Heating circuit of battery

A battery heating and charging circuit technology, which is applied to battery circuit devices, circuits, secondary battery charging/discharging, etc., can solve the problems of large battery temperature gradient, failure to maintain the battery, and slow heating, so as to achieve fast temperature rise and avoid The formation of dendrites and the effect of high temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

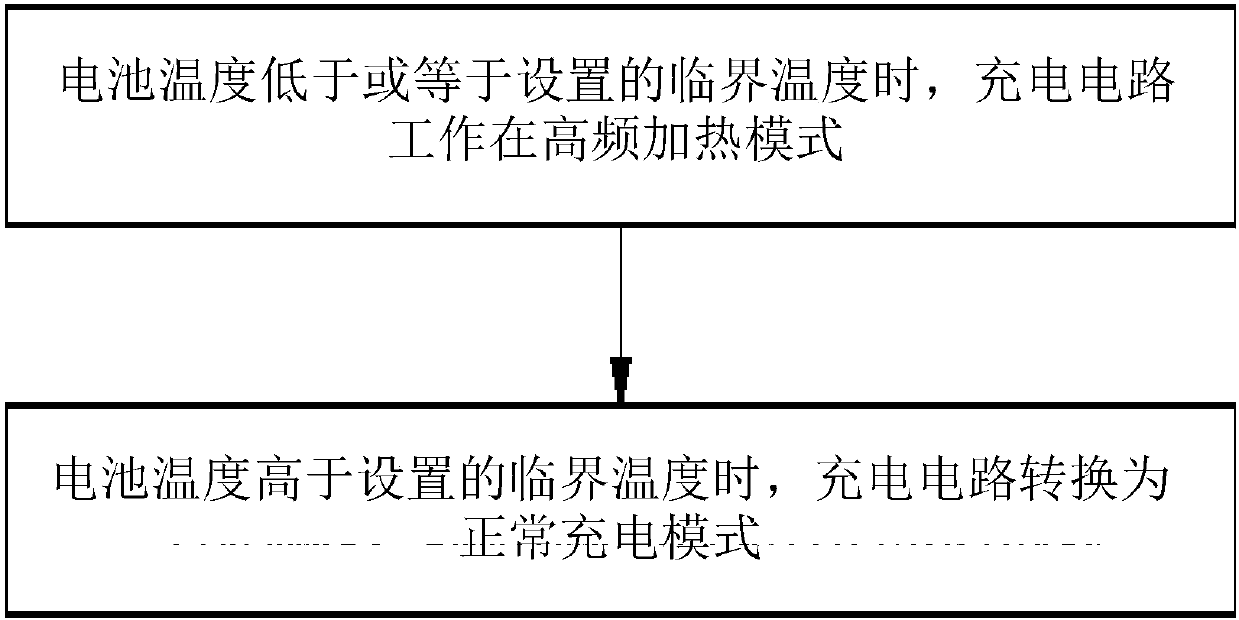

[0028] figure 1 A battery charging strategy adopted by a battery heating circuit according to an embodiment of the present invention is disclosed. In order to prolong the service life of the battery and shorten the charging time of the battery, it is not advisable to charge the battery directly under low temperature conditions, but to heat the battery first. refer to figure 1 As shown, the critical temperature is set in the charging strategy of the present invention. When the battery temperature is lower than or equal to the set critical temperature, the charging circuit works in the high-frequency heating mode, and the battery is heated by high-frequency charging and discharging of the battery, so that The battery temperature gradually rises. When the battery temperature is higher than the set critical temperature, the charging circuit switches to the normal charging mode to continuously charge the battery.

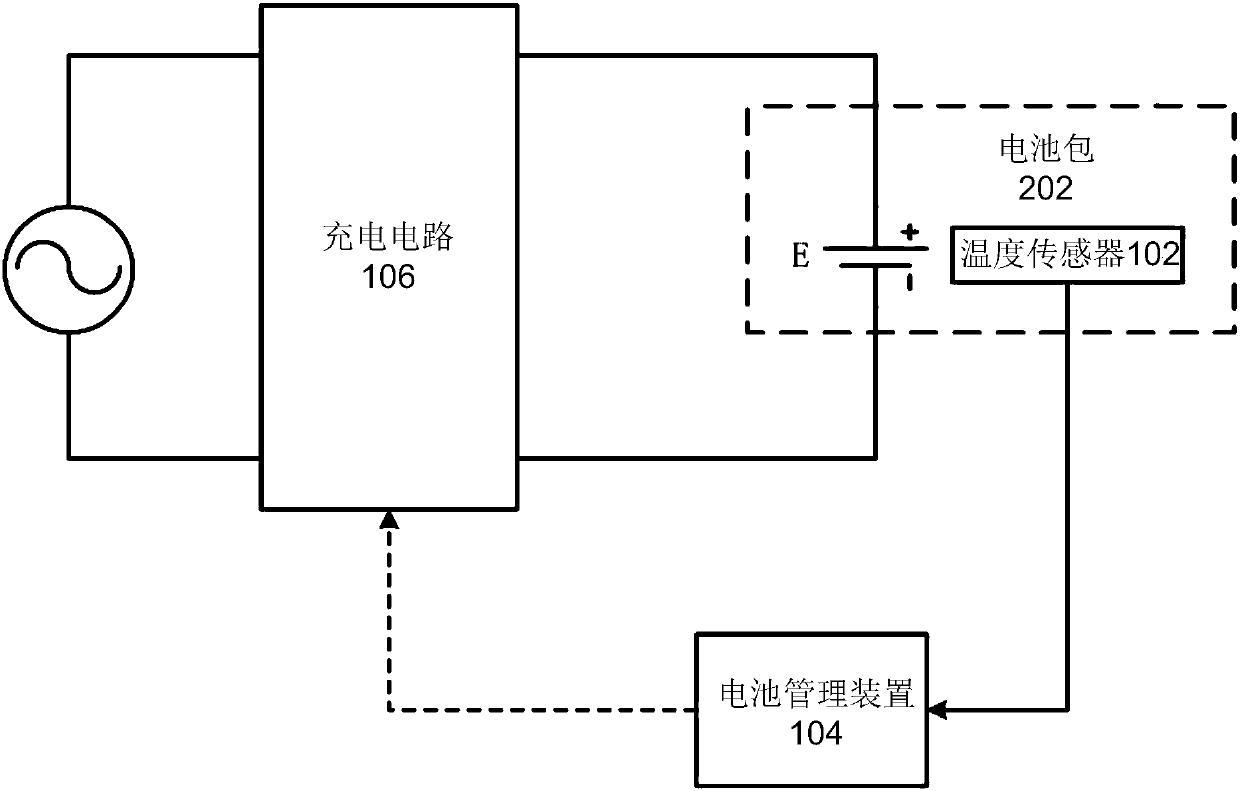

[0029] figure 2 A structural block diagram of a battery heating c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap