Flame-retardant finish paint for furniture

A technology for topcoat and furniture, applied in coatings, fire-retardant coatings, polyurea/polyurethane coatings, etc., can solve problems such as property loss, casualties, burnt-out furniture, etc., achieve excellent flame retardant performance, strong impact resistance, Excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Flame retardant topcoat for furniture, including main agent, curing agent and thinner, of which:

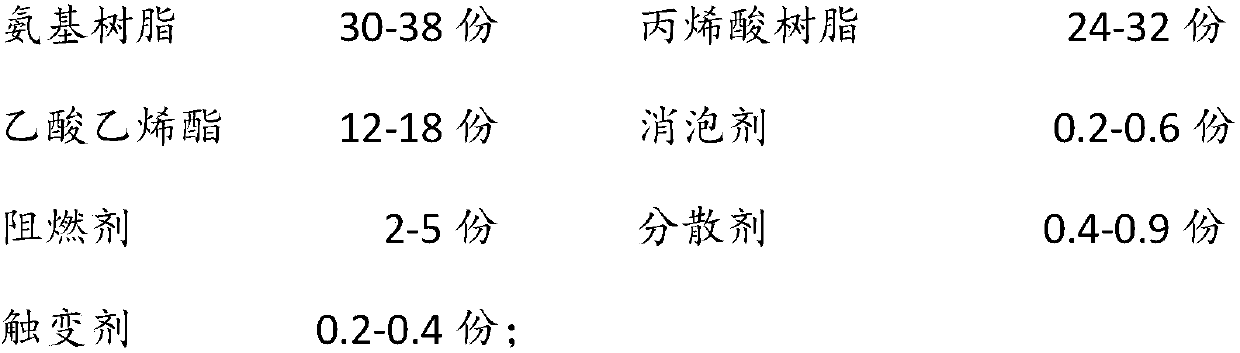

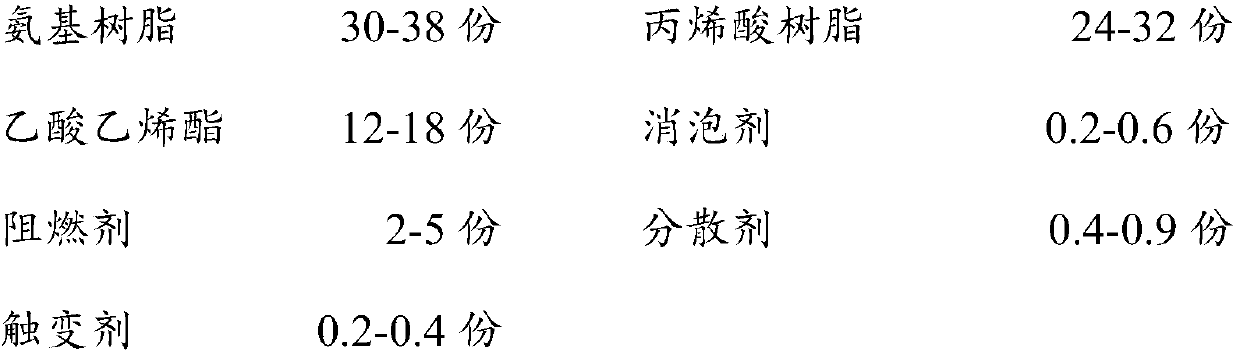

[0033] The raw material components of the main agent include in parts by mass:

[0034]

[0035] The raw material components of curing agent include by mass parts:

[0036] 25 parts of toluene diisocyanate trimer, 14 parts of iminodicarbonic acid diamide

[0037] Butyl acetate 15 parts

[0038] The raw material components of diluent include in parts by mass:

[0039] 20 parts of ethanol, 5 parts of paraffin oil

[0040] 40 parts of ethyl acetate

[0041] The preparation method of flame retardant topcoat for furniture is as follows:

[0042] (1) The preparation method of main agent

[0043] Accurately weigh the amino resin, acrylic resin, vinyl acetate, organic polyether ester, magnesium hydroxide, sodium oleate and fumed silica;

[0044] Add vinyl acetate into the reaction kettle, heat the reaction kettle, and turn on the cooling reflux, and raise the temperature to

Embodiment 2

[0061] The preparation method of flame retardant topcoat for furniture is as follows:

[0062] (1) The preparation method of main agent

[0063] Accurately weigh component amounts of amino resin, acrylic resin, vinyl acetate, mineral oil, zinc borate, sulfonate, and precipitated silica;

[0064] Add vinyl acetate into the reaction kettle, heat the reaction kettle, and turn on the cooling reflux, and raise the temperature to 63°C;

[0065] Slowly add amino resin and acrylic resin into the reaction kettle, turn on the stirrer, stir at a speed of 82r / min, and stir for 5min;

[0066] Add sulfonate and zinc borate to the reaction kettle, adjust the stirring speed to 410r / min, and mix well;

[0067] Then mineral oil and precipitated silica are added in the reaction kettle, the stirring speed is adjusted to 220r / min, and stirred for 56min to obtain the topcoat main agent;

[0068] Pressurize the topcoat main agent to pass through a 65-mesh sieve, weigh and pack.

[0069] (2) P

Embodiment 3

[0078] The preparation method of flame retardant topcoat for furniture is as follows:

[0079] (1) The preparation method of main agent

[0080] Accurately weigh the components of amino resin, acrylic resin, vinyl acetate, silicone, aluminum hydroxide, sodium oleate and fumed silica;

[0081] Add vinyl acetate into the reaction kettle, heat the reaction kettle, and turn on the cooling reflux, and raise the temperature to 62°C;

[0082] Slowly add amino resin and acrylic resin into the reaction kettle, turn on the stirrer, stir at a speed of 90r / min, and stir for 8min;

[0083] Add sodium oleate and aluminum hydroxide to the reaction kettle, adjust the stirring speed to 350r / min, and mix well;

[0084] Then add organic silicon and fumed silica into the reaction kettle, adjust the stirring speed to 280r / min, and stir for 40min to obtain the main ingredient of the topcoat;

[0085] Pressurize the topcoat main agent to pass through a 60-mesh sieve, weigh and pack.

[0086]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap