Center water-cooling convertor oxygen lance spraying head

A converter oxygen lance and water cooling technology, which is applied in the manufacture of converters, etc., can solve problems such as the lack of high life of the nozzle, the complexity of the manufacturing process of the nozzle, and the structural defects of the nozzle, and achieve strong oxygen penetration, good water cooling effect, and easy The effect of turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

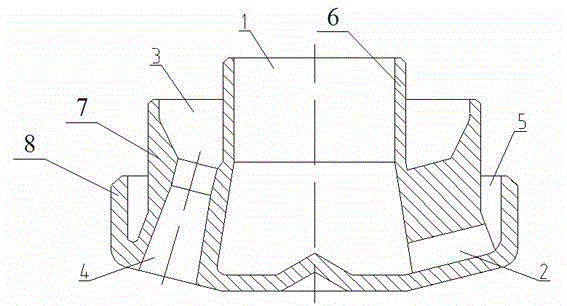

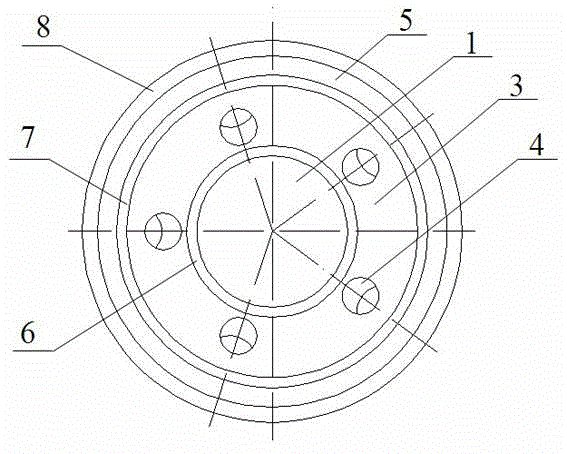

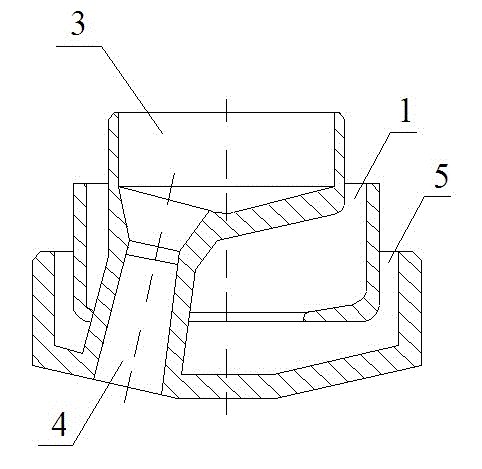

[0022] A central water-cooled converter oxygen lance nozzle, such as figure 1 As shown, it includes a nozzle main body composed of an inner pipe 6, a middle pipe 7 and an outer pipe 8. The inner pipe 6 is a water inlet channel 1, and the annular seam between the inner pipe 6 and the middle pipe 7 is an oxygen channel 3, and the middle pipe The annular seam between the pipe 7 and the outer pipe 8 is the water return channel 5; the oxygen channel 3 communicates with the oxygen nozzle 4 arranged at the bottom of the shower head body, and the water inlet channel 1 passes through the water provided on the shower head body. Hole 2 communicates with return channel 5 . The number of the oxygen injection holes 4 is 3 holes, 4 holes, 5 holes, 6 holes, 7 holes, 8 holes, 9 holes or 10 holes. A central water-cooled converter oxygen lance body matched with the nozz

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap