Water-resistant and light-corrosion-resistant exterior wall building coating

A technology for architectural coatings and exterior walls, used in anti-corrosion coatings, fire-retardant coatings, anti-fouling/underwater coatings, etc. Corrosion performance, simple selection, green and friendly effects in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

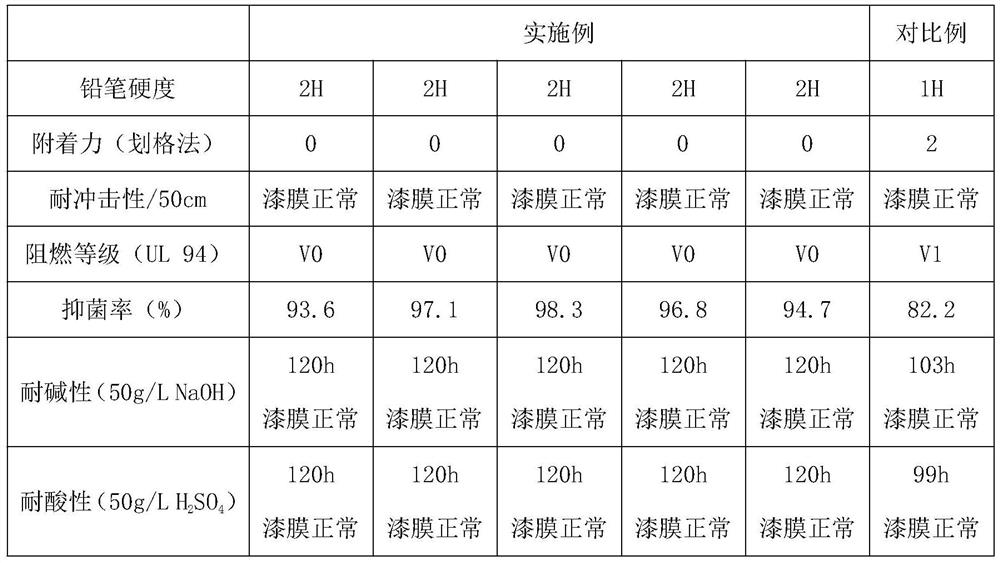

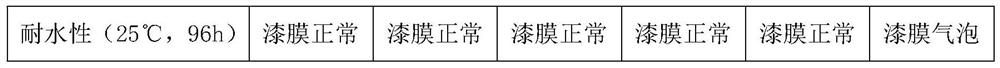

Examples

Embodiment 1

[0023] A water-resistant light anti-corrosion exterior wall architectural coating proposed by the present invention comprises the following raw materials in parts by weight: 50 parts of acrylic acid emulsion, 18 parts of natural mineral sand, 3 parts of titanium dioxide, 2 parts of organic silicon waterproofing agent, 1 part of preservative, paraffin oil 4 parts, 1 part of 4-carboxycinnamic acid, 5 parts of additives, 90 parts of water;

[0024] Among them, the natural mineral sand is a compound of quartz sand, vermiculite sand, and montmorillonite sand in any proportion; the organic silicon waterproofing agent is sodium methyl silicate; Compound of hexahydro-s-triazine, zinc dialkyldithiophosphate, zinc 2-ethylhexanoate and zinc borate; additives are thickener and anti-sedimentation agent.

[0025] The present invention also proposes a method for preparing a water-resistant light anti-corrosion exterior wall architectural coating, comprising the following steps:

[0026] S1. In

Embodiment 2

[0031] A water-resistant light anti-corrosion exterior wall architectural coating proposed by the present invention comprises the following raw materials in parts by weight: 55 parts of acrylic acid emulsion, 20 parts of natural mineral sand, 4 parts of titanium dioxide, 3 parts of organic silicon waterproofing agent, 1.5 parts of preservative, paraffin oil 5 parts, 1.2 parts of 4-carboxycinnamic acid, 6 parts of additives, 100 parts of water;

[0032] Among them, the natural mineral sand is a compound of quartz sand, vermiculite sand, and montmorillonite sand in any proportion; the organic silicon waterproofing agent is sodium methyl siliconate; Compound of hexahydro-s-triazine, zinc dialkyldithiophosphate, zinc 2-ethylhexanoate and zinc borate; additives are toughening agent, defoamer and leveling agent.

[0033] The present invention also proposes a method for preparing a water-resistant light anti-corrosion exterior wall architectural coating, comprising the following steps:

Embodiment 3

[0039] A water-resistant light anti-corrosion exterior wall architectural coating proposed by the present invention comprises the following raw materials in parts by weight: 60 parts of acrylic acid emulsion, 22 parts of natural mineral sand, 5 parts of titanium dioxide, 3.5 parts of organic silicon waterproofing agent, 2 parts of preservative, paraffin oil 6 parts, 1.5 parts of 4-carboxycinnamic acid, 7.5 parts of additives, 105 parts of water;

[0040]Among them, the natural mineral sand is a compound of any proportion of quartz sand, vermiculite sand, and montmorillonite sand; the silicone waterproofing agent is dimethyl silicone oil emulsion; The complex of hexahydro-s-triazine, zinc dialkyldithiophosphate, zinc 2-ethylhexanoate and zinc borate; the additives are leveling agent, anti-skinning agent and anti-sagging agent.

[0041] The present invention also proposes a method for preparing a water-resistant light anti-corrosion exterior wall architectural coating, comprising t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap