Reinforcing rib plate welding process and welding equipment thereof

A rib plate and welding process technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as the inability to accurately guarantee the welding position of the rib plate, the lack of effective fixing of the rib plate, and the decrease in welding efficiency. , to achieve the effect of improving welding efficiency, ensuring accuracy, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

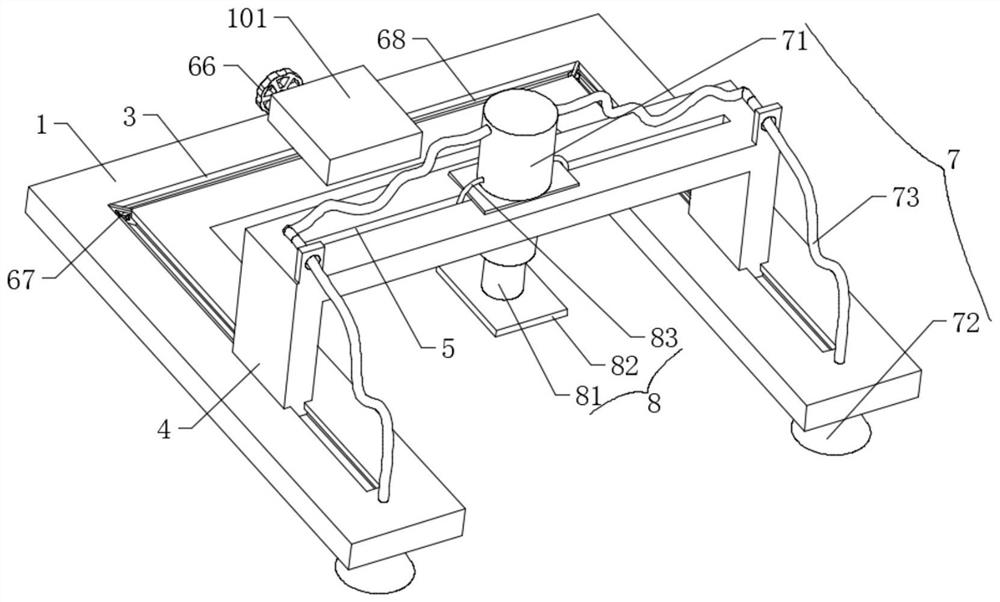

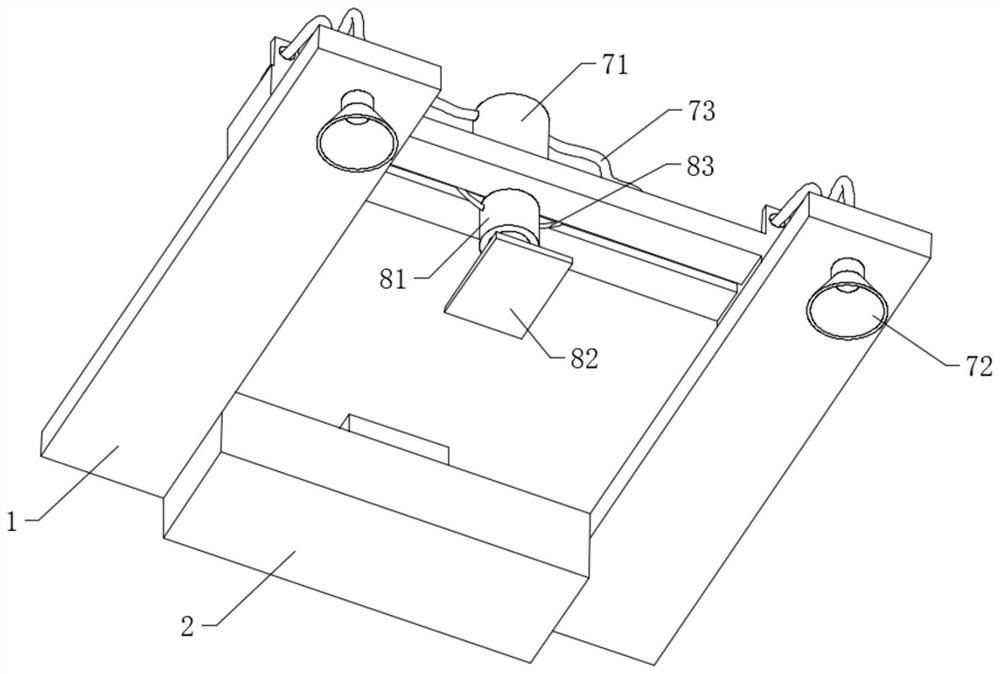

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

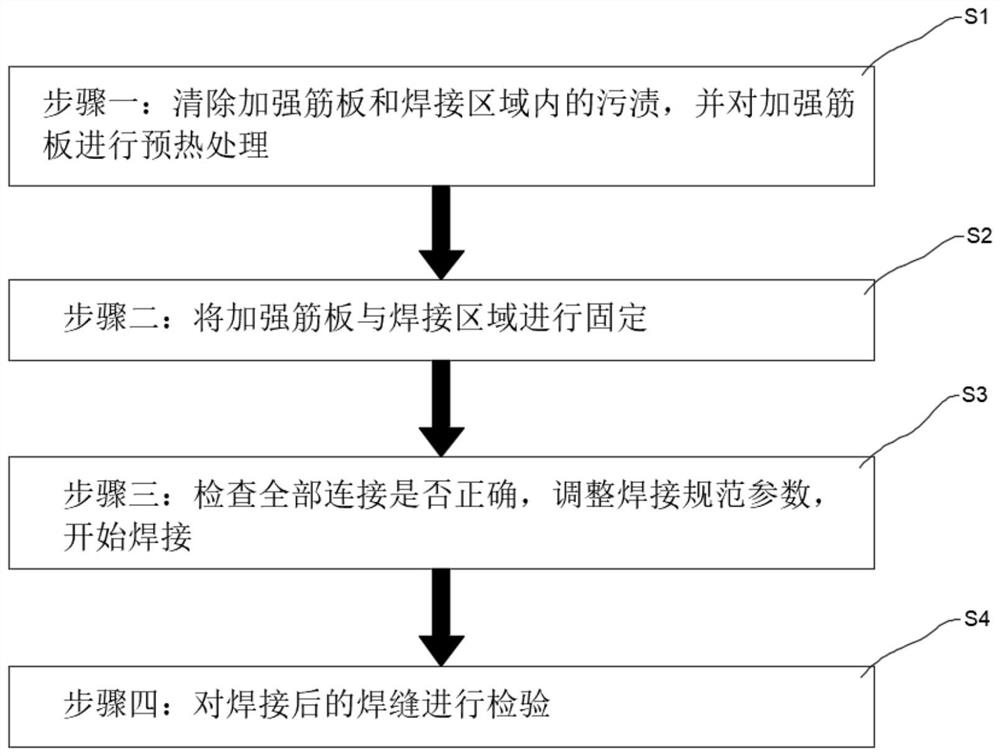

[0034] refer to figure 1 , a stiffener plate welding process, the steps are as follows;

[0035] First, clean up the oil, rust, scale and other sundries and impurities in the stiffener plate and welding area, and preheat the workpiece welding area and stiffener plate with propane, standard gas or acetylene torch. The heating temperature is 150-260°C, the preheating range is on both sides of the weld, and the preheating range on each side is not less than 3 times the thickness of the stiffener plate. The preheating temperature measurement point is 50mm away from the weld, and the preheating method is electric heating. The purpose of preheating the metal in the welding a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap