Transmission of manipulator for dredging slag from liquid zinc of zinc pot

A transmission device and a technology for zinc pot zinc, applied in the field of the transmission device of components, can solve the problems of small slag fishing area, low slag fishing efficiency, potential safety hazards, etc. The effect of expanding the scope of slag fishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Do further description below in conjunction with accompanying drawing:

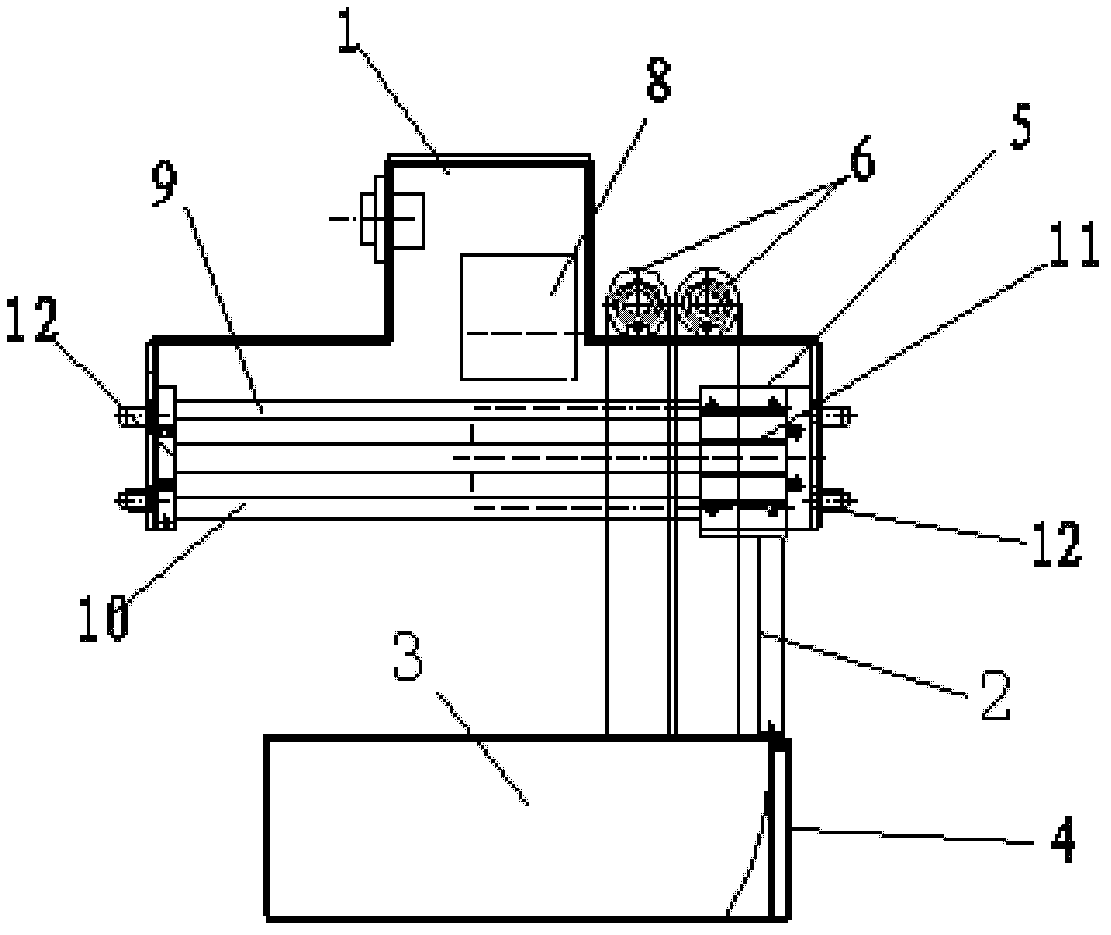

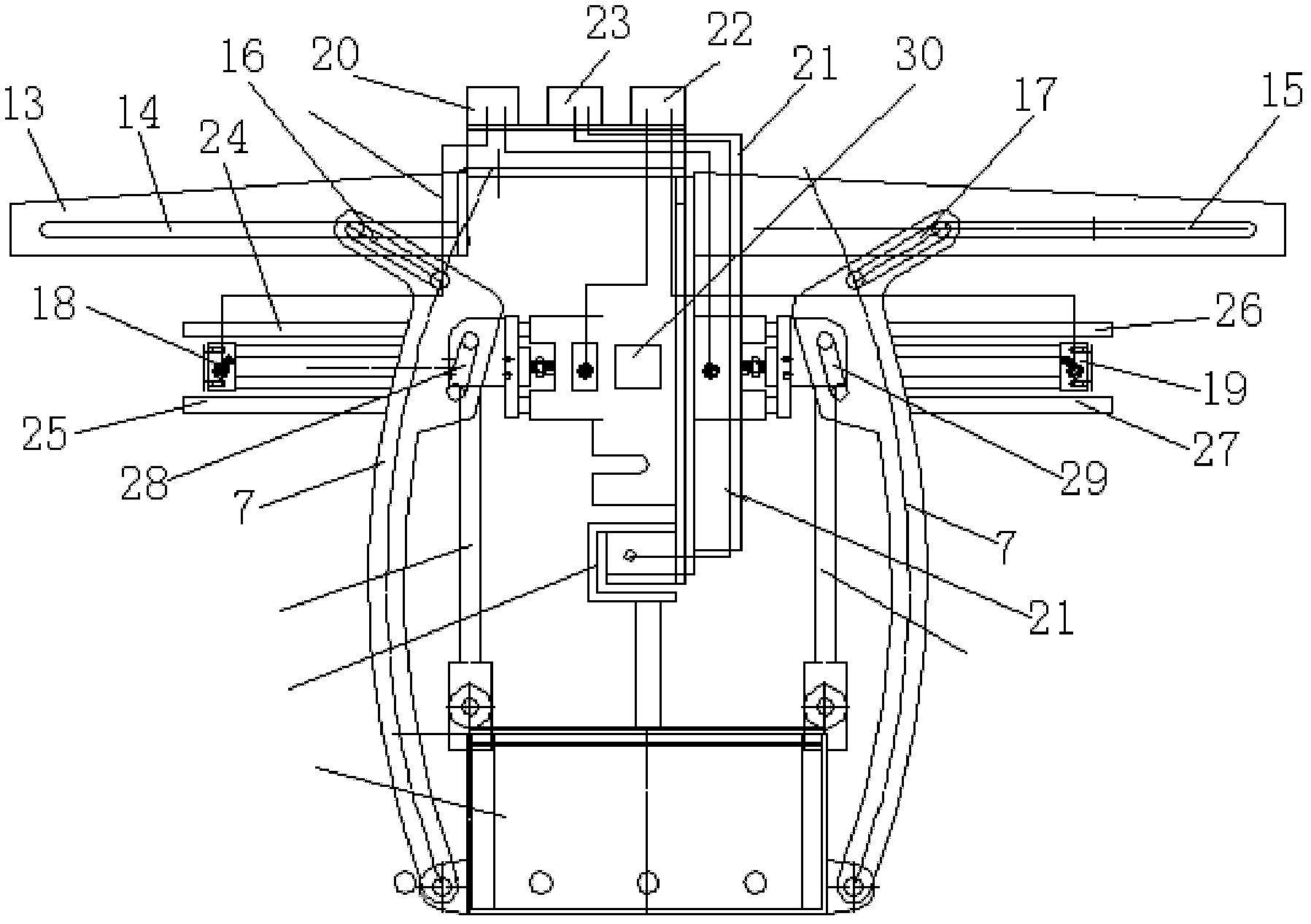

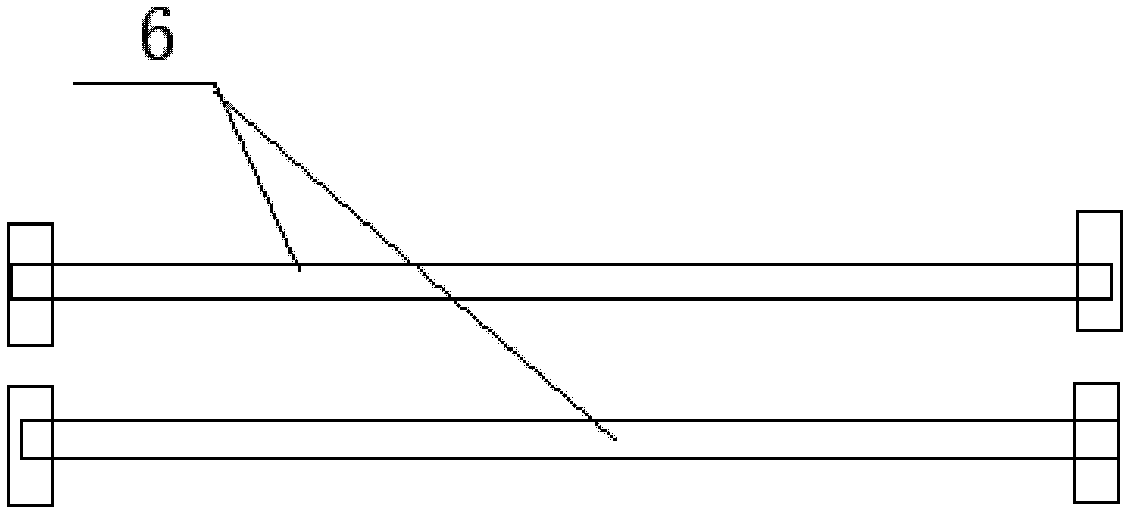

[0023] The transmission device of the manipulator for extracting slag from zinc pot zinc liquid, including saddle 1, slag pushing plate connecting rod 2, slag pushing plate 3, slag picking bucket 4, saddle seat drive 5, hopper balance bar 6, and slag picking bucket 4 Connected crank connecting rod 7, crank connecting rod transmission mechanism 8. It is that: the saddle seat transmission 5 is a rodless cylinder, and the saddle seat rodless cylinder 5 is connected with the connecting rod 2 of the slag ejector; the crank connecting rod transmission mechanism 8 is cylinder type; the hopper balance lever device 6 is double rod type.

[0024] The saddle seat rodless cylinder 5 is composed of an upper guide rail 9 connected to the saddle seat 1, a lower guide rail 10, and a piston 11 set on the upper guide rail 9 and the lower guide rail 10; Use bolts or lock nuts on both sides of the saddle seat 1 to conne

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap