High-efficiency floatation method for beryllium ore

A high-efficiency technology for beryllium ore, applied in the field of high-efficiency flotation recovery of beryllium-containing minerals, to achieve the effect of improving the quality of ore feeding, good beneficiation indicators, process structure and simple chemical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

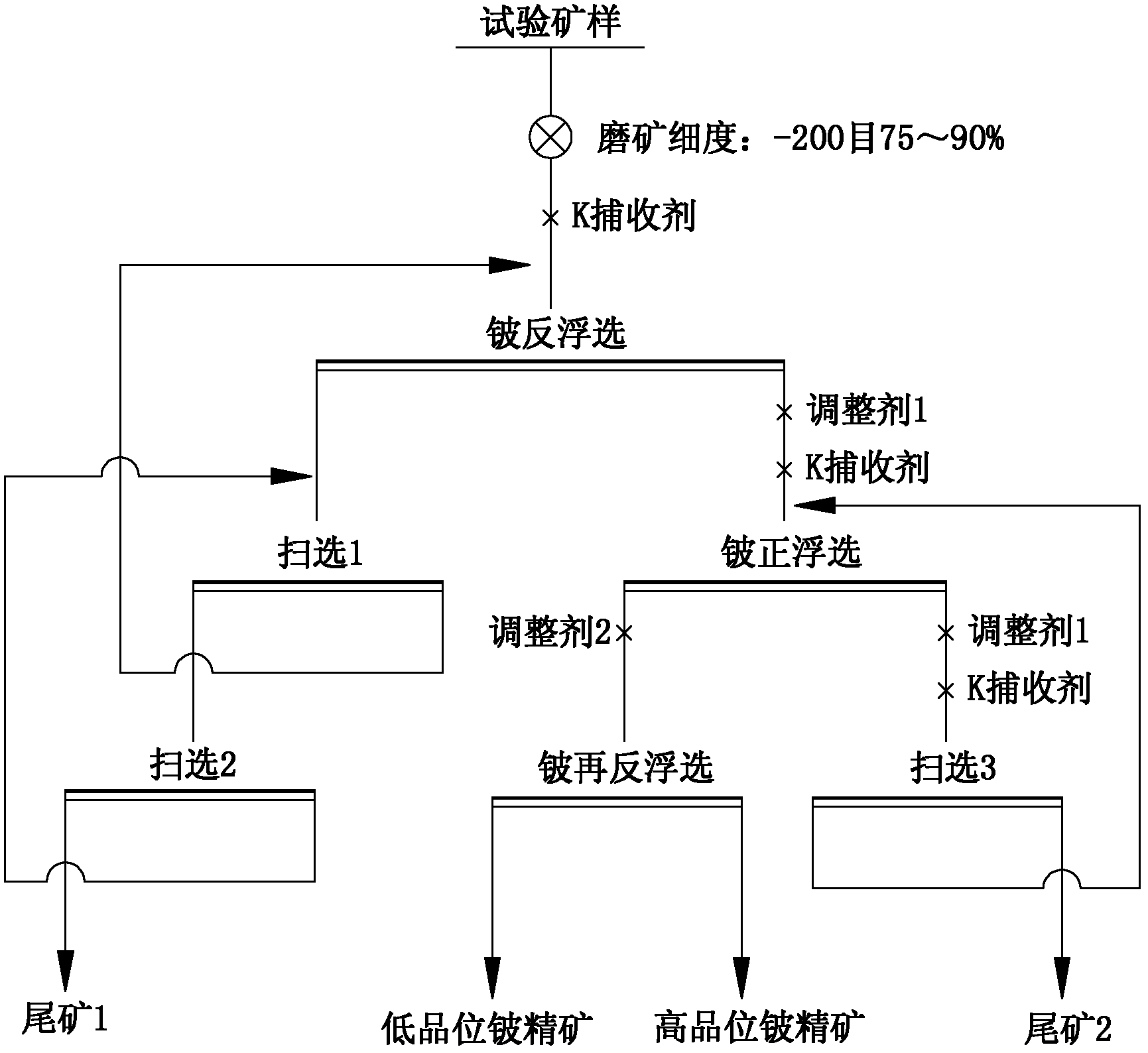

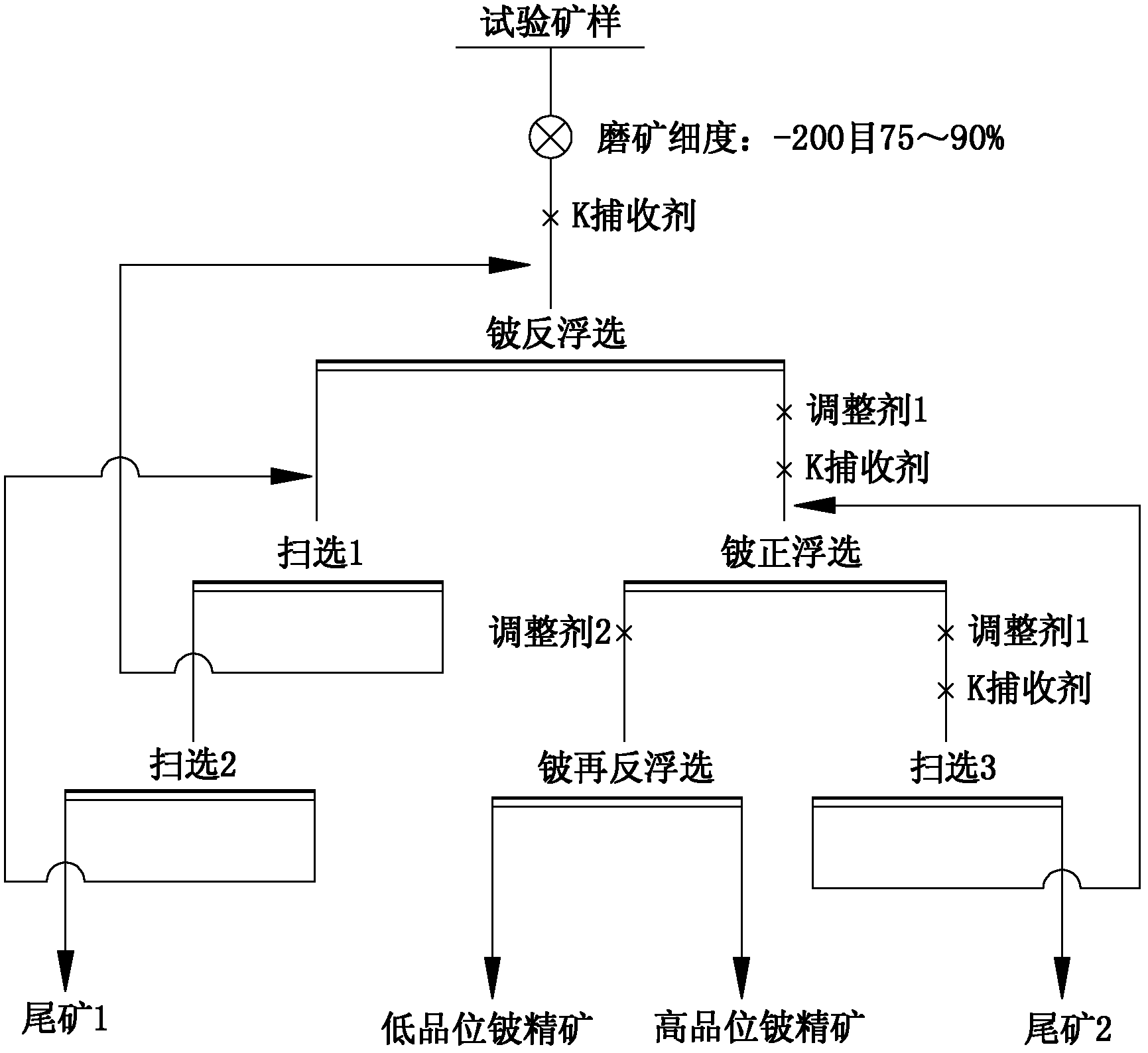

Method used

Image

Examples

Embodiment 1

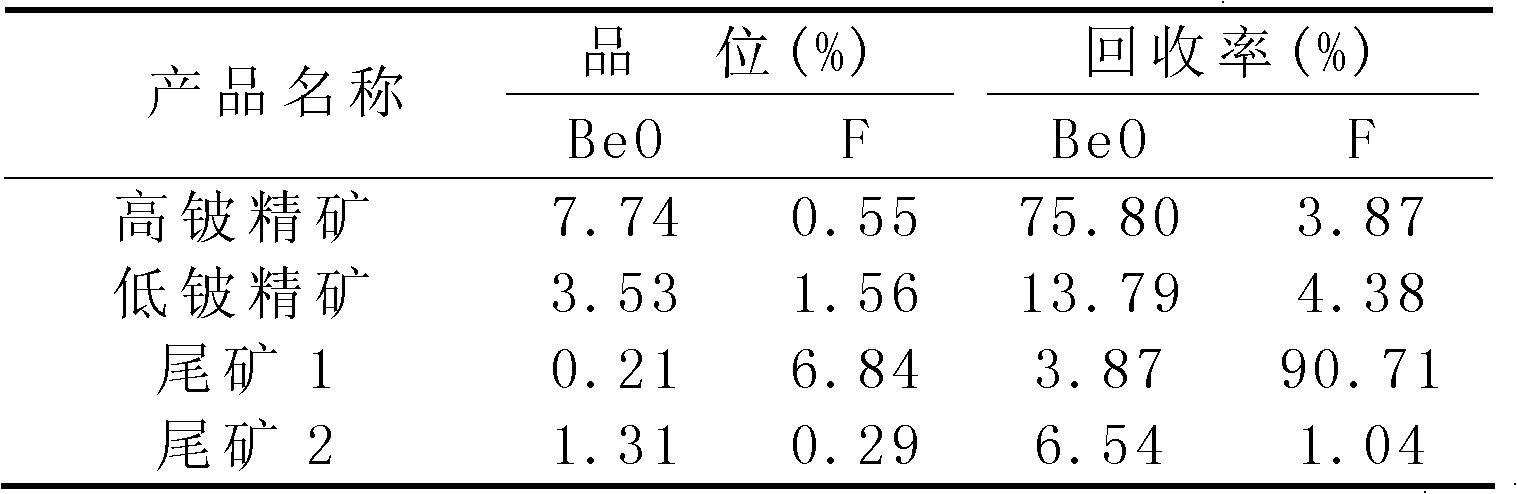

[0019] A kind of high-efficiency flotation method of beryllium ore provided by the invention is to process beryllium ore containing fluorite through the technological process of beryllium reverse flotation-beryllium forward flotation-beryllium reverse flotation again, and a certain beryllium ore in Yunnan is used as the test object. Containing BeO2.69%, F3.80%, BeO mainly exists in beryl and silicon beryllite, F exists in fluorite, fluorite accounts for about 7.8% of the total ore, and gangue minerals are mainly calcite and feldspar , quartz, fluorite, mica, etc. Although the BeO content of the ore is relatively high, because the ore contains a large amount of impurity minerals and harmful elements, the beryllium ore is currently only obtained by chemical acid leaching to obtain beryllium concentrate suitable for the production of beryllium oxide by the sulfuric acid method, and the recovery rate of beryllium is low. The production cost is high and the environmental pollution is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap