Air conduit for automobile refueling pipe and manufacture method thereof

An air duct and refueling pipe technology, which is applied to vehicle components, layout combined with internal combustion engine fuel supply, power plant and other directions, can solve the problems of narrow pipeline installation space, design of refueling pipe, troublesome manufacturing, etc., and achieves low manufacturing cost, The effect of simple processing and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

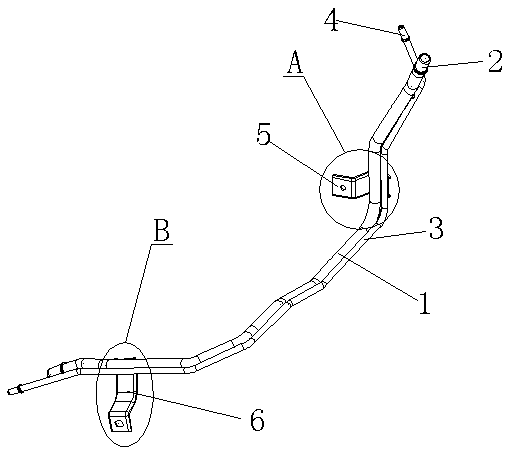

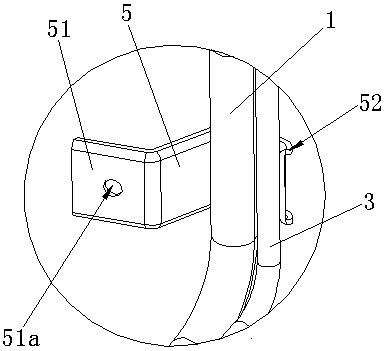

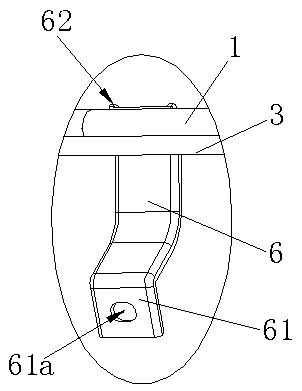

[0030] like Figure 1 to Figure 5 Shown is the structural representation of the present invention,

[0031] The reference signs therein are: carbon tank ventilation steel pipe 1, first shrinkage 2, first limit ring 21, first retraction arc 22, ventilation steel pipe 3, second shrinkage 4, second limit ring 41 , the second retracted arc 42, the first fixed bracket 5, the first fixed plane 51, the first fixed hole 51a, the first reinforced edge 52, the second fixed bracket 6, the second fixed plane 61, the second fixed hole 61a , the second reinforced edge 62 .

[0032] like Figure 1 to Figure 5 as shown,

[0033] An air duct for an automobile fuel pipe, comprising a carbon canister breather steel pipe 1 for connecting the fuel filler pipe and a carbon canister, the carbon canister breather steel pipe 1 is a continuous integral structure, and

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap