Non-aqueous electrolyte battery and method for producing the same

a non-aqueous electrolyte, battery technology, applied in the direction of wound/folded electrode electrodes, sustainable manufacturing/processing, instruments, etc., can solve the problems of battery being likely to be under abnormal conditions, short circuit current and large heat generation, etc., to achieve a safer non-aqueous electrolyte battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

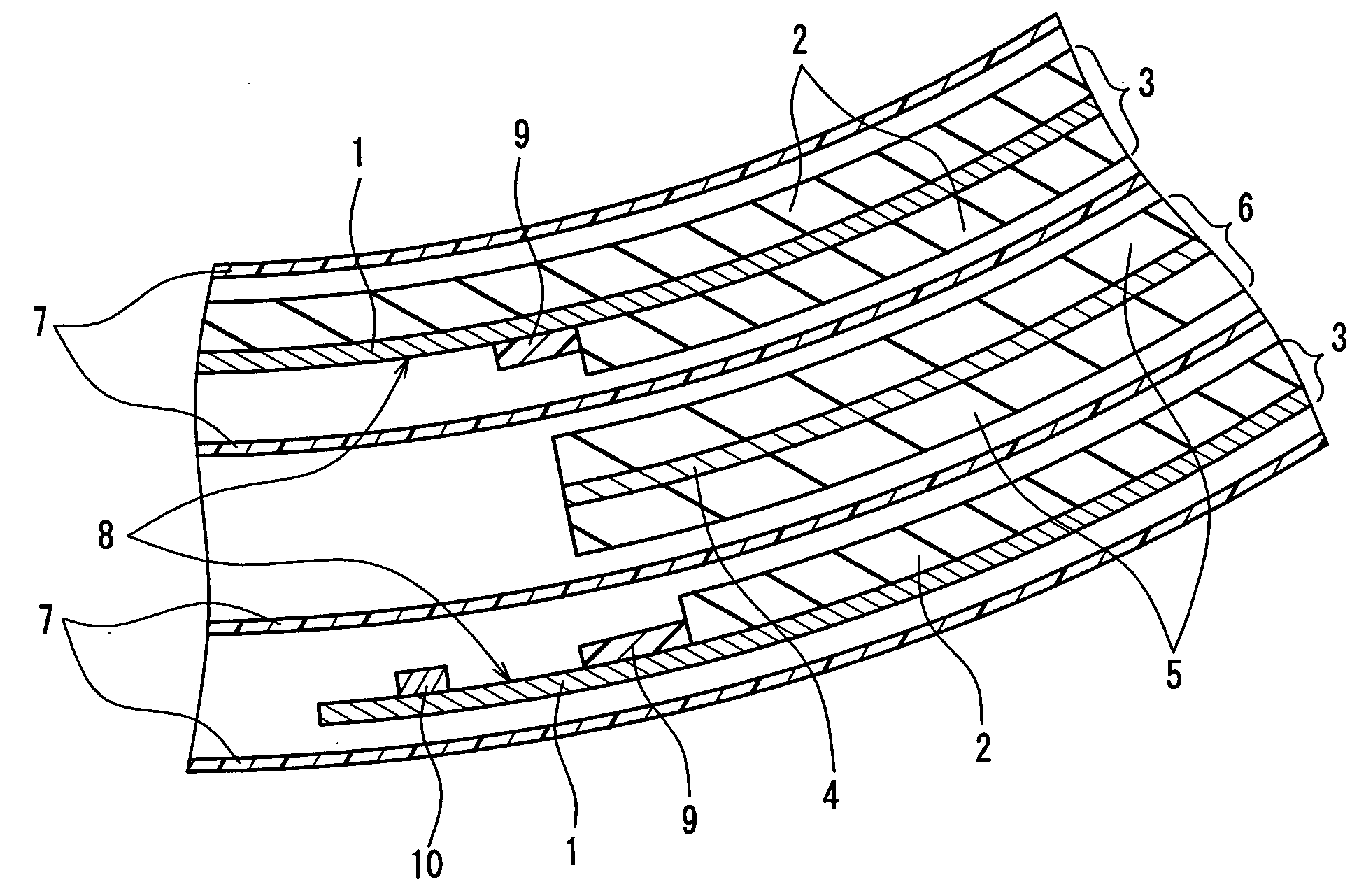

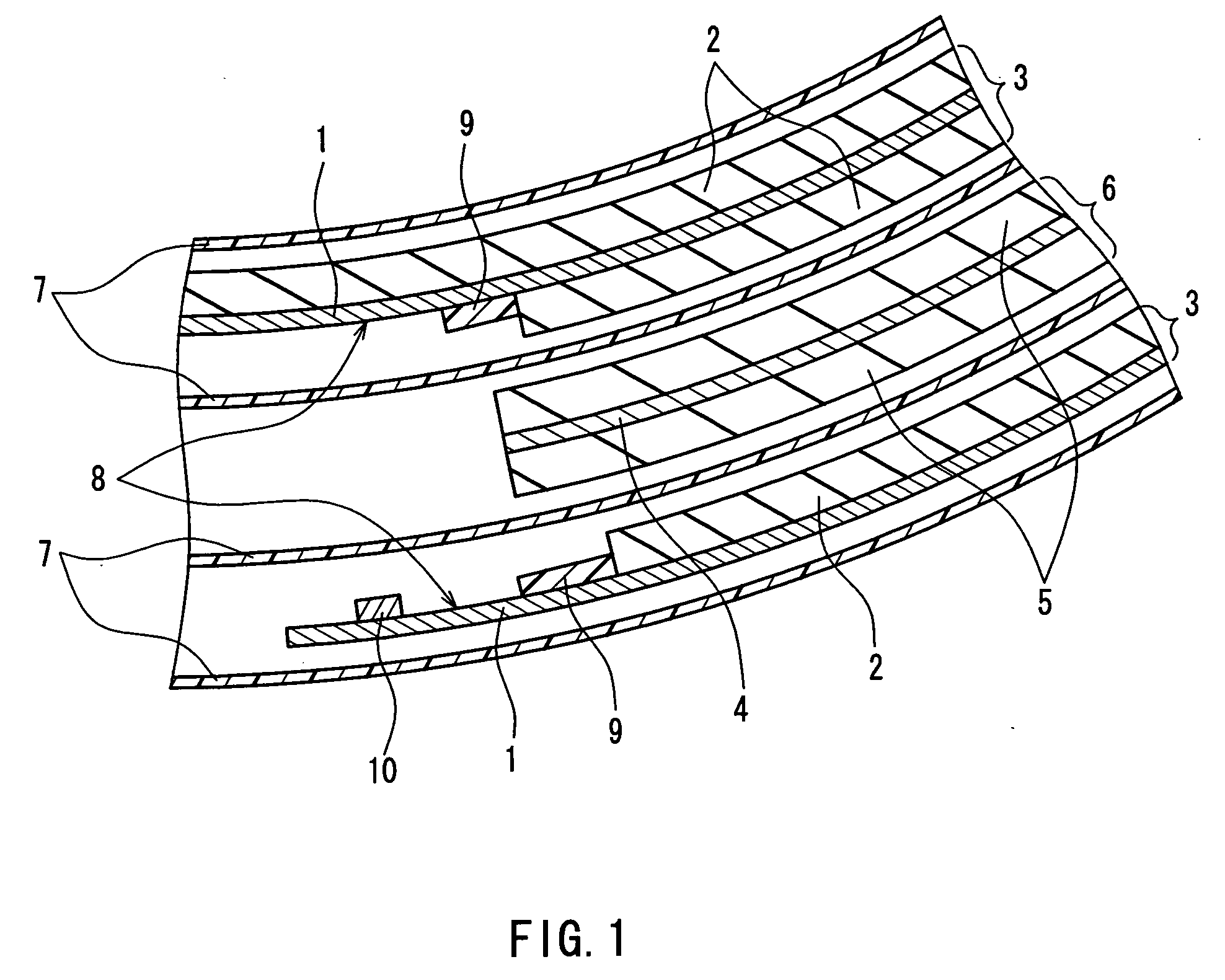

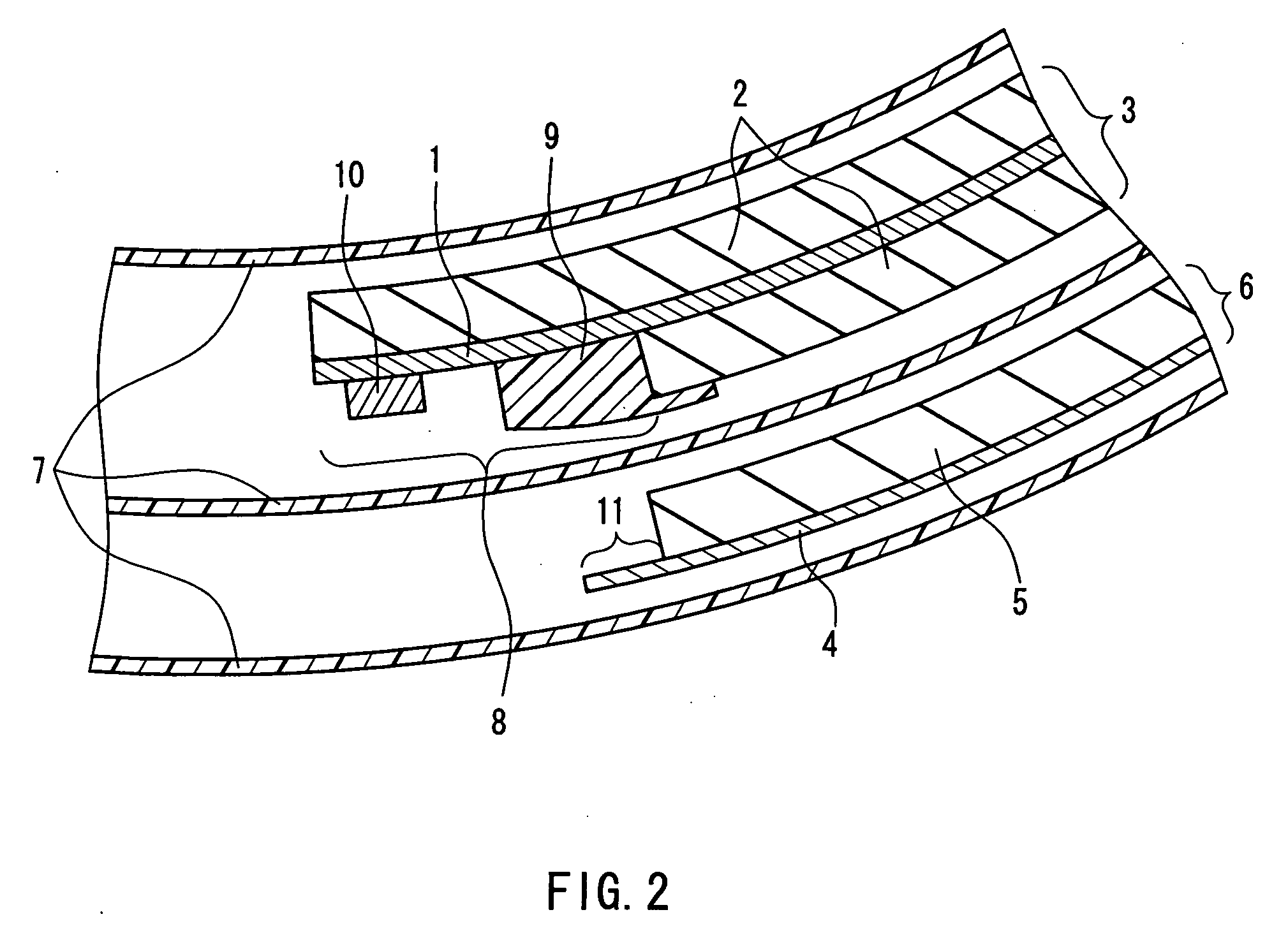

[0052] In the present example, members corresponding to those in the configuration of the winding body in FIG. 1 are described with the same reference numerals given thereto.

[Production of Positive Electrode]

[0053] 80 parts by mass of LiCoO2 as a positive active material, 10 parts by mass of acetylene black as a conductive assistant, and 5 parts by mass of PVDF as a binder were mixed uniformly in a solvent of N-methyl-2-pyrrolidone (NMP) to prepare a paste containing a positive electrode mixture. The paste containing a positive electrode mixture was applied intermittently to both surfaces of aluminum foil (thickness: 15 μm) to be the positive collector 1, such that the applied active material was 281 mm long on a front surface and 212 mm long on a back surface (the positive collector exposed portion 8 was 69 mm long), followed by drying. Thereafter, the positive active material containing layer 2 was adjusted to have a total thickness of 150 μm by calendar processing and cut to a wid

example 2

[0057] The positive electrode was produced in the same manner as in Example 1, except that 3 g of a polyethylene powder (ratio of PE to a total weight of PVDF and PE: 20 wt %) was used, and a non-aqueous electrolyte secondary battery was assembled.

example 3

[0058] The positive electrode was produced in the same manner as in Example 1, except that 5.14 g of a polyethylene powder (ratio of PE to a total weight of PVDF and PE: 30 wt %) was used, and a non-aqueous electrolyte secondary battery was assembled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap