Helium leakage detection device and method for double-layer pipe with interlayer

A double-layer pipe and leak detection technology, which is applied in the direction of measuring devices, fluid tightness testing, machine/structural component testing, etc., can solve the problems of limited detection structure, difficult inner layer and interlayer of double-layer pipe, etc., to achieve High leak detection accuracy, simple structure, and the effect of meeting the leak detection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

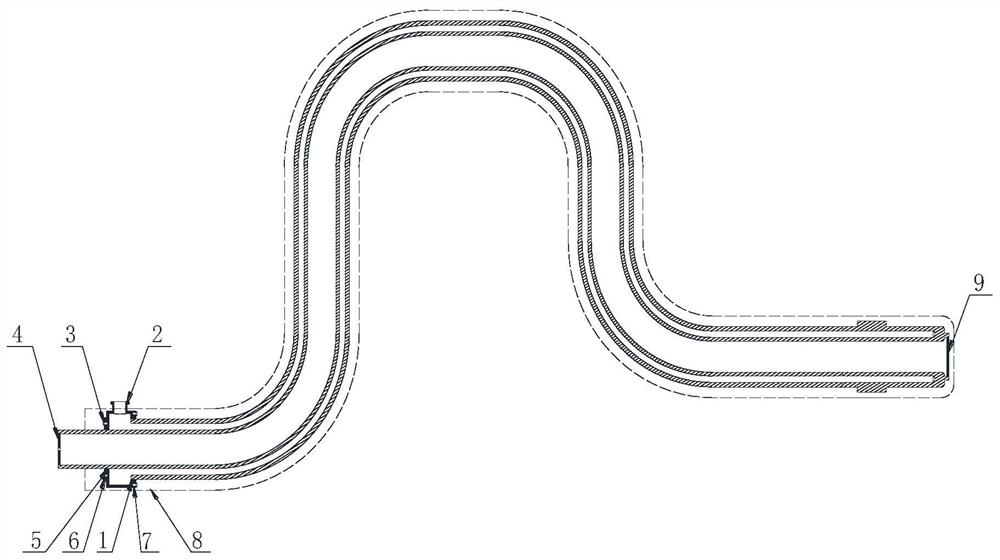

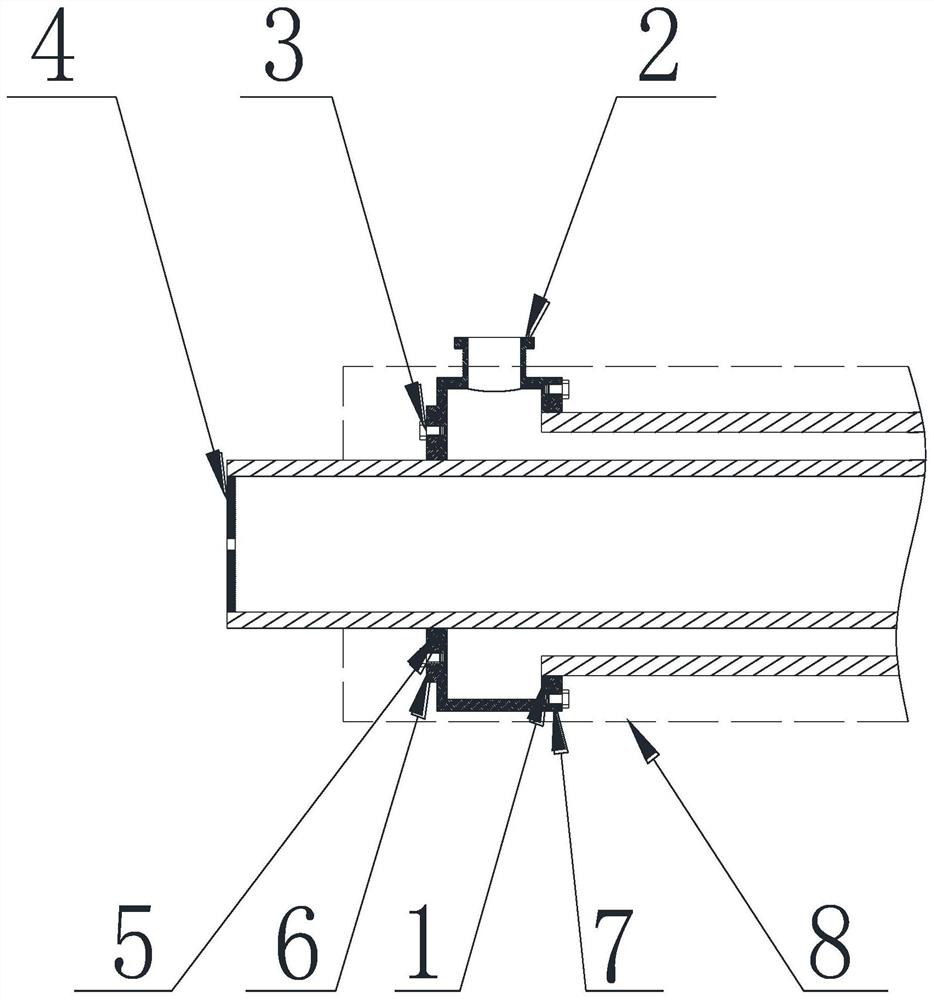

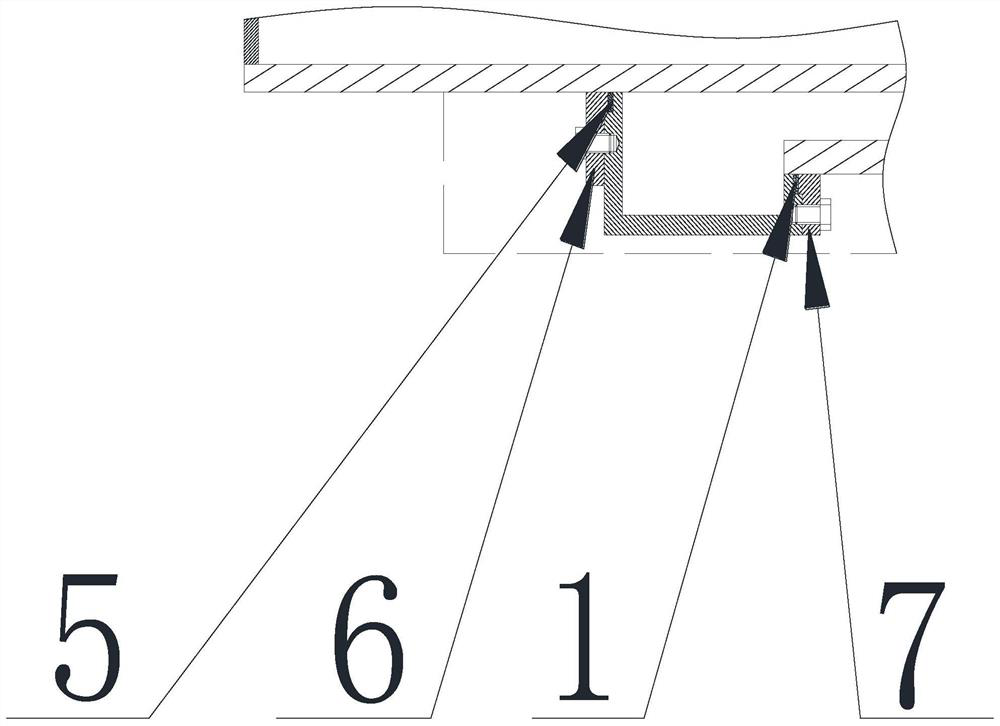

[0027] A double-layer tube helium leak detection device with an interlayer, comprising an inner tube, an outer tube and a helium leak detection tool, the helium leak detection tool includes a first seal, a second seal, a first blocking plate 4, a second Blocking plate 9, inflatable cover 8 and sealed flange box 2.

[0028] The inner tube is sleeved in the outer tube, the inner tube is sealed and connected to the first end of the sealing flange box 2 through a first sealing member, and the outer tube is connected to the sealing flange through a second sealing member The tank 2 is connected at a second end, said first end having a smaller diameter than said second end. One end of the inner tube is blocked with a first blocking plate 4, and the other end of the inner tube is blocked with a second blocking plate 9. The first blocking plate 4 is provided with a helium inlet hole. An inflatable cover 8 is arranged outside the outer tube, and a helium inlet hole is arranged on the inf

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that a helium leak detection method based on the above-mentioned double-layer tube helium leak detection device with interlayer is provided, including:

[0042] Helium is introduced into the inner tube through the helium inlet hole provided on the first blocking plate 4 , and the airtightness of the inner tube is detected by a helium mass spectrometer connected to the sealed flange box 2 .

[0043] Helium is passed into the outer tube through the helium inlet hole provided on the gas-filled cover 8 . And the airtightness of the outer tube is detected by a helium mass spectrometer connected to the sealed flange box 2 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap