Continuously welded vane

A technology for impellers and hubs, applied in the field of continuous welded impellers, to achieve high strength and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

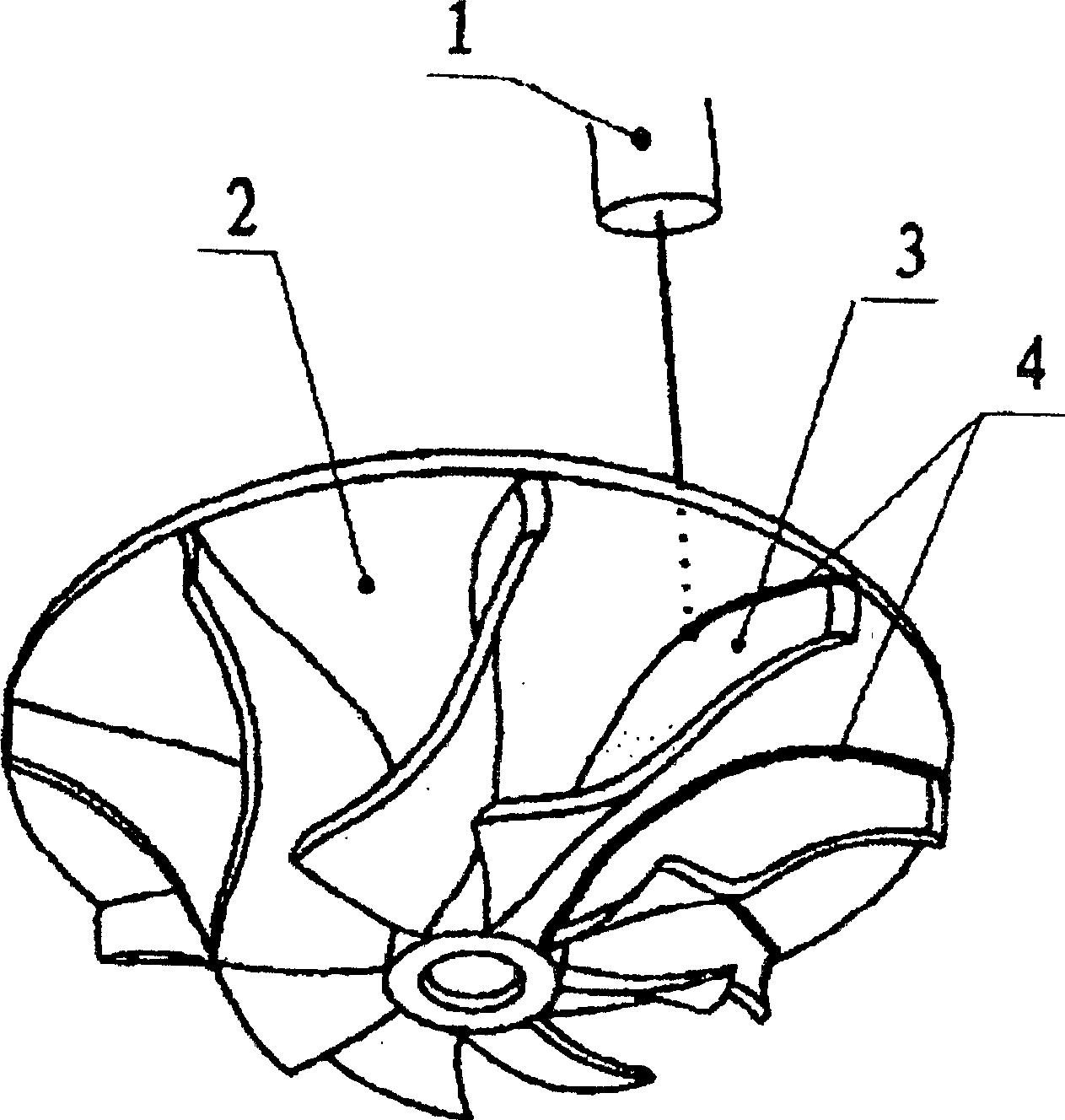

[0007] Below in conjunction with accompanying drawing and embodiment for further explanation: figure 1 The blade 3 and the hub 2 are made of sheet metal. The laser 1 focuses the laser beam on the joint between the blade 3 and the hub 2 from the other side of the hub 2 under the control of the computer, and along the blade 3 and the hub 2, a continuous weld 4 can be formed at this joint, and the blade 3 and the hub 2 are firmly connected. The joints between the plurality of blades 3 and the hub 2 are fixedly connected by a plurality of continuous welds 4 to form an impeller continuously welded by metal plates.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap