Method for preparing nesquehonite whiskers and nano flaky basic magnesium carbonate

A technology of magnesium carbonate trihydrate and nano flakes, applied in the directions of magnesium carbonate, nanotechnology, alkali metal chloride, etc. Low consumption, good dispersion and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

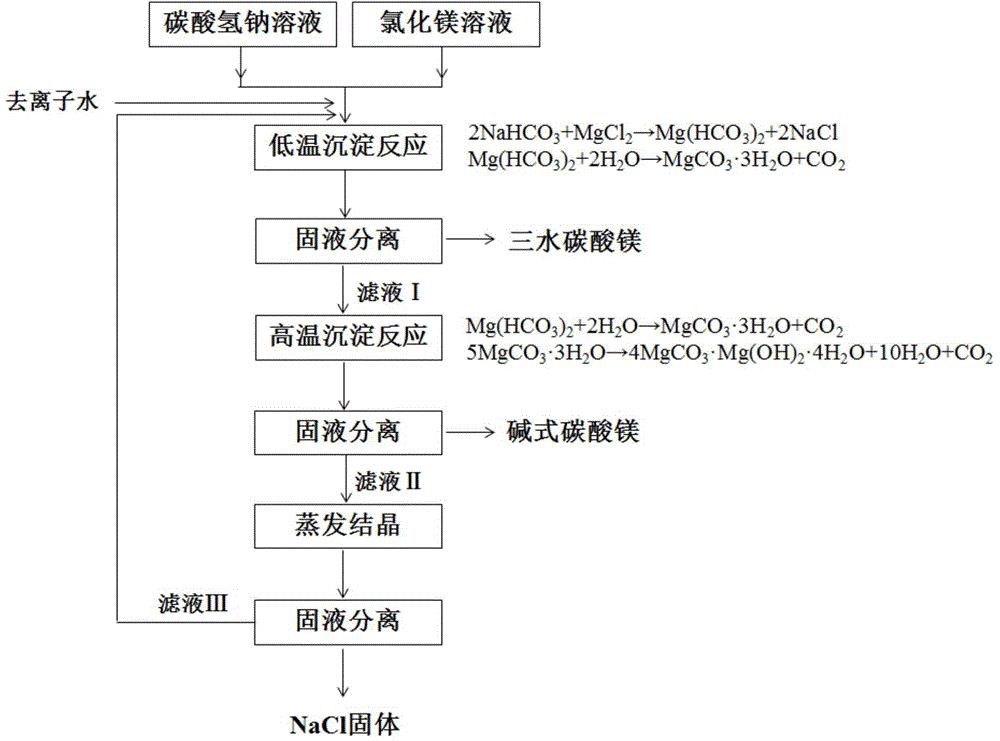

Method used

Image

Examples

Embodiment 1

[0049] (1) Magnesium chloride and sodium bicarbonate are prepared in a molar ratio of 1:2 to make the initial concentration of magnesium chloride 0.5mol / L (magnesium chloride hexahydrate 20.3g, distilled water 189.2g), the initial concentration of sodium bicarbonate 0.5mol / L (sodium bicarbonate 16.8 g, distilled water 400g) aqueous solution, the sodium bicarbonate solution is slowly dripped into the magnesium chloride solution at 40°C, the rate of addition is 6mL / min, and the speed of mechanical stirring is 300r / min. Precipitate, continue to stir and age for 50 minutes, and then filter to obtain filter cake and filtrate Ⅰ.

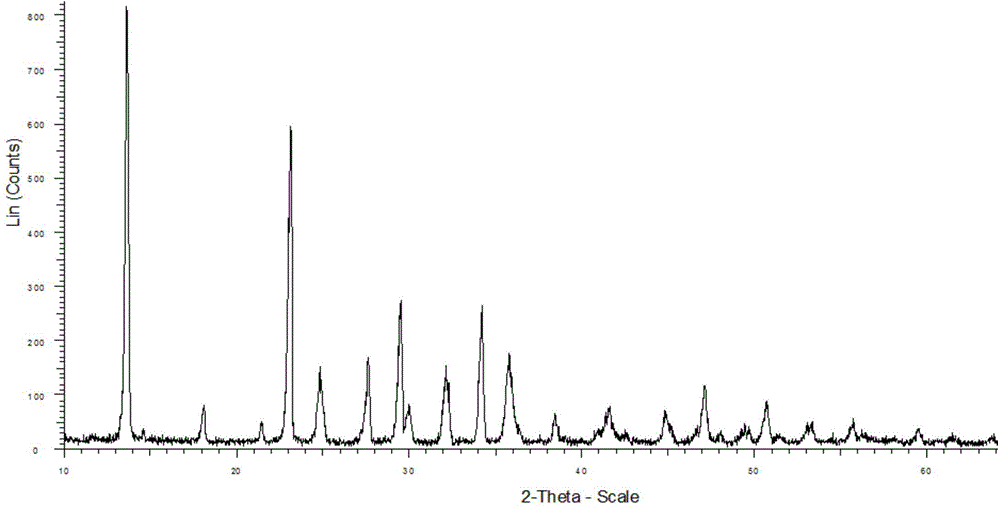

[0050] (2) Wash the filter cake obtained in step (1) with deionized water until no Cl is detected in the washing liquid - (detected with silver nitrate solution), then the filter cake was dried at 40° C. for 4 h to obtain 8.10 g of magnesium carbonate trihydrate whiskers in good shape; Between 27 and 30, please refer to the attached figure 2 with

Embodiment 2

[0054] (1) Magnesium chloride and sodium bicarbonate are prepared in a molar ratio of 1:2 to make the initial concentration of magnesium chloride 1.5mol / L (magnesium chloride hexahydrate 20.3g, distilled water 55.8g), the initial concentration of sodium bicarbonate 1mol / L (sodium bicarbonate 16.8g , distilled water 200g) aqueous solution, the sodium bicarbonate solution was slowly dropped into the magnesium chloride solution at 45°C, the dropping speed was 5mL / min, and the mechanical stirring speed was 600r / min. After the dropping was completed, the solution produced precipitation after the induction reaction period , continue to stir and age for 60min, and then filter to obtain filter cake and filtrate Ⅰ.

[0055] (2) Wash the filter cake obtained in step (1) with deionized water until no Cl is detected in the washing liquid - (detected with silver nitrate solution), then the filter cake was dried at 45°C for 5 hours to obtain 8.93g of magnesium carbonate trihydrate whis

Embodiment 3

[0059] (1) Magnesium chloride and sodium bicarbonate are prepared in a molar ratio of 1:2 to make the initial concentration of magnesium chloride 3mol / L (magnesium chloride hexahydrate 20.3g, distilled water 22.5g), the initial concentration of sodium bicarbonate 1.5mol / L (sodium bicarbonate 16.8g , distilled water 133.3g) aqueous solution, the sodium bicarbonate solution is slowly dripped into the magnesium chloride solution at 50°C, the dropping speed is 4mL / min, and the mechanical stirring speed is 900r / min. Precipitate, continue to stir and age for 80 minutes, and then filter to obtain filter cake and filtrate Ⅰ.

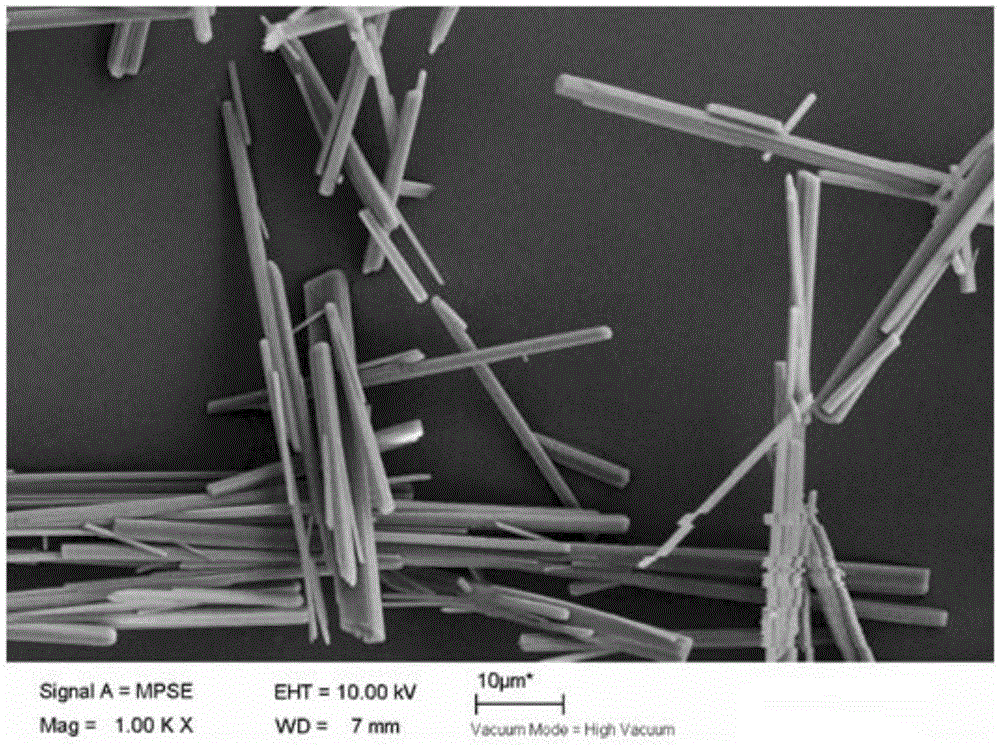

[0060] (2) Wash the filter cake obtained in step (1) with deionized water until no Cl is detected in the washing liquid - (detected with silver nitrate solution), then the filter cake was dried at 50°C for 6 hours to obtain 9.61 g of magnesium carbonate trihydrate whiskers in good shape; the average aspect ratio range of the obtained magnesium carbonate tri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap