Steel billet testing method, device and system

A steel billet inspection and steel billet technology, applied in the field of billet inspection methods, devices and systems, can solve the problems of low inspection efficiency and labor, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

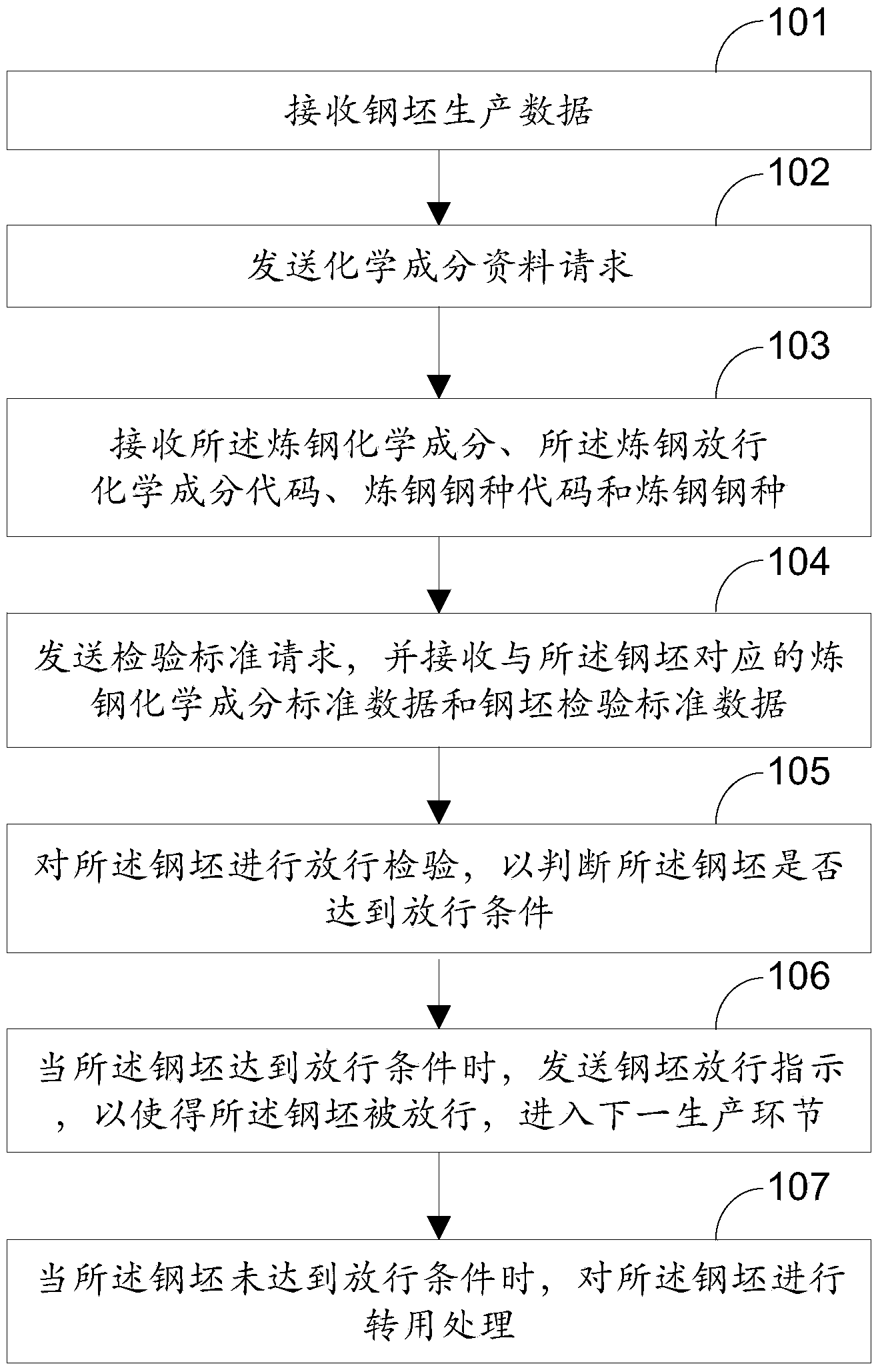

[0036] Such as figure 1 As shown, it is a flow chart of a billet inspection method provided in the embodiment of the present invention, the method includes:

[0037] Step 101, receiving billet production data;

[0038] Wherein, the billet production data includes the connecting billet mark of the billet, the T-shaped billet mark of the billet, the abnormal billet mark of the billet, the steel type code of the billet, the steel type of the billet, the The size of the steel billet, the use of the steel billet, and the whereabouts of the steel billet;

[0039] Among them, the steel billet can be divided into normal billet, connecting billet, T-shaped billet, abnormal process billet, defective billet and other types. The connecting bil

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap