Rubberizing mechanism and rubberizing device for assembling and producing microcrystalline far-infrared heater

A technology of gluing mechanism and gluing device, which is applied in the direction of electric heating devices, ohmic resistance heating, conveyor objects, etc., can solve the problems of poor bonding effect, low assembly efficiency, and large energy consumption, so as to improve the bonding effect, The effect of improving feeding efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

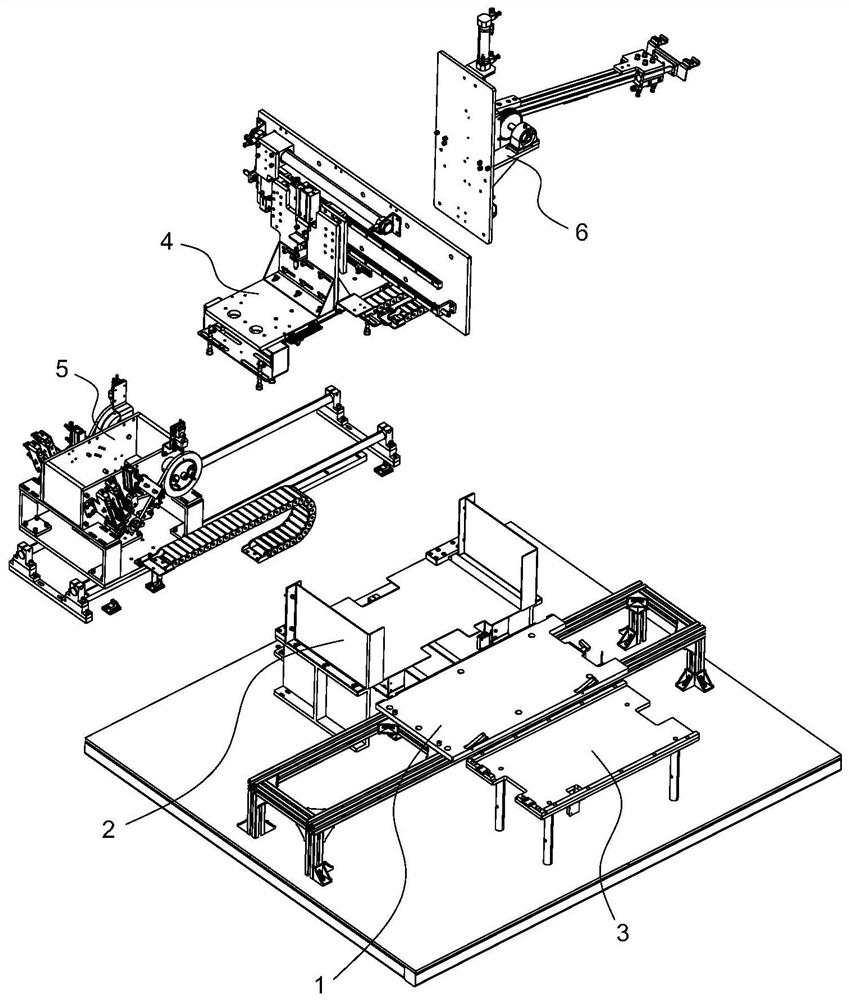

[0038] Such as Figure 1-13As shown, the microcrystalline far-infrared heater assembly production equipment includes a frame and a sticking platform 1 installed on the frame, a substrate feeding device 2, a microcrystalline heating film storage device 3, a microcrystalline heating film suction upper Feeding device 4, gluing device 5 and flipping and unloading device 6. The substrate loading device 2 is located on one side of the bonding platform 1 , and the microcrystalline heating film storage device 3 is located on the other side of the bonding platform 1 . The microcrystalline heating film suction and feeding device 4 is located above the pasting platform 1 , and the pasting platform 1 and the microcrystalline heating film storage device 3 are connected through the microcrystalline heating film suction and feeding device 4 . The gluing device 5 is connected above the gluing platform 1 , and the gluing device 5 moves along the gluing platform 1 . The turning and unloading dev

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap