Method for preparing ammonium dihydrogen phosphate and preparing special composite fertilizer for grapefruit trees as byproduct

A technology of ammonium dihydrogen phosphate and pomelo trees, which is applied in the direction of phosphate, phosphorus oxyacids, applications, etc., can solve the problem of no ammonium dihydrogen phosphate by-product pomelo tree compound fertilizers, so as to avoid soil pollution and reduce Waste and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

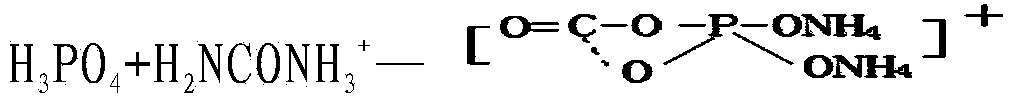

Method used

Image

Examples

Example Embodiment

[0033] Example one

[0034] a. Preparation of raw materials: first mix phosphoric acid and urea at a molar ratio of 2:1.4, and the concentration of phosphoric acid is 70%. The temperature rise rate is 6°C / min to 90°C, and the reaction is stirred for 28 minutes to prepare slurry and separate. Urea phosphate is obtained, and the reaction of phosphoric acid and urea is the reaction of phosphoric acid solution and urea solid;

[0035] b. Preparation of ammonium dihydrogen phosphate: slowly add ammonia water to the slurry containing urea phosphate to control the PH value of 3.6 and fully stir to obtain a slurry containing nitrogen and phosphorus. The slurry is cooled to 24°C in a cooling crystallizer, filtered, Separate and obtain ammonium dihydrogen phosphate;

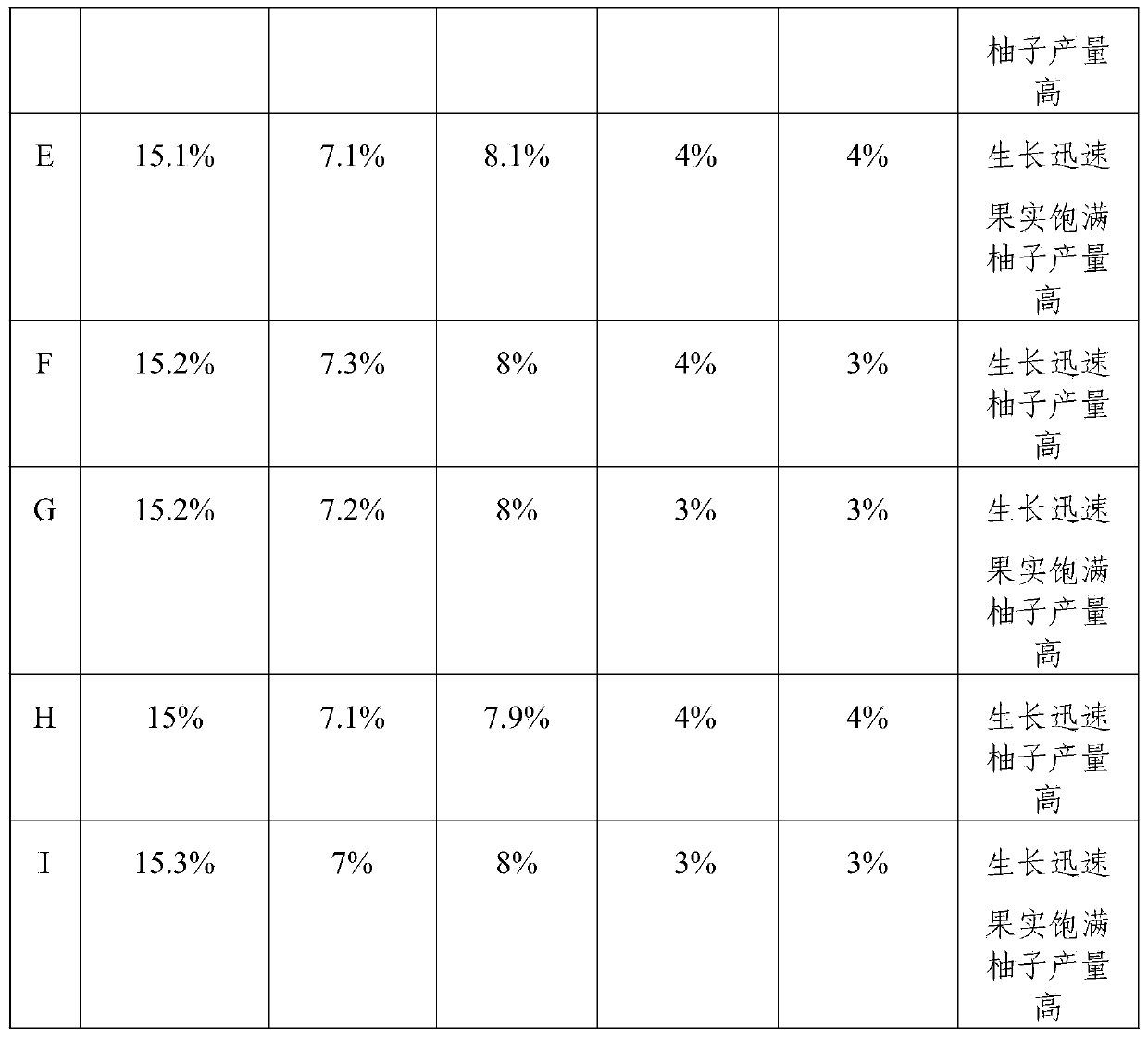

[0036] c. Filtrate element addition: Add potassium element and the trace element compound required by grapefruit tree to the separated filtrate to obtain the mother liquor of special compound fertilizer for grapefruit tree. The t

Example Embodiment

[0038] Example two

[0039] a. Preparation of raw materials: first mix phosphoric acid and urea at a molar ratio of 2:1.5, the concentration of phosphoric acid is 71%, and the temperature rises at a rate of 6°C / min to 95°C, stirring and reacting for 28 minutes to prepare a slurry, and separate Urea phosphate is obtained, and the reaction of phosphoric acid and urea is the reaction of phosphoric acid solution and urea solid;

[0040] b. Preparation of ammonium dihydrogen phosphate: slowly add ammonia water to the slurry containing urea phosphate to control the PH value of 3.5 and fully stir to obtain a slurry containing nitrogen and phosphorus. The slurry is cooled to 24°C in a cooling crystallizer, filtered, Separate and obtain ammonium dihydrogen phosphate;

[0041] c. Filtrate element addition: Add potassium element and the trace element compound required by grapefruit tree to the separated filtrate to obtain the mother liquor of special compound fertilizer for grapefruit tree. The

Example Embodiment

[0043] Example three

[0044] a. Preparation of raw materials: first mix phosphoric acid and urea at a molar ratio of 2:1.6, and the concentration of phosphoric acid is 73%. The temperature rise rate is 6°C / min to 90-120°C, and the mixture is stirred and reacted for 28 minutes to prepare a slurry. , The urea phosphate is separated, and the reaction of phosphoric acid and urea is the reaction of phosphoric acid solution and urea solid;

[0045] b. Preparation of ammonium dihydrogen phosphate: slowly add ammonia water to the slurry containing urea phosphate to control the PH value of 3.4 and fully stir to obtain a slurry containing nitrogen and phosphorus. The slurry is cooled to 24°C in a cooling crystallizer, filtered, Separate and obtain ammonium dihydrogen phosphate;

[0046] c. Filtrate element addition: Add potassium element and the trace element compound required by grapefruit tree to the separated filtrate to obtain the mother liquor of special compound fertilizer for grapefrui

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap