Insertion sheet type melting and distribution separation type optical fiber distribution module and distribution frame

An optical fiber distribution frame and optical fiber wiring technology, applied in the coupling of optical waveguides, fiber mechanical structure, etc., can solve problems such as redundant fiber jumper management, achieve compact structure, improve wiring efficiency, and facilitate modular operation habits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

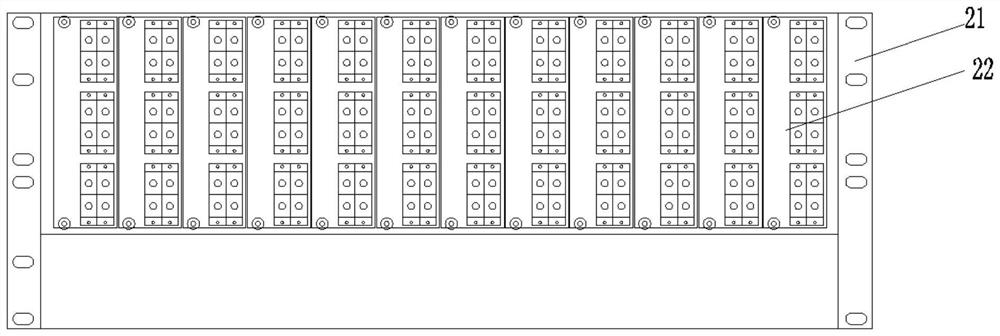

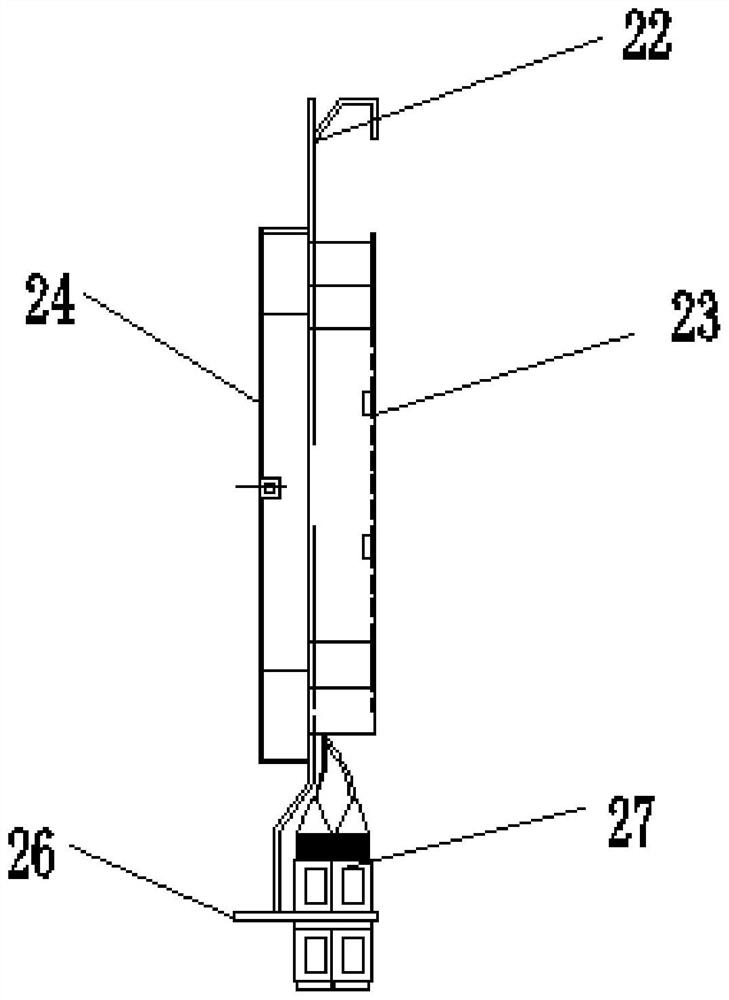

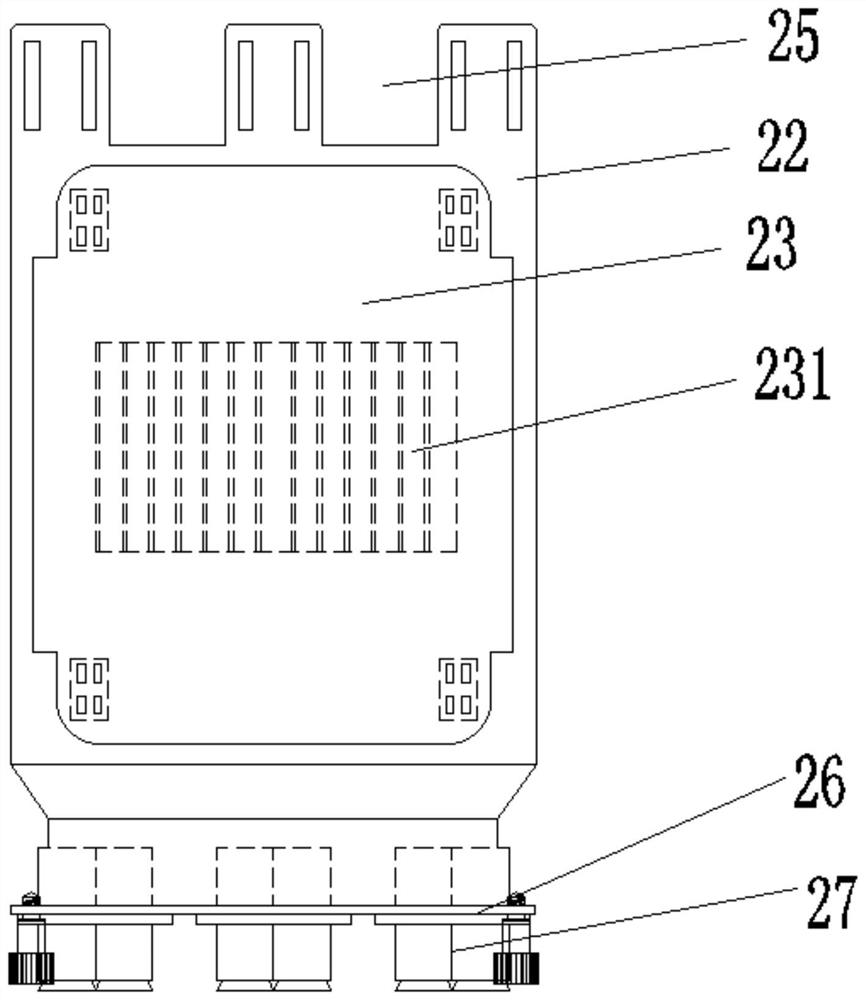

[0032] refer to figure 1 and figure 2 As shown, an insert-type fusion split optical fiber distribution module 20 of the present invention is used to separate the fusion and storage of jumpers, the jumper includes pigtails and connectors, and the insert-type fusion Separate optical fiber distribution module 20 includes:

[0033] The wiring box 21 is provided with a wiring section;

[0034] Fusion split distribution board 22 is drawn and installed in the distribution part, and all the fusion terminals and redundant pigtails are stored in the distribution box 21, so that the overall wiring of the distribution frame is clear and clear. When a part needs to be welded and wired, it is enough to directly pull the corresponding part of the welded separate distribution board 22, which not only improves the wiring efficiency, but also facilitates the maintenance personnel's modular operation habits;

[0035] The two sides of the fusion split distribution board 22 are respectively provi

Embodiment 2

[0045] refer to Figure 6 As shown, a plug-in type fusion split optical fiber distribution frame of the present invention is applied to the wiring connection between the communication optical cable and the optical communication equipment in the communication transmission room and the data room, including a frame 10, the machine The above-mentioned insert-type fusion-matching and separation-type optical fiber distribution modules 20 installed in the rack 10, multiple groups of the insert-type fusion-matching and separation-type optical fiber distribution modules 20 are stacked side by side or arranged in a matrix stack. The distribution frame is provided with as many insert-type fusion-matched and split-type optical fiber distribution modules 20 as possible, so as to meet the distribution requirements of a large number of cores as much as possible.

[0046] refer to Figure 6 and Figure 7 As shown, on both sides of the frame extending along the installation direction of the ins

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap