Portable rechargeable direct-current electric welding machine

A direct current, portable technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as inability to work, and achieve the effect of easy disassembly, easy handling, and easy portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

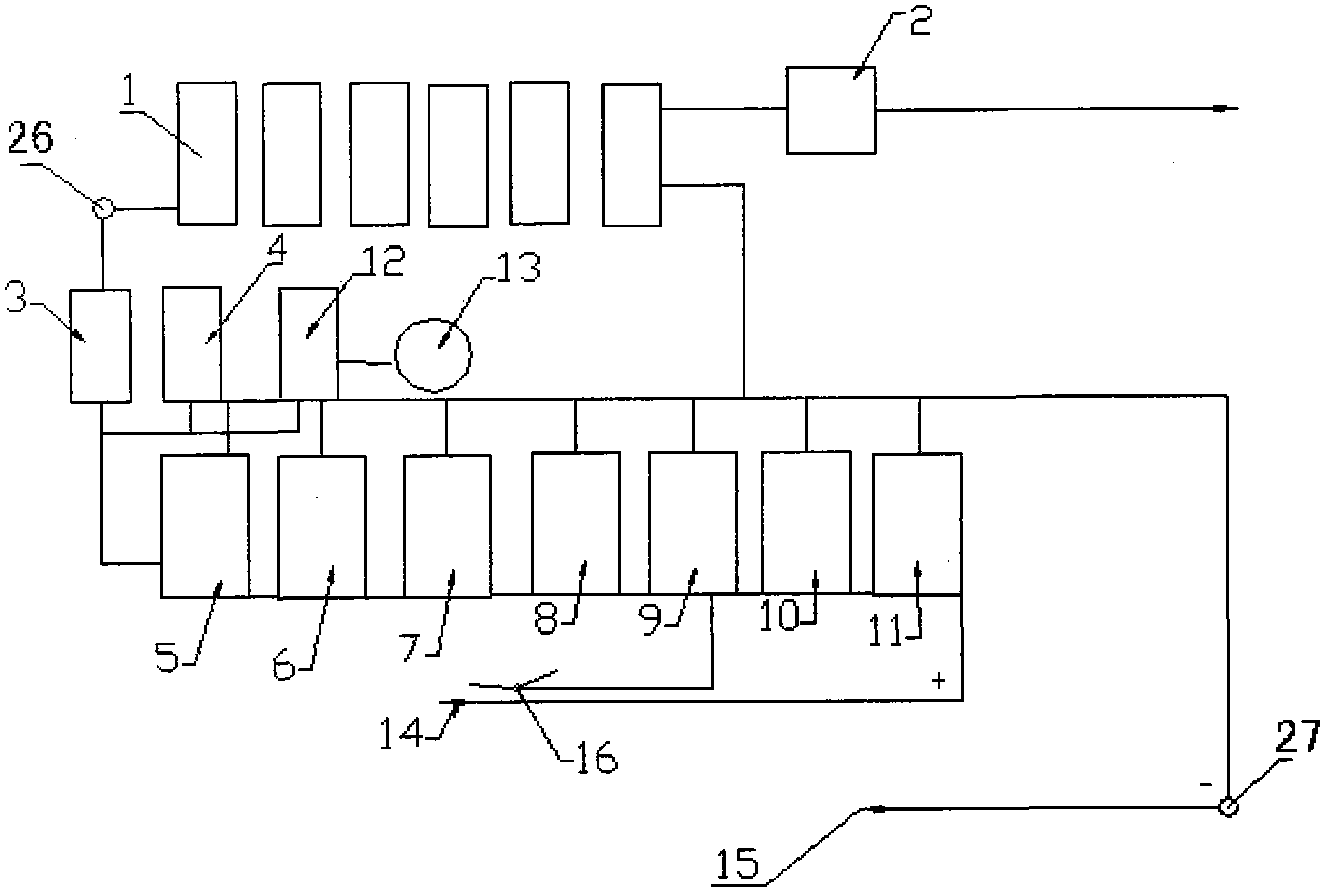

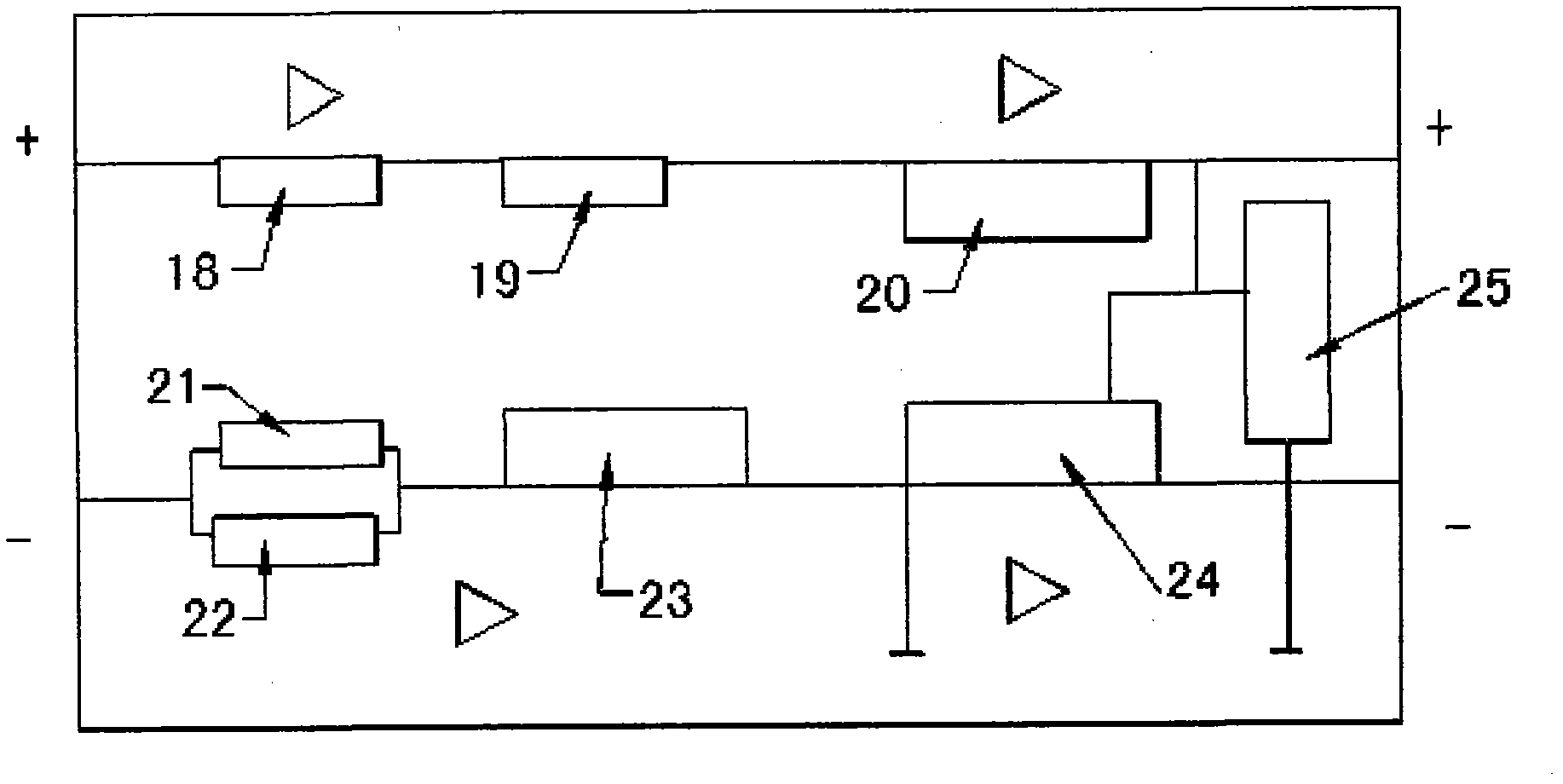

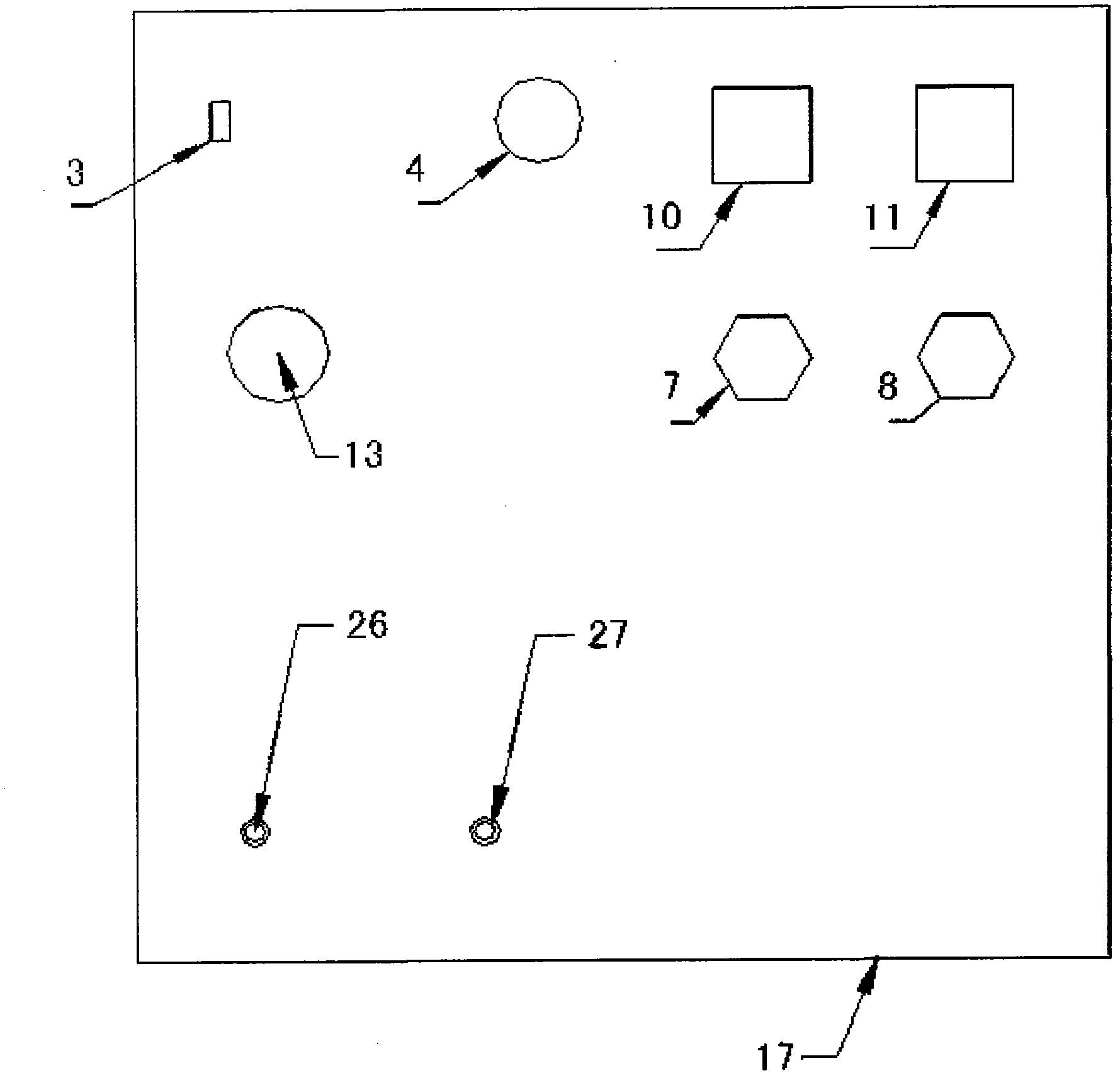

[0021] Such as figure 1 , 2 , 3, and 4, a portable rechargeable DC welding machine includes a housing 17, a welding handle terminal 26 and a ground wire terminal 27 arranged on the housing 17, and a switch 3 arranged in the housing 17. The casing 17 of the battery pack 1 is externally connected with a battery pack 1. The battery pack 1 includes a positive main wire, a positive sub-wire, a negative main wire, and a negative sub-wire. The positive main wire of the battery pack 1 is connected to the welding handle terminal 26, and the welding handle connecting terminal 26 is The switch 3 is connected, the switch 3 is connected with the voltage regulator 5, the voltage regulator 5 is connected with the control board 6, the control board 6 is connected with the voltage regulator 7, the voltage regulator 7 is connected with the current regulator 8, and the current The regulator 8 is connected to the contactor 9, the contactor 9 is connected to the welding voltmeter 10, the welding vol

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap