Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Air tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air Tightness. Air tightness is needed, as air exchange through the envelope increases the heat loss from the building. In extreme cases it may equal the transmission loss. Lack of air tightness may also cause moisture damage when heated moist air causes condensation in the construction.

Oil resistant rubber

The invention discloses an oil resistant rubber, which is composed of the following components by weight: 40-60 parts of fluorine rubber, 20-30 parts of natural rubber, 10-15 parts of nitrile rubber, 20-40 parts of carbon black, 15-30 parts of white carbon black, 0.5-2 parts of antioxidant RD, 1-2 parts of antioxidant 4010 Na, 2-4 parts of paraffin, 25-35 parts of light calcium carbonate, 2-3 parts of eleaostearic acid, 3-5 parts of zinc oxide, 5-10 parts of magnesium oxide, 1-2 parts of 2, 2'-dibenzothiazyl disulfide, 3-4 parts of coumarone and 0.2-0.8 parts of vulcanizing agents. The oil resistant rubber provided by the invention has the advantages of oil resistance, airtight and good high temperature resistance.

Owner:GUANGZHOU CHONGQI IND CO LTD

Electronic component

InactiveCN101599468AMiniaturizationImpedence networksSemiconductor/solid-state device detailsMiniaturizationElectronic component

The present invention provides an electronic component which can seal with higher air tightness and can realize miniaturization. The electronic component of the invention comprises the following components: an insulating substrate (10); a device chip (20) which is equipped on the insulating substrate (10) with a reverse mode; a pattern (32) which is equipped on the insulating substrate (10) along the side surface of the device chip (20) with a mode that a clearance is provided between the upper surface of the pattern (32) and the lower surface of the device; and an SOG oxide film (30) which covers the side surface of the device chip (20) and the pattern (32) with a mode that the SOG oxide film is inserted into the clearance between the upper surface of the pattern (32) and the lower surface of the device chip (20) and a clearance (26) is formed between the upper surface of the insulating substrate (10) and the lower surface of the device chip (20).

Owner:TAIYO YUDEN KK

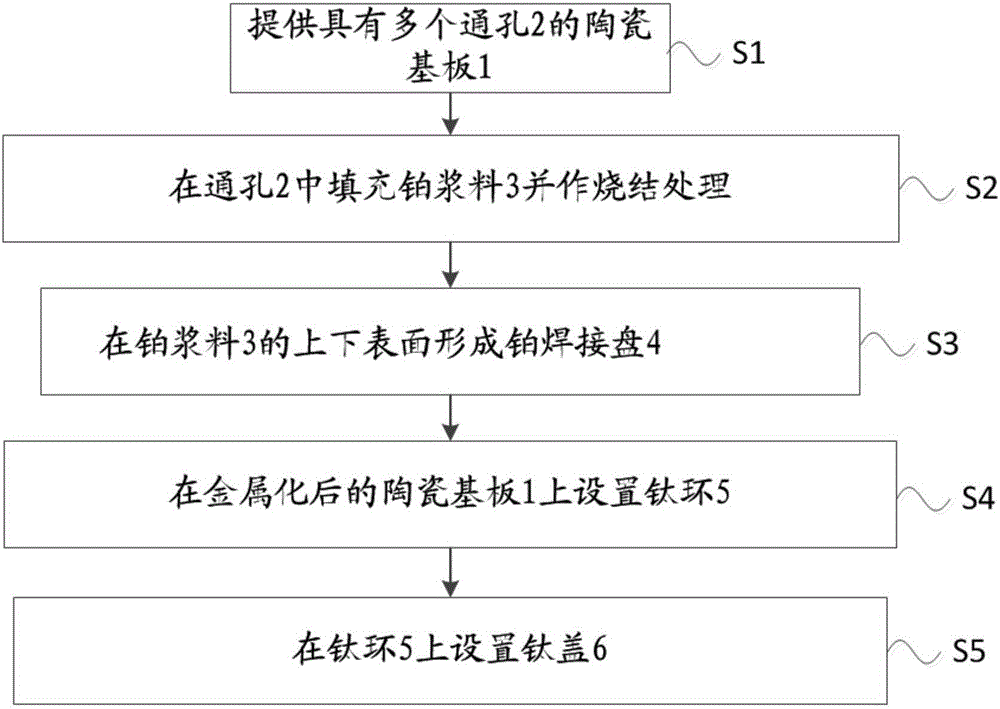

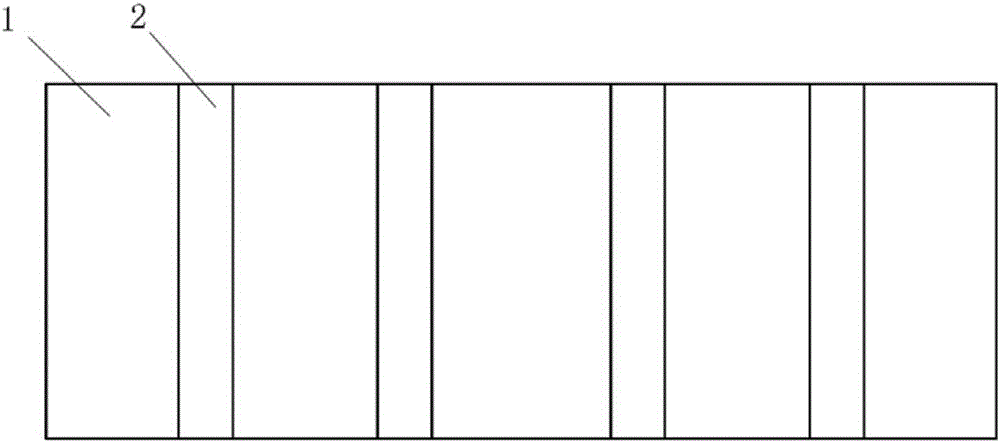

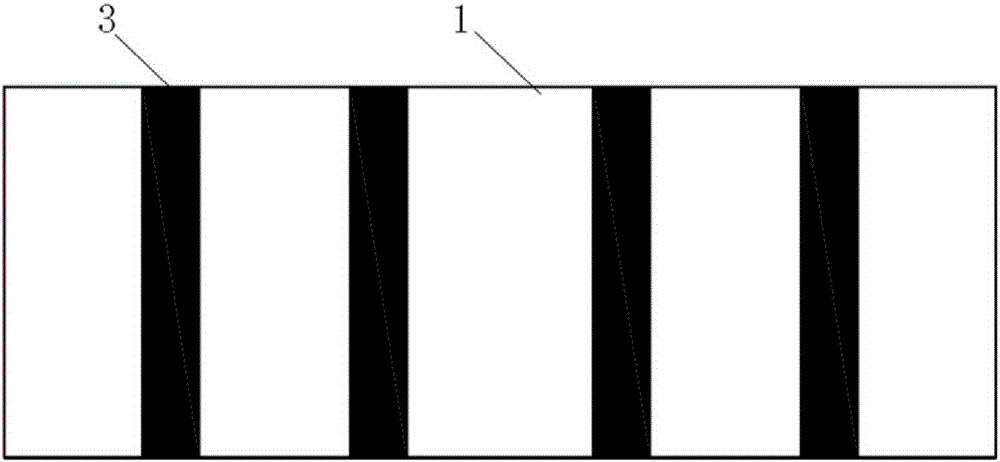

Manufacturing method of implantable artificial retina ceramic packaging body

Owner:深圳市勃望初芯半导体科技有限公司

Water tightness test device

Owner:WUHAN MARINE MACHINERY PLANT

Investment casting mould of high-temperature alloy bending pipe

Owner:江苏久保联实业有限公司

Airtightness detection device and airtightness detection method

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

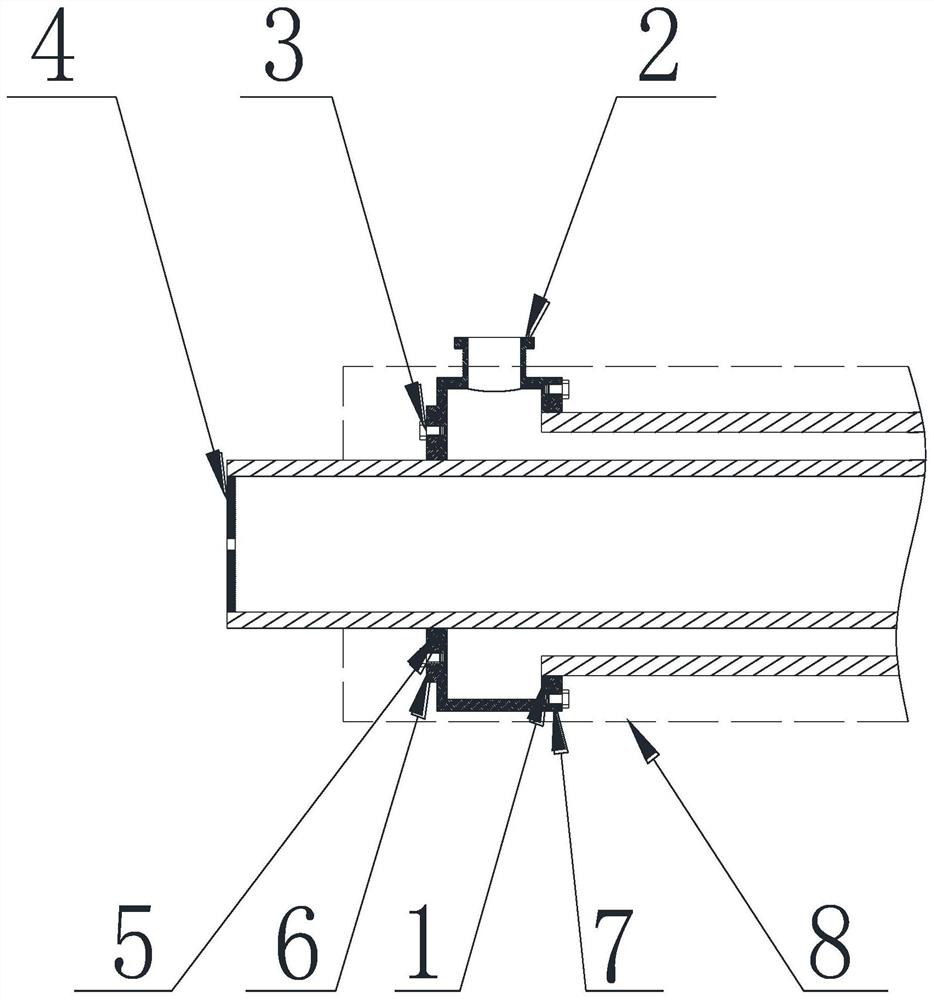

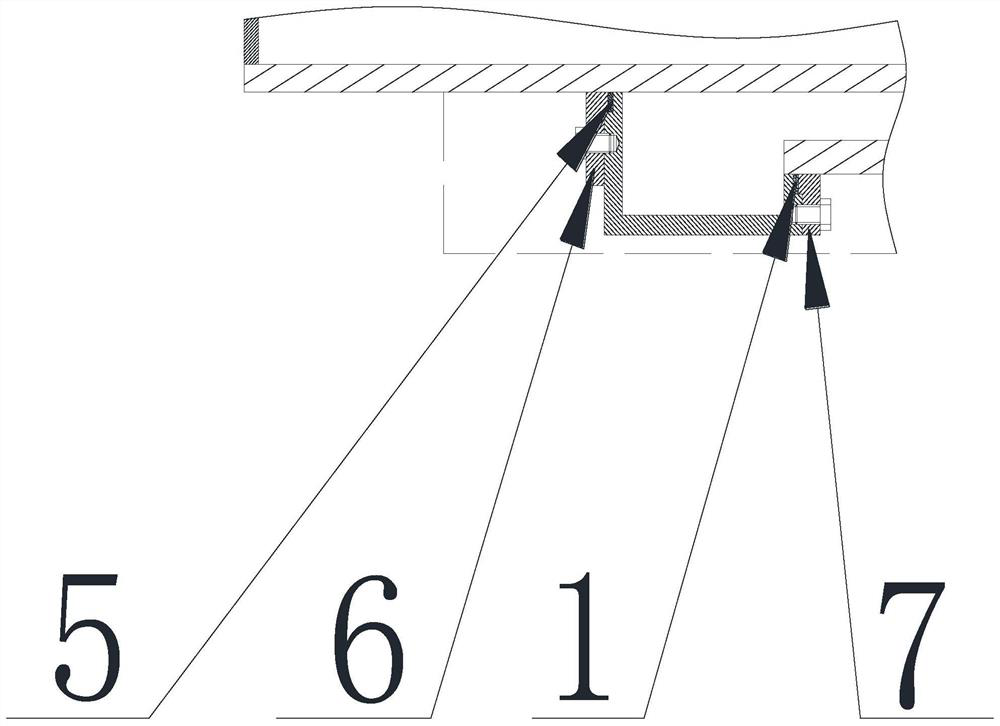

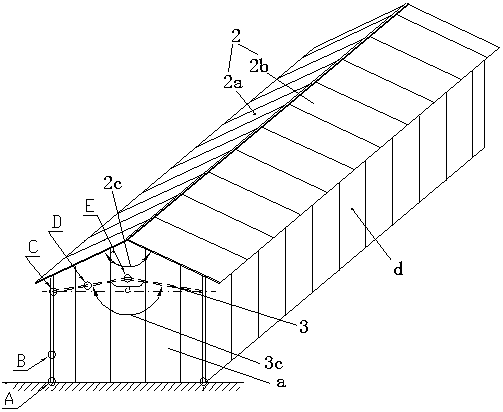

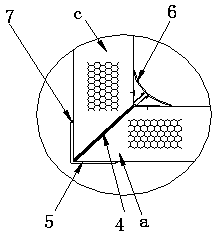

Aluminum-plastic compositedoor and window section bar

InactiveCN103216176AComposite installation is simpleImprove thermal insulationWing framesPolyvinyl chlorideEngineering

Owner:ZHEJIANG ROOMEYE ENERGY SAVING TECH CO LTD

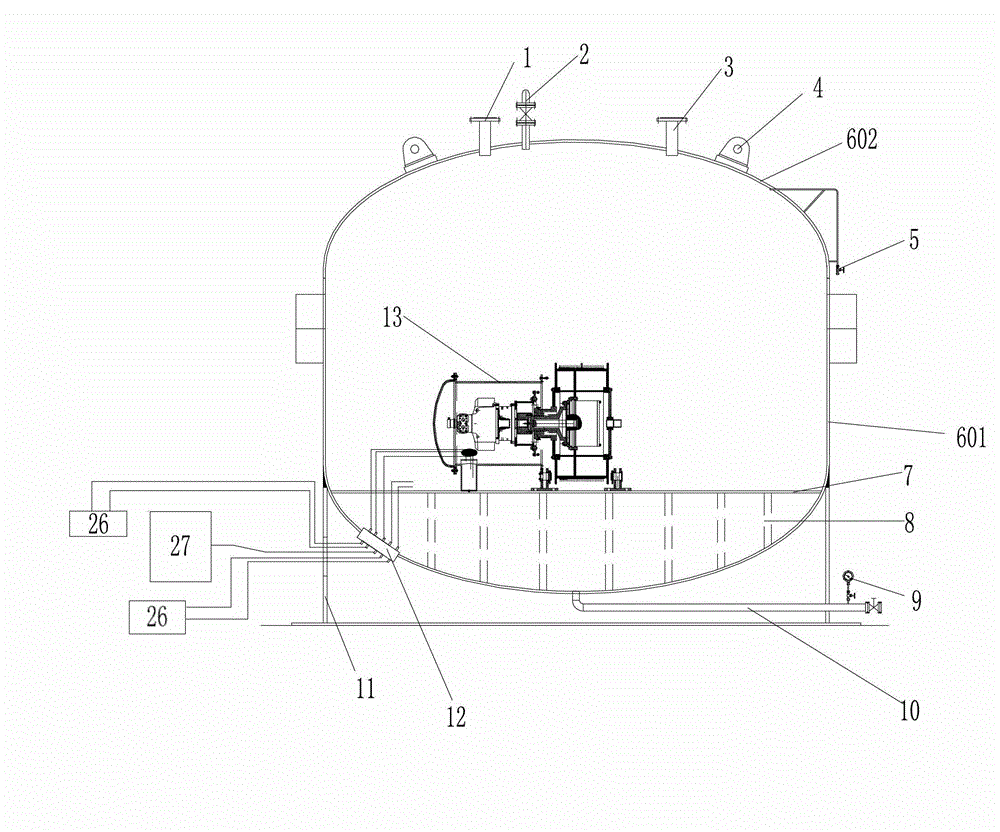

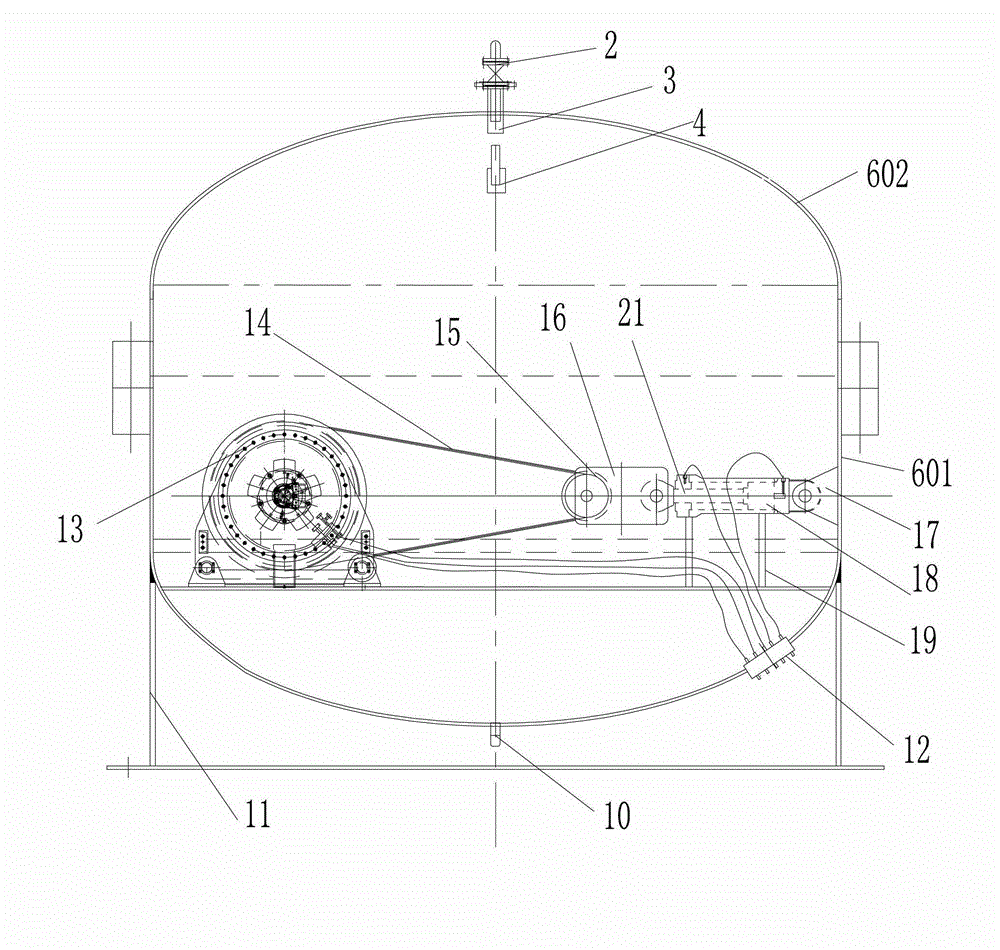

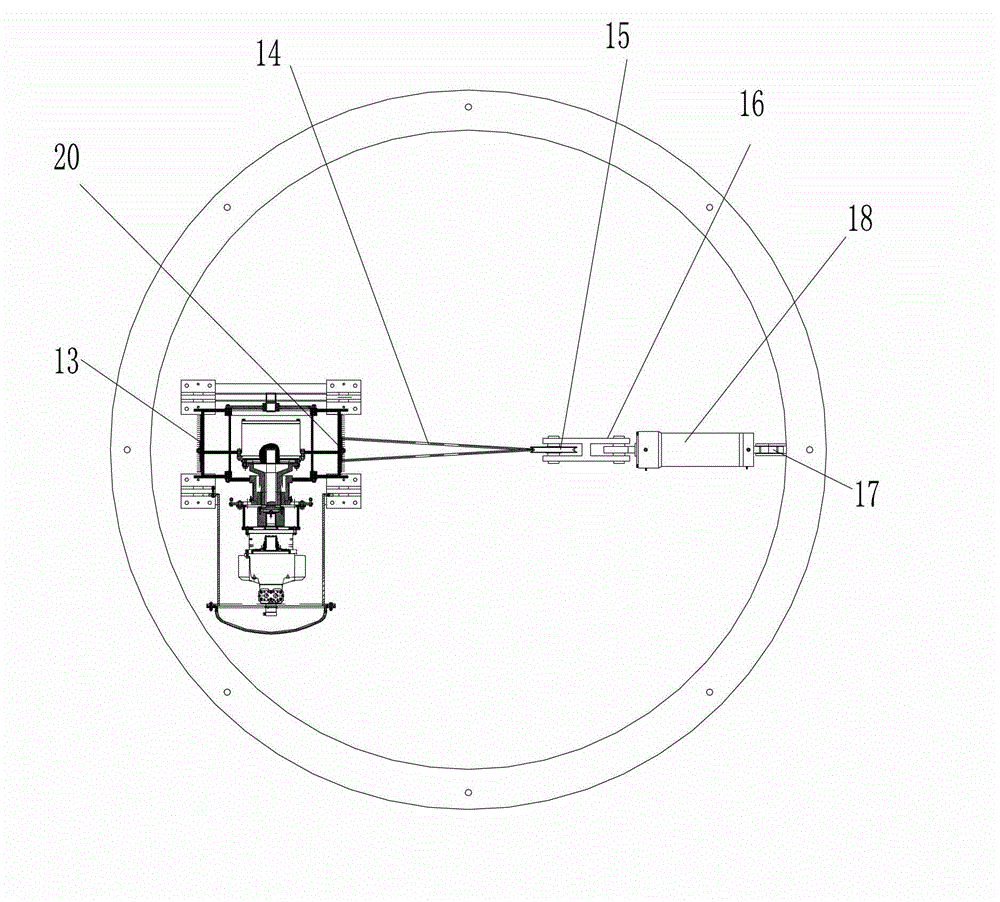

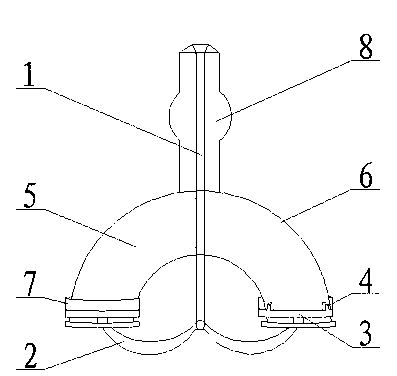

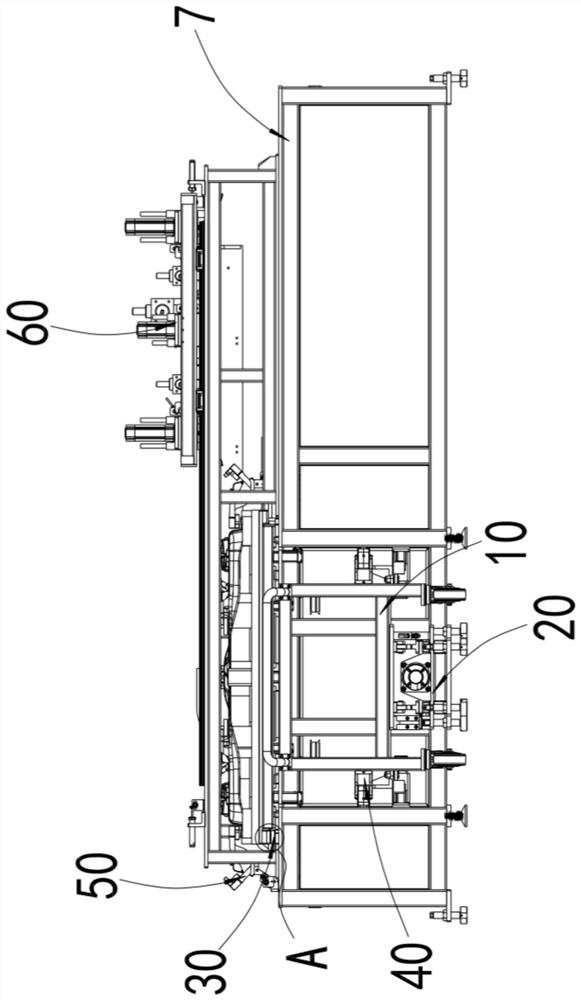

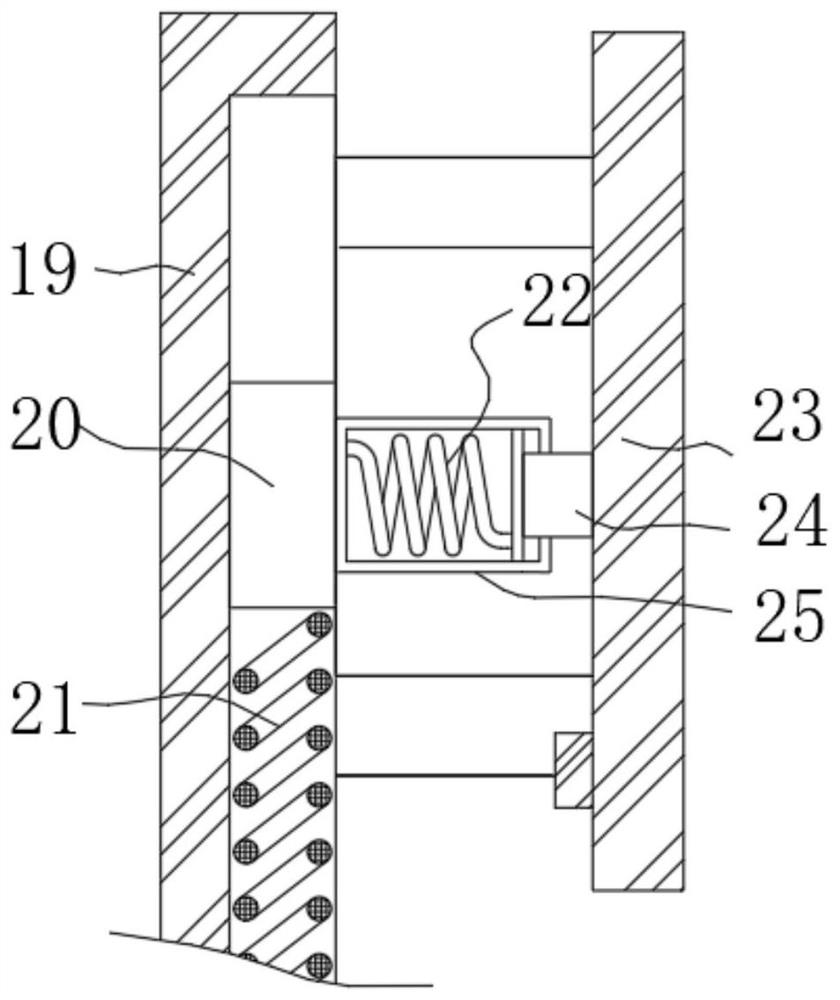

Self rotation device for vacuum cavity

ActiveCN103807119ASolve the sealing problemTroubleshoot spinning crafting issuesSpring motorMachines/enginesGear wheelEngineering

The invention discloses a self rotation device for a vacuum cavity. The self rotation device comprises a rotation tray, a casing and a spiral clockwork spring, an internal and outer inclined tooth gear, a directional rotation fork and a rotating shaft, wherein the internal and outer inclined tooth gear is an annular wheel, internal and external inclined teeth are respectively arranged on the inner and outer side surfaces of the annular wheel, the inclination directions of the internal and external inclined teeth are opposite, the upper end of the rotating shaft is fixedly arranged on the rotation tray, the lower end of the rotating shaft sequentially passes through the internal and external inclined tooth gear, the clockwork spring and a case, the directional rotation fork comprises a plurality of stop parts, the center of the directional rotation fork is fixed onto the rotating shaft, the tail ends of the stop parts are respectively butted with the internal inclined teeth, the internal end of the spiral clockwork spring is fixedly arranged on the rotating shaft, the outer end of the spiral clockwork spring is fixedly arranged on the casing, a plurality of pallets are arranged on the inner side surface of the casing, and the tail ends of the pallets are butted with the external inclined teeth. The self rotation device for the vacuum cavity has the advantages that the structure is simple, and in addition, the rotation smoothness and the airtightness requirement during the rotation can be met.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

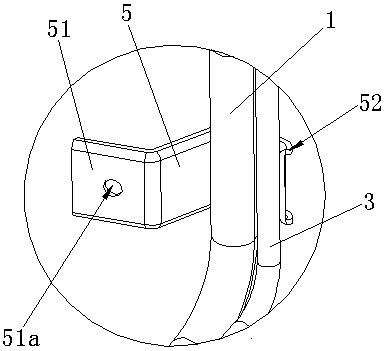

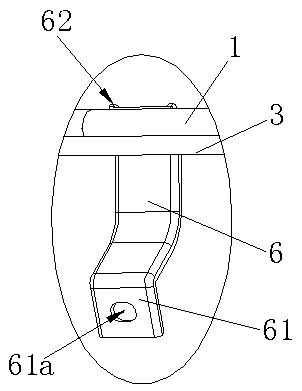

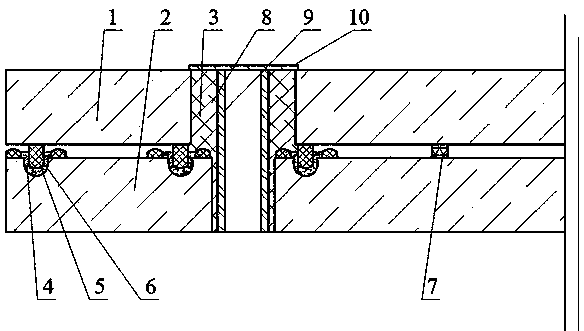

Plastic welding device and laser welding method thereof

InactiveCN107672187AImprove waterproof performanceImprove air tightnessHeat-affected zoneAir tightness

Owner:HANS LASER TECH IND GRP CO LTD

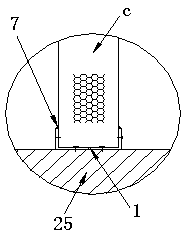

Testing apparatus for plastic airtightness and method thereof

ActiveCN102445312BReduce leakageReduce mistakesMeasurement of fluid loss/gain rateMaterial analysisVacuum pumpingAir filter

The invention discloses a testing apparatus for plastic airtightness and a method thereof. The apparatus comprises an air pump, a pressure reducing valve, an air filter, an air inlet on-off valve, a high pressure element, a differential pressure measuring element, an air pipe, a testing chamber, a reference chamber and a three-way cutting sleeve ball valve. The testing chamber is composed of a high pressure chamber, a low pressure chamber, a sealing ring, and a plastic sample. The reference chamber consists of a high pressure chamber, a low pressure chamber, a sealing ring and a reference iron sheet sample. And the structural size of the testing chamber is identical with that of the reference chamber. According the above-mentioned technical scheme in the invention, the reference chamber is arranged and the size of the reference chamber is completely identical with that of the testing chamber, so that the two chambers can be contrasted and a system error can be reduced; besides, an initial testing pressure of the low pressure chamber is an atmospheric pressure, so that an occurrence of an air leakage phenomenon can be reduced; and there is no need for vacuum pumping, apparatus investment can be reduced, and energy can be saved.

Owner:BEIJING UNIV OF CHEM TECH

Helium leakage detection device and method for double-layer pipe with interlayer

PendingCN111947850AMeet the requirements of double-layer pipe leak detectionRealize air tightness testDetection of fluid at leakage pointDouble-walled pipeEngineering

Owner:SOUTHWESTERN INST OF PHYSICS

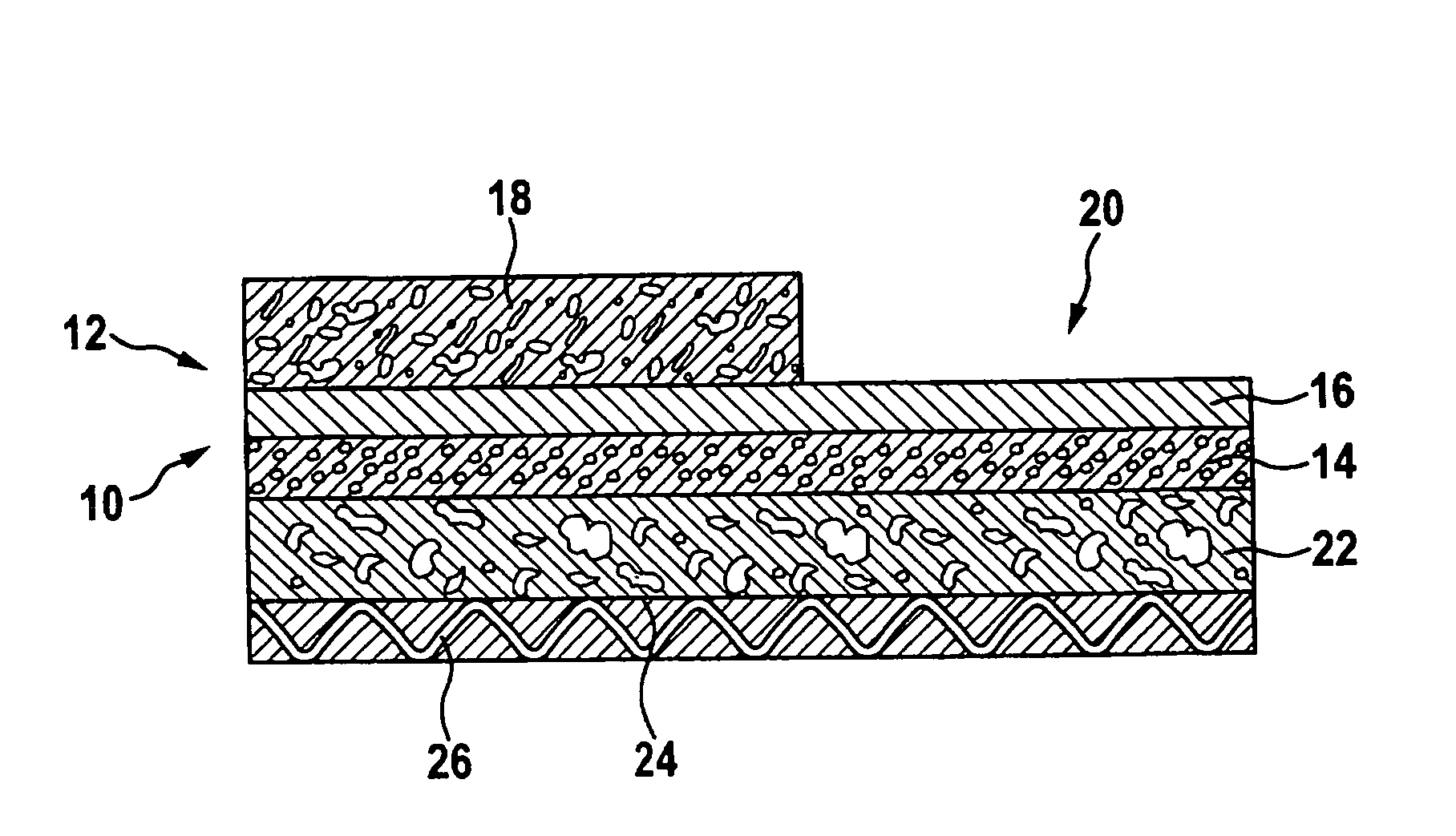

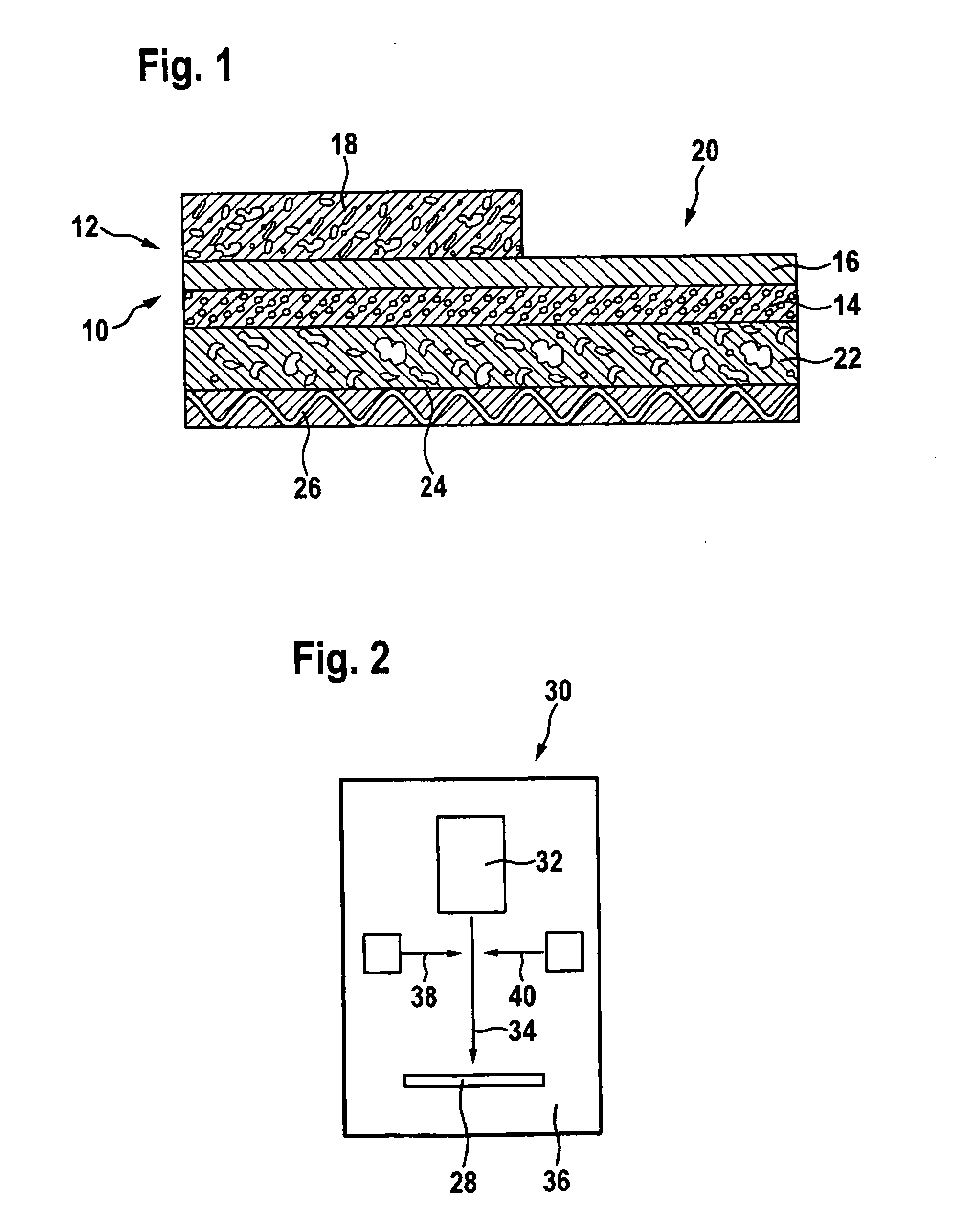

Method of producing a gas-tight solid electrolyte layer and solid electrolyte layer

InactiveUS20100151353A1Improve air tightnessMolten spray coatingFinal product manufactureFuel cellsMetal particle

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

Plastic packaging box air tightness detection equipment for food processing

InactiveCN113418658AQuick checkHigh precisionDetection of fluid at leakage pointPlastic packagingAgricultural engineering

Owner:徐国发

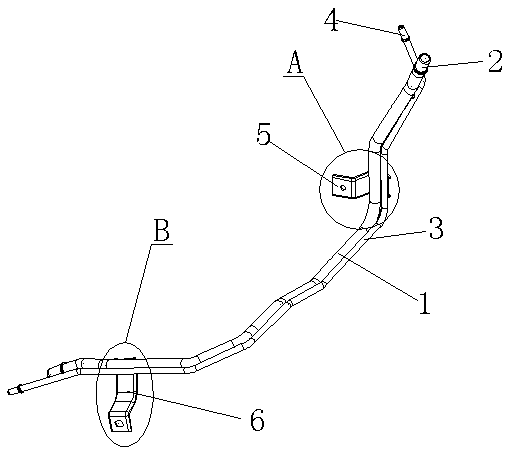

Air bag valve vacuum working condition execution device

PendingCN114413528APerform operations reliablyQuick actionOperating means/releasing devices for valvesCompression machines with non-reversible cycleEngineeringAir tightness

The air bag valve vacuum working condition executing device comprises a compressor, a condenser, a solution collector and a fin assembly which are sequentially connected through a pipeline, the tail end of the pipeline is in backflow communication with the starting end of the pipeline, and a closed loop is formed by the pipeline and a cavity between a pipe sleeve and a valve body of an air bag valve; an outlet electromagnetic valve is arranged on a pipeline between the compressor and the air bag valve, and an inlet electromagnetic valve is arranged between the fin assembly and the air bag valve. The air bag valve executing device is reliable in structure and good in use performance, effectively achieves rapid and reliable executing operation on an air bag valve under the vacuum working condition, meanwhile, in the executing operation process, the air tightness problems such as blocking and untight closing cannot be caused, and the working technical requirements of the air bag valve can be greatly met.

Owner:PANZHIHUA GANGCHENG GROUP RUITONG REFRIGERATION EQUIP

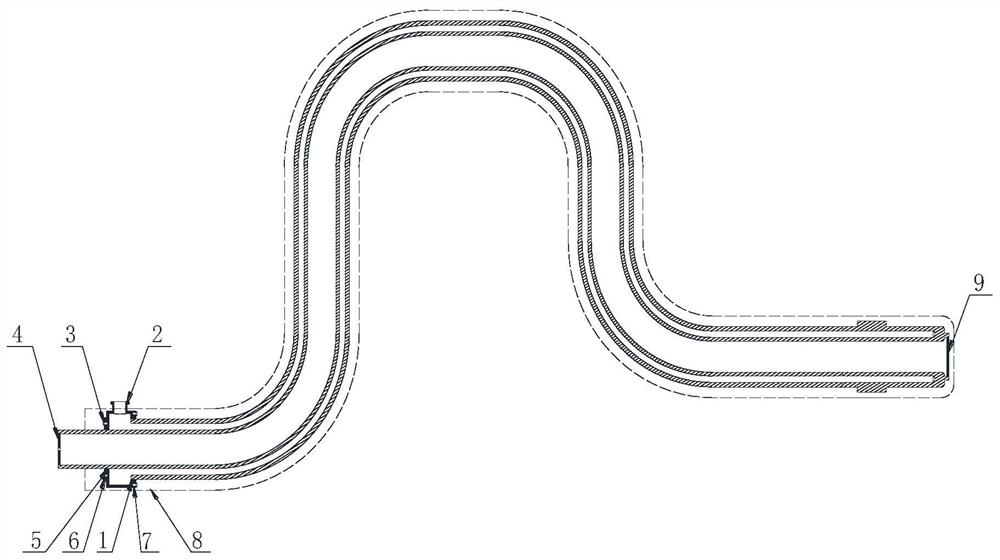

Air conduit for automobile refueling pipe and manufacture method thereof

Owner:NINGBO SHUNJIANG AUTO PARTS MFG

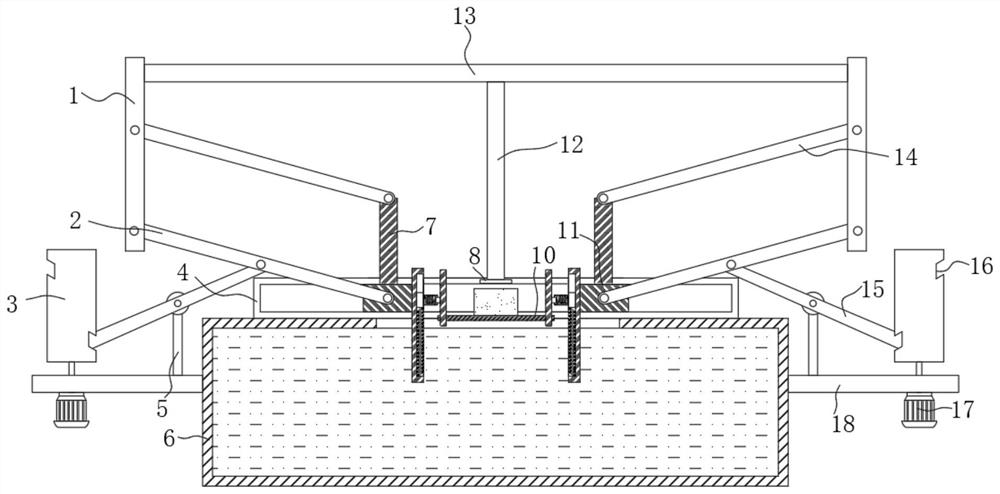

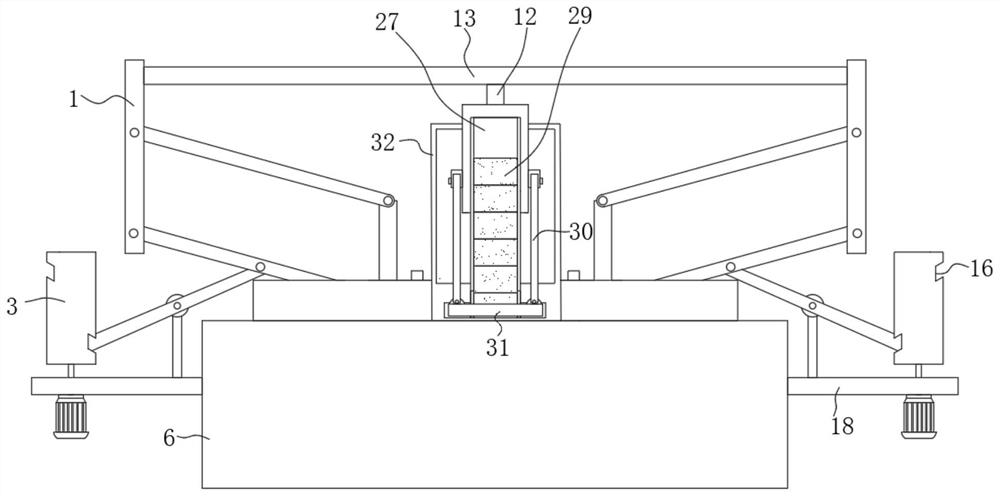

Manned test device for people, fishes and Azolla imbircata and working method

ActiveCN108012910ARealize a closed loopHigh simulationMeasurement of fluid loss/gain rateClimate change adaptationEngineeringAir tightness

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap