Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Magnetic separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic Separation is the process of separating components of mixtures by using magnets to attract magnetic materials. The process that is used for magnetic separation detaches non-magnetic material with those who are magnetic. This technique is useful for not all, but few minerals such as ferromagnetic (materials strongly affected by magnetic fields) and paramagnetic (materials that are less affected but the effect is still noticeable). Not all metals are magnetic; gold, silver and aluminum are some examples.

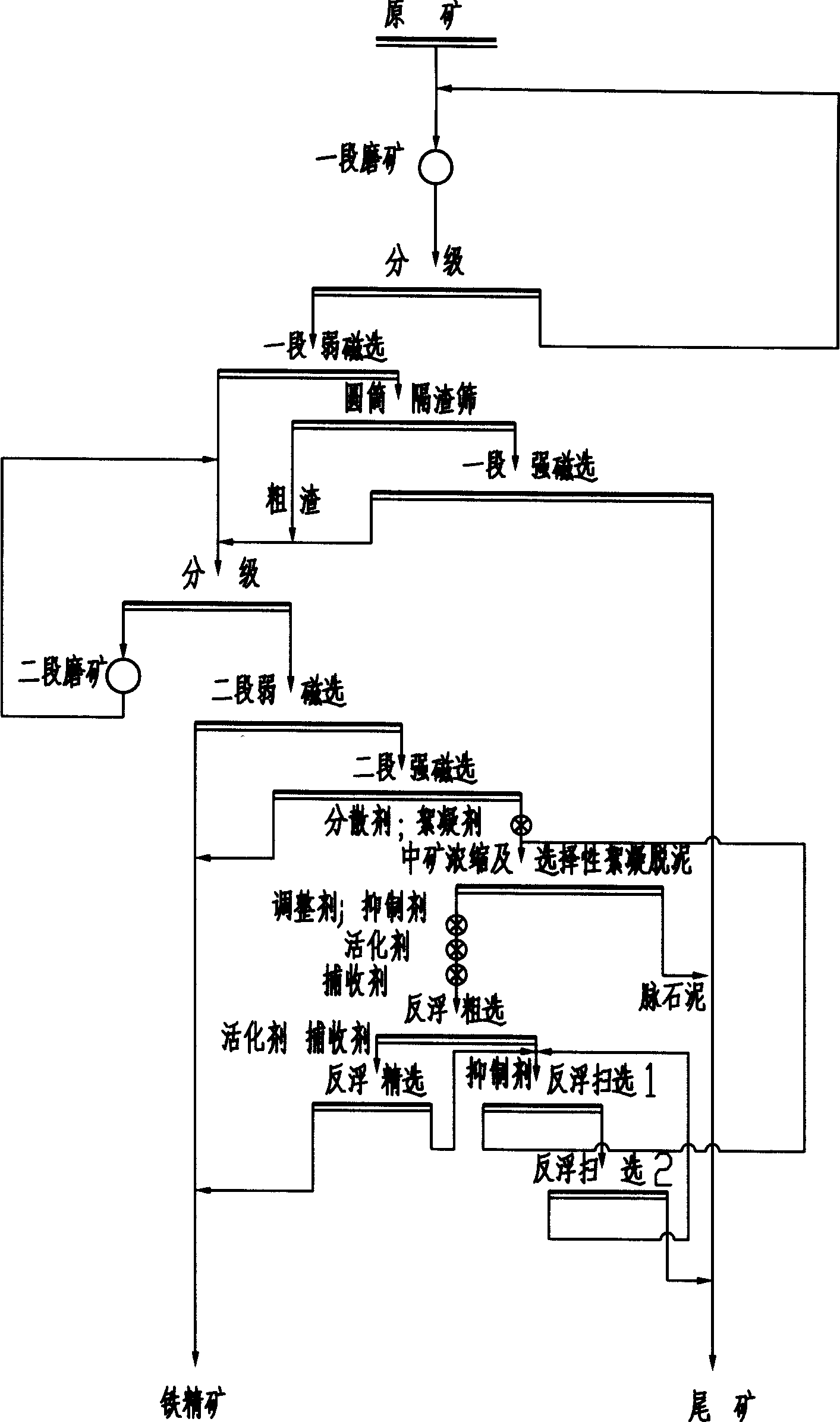

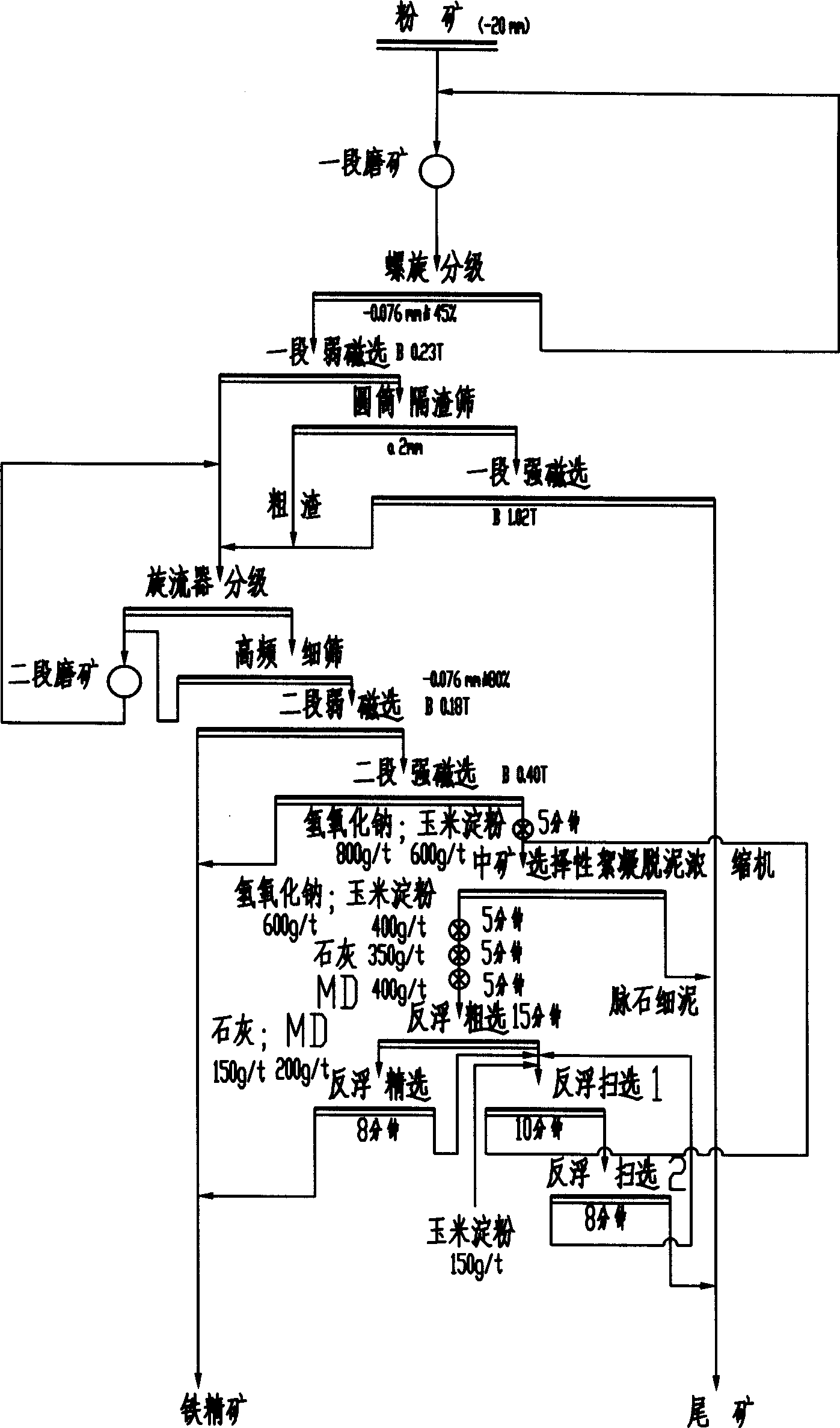

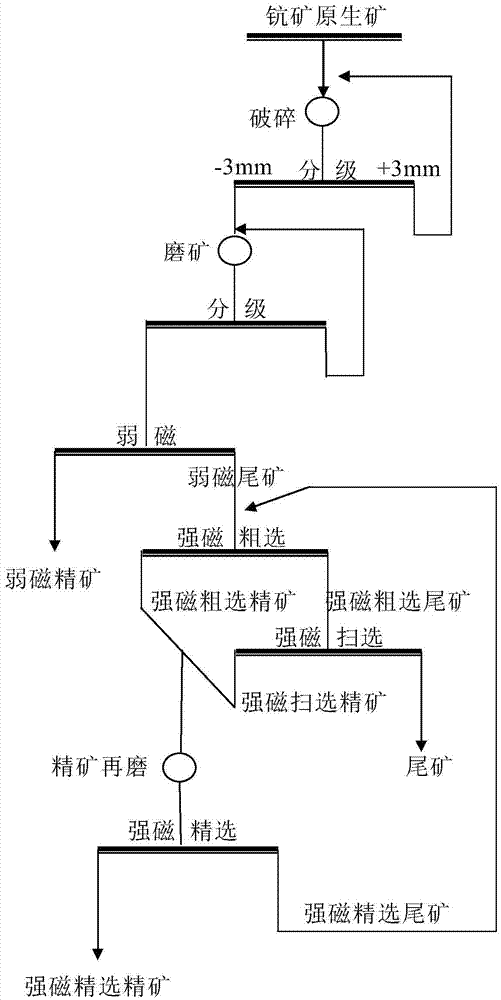

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals

The invention relates to a mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals, and belongs to the fields of mineral process engineering and comprehensive recycling of resources. The mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals comprises the following steps: carrying out low intensity magnetic separation and high intensity magnetic separation pre-concentration by taking bayan obo tailings as raw materials, then carrying out fluid bed roasting on obtained pre-concentrated concentrates, and carrying out low intensity magnetic separation operation on roasted minerals obtained by roasting so as to obtain weak-magnetism concentrates and rare-earth-containing weak-magnetism tailings; and carrying out rare earth flotation operation on the weak-magnetism tailings to obtain rare earth flotation concentrates and rare earth flotation tailings finally, then carrying out acid leaching process on the rare earth flotation tailings to obtain niobium-enriched slag and acid pickling tailings, and meanwhile, carrying out fluorite flotation operation on pre-concentrated strong-magnetism tailings to obtain fluorite flotation concentrates and fluorite flotation tailings. By the method, fluorite concentrates, iron core concentrates, rare earth concentrates and the niobium-enriched slag are obtained finally, and thus, the bayan obo tailings are utilized comprehensively.

Owner:NORTHEASTERN UNIV LIAONING

Nickel slag processing method for efficiently recovering iron resource

InactiveCN104988302APromote resource reuseSafe and easy to recycleProcess efficiency improvementSlagMagnetic separation

The invention provides a nickel slag processing method for efficiently recovering an iron resource. The method includes the steps that nickel slag is fused, the temperature is kept, a modification agent is added, heat preservation is carried out, and modified nickel slag with the alkalinity ranging from 1.0 to 1.4 is obtained after complete reacting is made; air or oxygen is blown from the bottom or from the top below the liquid face, weak oxidation treatment is carried out on the modified nickel slag, and oxidized nickel slag is obtained; after the temperature of the oxidized nickel slag falls to 1200 DEG C with the temperature fall rate smaller than or equal to 5 DEG C / min, water quenching cooling is carried out, and solidified nickel slag is obtained after complete solidification; the solidified nickel slag is crushed and ground until the particle size is smaller than 200 meshes; and magnetic separation is carried out on slag obtained after cracker grinding, magnetic materials are recovered, and nickel slag processing is completed. By means of the processing method, the iron resource can be recovered from the nickel slag, harmful elements in the nickel slag cannot be brought into iron-rich phases, and an iron ore concentrate can be completed replaced in use. Low-energy-consumption, low-cost and safe and easy processing recovery of the iron resource is achieved, and the method is of great significance in promoting nickel slag resource recycling, enterprise energy saving and emission reduction and environmental protection.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

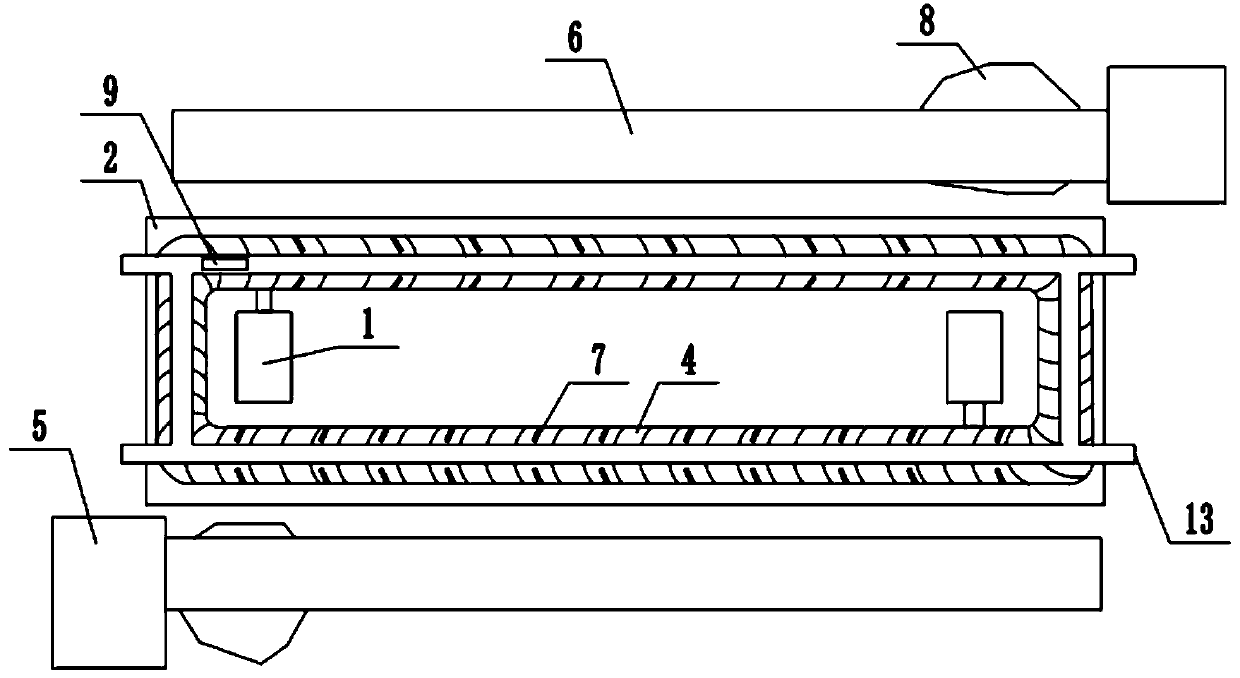

Magnetic separation type immunological reaction detection device of using fluorescence imaging and detection method

InactiveCN1431504ASimple structureEasy to separateBiological testingFluorescence/phosphorescenceAntigen assaysFluorescein

The detection device is composed of the immune reaction tank and the magnetic pole. The magnetic particles of coating antibody are used as the reaction substrate. Specificity fluorescein-labelled antibody is utilized to display antigen to form antibodies-antigens-fluorescein-labelled antibody resultant of reaction. Since the action of the magnetic pole, the immune reaction resultant in combination with magnetic particles is adsorbed at the bottom of the immune reaction pond. The limited solution makes the antigen tested distribute on the bottom of the reaction tank. The fluorescence image of the reaction resultant is obtained by using laser source to irradiate the reaction tank. The invention raises the detection sensitivity, realizes real time, sensitive, accurate and multiform immune reaction detection.

Owner:SHANGHAI JIAOTONG UNIV

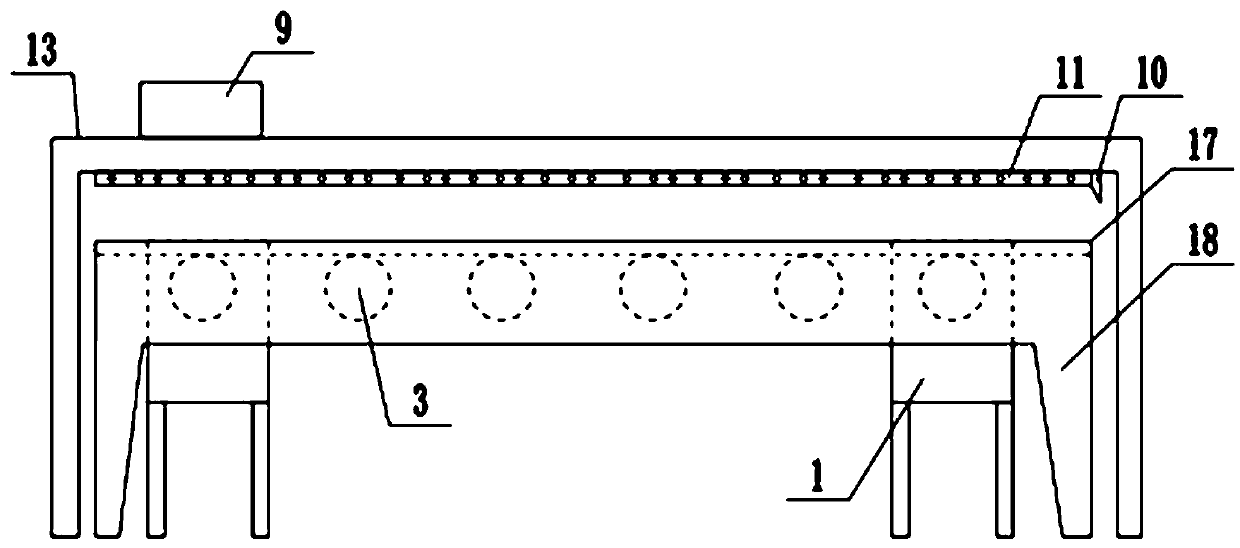

Comprehensive rubbish sorting technology and comprehensive rubbish sorting machine

InactiveCN104722494AAchieve separationRealize sortingSievingGas current separationMagnetic separatorEngineering

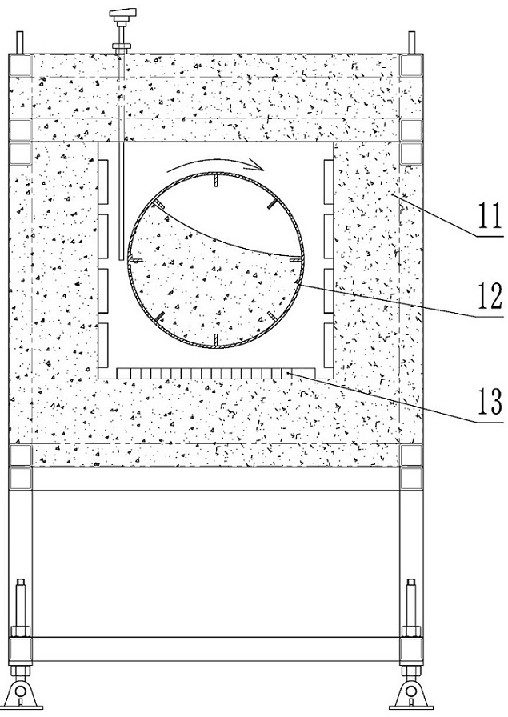

A comprehensive garbage sorting technology includes the steps of garbage grinding, bag breaking, magnetic separation, primary winnowing, two-grade sorting in a rotary screen and secondary winnowing. A comprehensive garbage sorting machine comprises a plate-type feeder, a garbage grinding and bag breaking machine and a magnetic separator are mounted in a feeding section and a discharging section of the plate-type feeder respectively, a first winnower and a first U-shaped belt conveyer are sequentially arranged below the discharging end of the plate-type feeder, the rotary screen comprising a first screening section and a second screening section is arranged at the rear end of the plate-type feeder, a first discharging hopper and a second discharging hopper are arranged below the first screening section and the second screening section of the rotary screen respectively, a second U-shaped belt conveyer and a third U-shaped belt conveyer are arranged below the two discharging hoppers respectively, a fourth U-shaped belt conveyer is arranged at the rear end of the rotary screen, and a second winnower is mounted below the discharging end of the rotary screen. The comprehensive garbage sorting technology and the comprehensive garbage sorting machine have the advantages that magnetic metal, building garbage, organic matters and the like in garbage can be sorted out step by step, thorough separation of various materials in household garbage is achieved, and recovery and utilization of useful materials are facilitated.

Owner:TIANJIN BAILI SUN ENVIRONMENTAL PROTECTION EQUIP CO LTD

Method for processing red mud by utilizing iron pyrites

Owner:BEIJING UNIV OF CHEM TECH

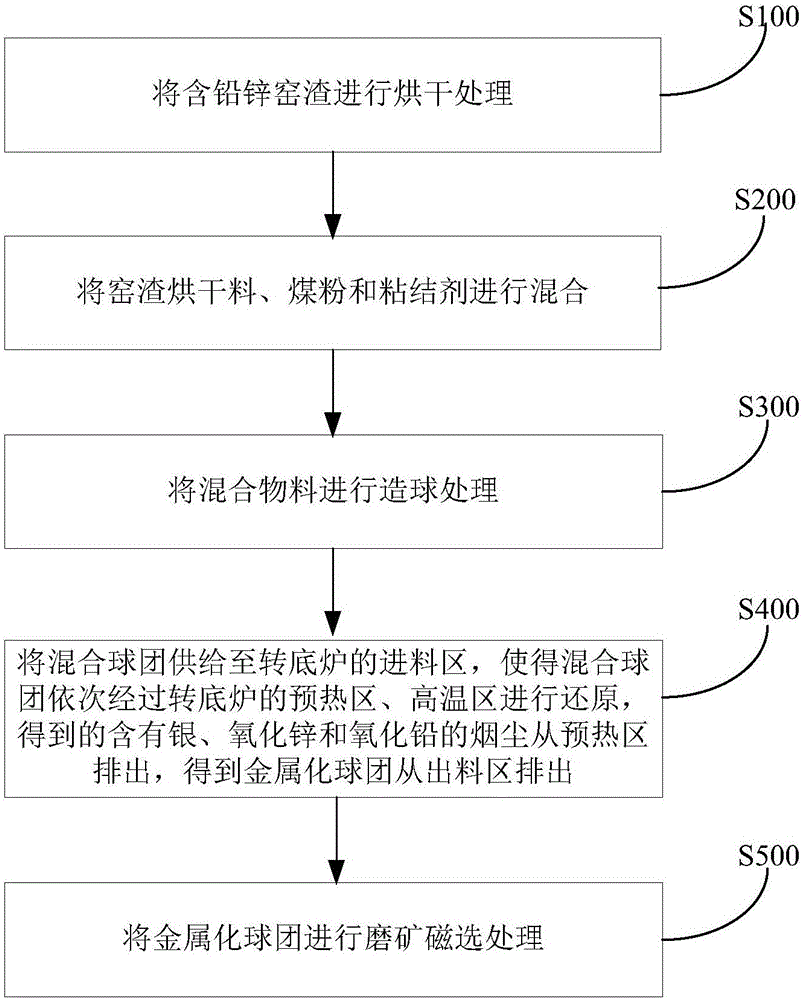

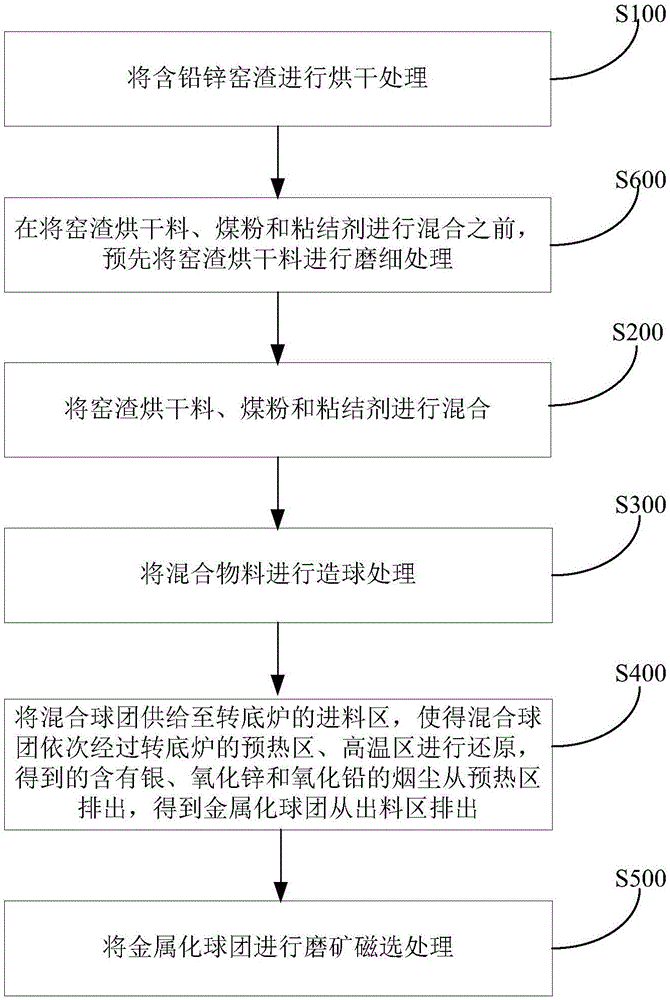

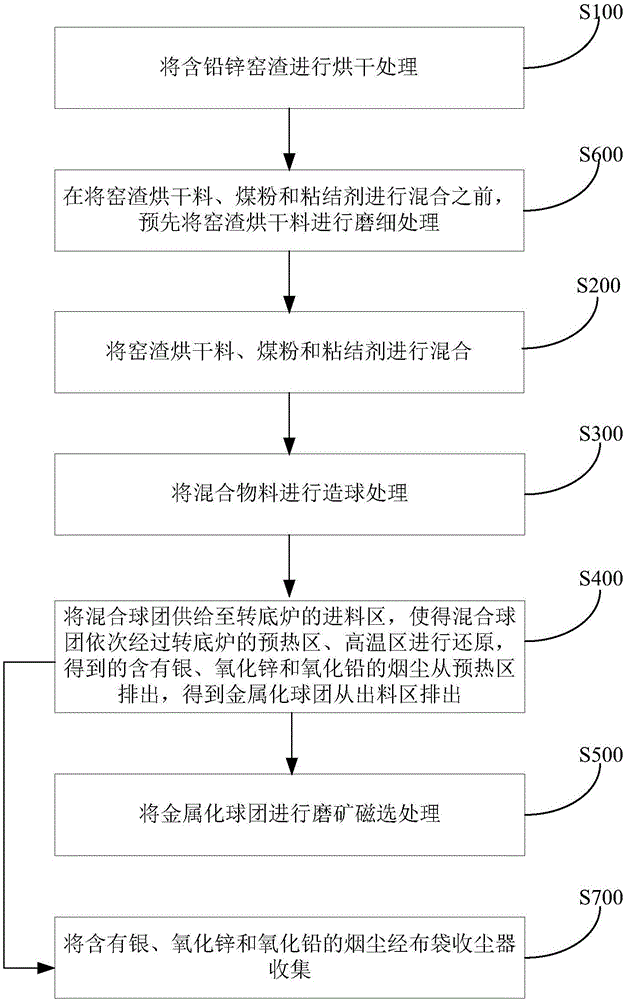

Method and system for treatment of kiln slag including lead and zinc

InactiveCN106148715AAchieve recyclingRealize resource utilizationProcess efficiency improvementIron powderSlag

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Mineral separation and enrichment method for primary scandium ore

ActiveCN105435958ASimple processEconomically reasonableMagnetic separationWet separationChemical industryEnrichment methods

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

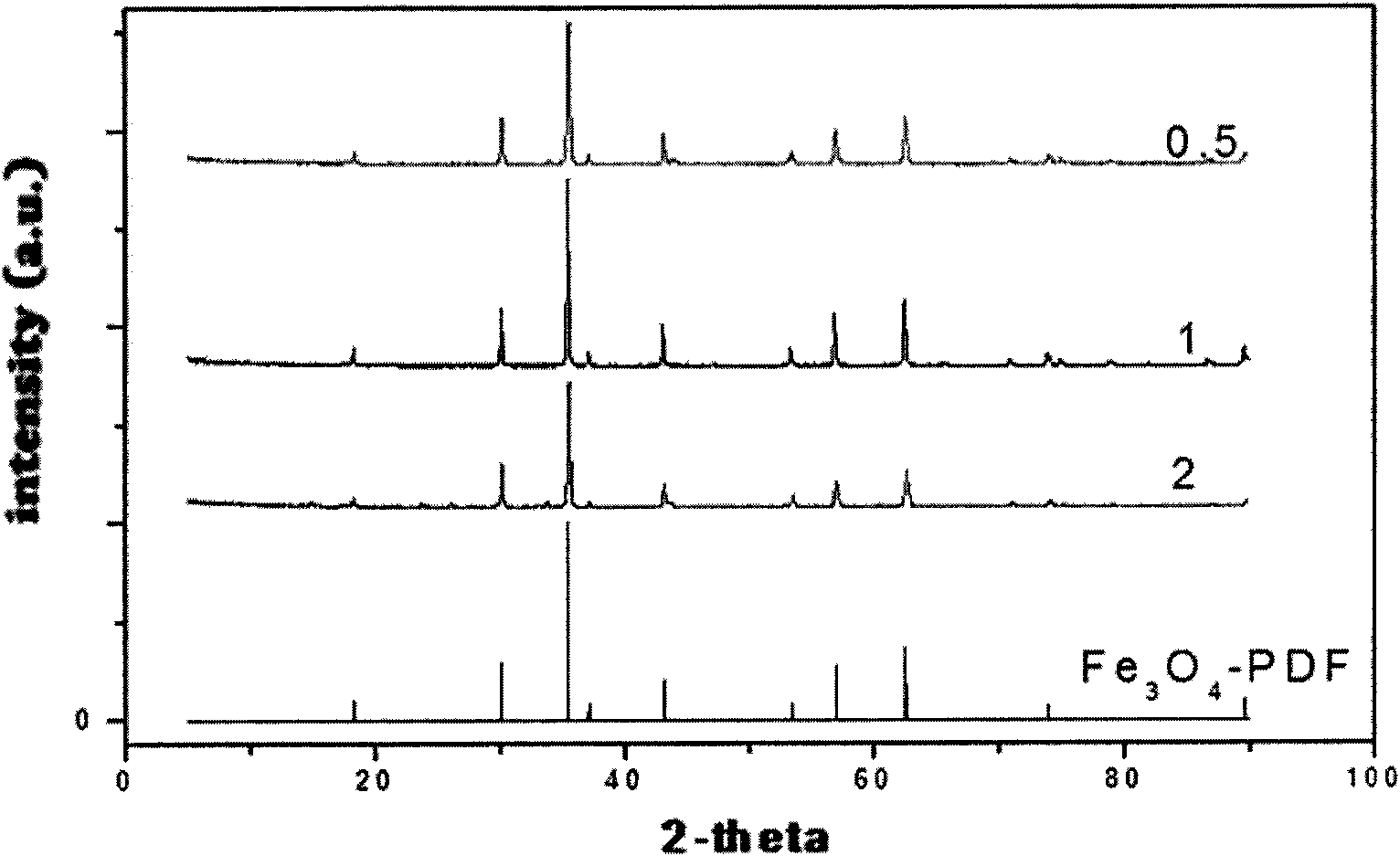

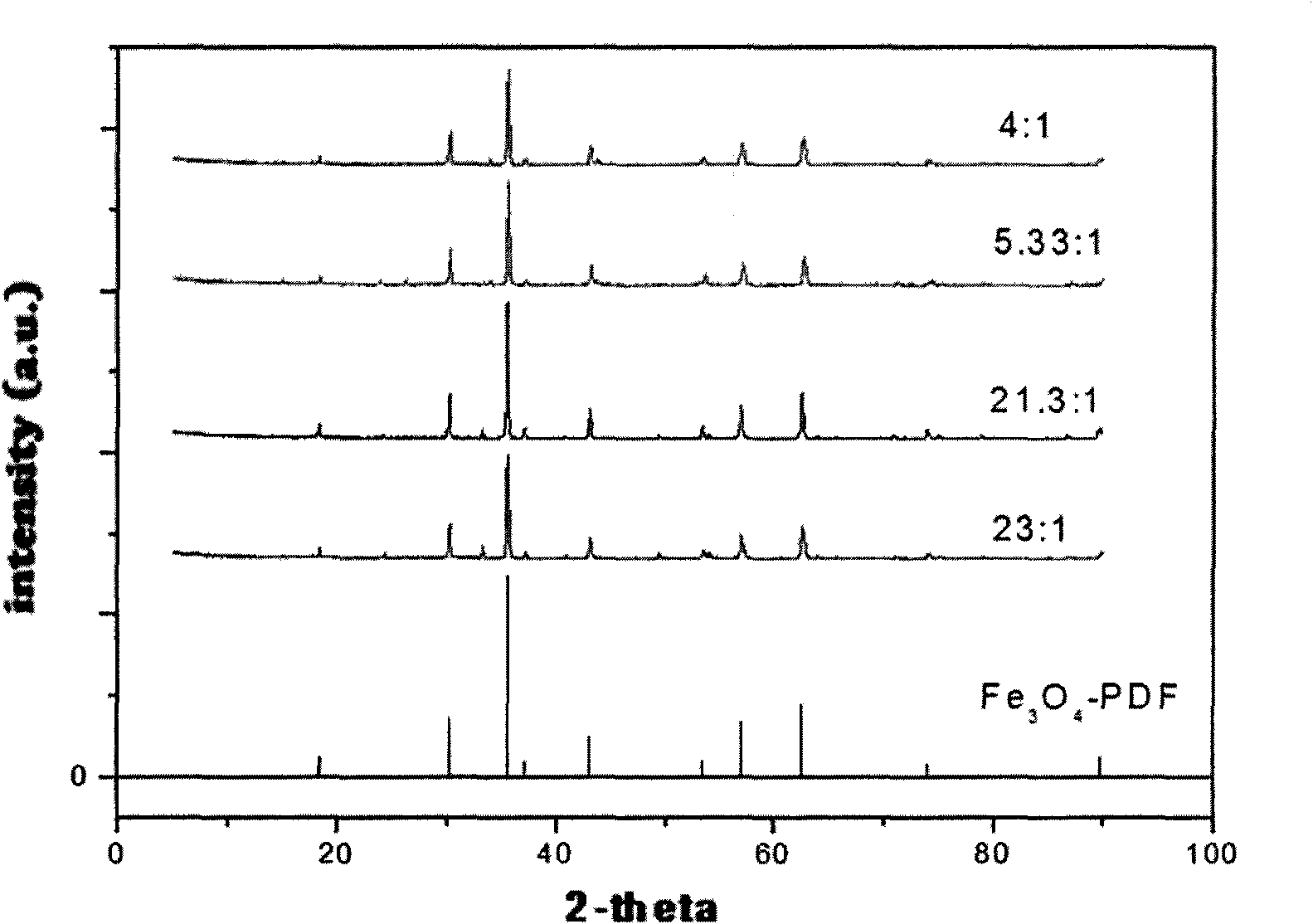

Method for preparing bioactive peptide from immobilized bi-enzyme of composite carrier magnetic nano-particles

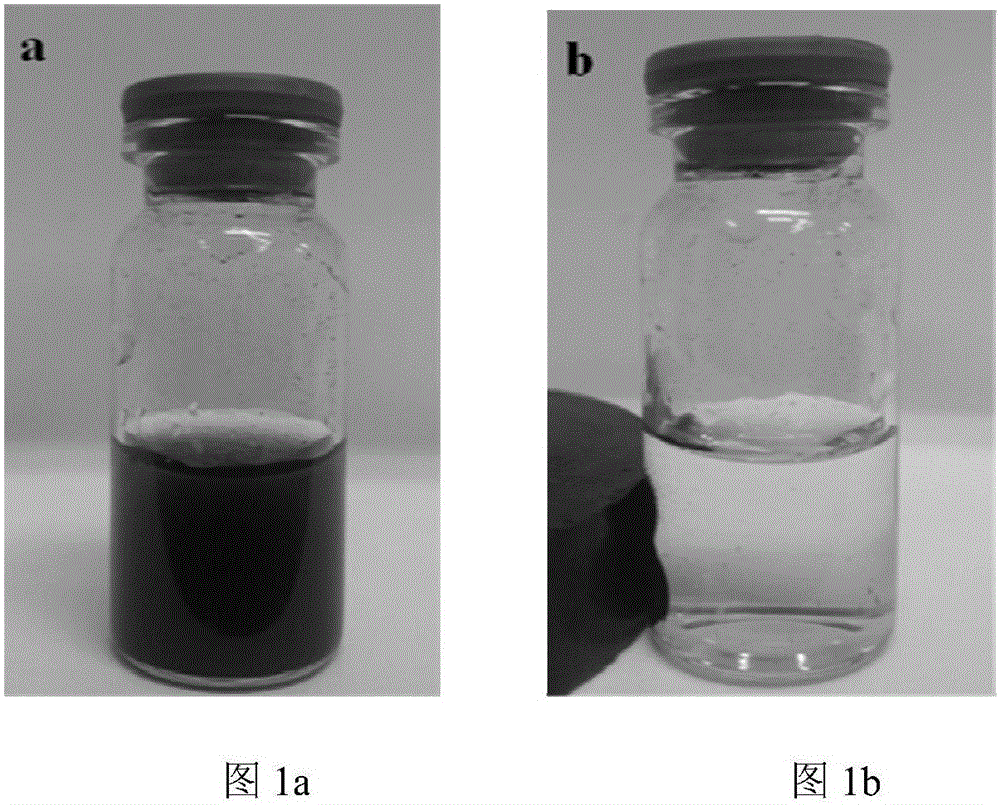

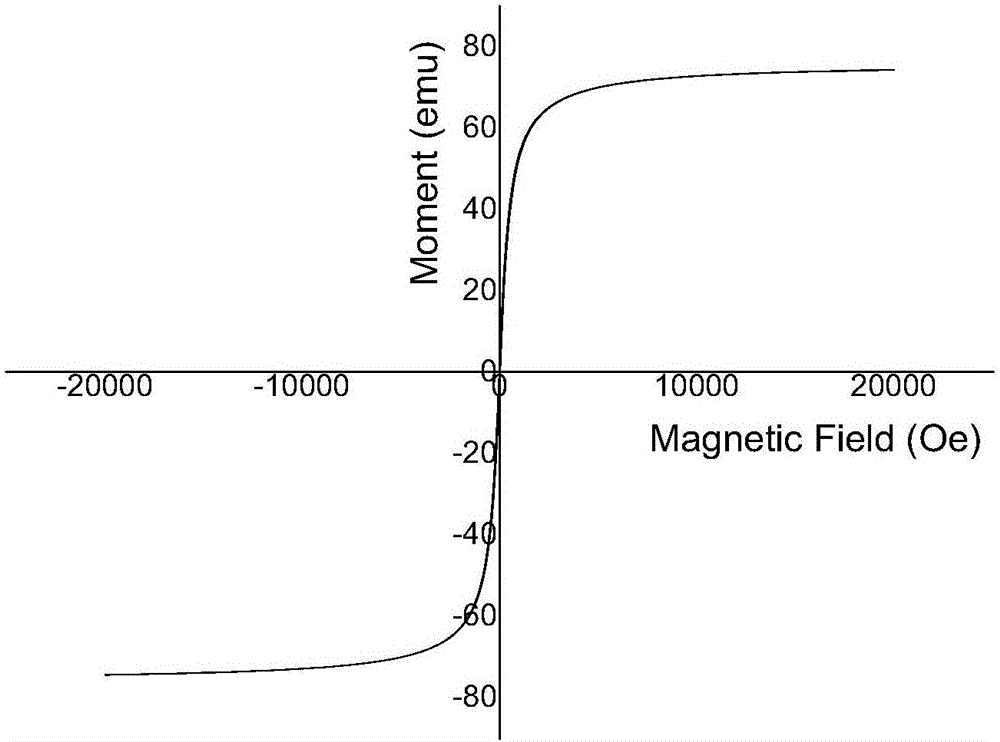

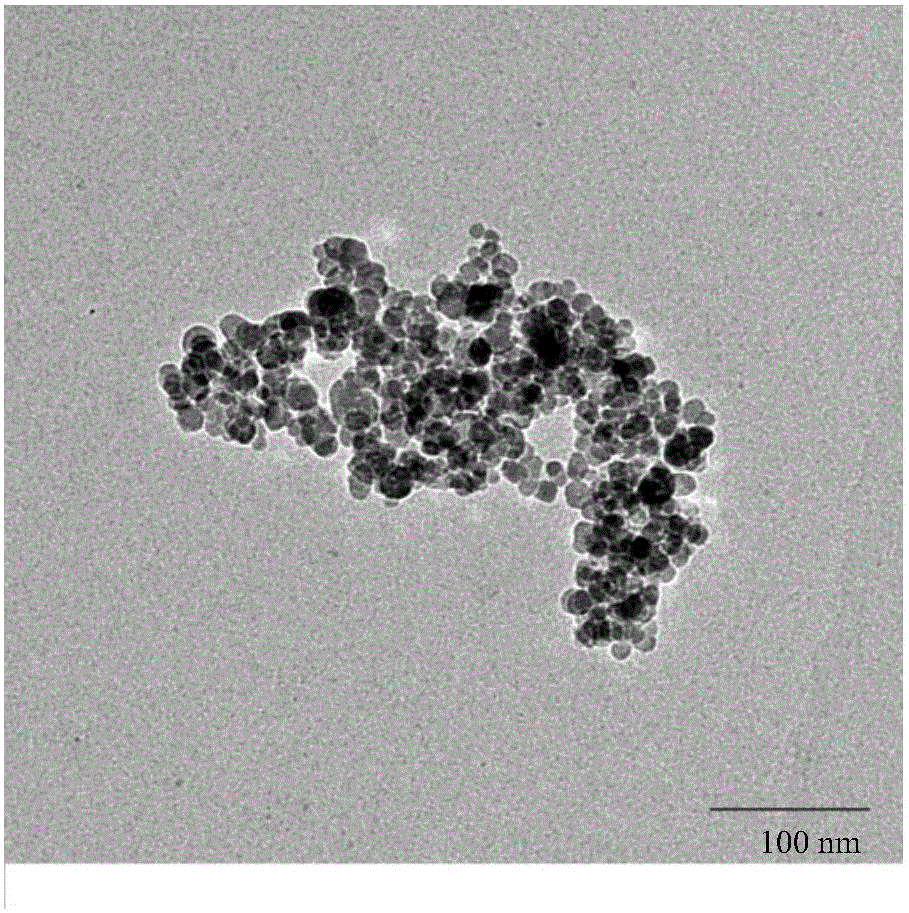

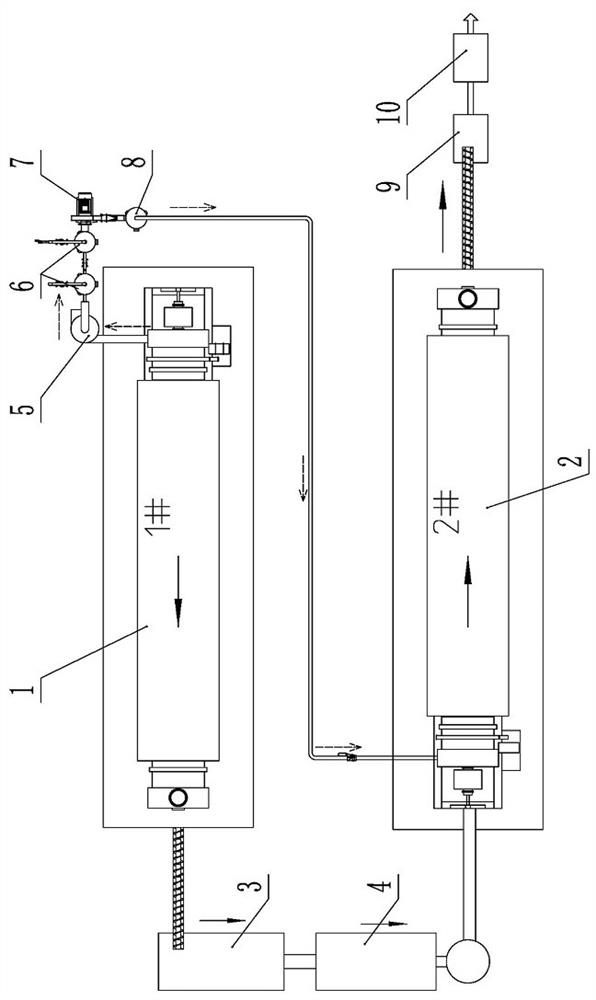

InactiveCN106011206AHigh yieldImproves antioxidant activityFermentationOn/in organic carrierProtein solutionMagnetite Nanoparticles

Owner:TIANJIN UNIV

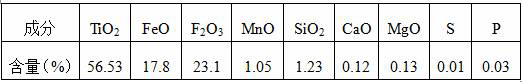

Preparation process and system for producing high-grade titanium-rich material by utilizing ilmenite

ActiveCN111733336AThere is no limit to the choice of materialsLow failure rateRotary drum furnacesMagnetic separationDust controlIlmenite

Owner:湖南碳谷装备制造有限公司

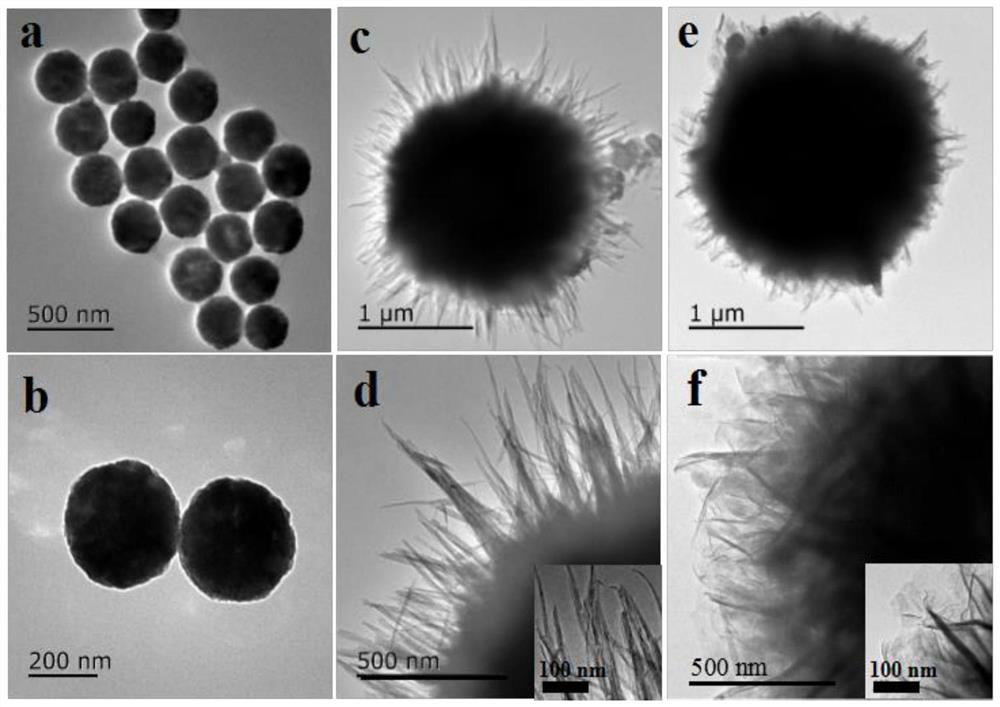

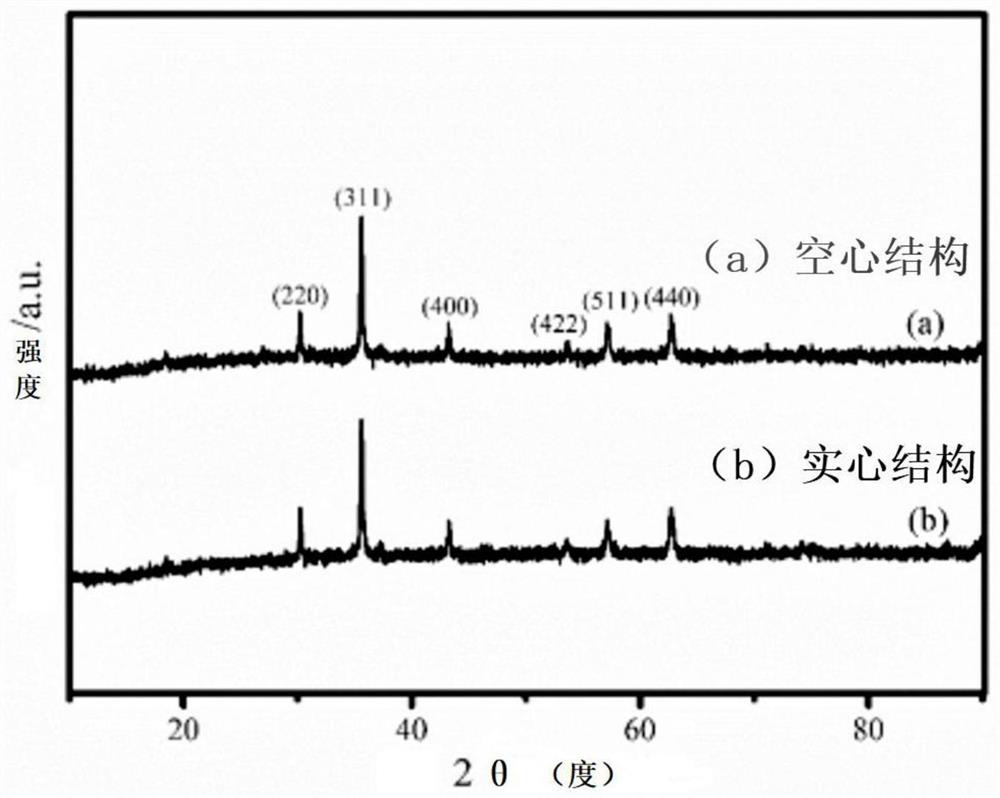

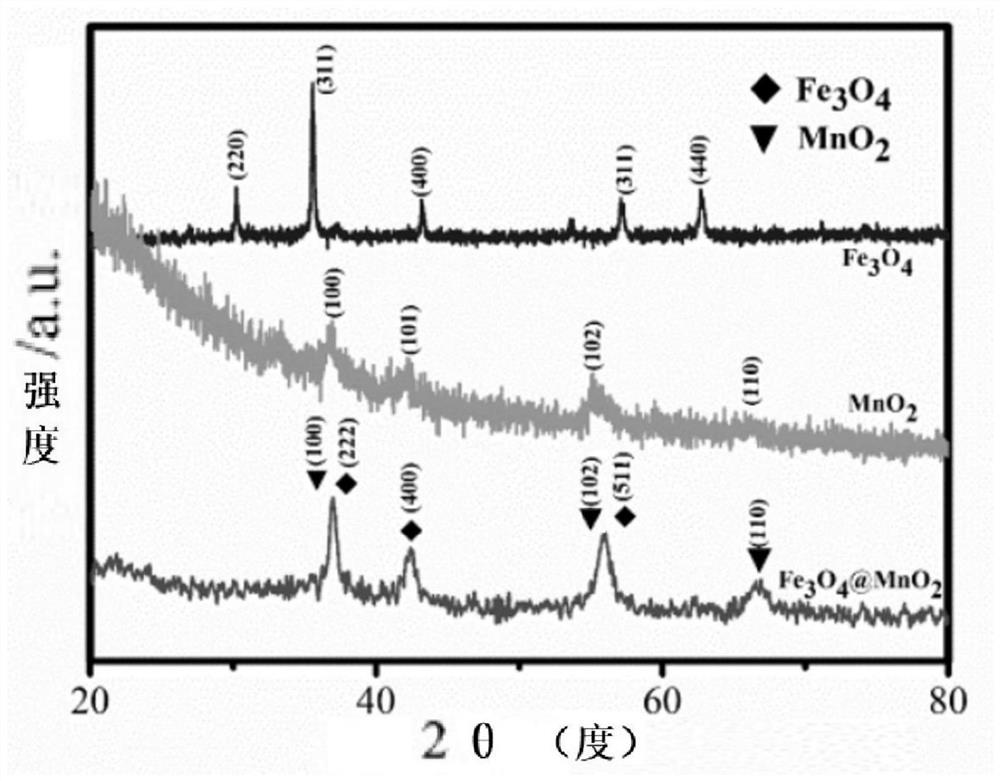

Reusable nano core-shell structure mimic enzyme material and preparation method thereof

PendingCN113755884AAchieve controlled growthImprove catalytic performanceNanotechnologyElectrodesPhysical chemistryEngineering

Owner:WUHAN INSTITUTE OF TECHNOLOGY

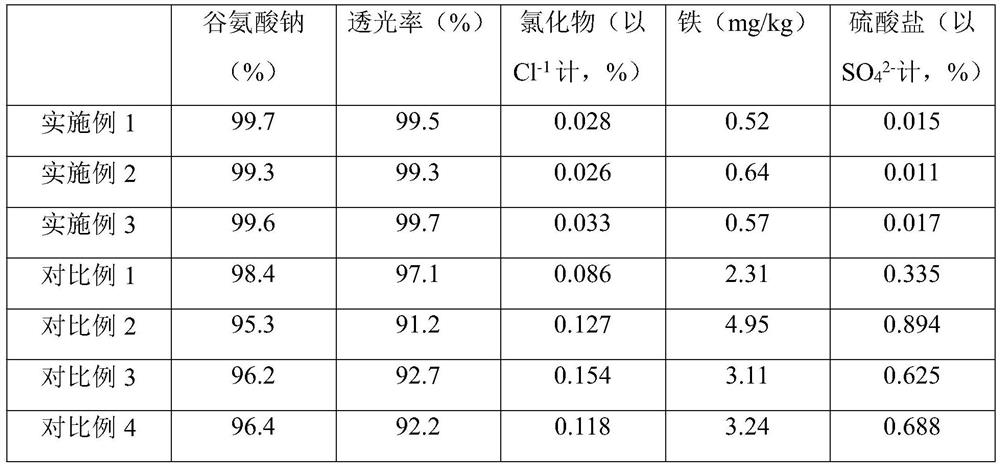

Refining process of monosodium glutamate

ActiveCN113558217AImprove qualitySimple processOrganic compound preparationMicroorganism based processesMonosodium glutamatePhysical chemistry

Owner:温州快鹿集团有限公司

Silicon carbide ultrafine powder and production method thereof

PendingCN111960419AHigh purityConsistent densitySilicon carbideMagnetic separationCarbide siliconFoaming agent

Owner:惠州市中惠宇航半导体新材料有限公司

Transmission device special for municipal waste

Owner:广西大自然再生资源有限公司

Magnetic mobile phone side button

InactiveCN108155045AFeel goodImprove reset abilityEmergency casingsElectric switchesEngineeringMagnetic isolation

The invention provides a magnetic mobile phone side key, the keyway comprises an outer section groove, a middle section groove and an inner section groove. The outer section groove and the middle section groove are connected to the step. The inner section groove upper and lower ends are inclined surfaces. The middle section groove is built in elastic a portion, the outer end of which extends intothe outer section groove and is provided with a pressing portion, the outer circumference of which is located at the step and is provided with an elastic resetting member between the steps. The elastic portion is provided with elastic supporting legs which are fitted with the inclined surface at both ends, and the connecting porting is provided at the end. The elastic support leg and the oppositesides of the inclined surface are respectively provided with a magnetic element and a magnetic conductive element. Elastic protrusion and a conductive base are arranged inside the elastic part. A magnetic isolation plate is arranged inside the side wall of the mobile phone case, and the connecting section is pressed and fixed on the side wall of the mobile phone case. A connecting groove for accommodating connecting section is disposed at the lower ends of the magnetic shielding plate and the side wall of the mobile phone case. The magnetic separation plate is provided with a supporting columnand a through hole, and the elastic protrusion passes through the through hole. An elastic sleeve is sleeved on the protrusion. The invention automatically aligns when assembling, avoids the loss ofthe side key drop, avoids the linkage phenomenon, improves the pressing feel, and prevents the water from entering.

Owner:ZHEJIANG PROVINCE SHUANGYUAN ALLOY FOUNDRY CO LTD

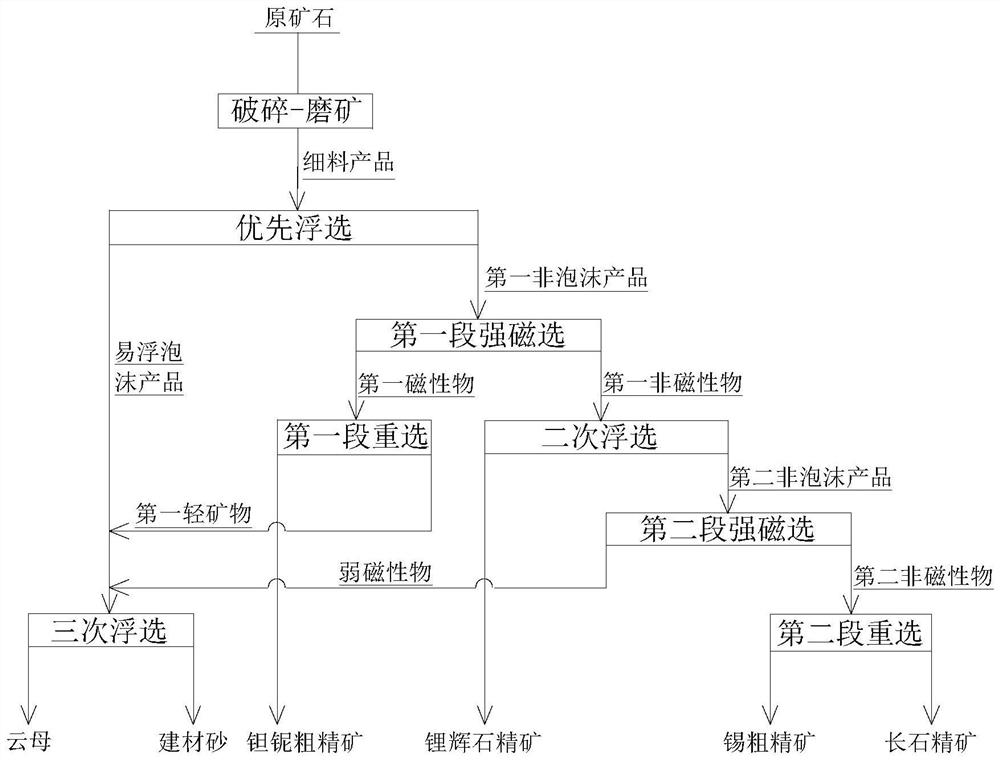

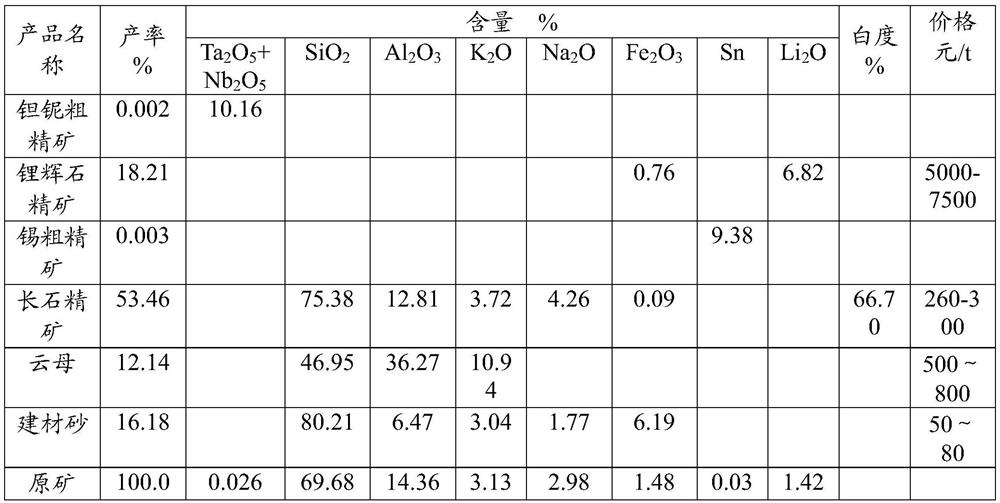

Comprehensive utilization method of pegmatite containing tantalum niobium, cassiterite, feldspar and spodumene

PendingCN114588998AImprove recycling ratesTake advantage ofHigh gradient magnetic separationFlotationNiobiumMagnetic separation

Owner:SHANDONG HUATE MAGNET TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap