Fiber composite warm-keeping flocculus and preparation method thereof

A technology of fiber composite and wadding, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of easy peeling, failure to achieve uniform distribution, loose connection between layers, etc., and achieve excellent thermal performance and enhanced mechanical properties , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example 1

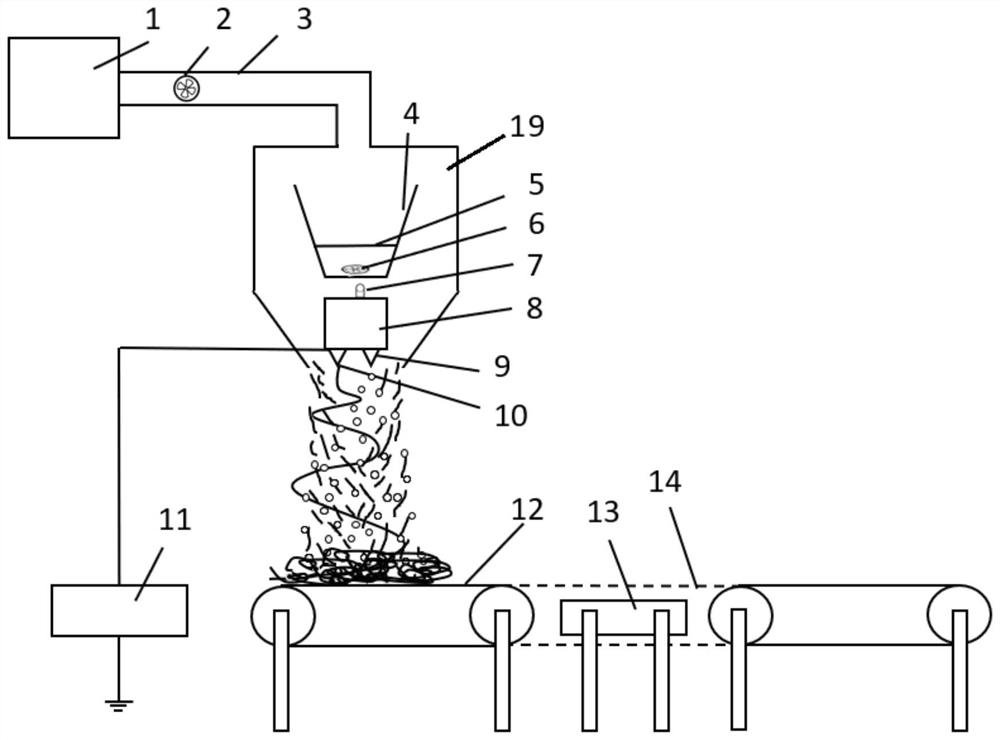

[0033] A preparation method of fiber composite thermal insulation flakes:

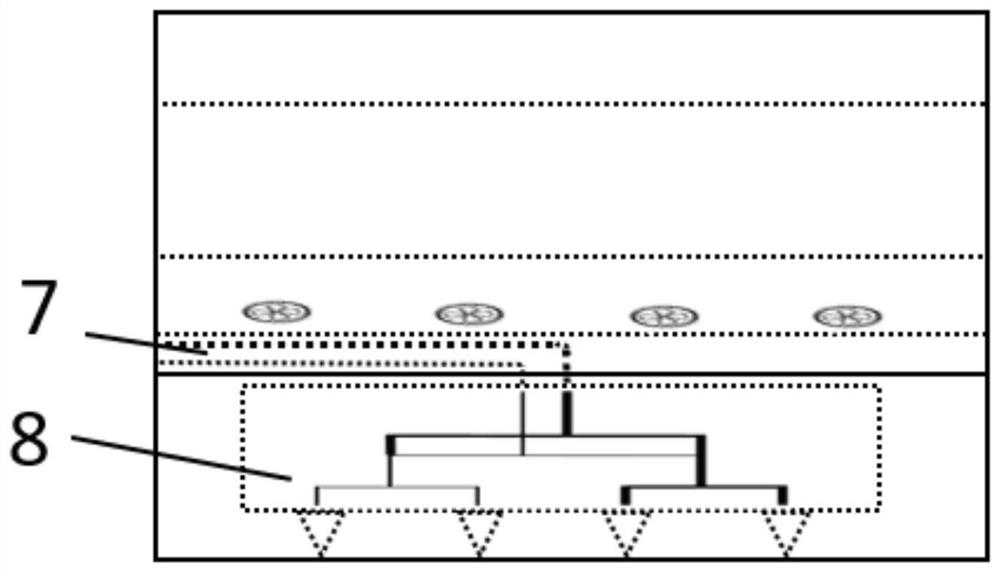

[0034] First, set up a three-in-one flake preparation device with electrospinning nozzle, micron short fiber supply nozzle, and adhesive electrostatic spray nozzle. The number of needle nozzles in flow channel 15 and flow channel 2 16 is 4 each, and the diameter of the nozzle is 0.6mm. , the needle spacing is 30mm, the diameter of the flow channel is 3mm, and the total length of the flow channel is 30cm. Subsequently, polyacrylonitrile was dissolved in N,N-dimethylformamide to obtain a polyacrylonitrile solution with a polymer concentration of 31 wt% (wherein the crosslinking agent was a trifunctional aziridine crosslinking agent, and the concentration was 13% of the amount of material), select methyl cellulose as the binding agent, inject flow channel one 15 and flow channel two 16 through the liquid supply device, then set the spinning process parameters, the spinning voltage is 50kV

Example Embodiment

[0036] Example 2

[0037] A preparation method of fiber composite thermal insulation flakes:

[0038] First, set up a three-in-one flake preparation device with electrospinning nozzle, micron short fiber supply nozzle, and adhesive electrostatic spray nozzle. The number of needle nozzles in flow channel 15 and flow channel 2 16 is 2 each, and the diameter of the nozzle is 0.6mm. , the needle spacing is 90mm, the diameter of the flow channel is 5mm, and the total length of the flow channel is 20cm. Subsequently, polystyrene is dissolved in isobutanol to obtain a polystyrene solution with a polymer concentration of 40wt% (wherein the crosslinking agent is tetraisocyanate, and the concentration is 1% of the polymer mass), and cyanoethyl fiber is selected. As a binder, inject the first flow channel 15 and the second flow channel 16 through the liquid supply device, and then set the spinning process parameters, the spinning voltage is 60kV, the receiving distance is 40cm, the perfusi

Example Embodiment

[0040] Example 3

[0041] A preparation method of fiber composite thermal insulation flakes:

[0042] First of all, build a three-in-one flake preparation device with electrospinning nozzle, micron short fiber supply nozzle, and adhesive electrostatic spray nozzle. The number of needle nozzles in channel 1 15 and channel 2 16 is 10 each, and the diameter of the nozzle is 1.8mm. , the needle spacing is 60mm, the diameter of the flow channel is 7mm, and the total length of the flow channel is 200cm. Subsequently, polyarylsulfone was dissolved in acetone to obtain a polyarylsulfone solution with a polymer concentration of 19 wt% (wherein the crosslinking agent was p-toluenesulfonic acid, and the concentration was 25% of the polymer mass), and hydroxyethyl cellulose was selected. As a binder, inject the first flow channel 15 and the second flow channel 16 through the liquid supply device, and then set the spinning process parameters, the spinning voltage is 40kV, the receiving dista

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap