Water tightness test device

A test device, water tightness technology, used in liquid/vacuum measurement for liquid tightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

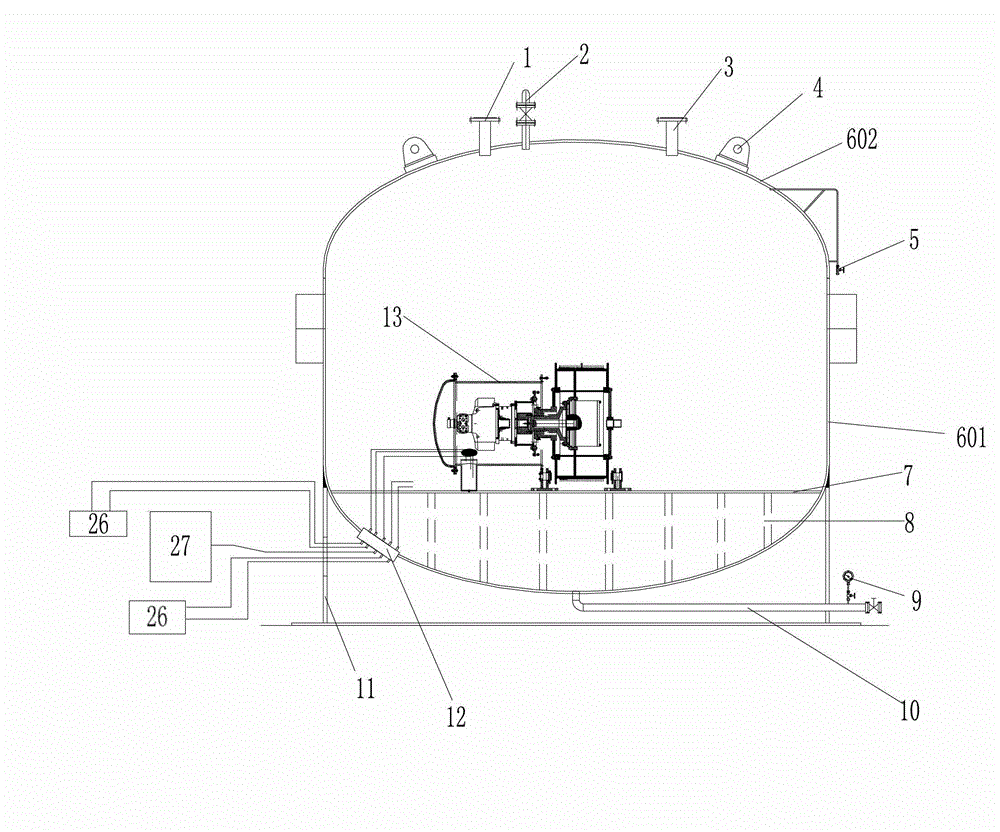

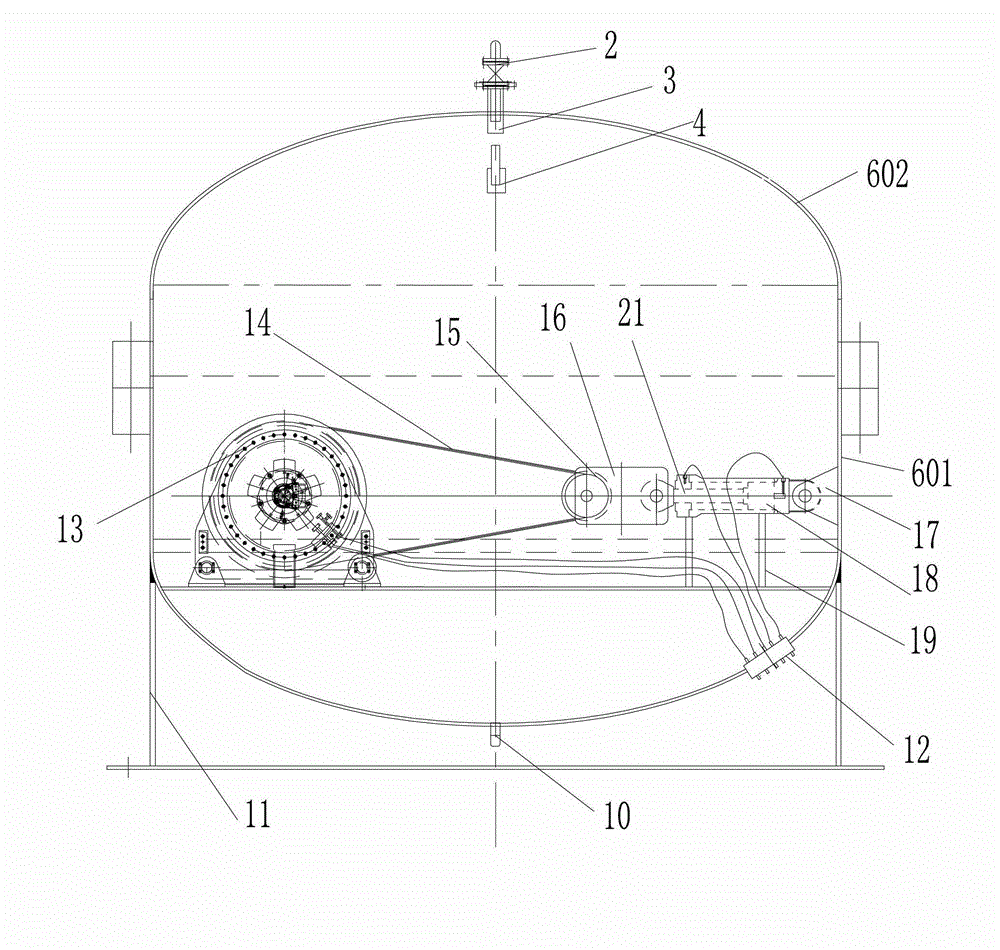

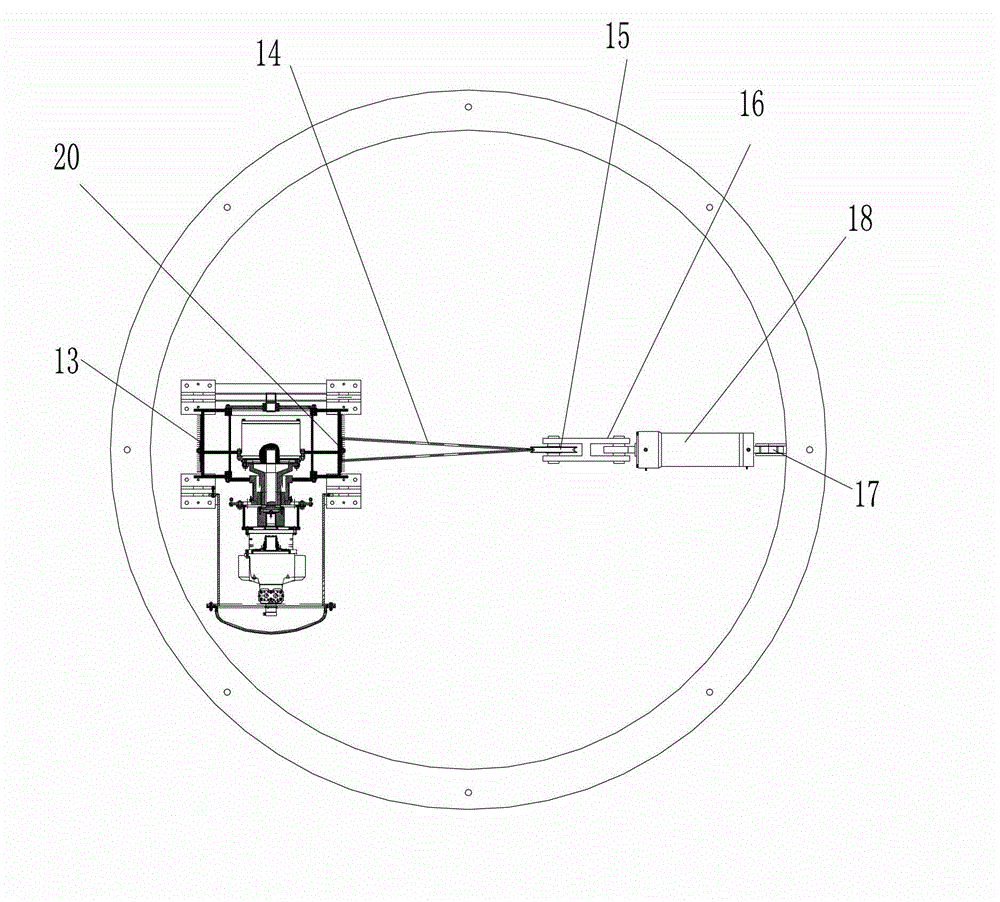

[0029] Embodiments of the present invention provide a watertightness test device, such as figure 1 and figure 2 As shown, the device includes: a watertight storage tank shell, a loading cylinder 18 for providing a loading force, a pulley 15, a mounting seat 7 for installing a tested winch and a loading cylinder 18, and a closing connection rope 14. The closing connection rope 14 One end of the pulley is set on the pulley 15, the pulley 15 is installed on the telescopic end of the loading cylinder 18, the loading cylinder 18 is installed on the mounting seat 7, the mounting seat 7 is arranged on the inner bottom surface of the watertight storage tank shell, and on the watertight storage tank shell A water source inlet 1 is provided, and the watertight storage tank shell includes an upper semi-watertight storage tank 602 and a lower semi-watertight storage tank 601 which are sealed and connected. The bottom of the lower semi-watertight storage tank 601 is provided with an interfac

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap