Magnetic separator

A technology of magnetic separator and separation body, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc. It can solve the problems of magnet load, affecting the adsorption efficiency of impurities such as iron filings, and the separation efficiency of the separator is not high, so as to meet the requirements of the work. Demand, the effect of high magnetic suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

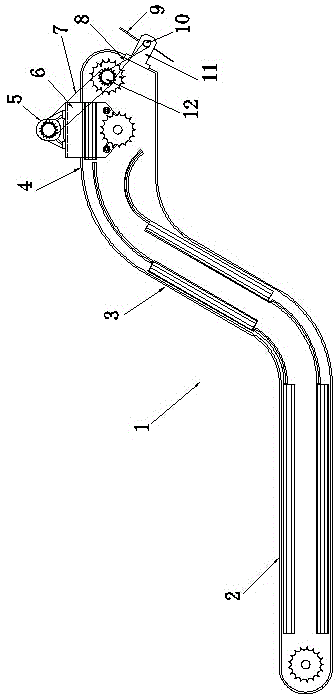

[0019] As shown in the figure, the magnetic separator of the present invention is the main structural part of the separator. The separator 1 is a hollow shell-shaped body, which is in the shape of a "Z" as a whole. The separator 1 has a liquid immersion part 2, a rising part 3 and a discharge Part 4, the immersion part 2 and the discharge part 4 are parallel, the rising part 3 is arranged obliquely and connects the immersion part 2 and the discharge part 4, and the discharge position of the separated material is located at the outer end of the discharge part 4 The outer end is also called the discharge end.

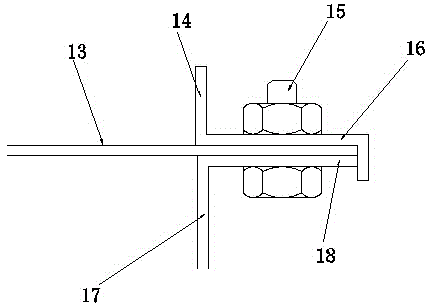

[0020] Separator 1 is surrounded by two side plates 17 and a closed annular flat plate 13. The separation surface on the separation body 1 is formed on the surface of flat plate 13. The separation surface is adapted to the direction of flat plate 13 and is also annular closed. The periphery of side plate 17 and flat plate 13 can be fixed together by the mode of welding, also

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap