Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Winnowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wind winnowing is an agricultural method developed by ancient cultures for separating grain from hay. It can also be used to remove pests from stored grain. Winnowing usually follows threshing in grain preparation.

Comprehensive rubbish sorting technology and comprehensive rubbish sorting machine

InactiveCN104722494AAchieve separationRealize sortingSievingGas current separationMagnetic separatorEngineering

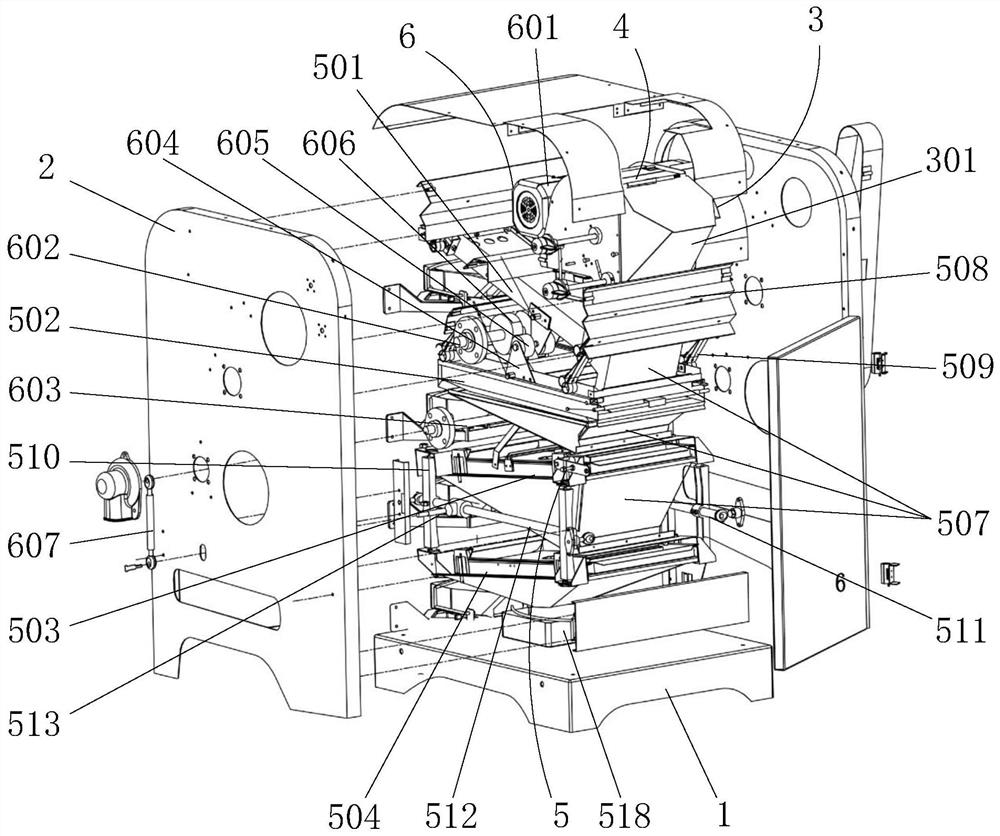

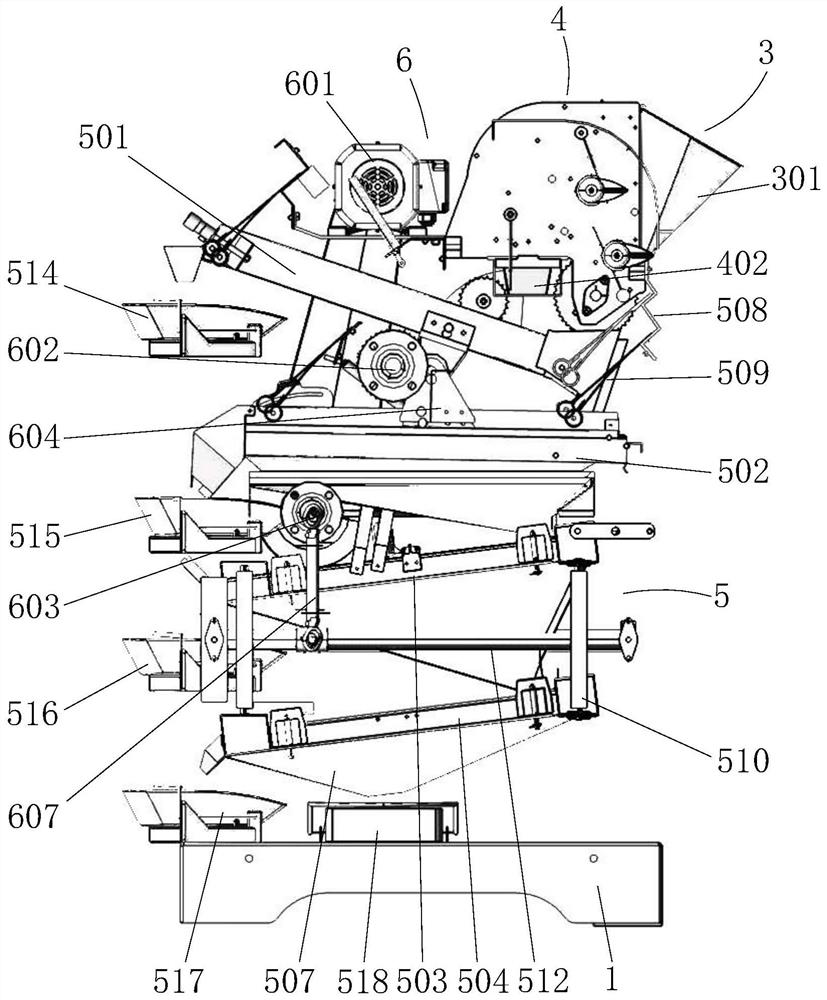

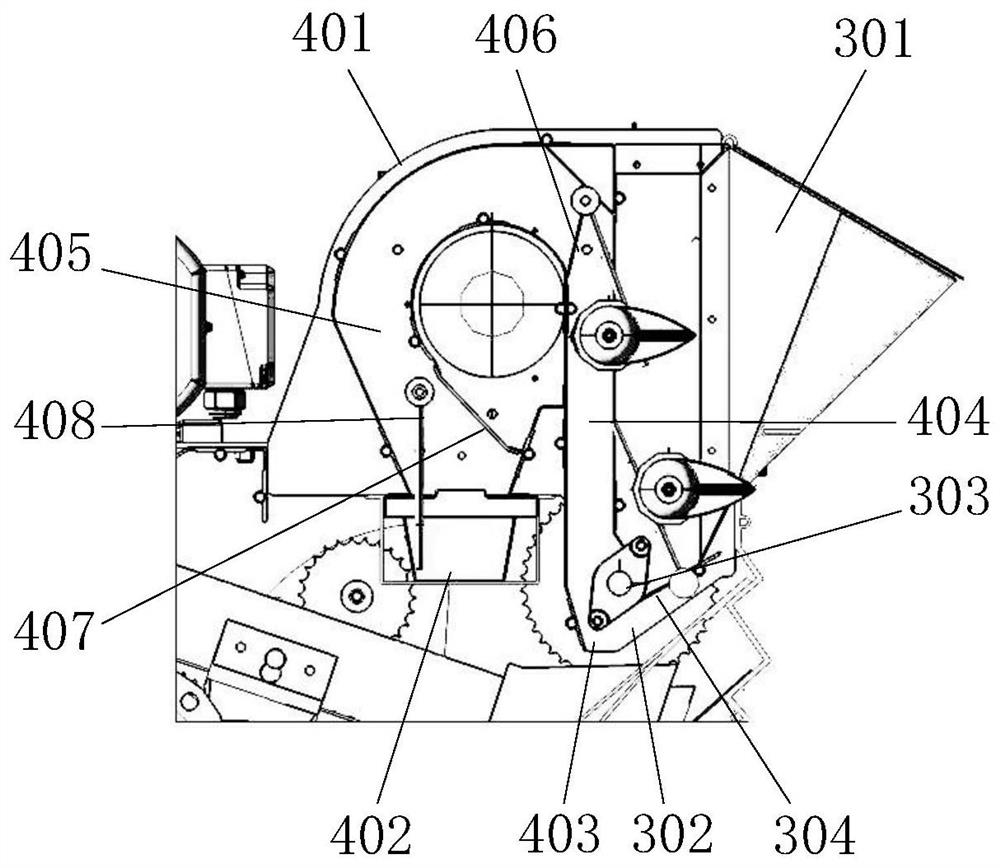

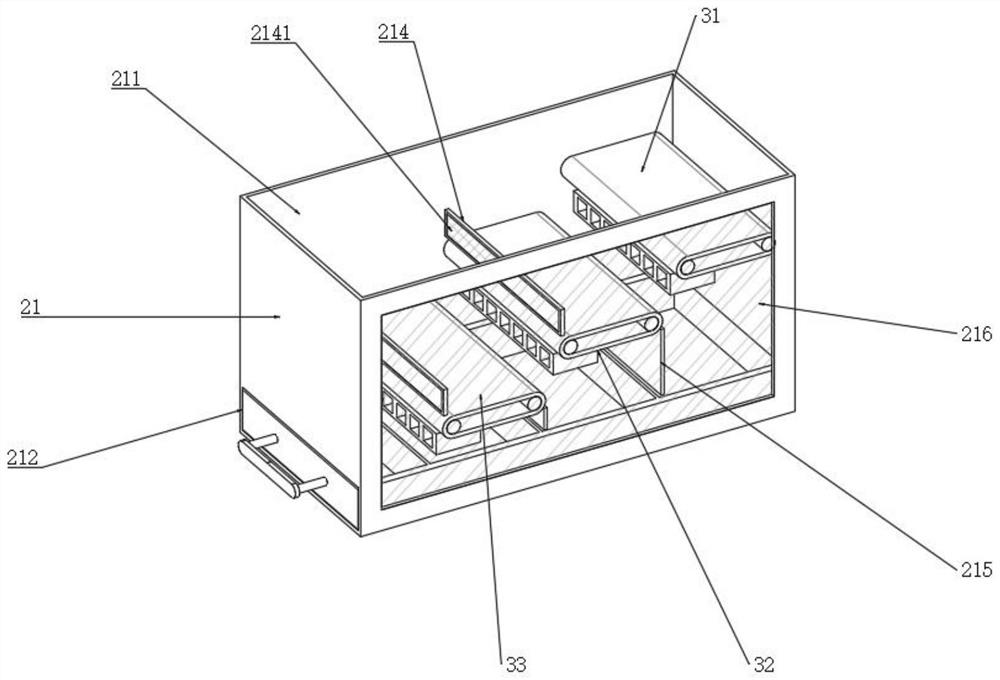

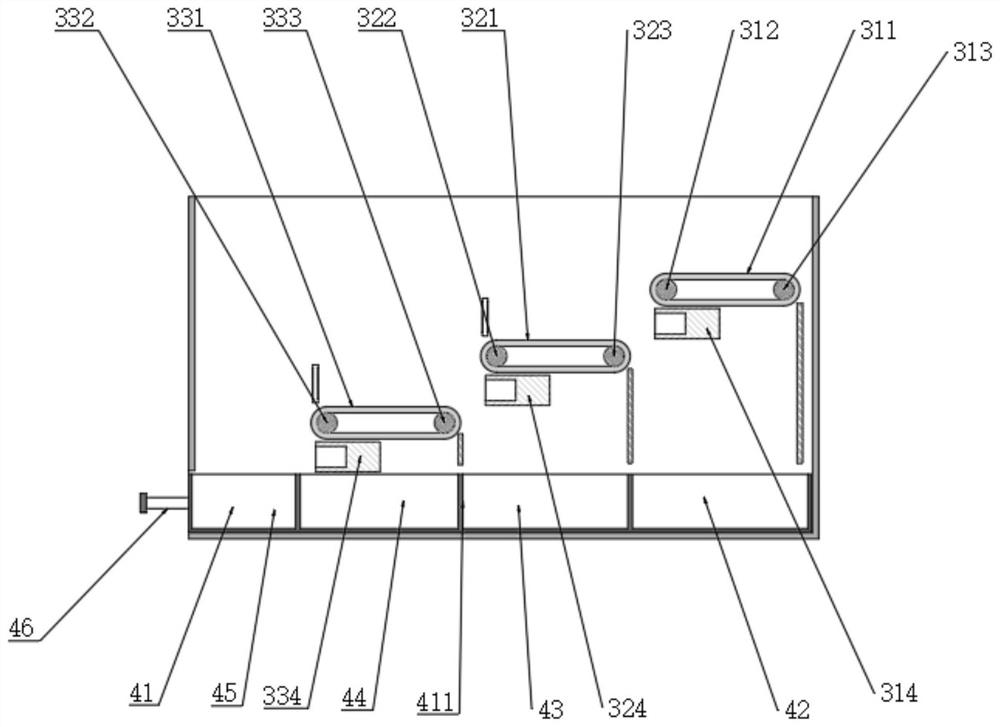

A comprehensive garbage sorting technology includes the steps of garbage grinding, bag breaking, magnetic separation, primary winnowing, two-grade sorting in a rotary screen and secondary winnowing. A comprehensive garbage sorting machine comprises a plate-type feeder, a garbage grinding and bag breaking machine and a magnetic separator are mounted in a feeding section and a discharging section of the plate-type feeder respectively, a first winnower and a first U-shaped belt conveyer are sequentially arranged below the discharging end of the plate-type feeder, the rotary screen comprising a first screening section and a second screening section is arranged at the rear end of the plate-type feeder, a first discharging hopper and a second discharging hopper are arranged below the first screening section and the second screening section of the rotary screen respectively, a second U-shaped belt conveyer and a third U-shaped belt conveyer are arranged below the two discharging hoppers respectively, a fourth U-shaped belt conveyer is arranged at the rear end of the rotary screen, and a second winnower is mounted below the discharging end of the rotary screen. The comprehensive garbage sorting technology and the comprehensive garbage sorting machine have the advantages that magnetic metal, building garbage, organic matters and the like in garbage can be sorted out step by step, thorough separation of various materials in household garbage is achieved, and recovery and utilization of useful materials are facilitated.

Owner:TIANJIN BAILI SUN ENVIRONMENTAL PROTECTION EQUIP CO LTD

Impurity removing machine

Owner:ZHEJIANG BETHLEHEM APP

Tobacco shred repeated winnowing device

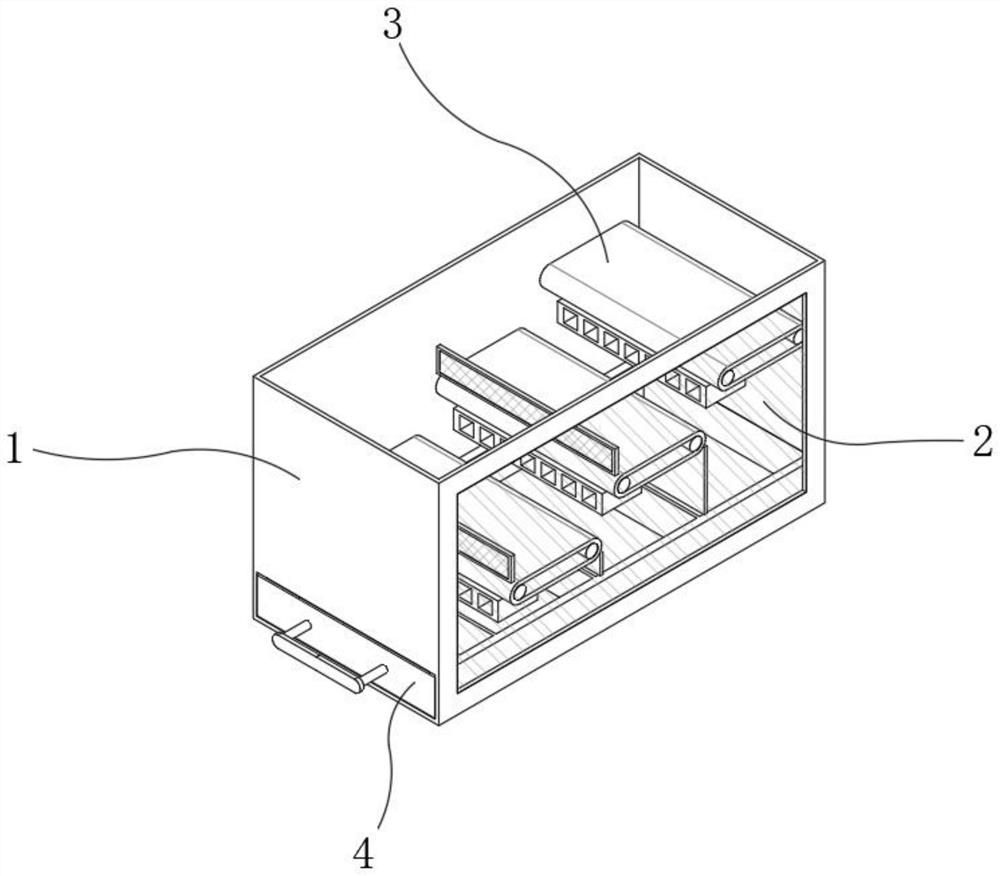

PendingCN114798445AReduce lossEasy to handleGas current separationEconomic benefitsProcess engineering

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap