Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Thin metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

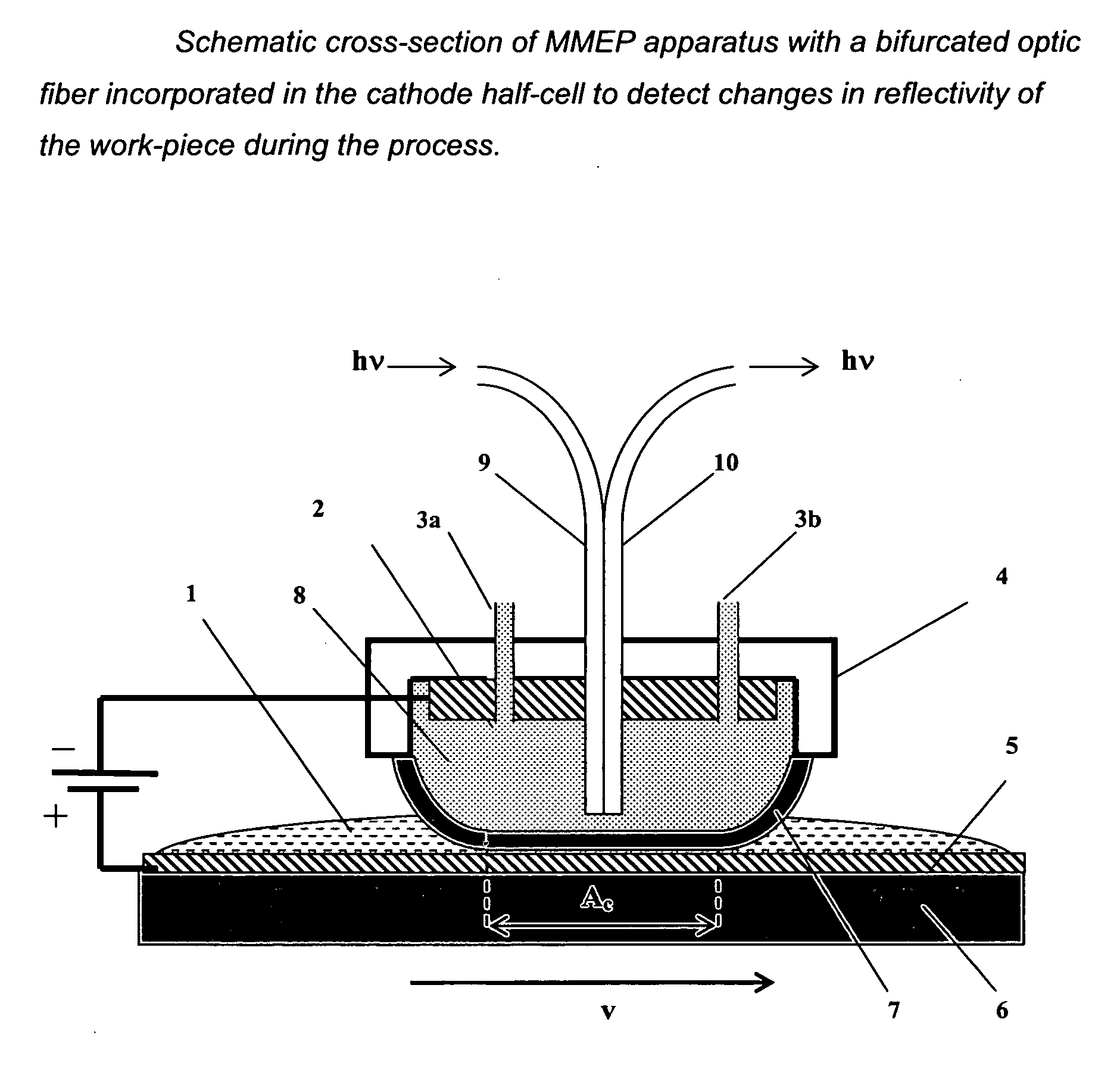

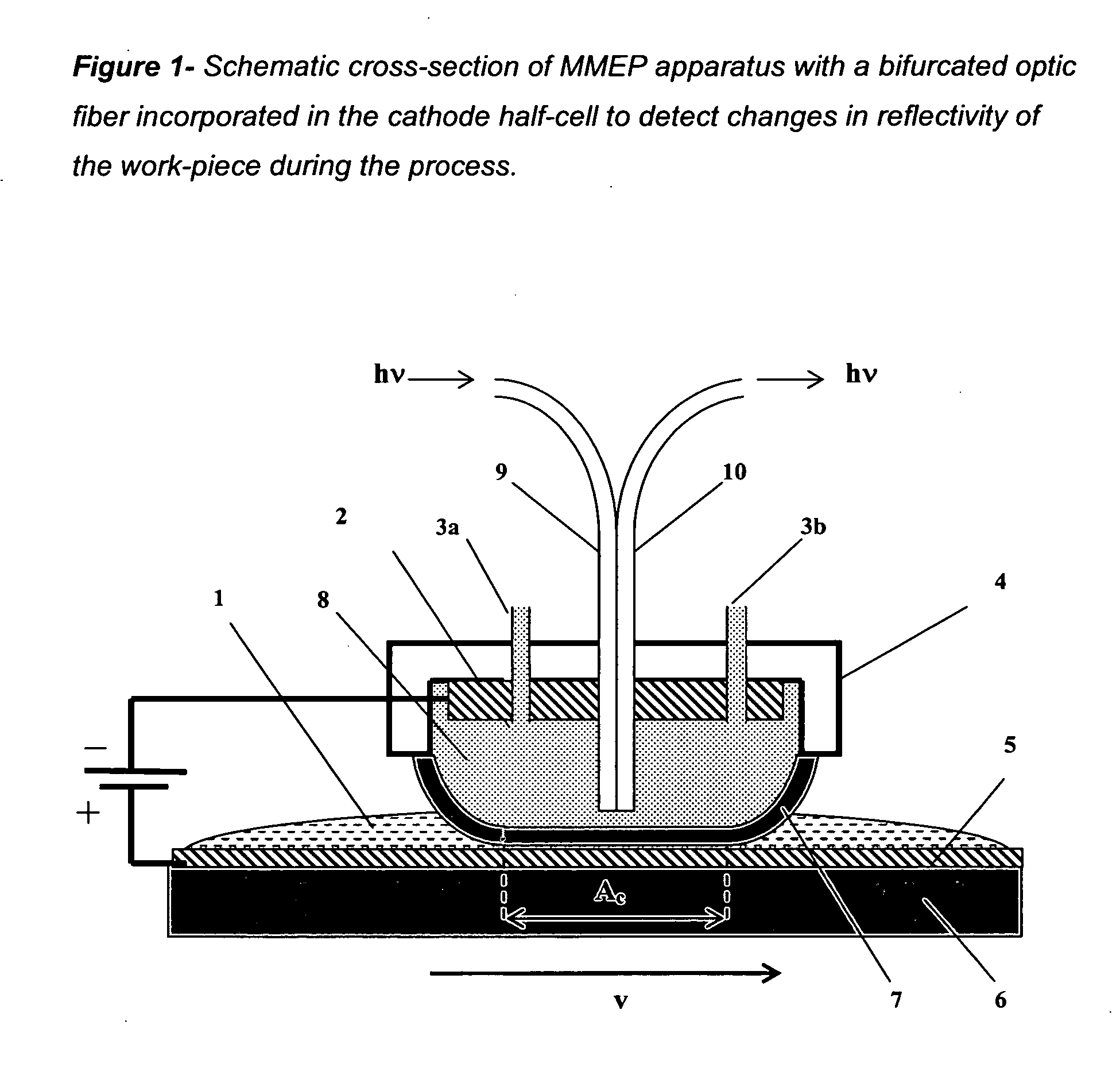

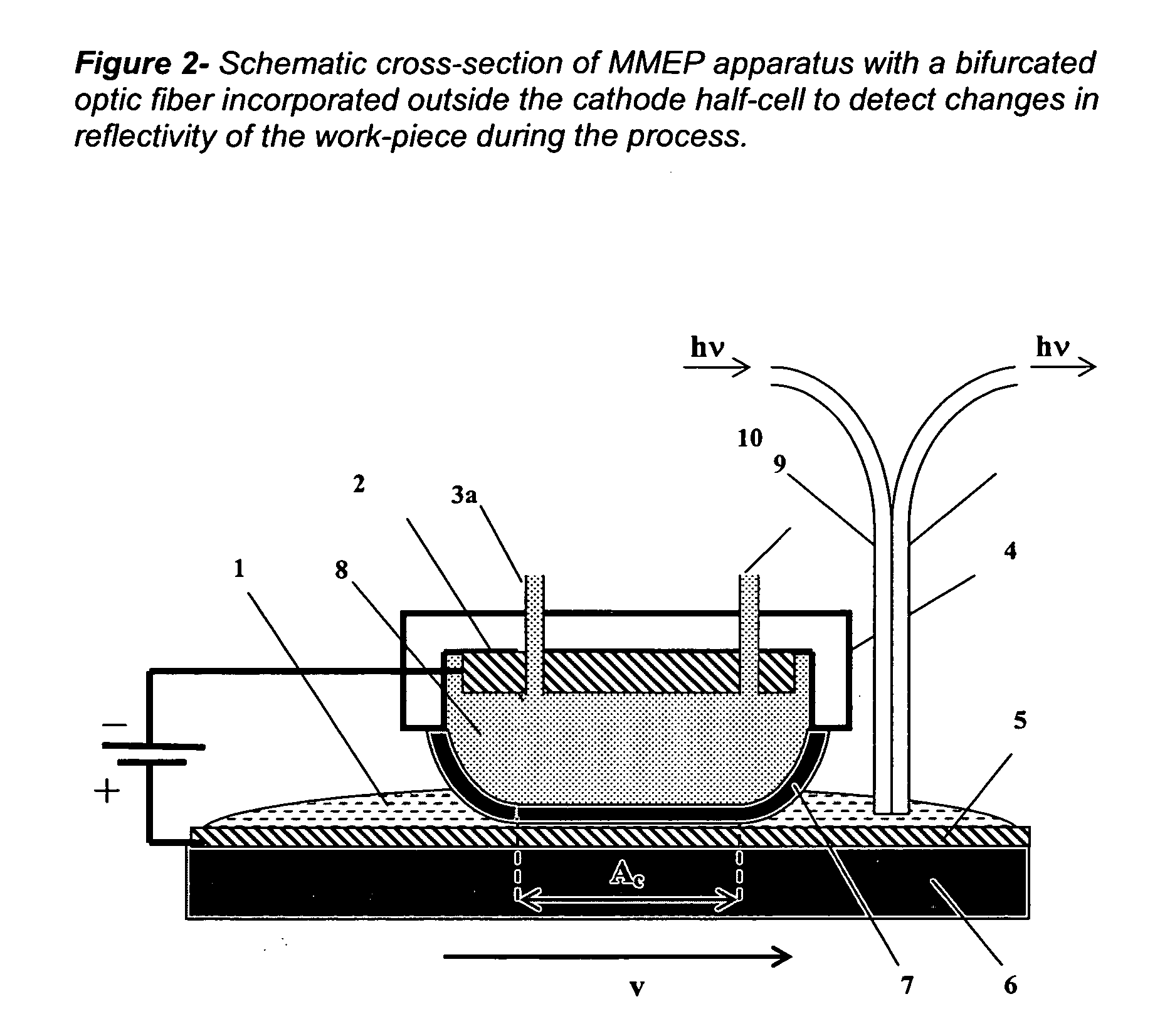

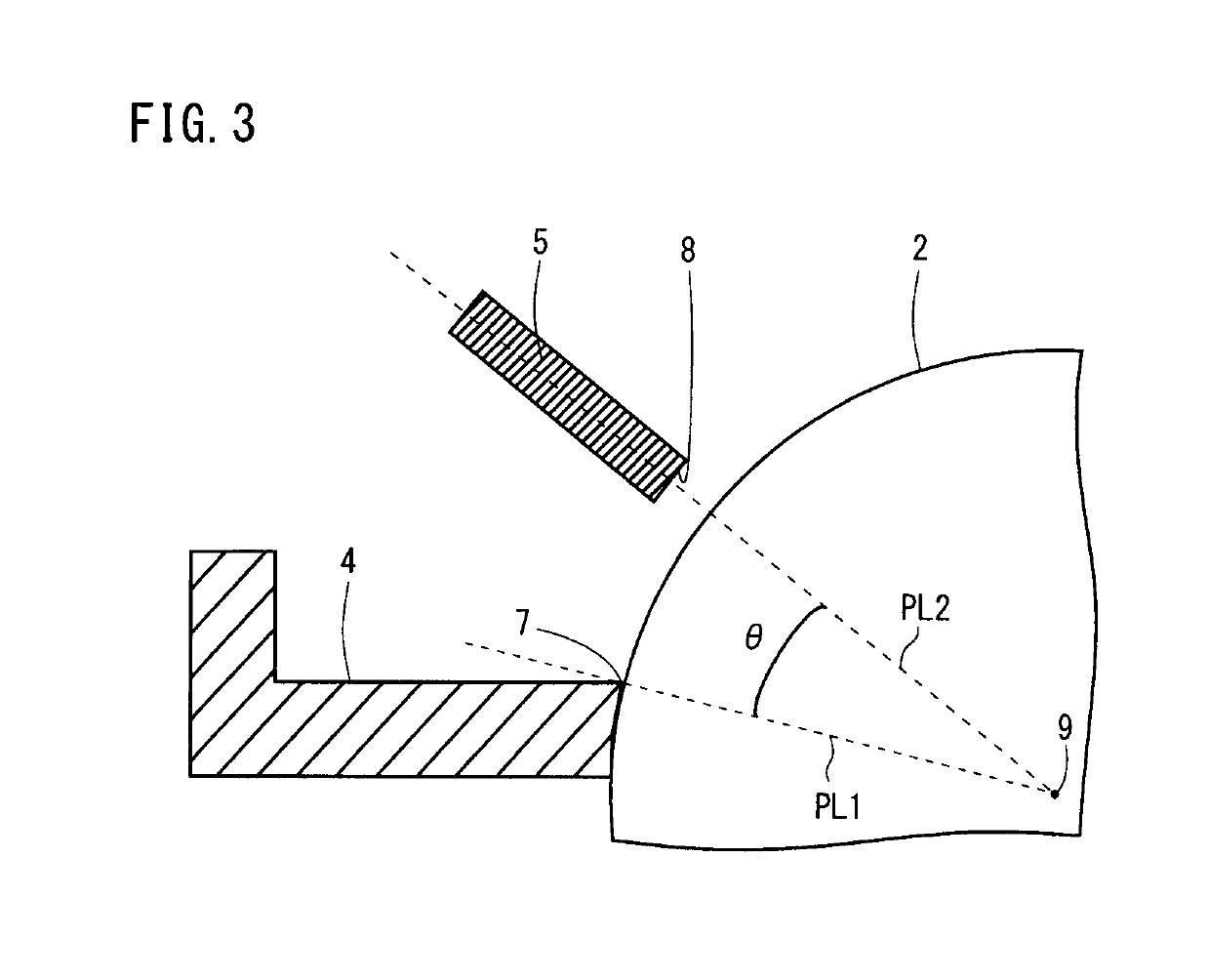

Optical detection of planarization, breakthrough and end-point in membrane-mediated electropolishing of metal layers

InactiveUS20110094895A1CellsConductive material chemical/electrolytical removalThin metalMaterials science

Owner:EI DU PONT DE NEMOURS & CO

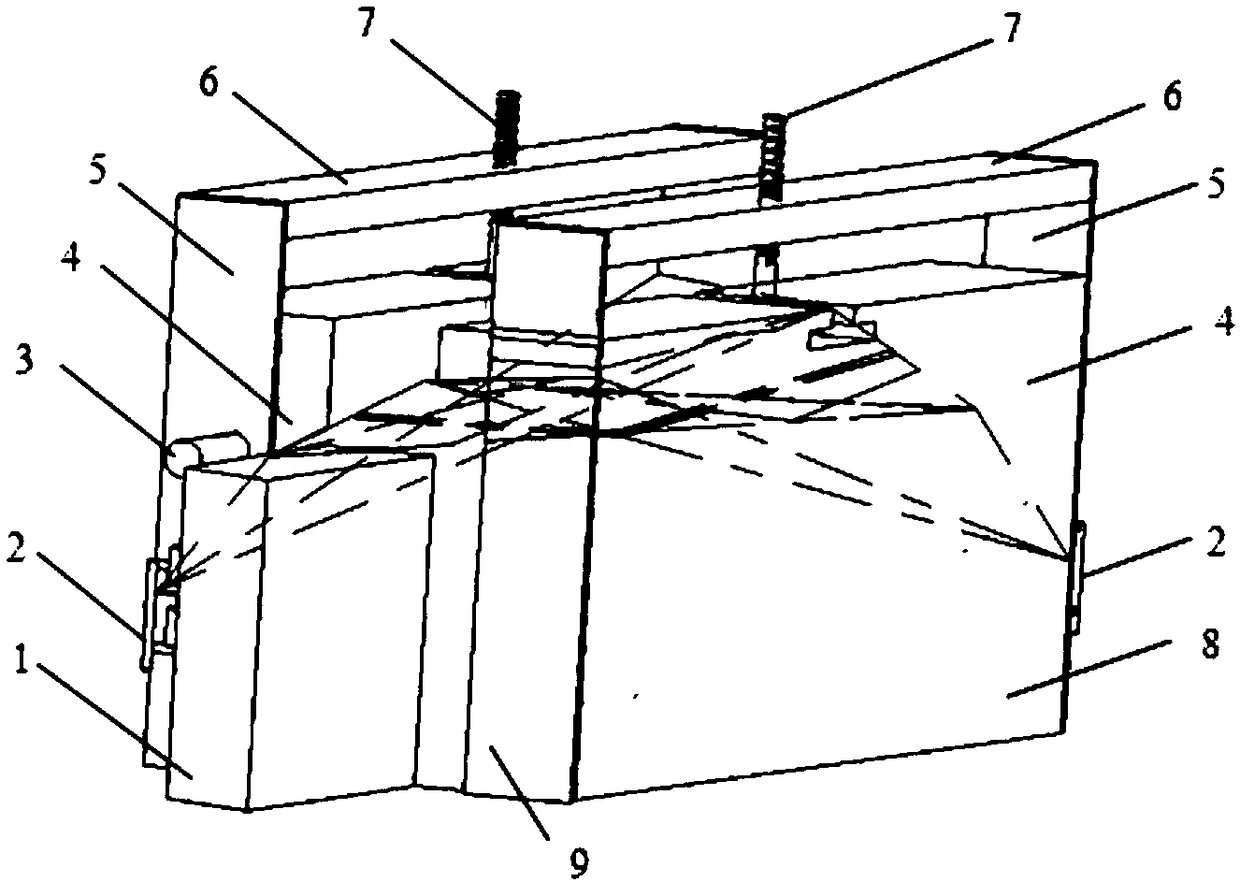

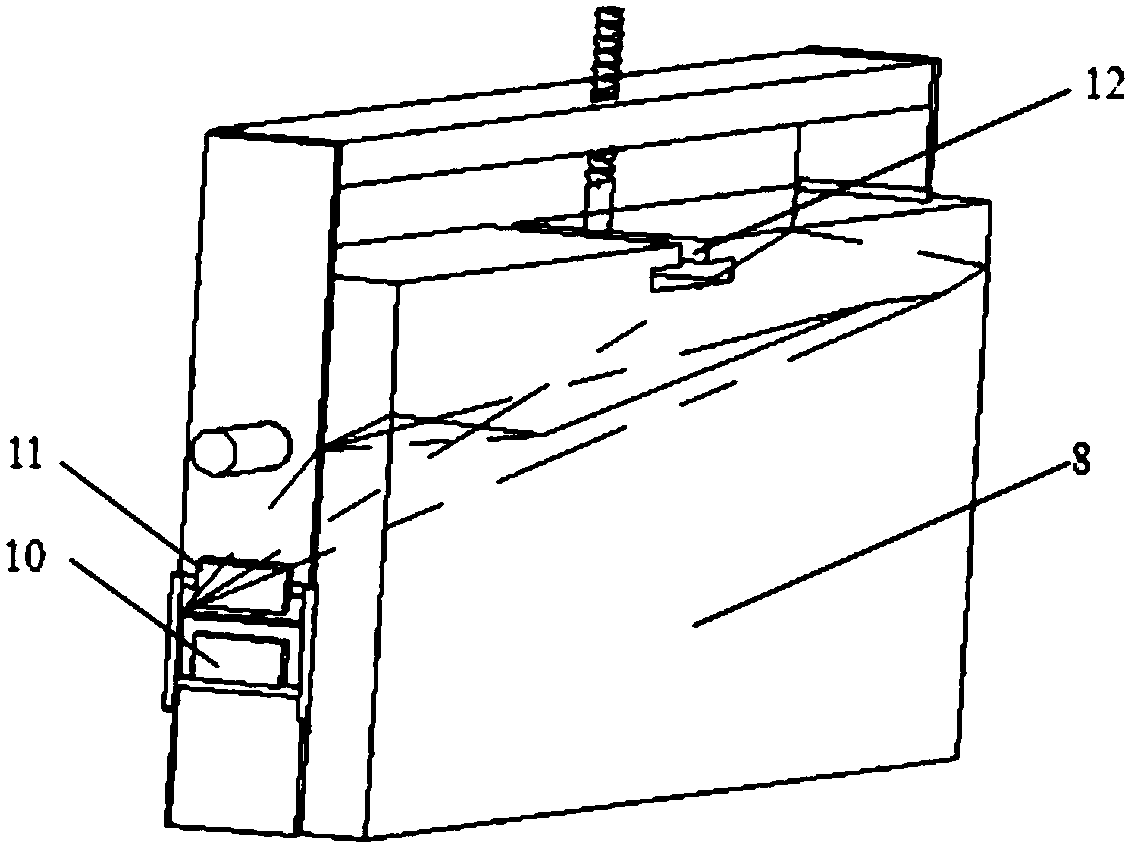

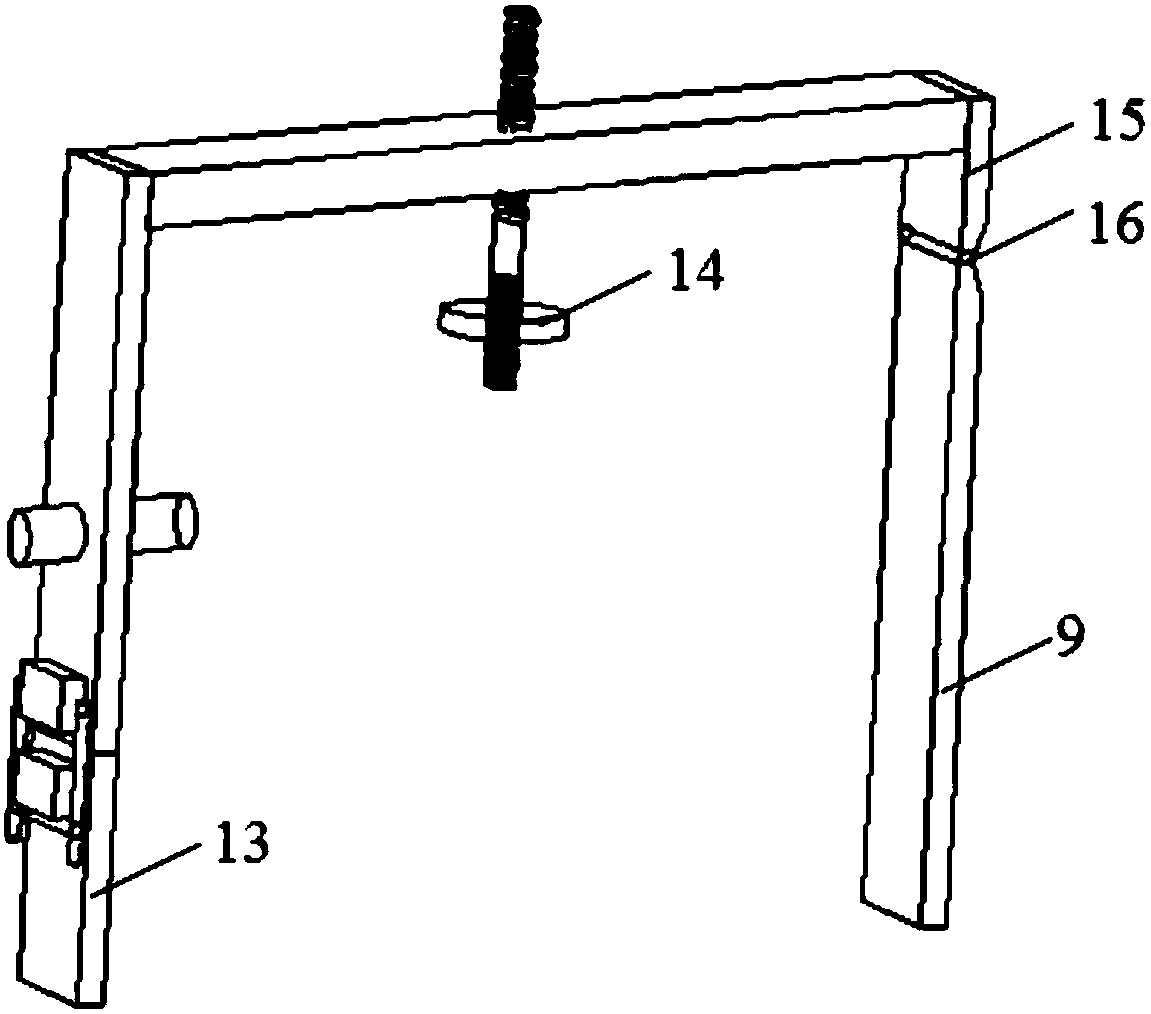

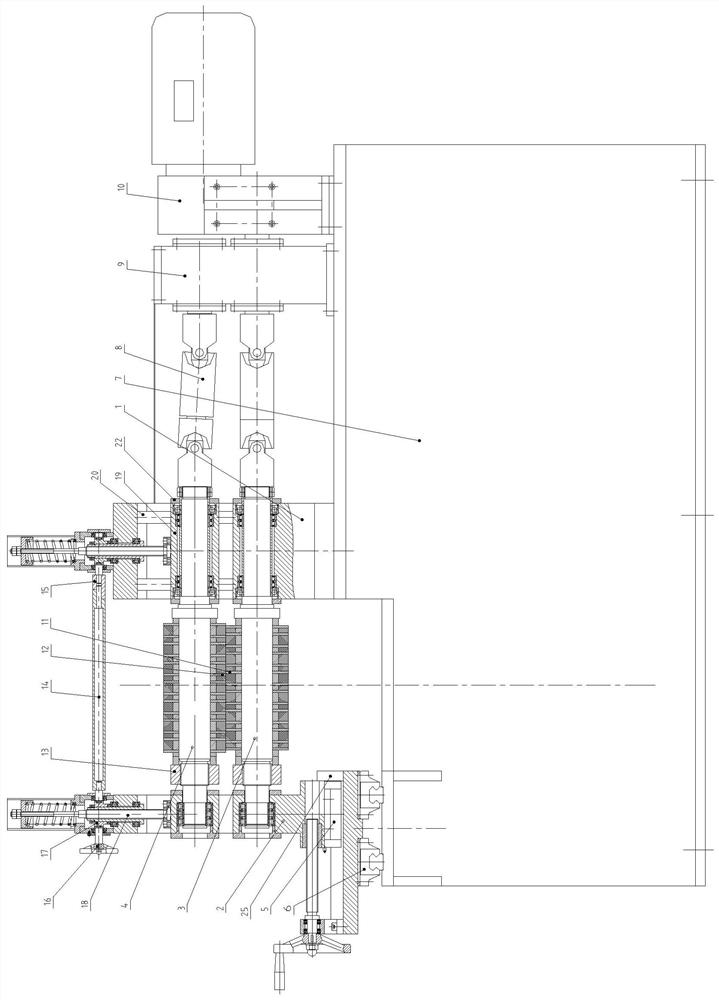

Lateral joint welding and fixing device of deformable ultra-thin metal structure and method for welding lateral structure using same

InactiveCN108381103AReliable weldingGuarantee welding qualityWelding/cutting auxillary devicesArc welding apparatusThin metalPetroleum engineering

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

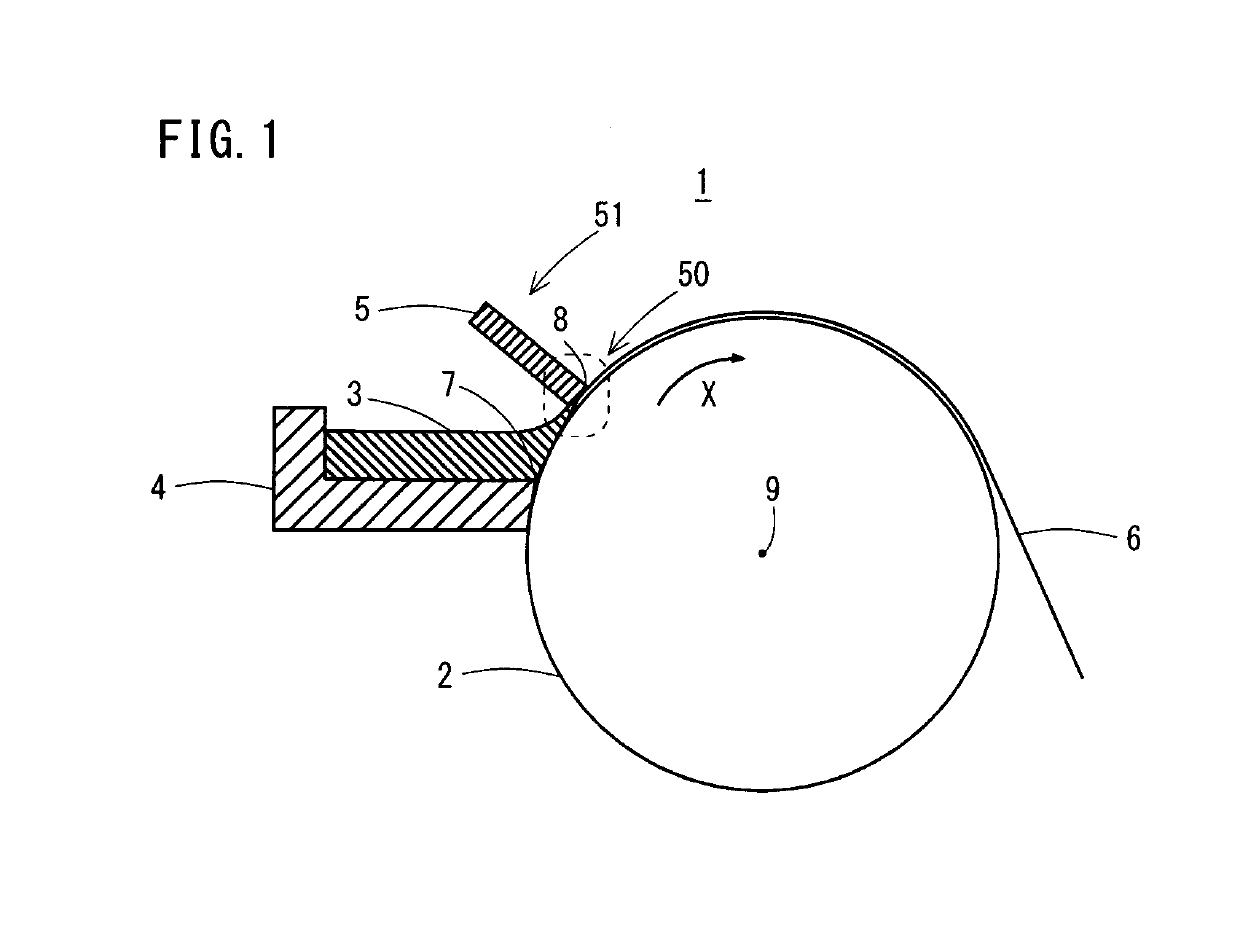

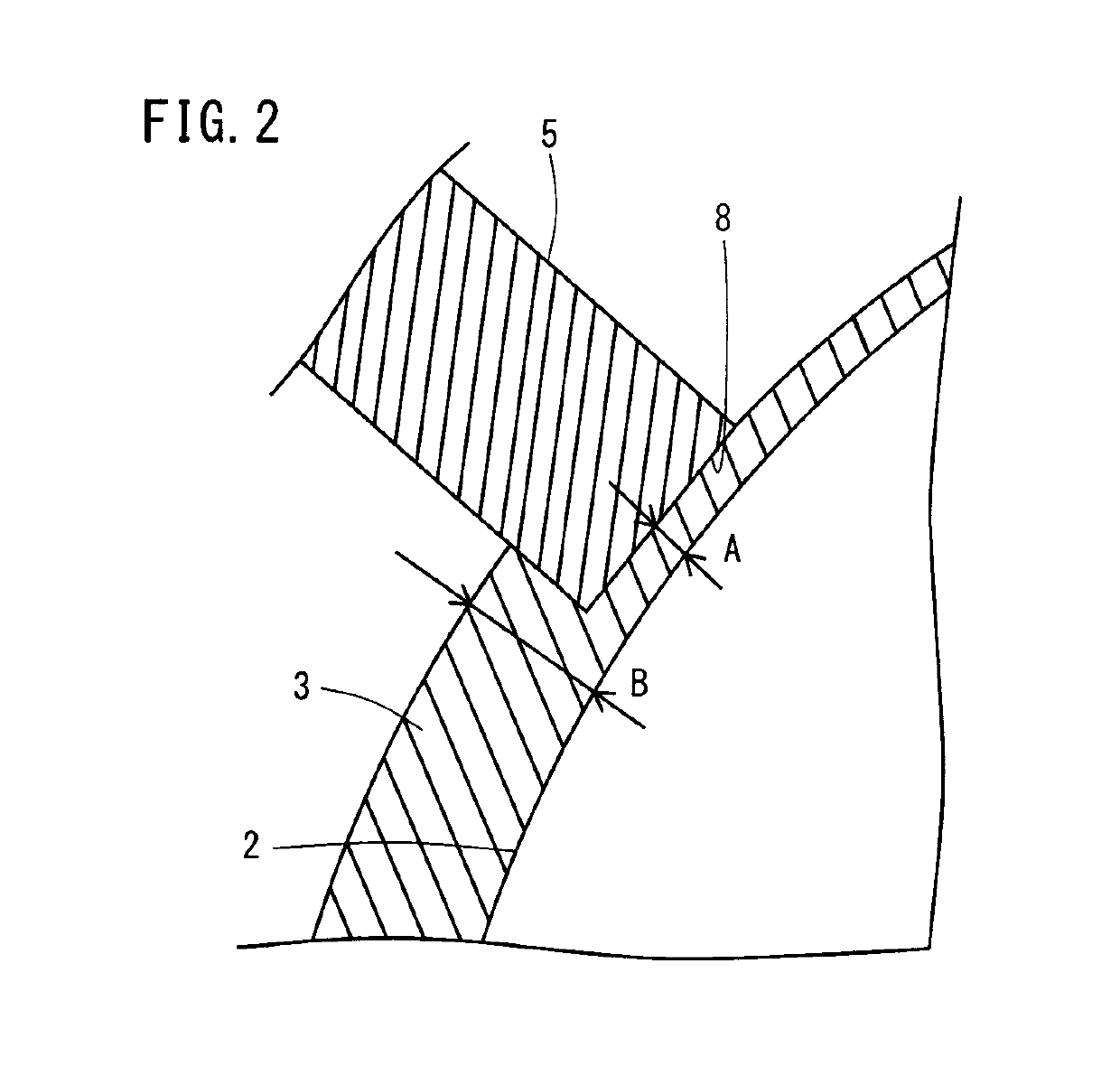

Apparatus for producing thin metal strip and method for producing thin metal strip using the same

Owner:NIPPON STEEL CORP

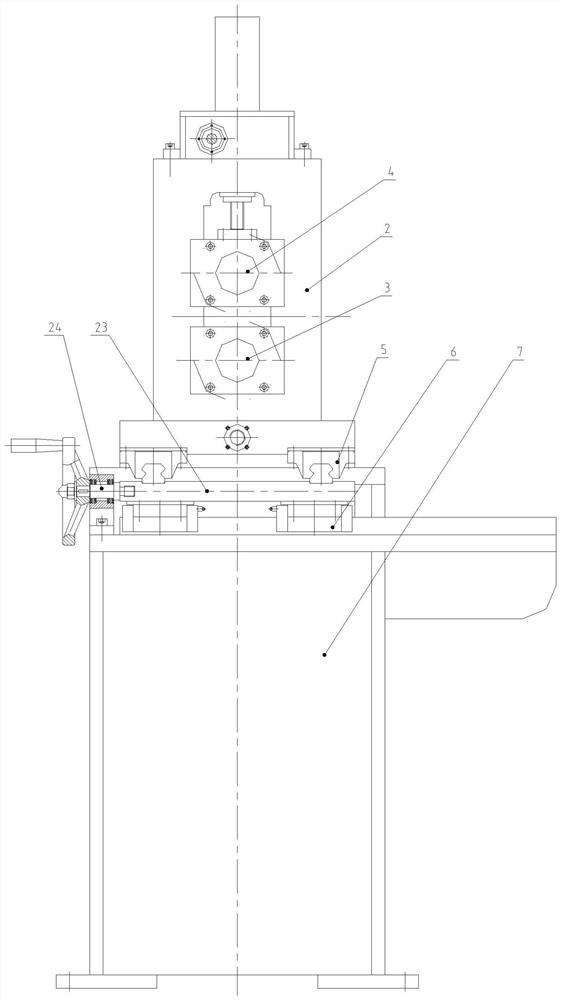

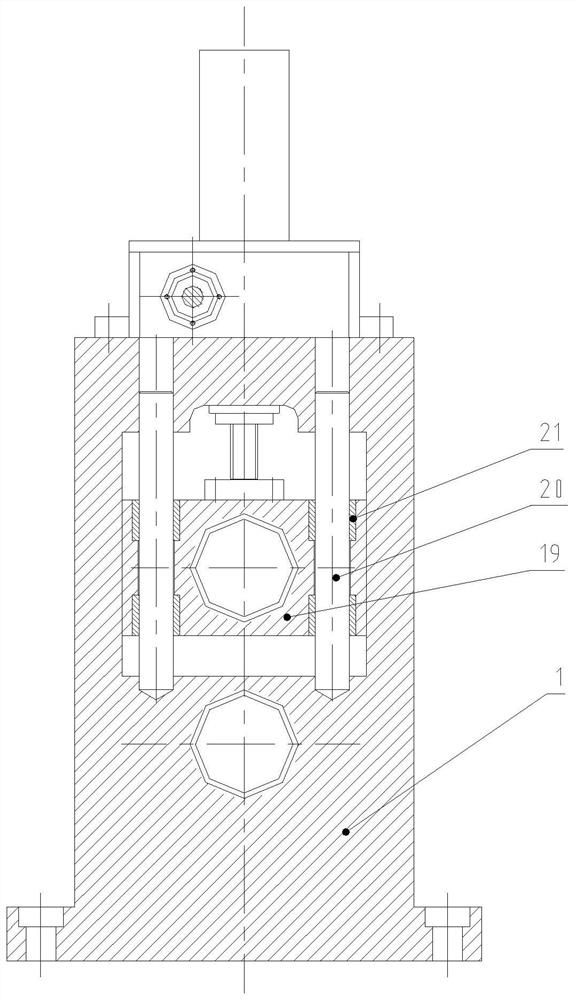

Shearing precise adjusting device for ultrathin metal strip slitting machine

PendingCN111774649AEasy to replaceSo as not to damageShearing machinesShearing toolsMetal stripsThin metal

Owner:宝鸡西冶机器制造有限公司

Conductive heating type drying bin

InactiveCN113513892AExtend the lifespanIncrease resistanceDrying machines with non-progressive movementsDrying solid materialsThin metalThick wall

The invention provides a conductive heating type drying bin which comprises a drying bin body and a metal pipe. The drying bin is a double-cone drying bin or a single-cone drying bin or a roller drying bin. Two ends of the metal pipe are inserted into the upper and lower corresponding hot melting holes of the drying bin body, and the a head of the metal pipe and the bosses of the hot melting holes are fixedly welded into a whole. The bosses of the hot melting holes have certain widths and thicknesses, and the bin body of the thin metal plate with the hot melting holes has low requirements on the welding process. Under the supporting effect of a hot melting hole taper sleeve thick wall layer, the metal pipe has high resistance and high torsion resistance, the welding position between the metal pipe and the bosses of the hot melting holes cannot be damaged under the shaking stress effect of the metal pipe, and the service life of the conductive heating type drying bin is prolonged.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap