Method of producing a gas-tight solid electrolyte layer and solid electrolyte layer

a solid electrolyte layer and gas-tight technology, applied in the direction of electrochemical generators, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problems of reducing the gas permeability and the redensification of the solid electrolyte layer, and achieve the effect of high gas-tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

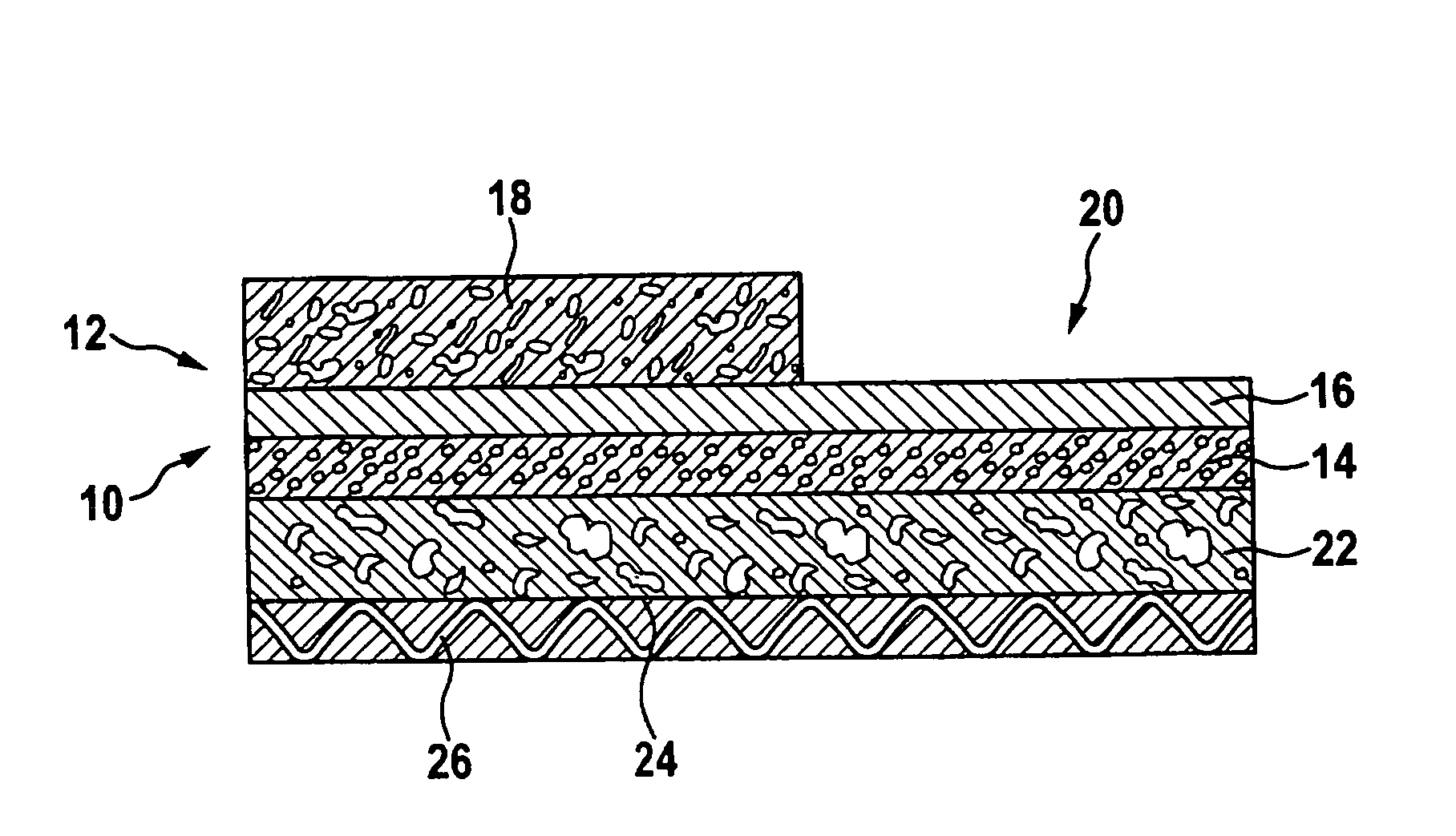

[0042]One embodiment of a high-temperature fuel cell is an oxide-ceramic fuel cell (SOFC—solid oxide fuel cell). A high-temperature fuel cell module, which is shown schematically in a partially sectional representation in FIG. 1 and designated therein by 10, comprises an electrochemical functional device 12 with an anode 14, a solid electrolyte 16 and a cathode 18. The anode 14, the solid electrolyte 16 and the cathode 18 form an anode-electrolyte-cathode unit 20.

[0043]The anode 14 is arranged on an anode carrier 22. The anode carrier 22 is electrically conductive (electron conducting) and made of a porous material, so that the gaseous fuel can pass through the anode carrier 22 to the anode 14. The anode carrier 22 is a mechanical carrier for the anode 14, through which an electrical contacting of the anode 14 with, for example, a housing (not shown in the drawing) is enabled.

[0044]An electrical contact device 26 can be arranged on the anode carrier 22 at a side 24 located opposite the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap