Environment-friendly modified isocyanate resin aqueous emulsion and manufacturing method thereof

A technology of isocyanate resin and water-based emulsion, which is applied in the manufacture of tools, flat products, and other household appliances, can solve the problems of high cost, lack of practicability, and poor practicability of modification methods, and achieve low cost, long storage period, and no The effect of formaldehyde release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

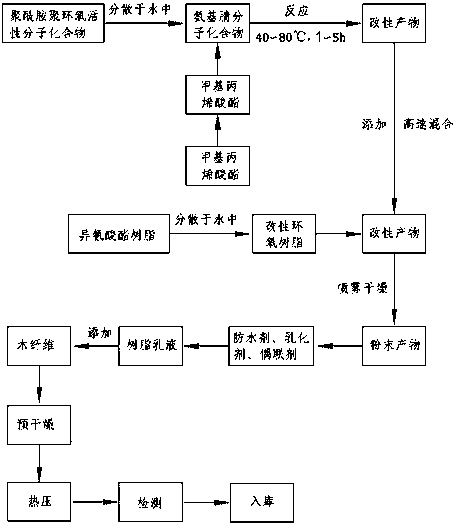

Method used

Image

Examples

Embodiment Construction

[0120] In order to understand the present invention more deeply, the present invention will be further described below in conjunction with the examples. It should be noted that the protection scope of the present invention is not limited to the scope described in the examples.

[0121] In the following examples, the internal bonding strength and static bending strength were tested according to the ISO7500-1 national test standard, and the elastic modulus was tested according to the ISO9513 national standard; the water temperature used in the 5-min boiling water bath was 100°C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap