Battery module

a battery module and battery technology, applied in the field of batteries, can solve the problems of high cost, high cost, and high cost of battery modules, and achieve the effects of increasing assembling efficiency, reducing the number of screws used for connecting parallel cell units, and improving the assembling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be apparent from the following detailed description, which proceeds with reference to the accompanying drawings, wherein the same references relate to the same elements.

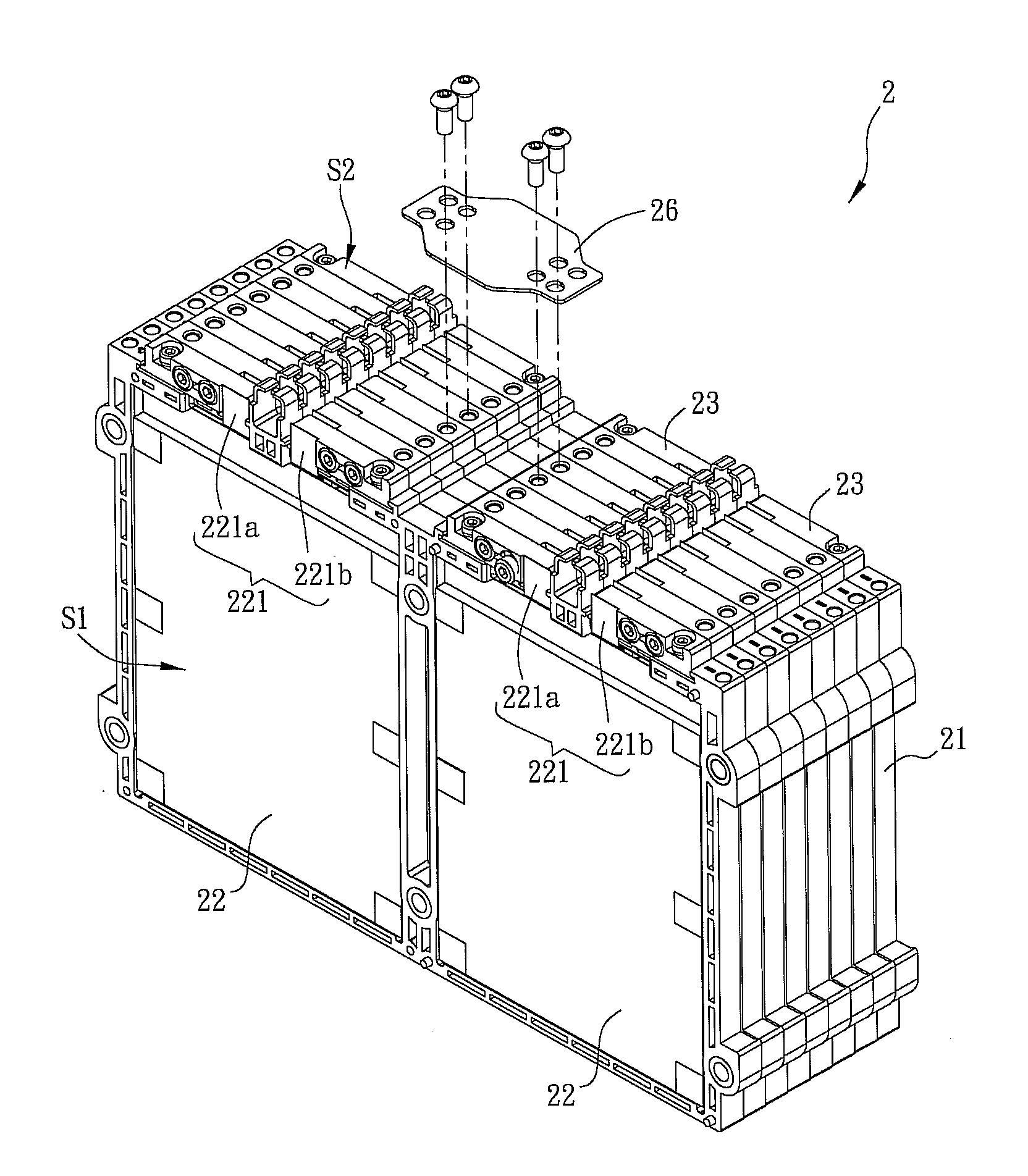

[0031]FIG. 3A is a schematic diagram of an assembled battery module 2 according to a preferred embodiment of the present invention, and FIG. 3B is a partial exploded view of the battery module 2. Referring to FIGS. 3A and 3B, the battery module 2 includes a plurality of cell units 20, which are stacked alone a direction Dl. Each cell unit 20 has a first surface S1 and a second surface S2, and includes a frame 21, at least one cell 22, and at least two conductors 23. In this embodiment, the battery module 2 includes 8 battery units 20, and each battery unit 20 includes two cells 22. The surface of the cell 22 is covered by insulating tapes for increasing its pressure resistance. The battery module 2 can be used as a vehicle battery module. In practice, multiple battery modules 2 are stack

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap