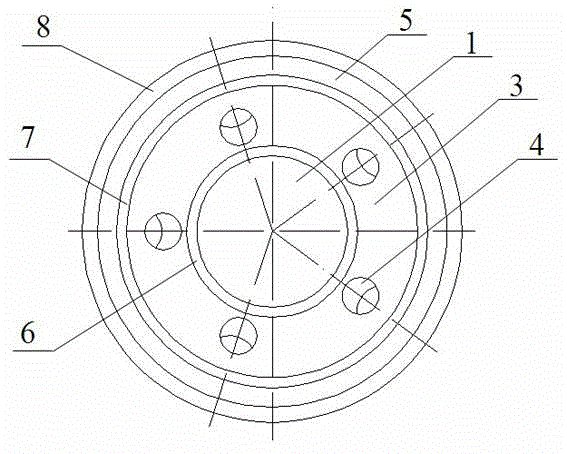

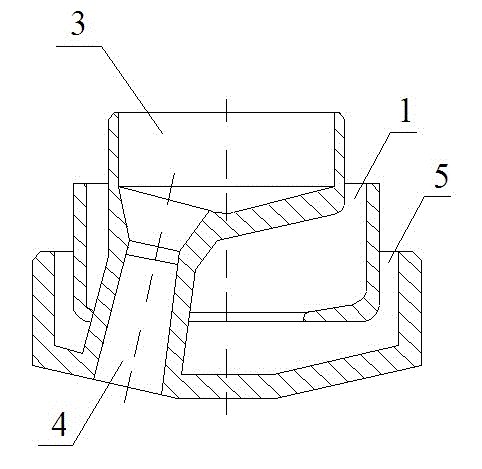

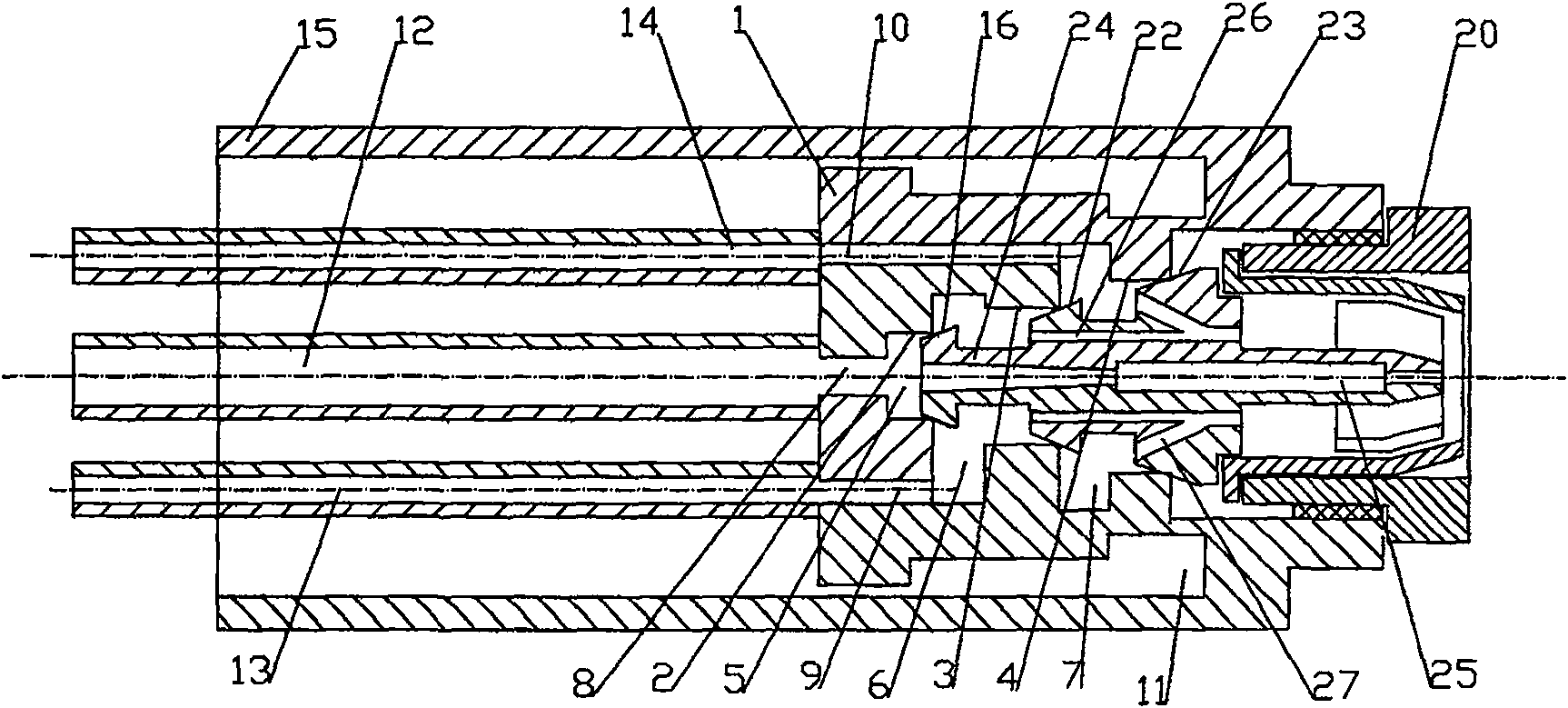

Center water-cooling convertor oxygen lance spraying head

InactiveCN102719604ASolution to short lifeImprove water cooling effectManufacturing convertersSteelmakingEngineering

Owner:沈阳东冶汉森冶金装备有限公司

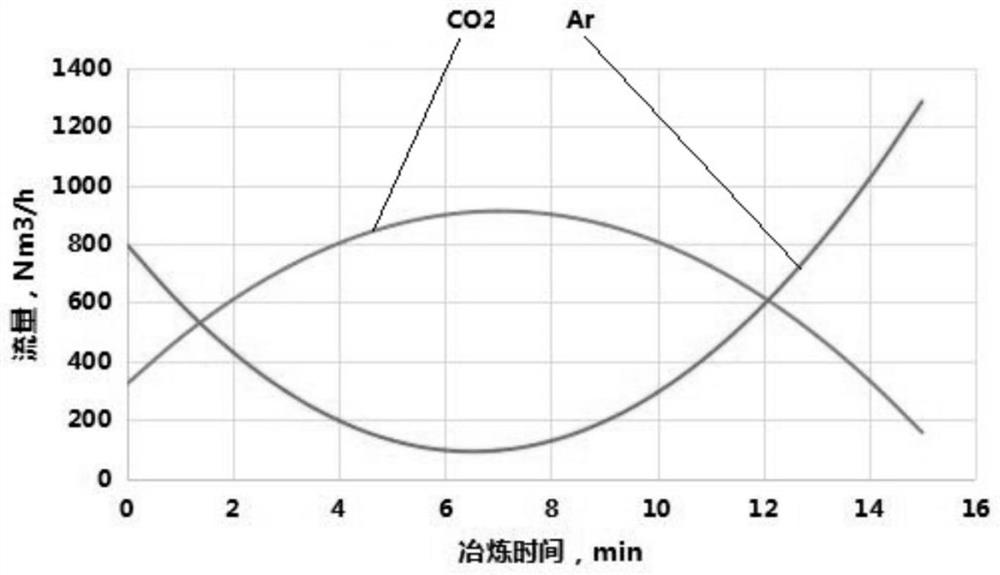

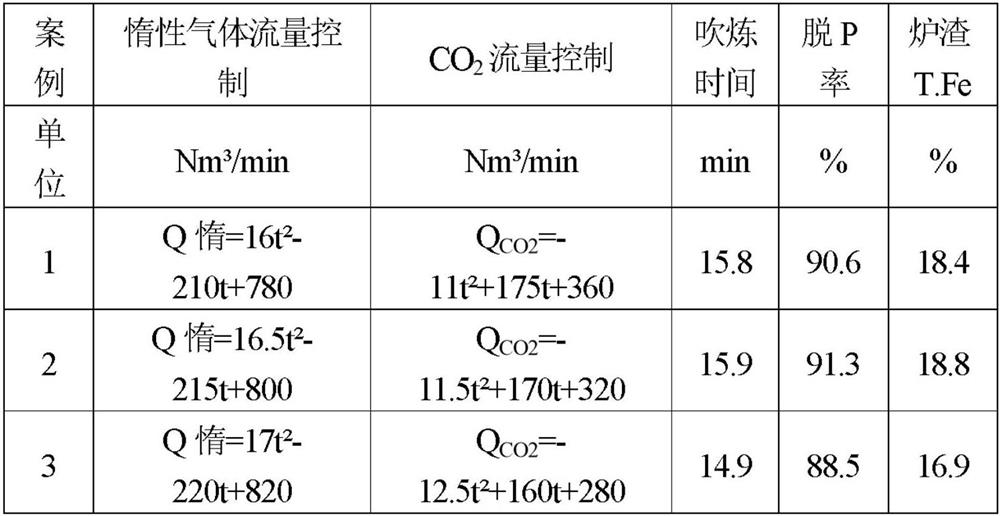

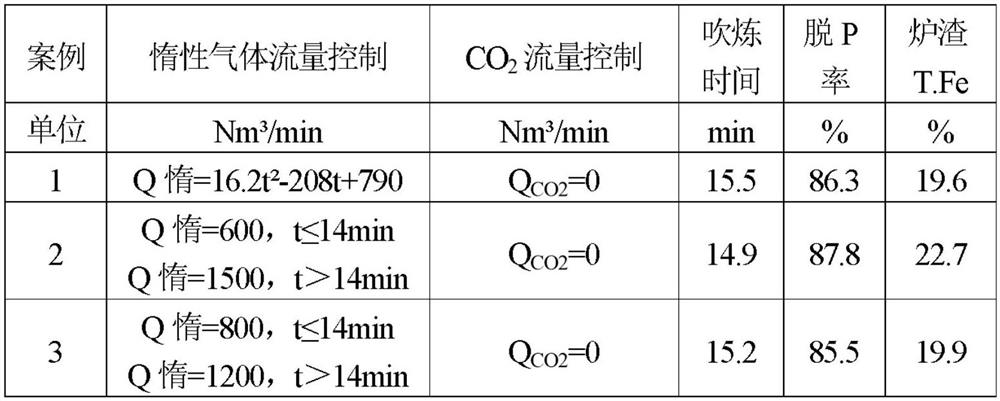

Converter smelting method

ActiveCN114369698AReduce oxidationReduce terminal oxidationSteel manufacturing process aspectsManufacturing convertersSteelmakingMolten steel

Owner:SHOUGANG CORPORATION

Method for treating various steel slags by tipping hot disintegration process

ActiveCN114774597AFully digestedReduce processing stepsRecycling and recovery technologiesSteelmakingMolten steel

Owner:中钢石家庄工程设计研究院有限公司

Steel-smelting continuous casting cutting torch

InactiveCN100561048CImprove cooling effectAvoid deformationGaseous fuel burnerSteelmakingCooling effect

Owner:陈寅明

Feeding control device and control method for cross-over rolling-up unit

PendingCN114560263APrevent tipping overPrevent fallingBio-organic fraction processingControl devices for conveyorsSteelmakingEngineering

The invention discloses a feeding control device and a feeding control method for a crossing coil upender unit, and belongs to the technical field of steelmaking equipment manufacturing, the device comprises a first detector, a second detector, a third detector and a monitor which are connected with a PLC, when a steel coil is placed on a saddle, the PLC receives distance information detected by the first detector and makes a judgment, and when the steel coil is placed on the saddle, the PLC sends the distance information to the controller; therefore, the alarm and the operation of the entrance stepping beam are controlled; when the steel coil is conveyed to the coil receiving saddle, the PLC receives information, detected by the second detector, about whether the steel coil exists or not, receives information, detected by the third detector, about whether the rolled edge of the steel coil is attached to the coil receiving face of the coil upender or not at the same time, and controls the stepping beam driver to enable the stepping beam to operate when the steel coil exists or is attached to the coil receiving face of the coil upender. According to the invention, the problem that the steel coil falls off due to difficulty in judging whether the center of the steel coil is aligned with the center of the saddle or not and whether the overflow edge of the steel coil is out of tolerance or not when the steel coil enters the coil receiving saddle of the coil upender during feeding of the cross coil upender unit can be solved.

Owner:LIUZHOU IRON & STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap