Imprinting apparatus and imprinting method using the same

a technology of imprinting apparatus and imprinting process, which is applied in the direction of electrical/magnetic/electromagnetic heating, instruments, applications, etc., can solve the problems of blurs on the substrate with patterns, increase of manufacturing cost of the imprinting process, and deterioration of picture quality of images displayed on the display device, so as to facilitate the formation of patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0021]Hereinafter, an imprinting apparatus according to the present invention will be described with reference to the accompanying drawings.

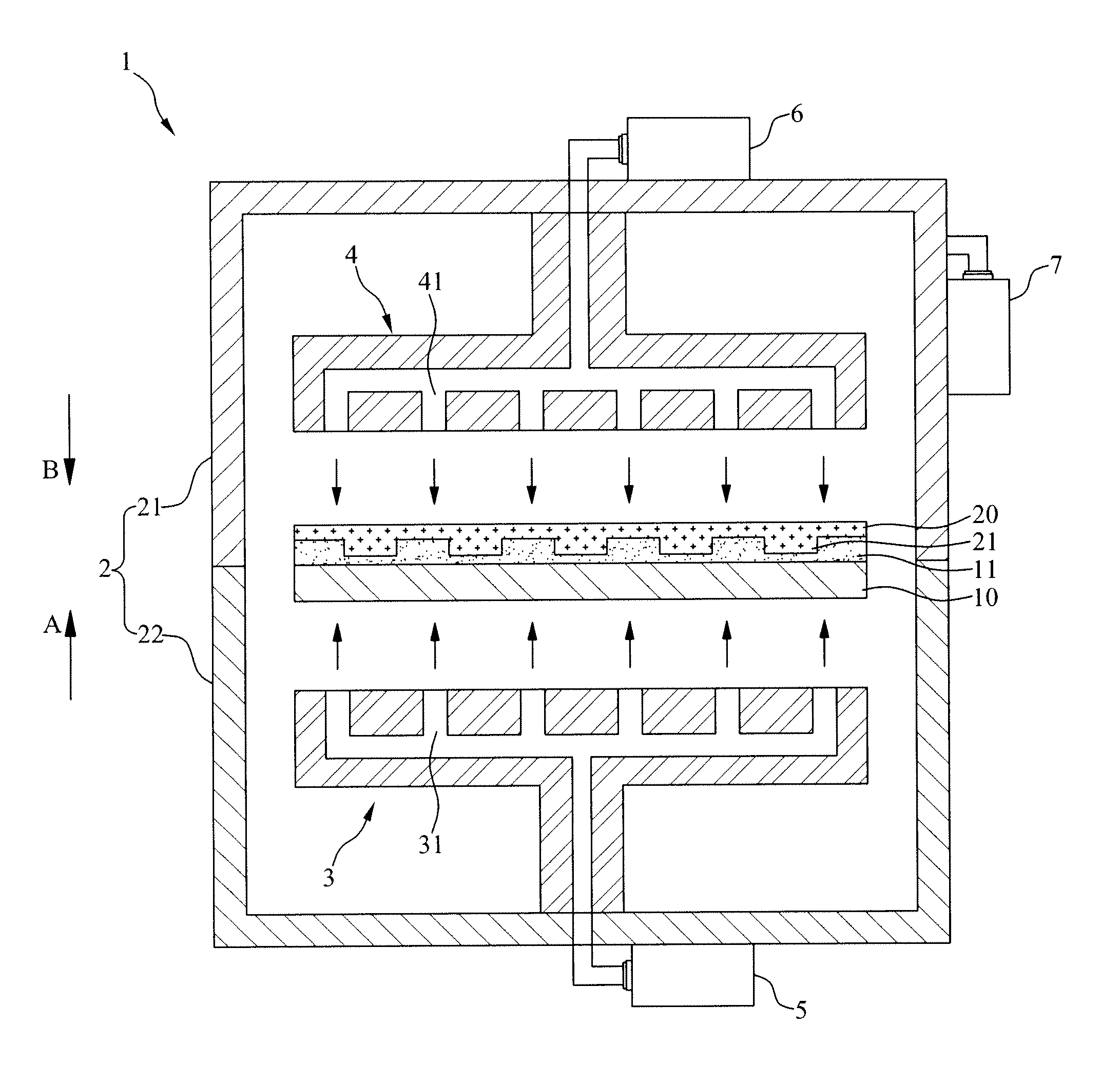

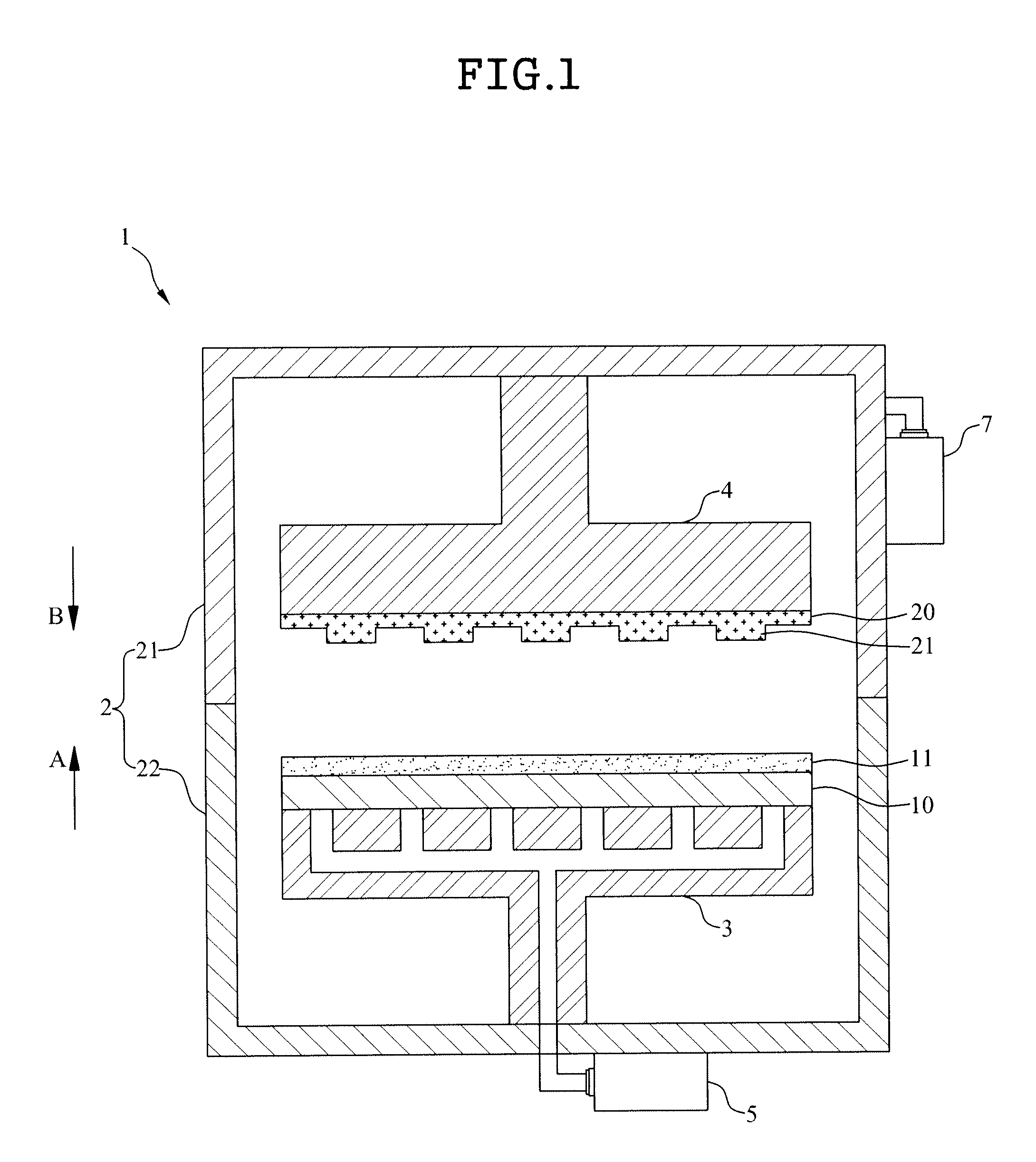

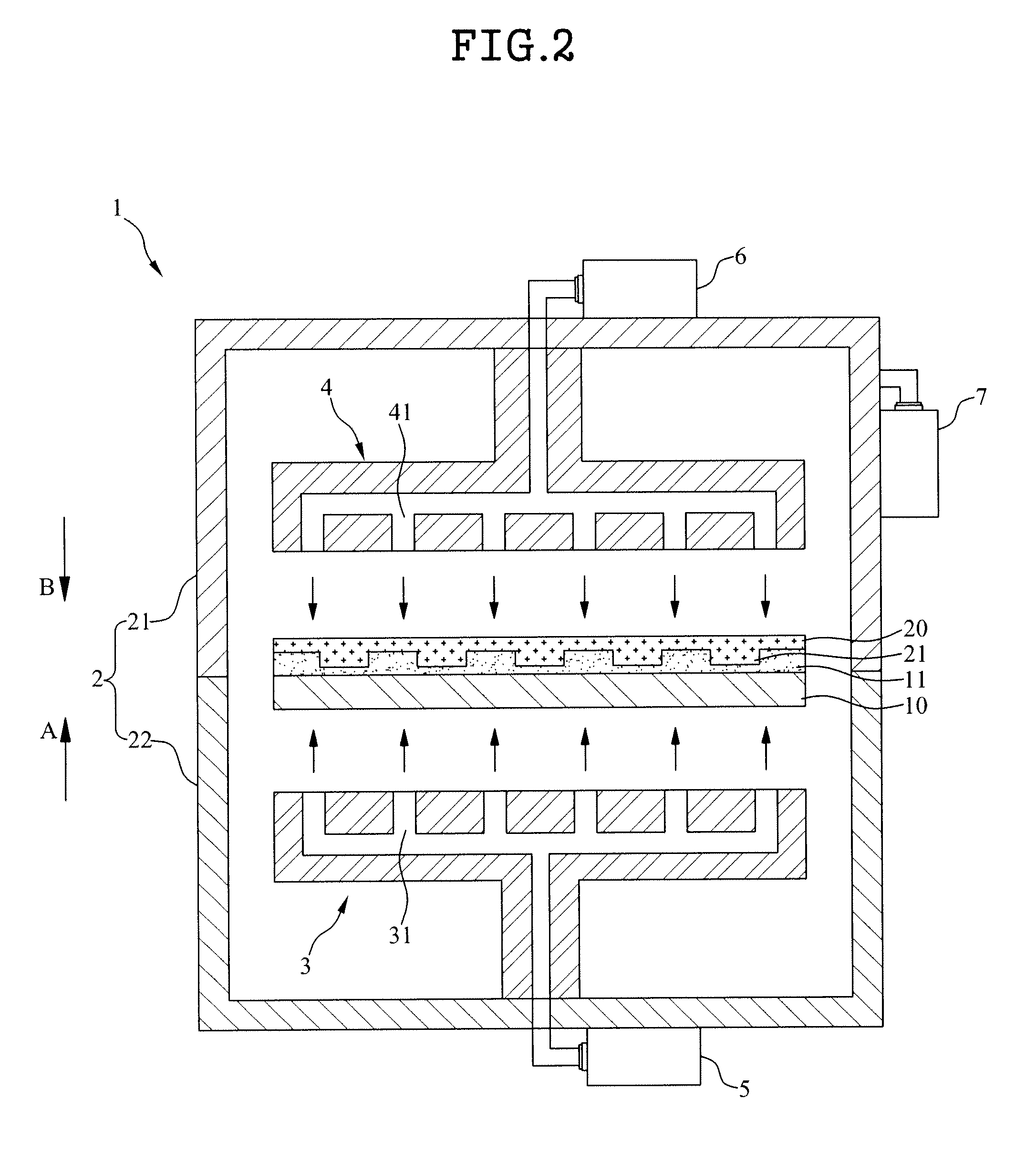

[0022]FIG. 1 is a cross section view illustrating an imprinting apparatus according to the present invention. FIG. 2 is a cross section view illustrating an operational relationship in an imprinting apparatus according to the present invention. FIGS. 3 and 4 are plane views illustrating a stage according to the present invention. FIG. 5 is a cross section view illustrating an imprinting apparatus according to a modified embodiment of the present invention.

[0023]Referring to FIG. 1, the imprinting apparatus 1 according to the present invention includes a chamber unit 2; a st

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap