Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Magnetic separator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air separation device and method of garbage

InactiveCN101823019AObvious superiorityImprove sorting efficiencyGas current separationWet separationAir volumeMagnetic separator

Owner:BEIJING HAOHAI TIANJI TECH +1

Comprehensive rubbish sorting technology and comprehensive rubbish sorting machine

InactiveCN104722494AAchieve separationRealize sortingSievingGas current separationMagnetic separatorEngineering

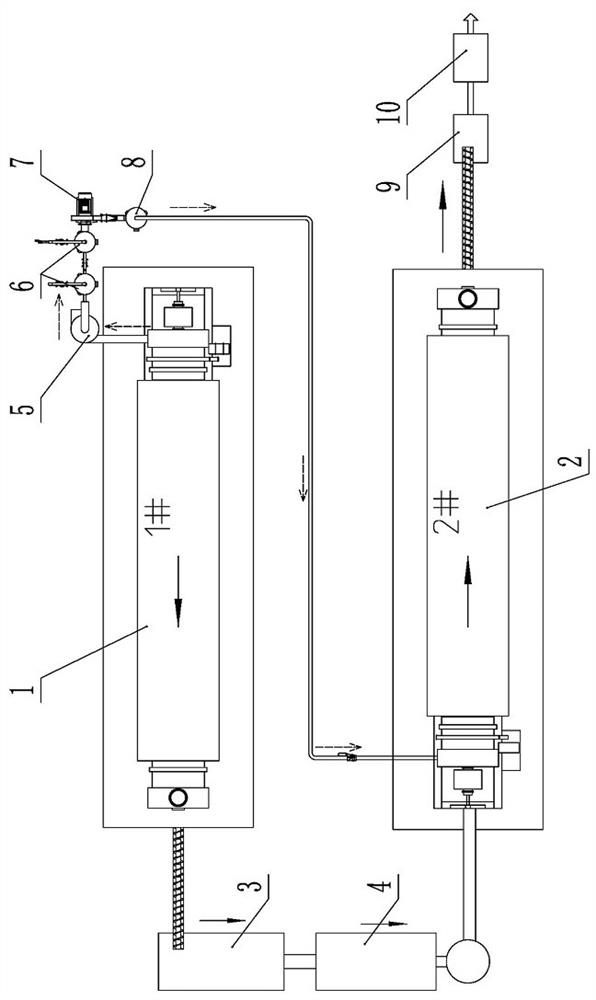

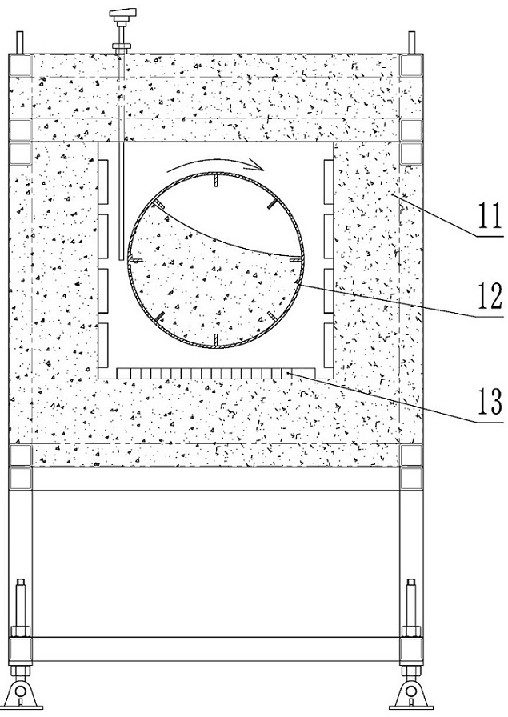

A comprehensive garbage sorting technology includes the steps of garbage grinding, bag breaking, magnetic separation, primary winnowing, two-grade sorting in a rotary screen and secondary winnowing. A comprehensive garbage sorting machine comprises a plate-type feeder, a garbage grinding and bag breaking machine and a magnetic separator are mounted in a feeding section and a discharging section of the plate-type feeder respectively, a first winnower and a first U-shaped belt conveyer are sequentially arranged below the discharging end of the plate-type feeder, the rotary screen comprising a first screening section and a second screening section is arranged at the rear end of the plate-type feeder, a first discharging hopper and a second discharging hopper are arranged below the first screening section and the second screening section of the rotary screen respectively, a second U-shaped belt conveyer and a third U-shaped belt conveyer are arranged below the two discharging hoppers respectively, a fourth U-shaped belt conveyer is arranged at the rear end of the rotary screen, and a second winnower is mounted below the discharging end of the rotary screen. The comprehensive garbage sorting technology and the comprehensive garbage sorting machine have the advantages that magnetic metal, building garbage, organic matters and the like in garbage can be sorted out step by step, thorough separation of various materials in household garbage is achieved, and recovery and utilization of useful materials are facilitated.

Owner:TIANJIN BAILI SUN ENVIRONMENTAL PROTECTION EQUIP CO LTD

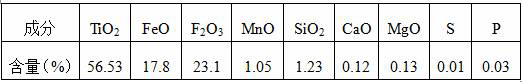

Method for extracting Fe from ion ore tailings

InactiveCN1765520ARaise the gradeAlleviate the lack ofMagnetic separationOrganic acidEconomic benefits

Owner:毕舒

Preparation process and system for producing high-grade titanium-rich material by utilizing ilmenite

ActiveCN111733336AThere is no limit to the choice of materialsLow failure rateRotary drum furnacesMagnetic separationDust controlIlmenite

Owner:湖南碳谷装备制造有限公司

Magnetic separator

Owner:台州飞亚鸿丰科技有限公司

Silicon carbide ultrafine powder and production method thereof

PendingCN111960419AHigh purityConsistent densitySilicon carbideMagnetic separationCarbide siliconFoaming agent

Owner:惠州市中惠宇航半导体新材料有限公司

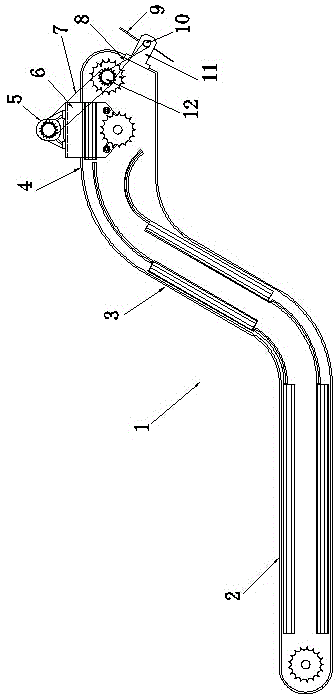

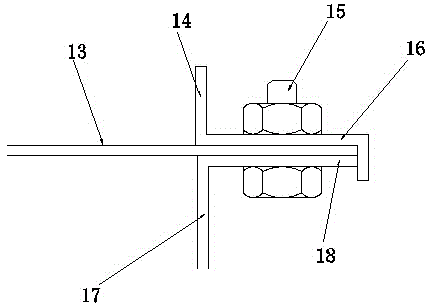

Automatic ore feeding device of magnetic separators and automatic ore feeding control method

ActiveCN112173743AChange open and close stateChange opening sizeConveyorsMagnetic separationMining engineeringMagnetic separator

Owner:SHOUGANG CORPORATION

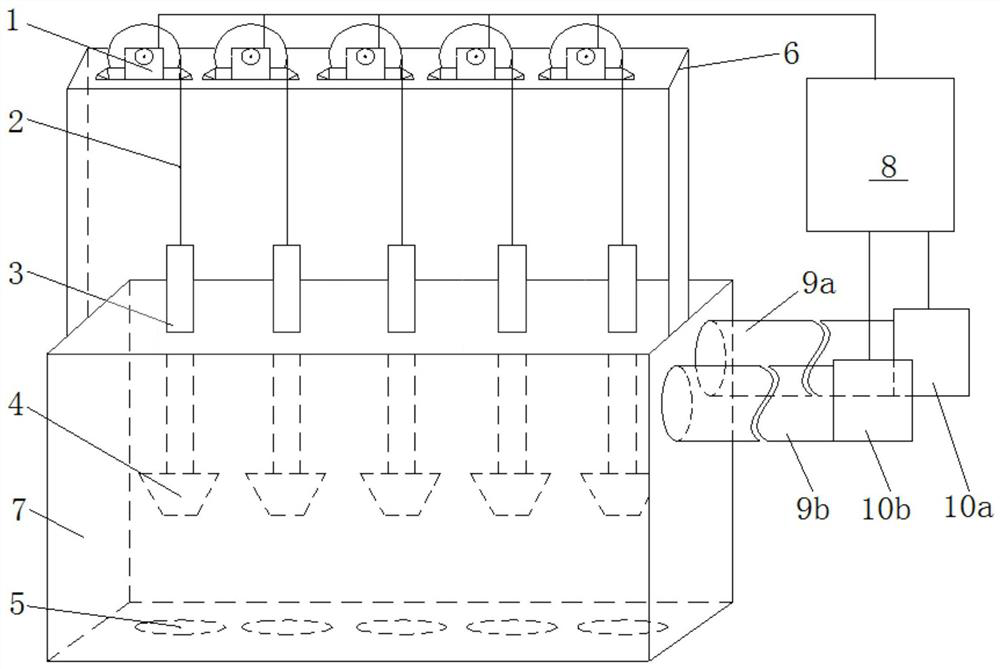

Pretreatment device applying magnetic coagulation to reuse water of printed circuit board wastewater

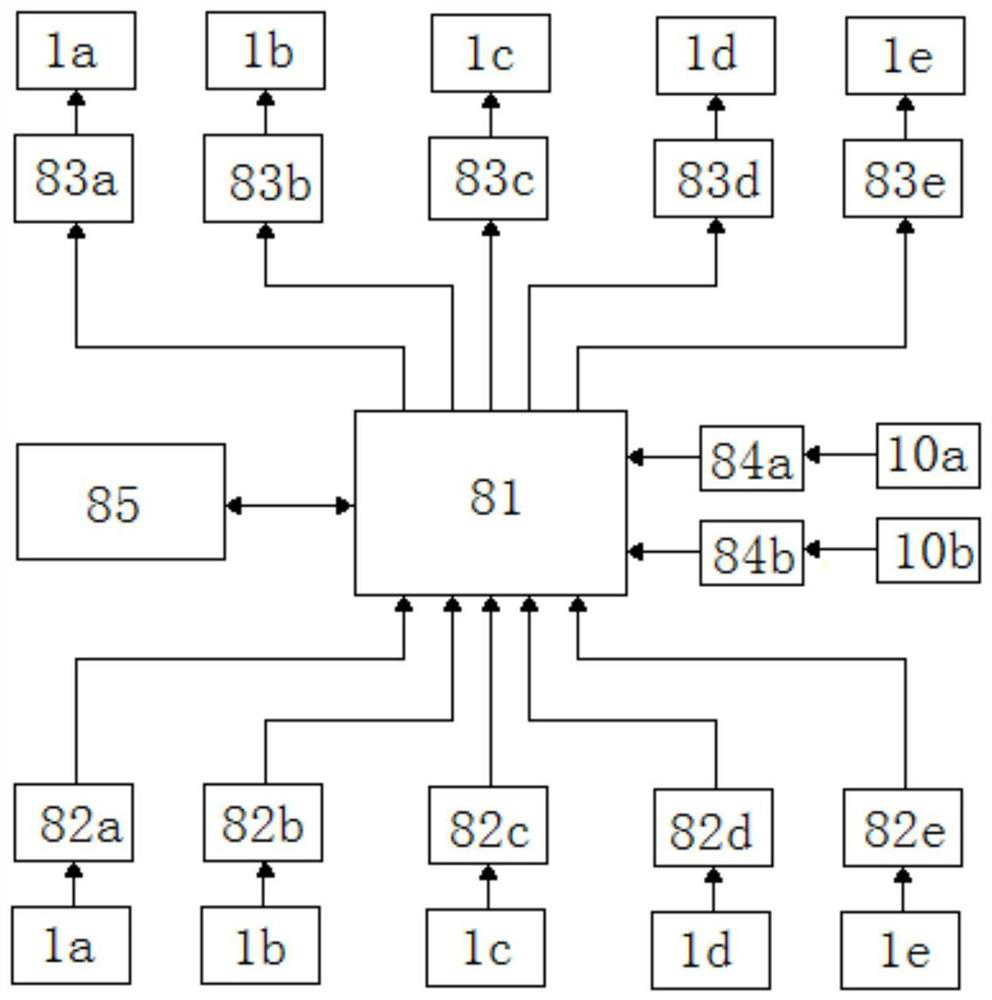

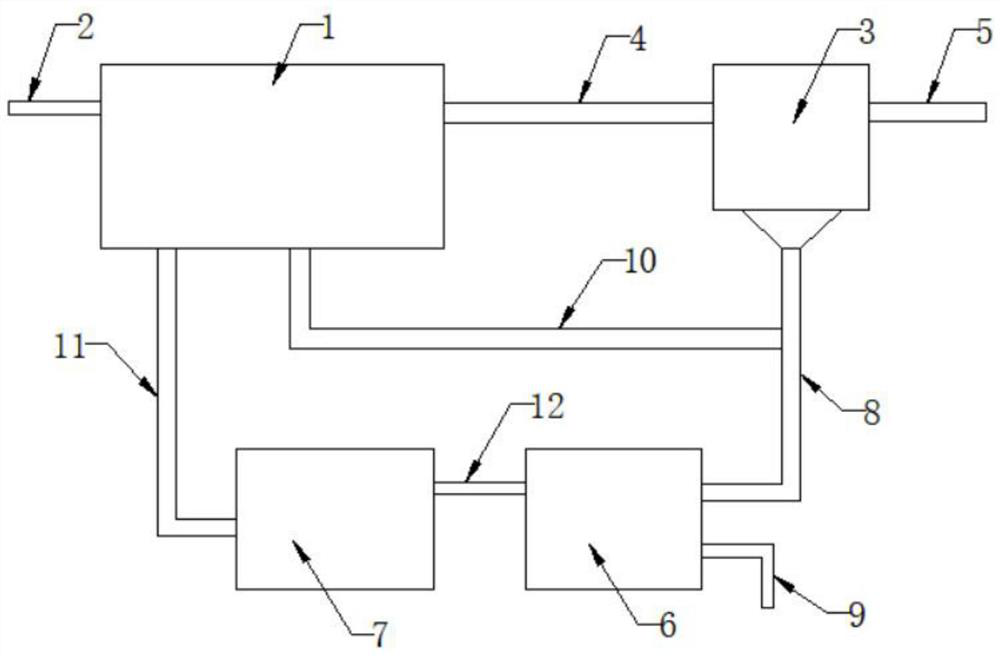

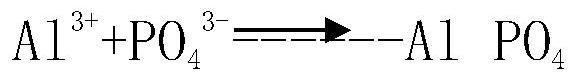

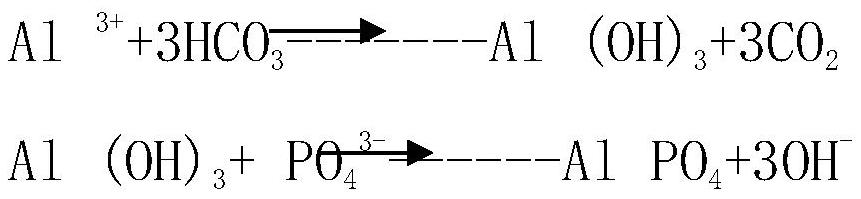

InactiveCN112723646AMultistage water/sewage treatmentTreatment involving sedimentationMagnetic separatorPre treatment

Owner:深圳市诺金环保技术有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap