Preparation method of water-soluble acrylic acid solid resin

A technology of water-soluble acrylic and solid resin, which is applied in the field of preparation of acrylic solid resin, which can solve the problems of insufficient solvent resistance and small weather resistance, and achieve the effects of excellent printability, fast drying speed and outstanding compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A kind of preparation method of water-soluble acrylic acid solid resin, concrete steps are as follows:

[0021] 1) Prepare the required soft monomers, hard monomers, other functional monomers, other components, initiators, and flow aids as raw materials;

[0022] 2) Directly introduce soft monomers, hard monomers, other functional monomers, other components and initiators into the tubular reactor for mixing, and at the same time introduce flow aids to obtain mixed materials, and keep the mixed materials in the tubular reactor Maintain a certain flow rate to ensure that the mixed material stays in the tubular reactor for 1 to 120 minutes, the pressure of the tubular reactor is maintained at 0.2 to 3.5Mpa, and the temperature of the mixed material in the tubular reactor is maintained at 150 to 350°C. Flow out from the tubular reactor to obtain a fluid semi-finished product containing residual monomers;

[0023] 3) Devolatize the fluid semi-finished product containing residu

Embodiment 1

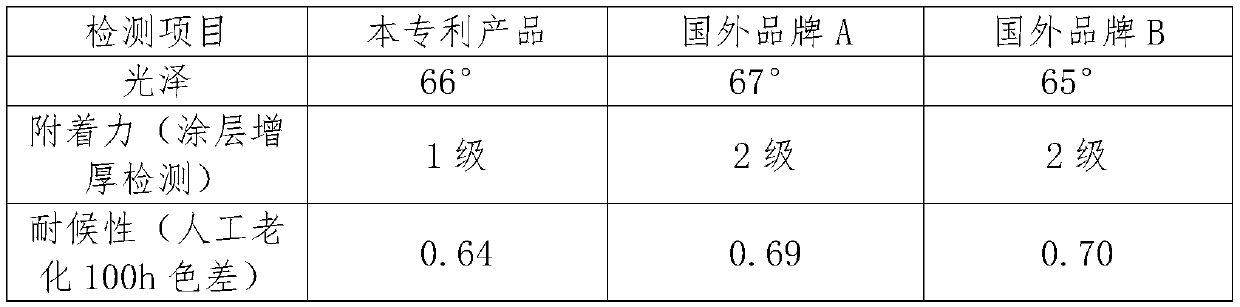

[0030] Embodiment one: the initiator of 1.1kg (2.36%) soft monomer, 29kg (62.11%) hard monomer, 13kg (27.84%) functional monomer, 0.3kg (0.64%), 3.29kg (7.05%) other Components and 2kg (4.28%) of flow aid are mixed and then introduced into the reactor for reaction. The temperature is kept at 240°C and the pressure is 0.5mpa. Material cooling obtains product (reference table 1);

Embodiment 2

[0031] Embodiment two: with the initiator of 0.4kg (2.35%) soft monomer, 11kg (64.71%) hard monomer, 5.5kg (32.35%) other functional monomers, 0.1kg (0.59%), 1.5kg (8.82%) ) flow aid mixed and then introduced into the reactor for reaction, the temperature is maintained at 230°C and the pressure is 0.3mpa, and then the material obtained after the reaction is subjected to devolatilization treatment, vacuum-0.07mpa, and the material after devolatilization is cooled to obtain the product (reference table 1);

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap