Building exterior wall coating with good weather resistance and exterior wall coating construction process

A technology for building exterior walls and weather resistance, applied in coatings, buildings, building structures, etc., can solve problems such as peeling, coating cracking, coating loss of decorative protection functions, etc., to improve adhesion, improve weather resistance, Effect of improving crack resistance and peeling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, is a kind of good weather resistance architectural exterior wall paint disclosed by the present invention, comprises the coating for the first topcoat layer and the coating for the second topcoat layer, and the coating for the first topcoat layer comprises the following groups by weight: Minute:

[0044] components parts by weight components parts by weight Polyacrylate Emulsion 55 magnesium hydroxide 2.1 calcium bicarbonate 12 Sodium lignosulfonate 0.65 Polyacrylamide Resin Particles 6.5 AMP-95 0.33 polyvinyl alcohol 3 ASE 0.67 Propylene Glycol 1.5 Quartz sand 7.5

[0045] The particle size of polyacrylamide resin particles is 0.1mm; the particle size of quartz sand is 1.5mm;

[0046] The coating for the second topcoat layer comprises the following components by weight:

[0047] components parts by weight components parts by weight PTFE emulsion 55 UV-O 0.45 Titan

Embodiment 2

[0057] Embodiment 2, is a kind of good weather resistance architectural exterior wall paint disclosed by the present invention, comprises the coating for the first topcoat layer and the coating for the second topcoat layer, and the coating for the first topcoat layer comprises the following groups by weight: Minute:

[0058] components parts by weight components parts by weight Polyacrylate Emulsion 65 magnesium hydroxide 3 calcium bicarbonate 15 Sodium lignosulfonate 0.8 Polyacrylamide Resin Particles 8 AMP-95 0.375 polyvinyl alcohol 4 ASE 1.125 Propylene Glycol 2 Quartz sand 10

[0059] The particle size of polyacrylamide resin particles is 0.1mm; the particle size of quartz sand is 1.5mm;

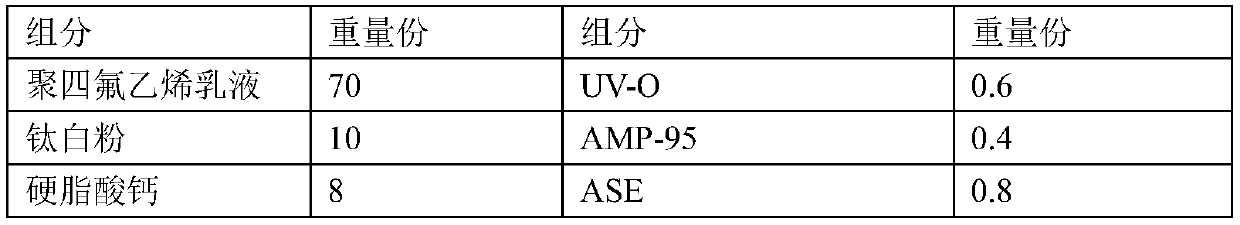

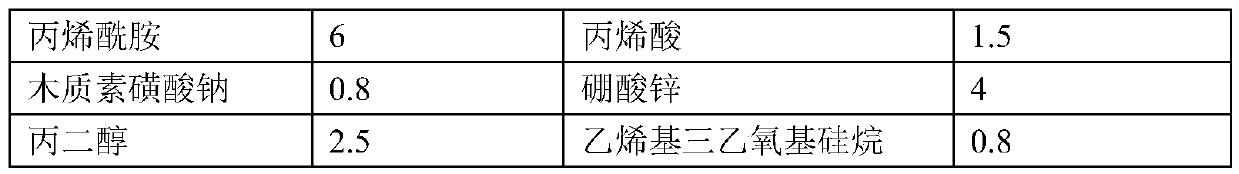

[0060] The coating for the second topcoat layer comprises the following components by weight:

[0061]

[0062]

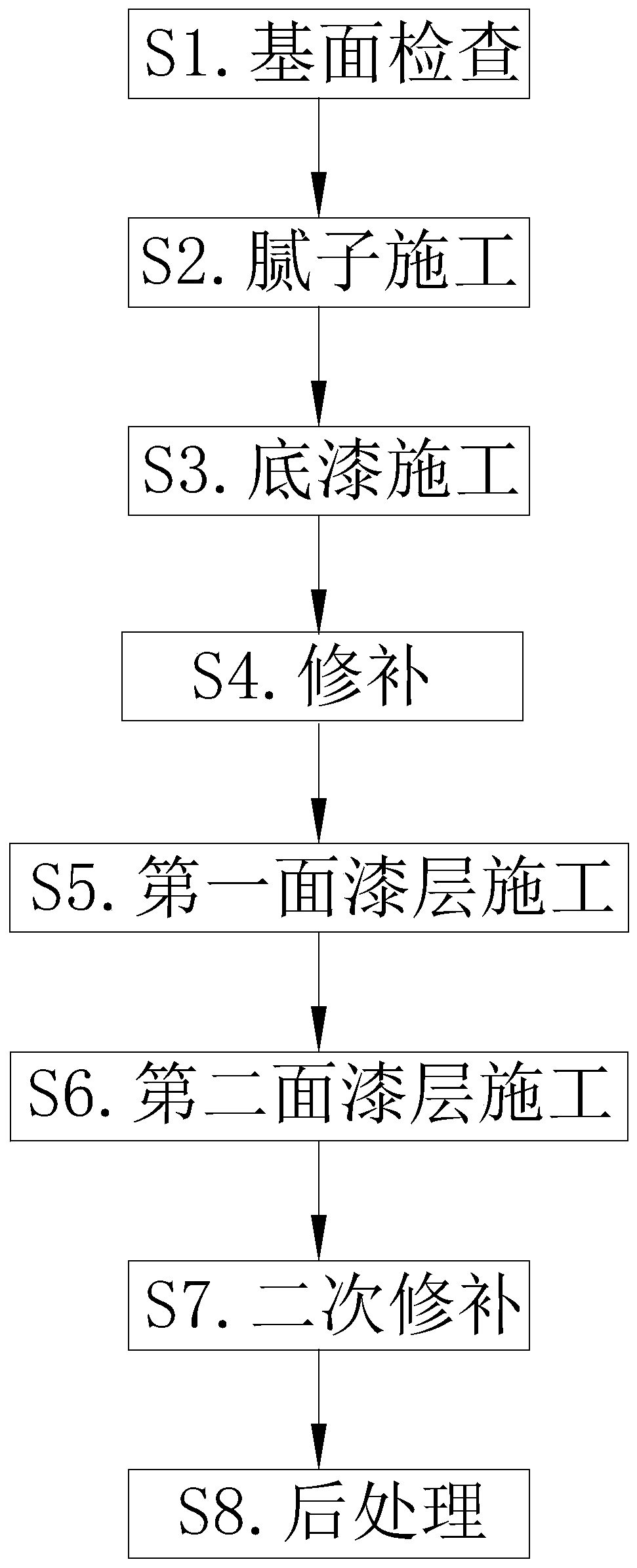

[0063] An exterior wall coating construction process, the specific process steps are the same as in Examp

Embodiment 3

[0064] Embodiment 3, is a kind of good weather resistance architectural exterior wall paint disclosed by the present invention, comprises the coating for the first topcoat layer and the coating for the second topcoat layer, and the coating for the first topcoat layer comprises the following groups by weight: Minute:

[0065] components parts by weight components parts by weight Polyacrylate Emulsion 45 magnesium hydroxide 1 calcium bicarbonate 10 Sodium lignosulfonate 0.4 Polyacrylamide Resin Particles 5 AMP-95 0.25 polyvinyl alcohol 2 ASE 0.25 Propylene Glycol 1 Quartz sand 5

[0066] The particle size of polyacrylamide resin particles is 0.1mm; the particle size of quartz sand is 1.5mm;

[0067] The coating for the second topcoat layer comprises the following components by weight:

[0068] components parts by weight components parts by weight PTFE emulsion 40 UV-O 0.3 Titanium dioxid

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap