Apparatus for producing thin metal strip and method for producing thin metal strip using the same

a technology of thin metal strips and apparatus, which is applied in the field of apparatus for producing thin metal strips and producing thin metal strips, can solve the problems of low cooling rate of molten metal, difficulty in producing thin metal strips in volume, and limitation of the production capability of melting process, and achieve the effect of efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

[0091]Using a producing apparatus described in the following Example 1 to Example 3, thin metal strips made of Si alloy were produced. A raw material contained nickel (Ni), titanium (Ti), and silicon (Si). The composition of the raw material was, in mass ratio, Ni:Ti:Si=25:17:58. One kilogram of the raw material in a mixed state was heated to 1450° C. to be produced into molten metal. The molten metal was supplied from the tundish onto the cooling roll. The cooling roll was one the outer peripheral surface of which is covered with copper and the inside of which is cooled by water. The cooling roll had a diameter of 20 cm and a width of 18 cm. The peripheral speed of the roll was 120 m / min. The thin metal strips made of Si alloy obtained in Example 1 to Example 3 were cut, and cross sections were observed under a scanning electron microscope (SEM).

Example 1

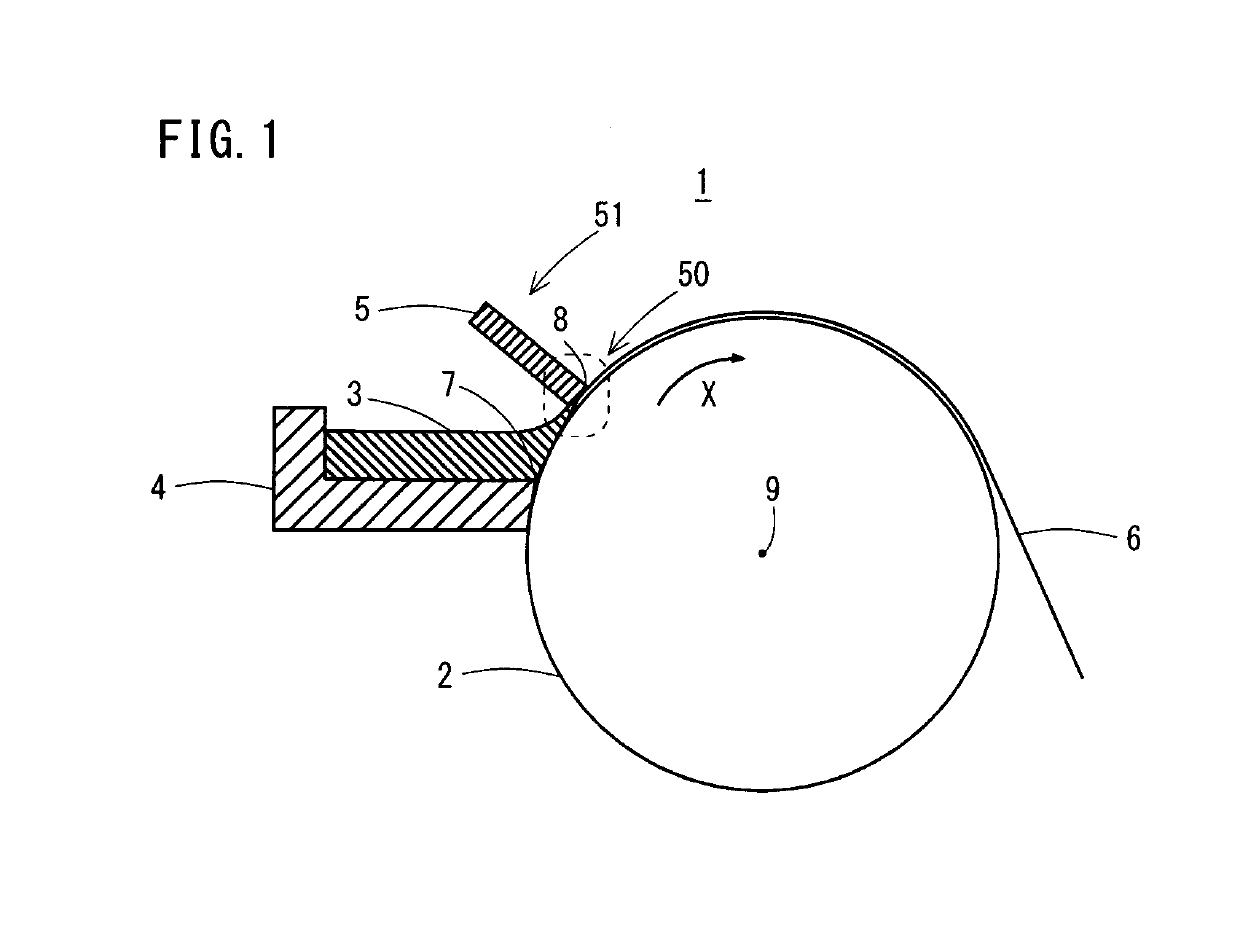

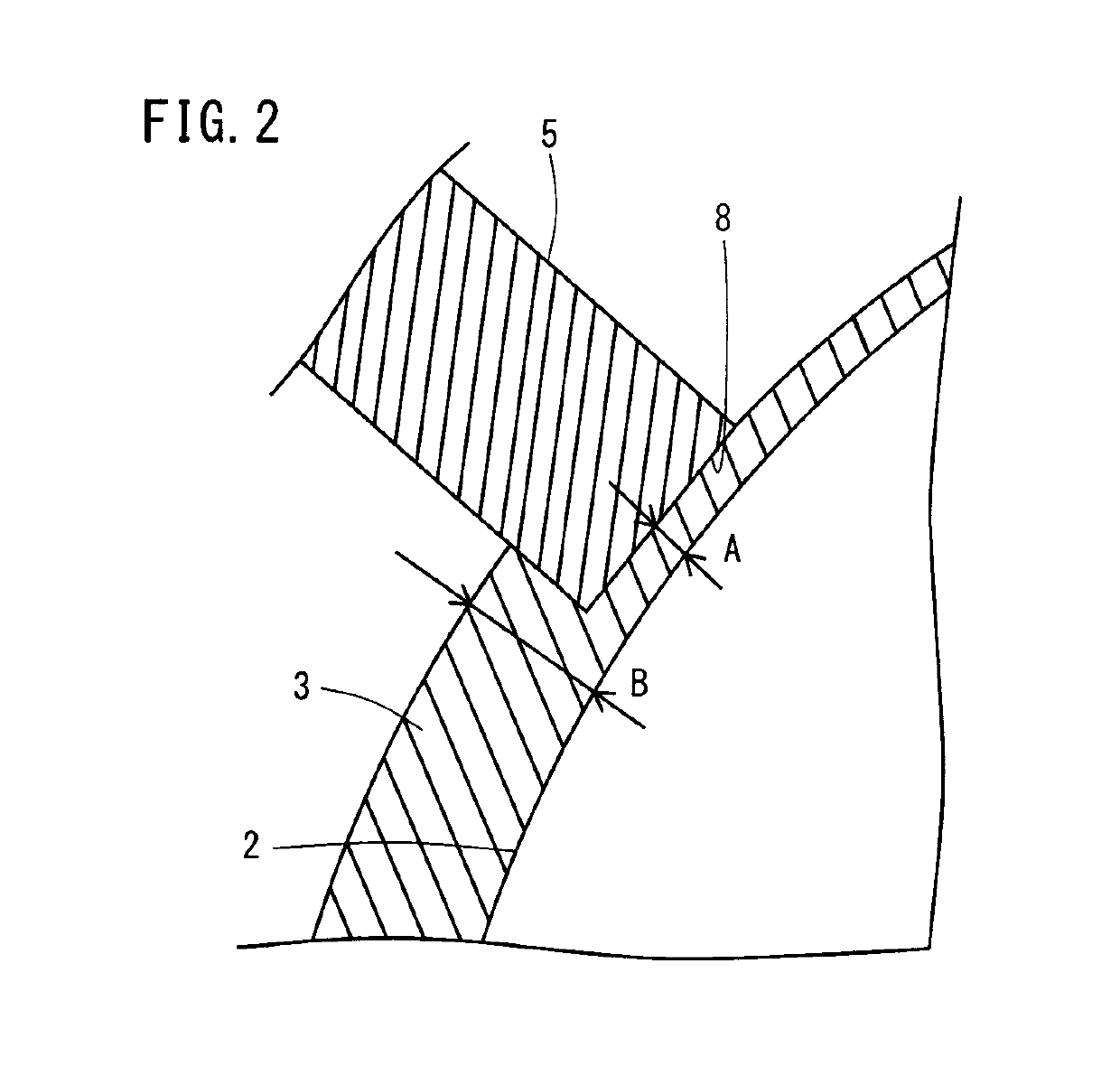

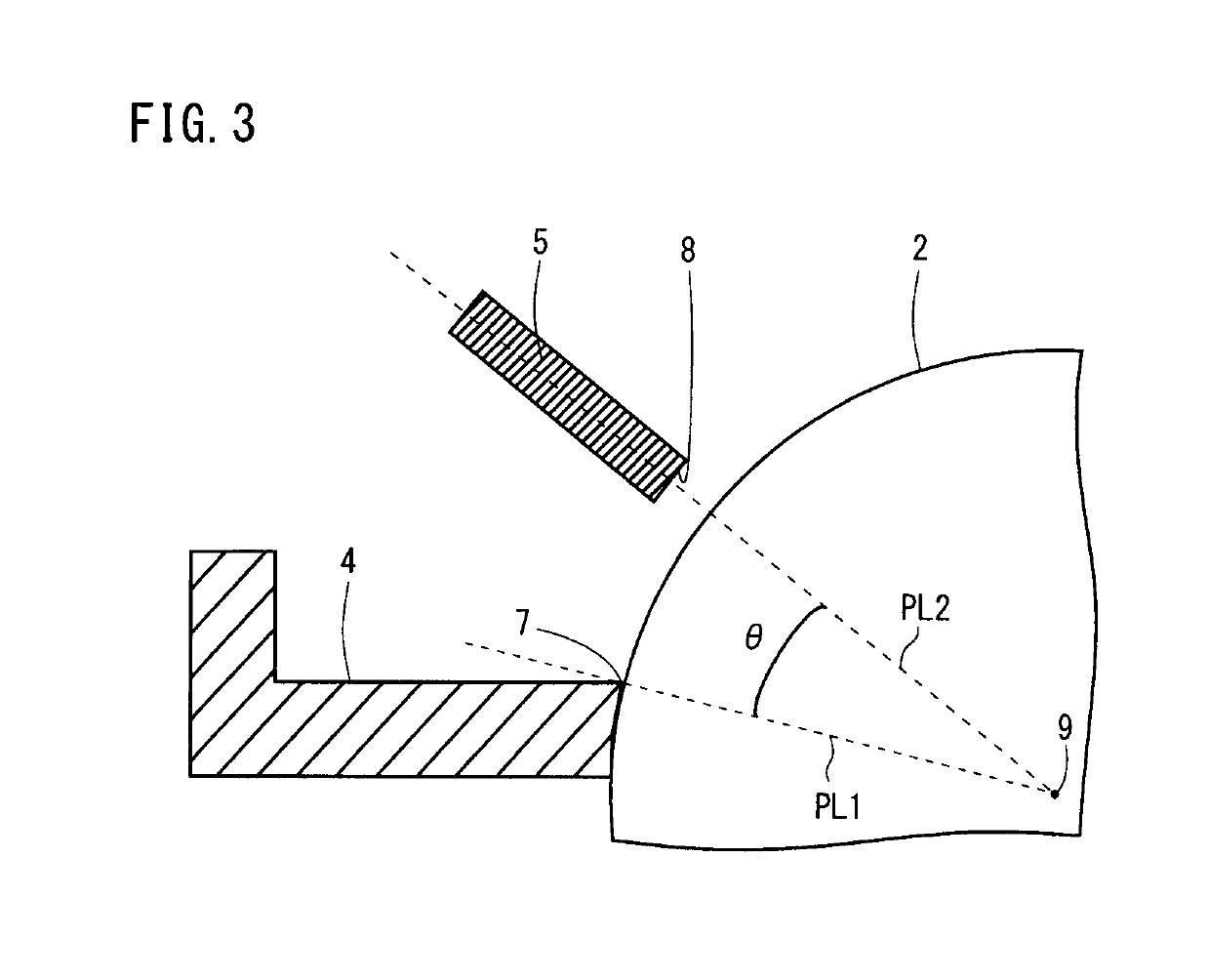

[0092]In Example 1, the producing apparatus according to the present embodiment was used to produce a thin metal strip made of Si

example 1

[0095]FIG. 9 is a picture of a cross section of the thin metal strip produced by the producing method according to the present embodiment (with the molten metal remover), taken under the electron microscope (SEM). The thin metal strip produced by the method according to the present embodiment had an average coating thickness of 80 μm. In addition, the size of a grain in a Si phase of the thin metal strip produced by the method according to the present embodiment (equivalent to the width of a gray portion in FIG. 9) was not more than 2 μm.

example 2

[0096]FIG. 10 is a picture of a cross section of the thin metal strip produced by a conventional method (without the molten metal remover), taken under the electron microscope (SEM). The thin metal strip produced by the conventional method had an average coating thickness of 440 μm. In addition, the size of a grain in a Si phase of the thin metal strip produced by the conventional method (equivalent to the width of a gray portion in FIG. 10) was 20 to 30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap