Preparation method of environment-friendly food packaging material

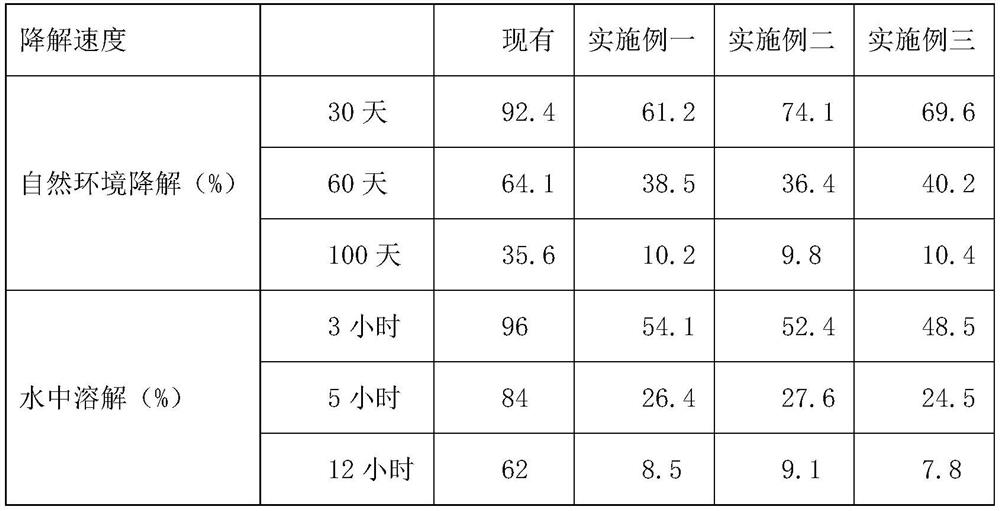

A food packaging and environmental protection technology, applied in the field of preparation of food packaging materials, can solve problems such as slow degradation speed, and achieve the effects of fast degradation speed, low cost and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An environmentally friendly preparation method for food packaging materials, comprising the following steps:

[0026] Step 1: Weigh plant raw materials, antiviral raw materials and cross-linking agent according to parts by weight. The plant raw materials are composed of the following raw materials in parts by weight: 10 parts of potatoes, 10 parts of cassava, 5 parts of corn, 5 parts of bananas, 20 parts of seaweed, 10 parts of celery leaves, 10 parts of eggplant leaves, the antiviral raw materials are composed of the following raw materials in parts by weight: 10 parts of garlic, 20 parts of turmeric, and 10 parts of ginger, and the cross-linking agent is composed of the following raw materials in parts by weight: 20 parts of distilled water, 2 parts of compound essential oil, 2 parts of food-grade glycerin, put the plant raw materials into a pulverizer for crushing, and then sieve and dry after crushing. The drying temperature is 40°C, and the drying time is 60 minutes;

Embodiment 2

[0031] An environmentally friendly preparation method for food packaging materials, comprising the following steps:

[0032] Step 1: Weigh plant raw materials, antiviral raw materials and cross-linking agent according to parts by weight. The plant raw materials are composed of the following raw materials in parts by weight: 14 parts of potatoes, 16 parts of cassava, 7 parts of corn, 7 parts of bananas, 24 parts of seaweed, 16 parts of celery leaves, 16 parts of eggplant leaves, the antiviral raw materials are made up of the following parts by weight: 15 parts of garlic, 23 parts of turmeric, 22 parts of ginger, and the cross-linking agent is made up of the following parts by weight of raw materials: 25 parts of distilled water, 3 parts of compound essential oil, 3 parts of food-grade glycerin, put the plant raw materials into a pulverizer for crushing, and then sieve and dry after crushing. The drying temperature is 60°C, and the drying time is 40 minutes;

[0033] Step 2: Put th

Embodiment 3

[0037] An environmentally friendly preparation method for food packaging materials, comprising the following steps:

[0038] Step 1: Weigh plant raw materials, antiviral raw materials and cross-linking agent according to parts by weight. The plant raw materials are composed of the following raw materials in parts by weight: 20 parts of potatoes, 20 parts of cassava, 10 parts of corn, 10 parts of bananas, 30 parts of seaweed, 20 parts of celery leaves, 20 parts of eggplant leaves, the antiviral raw materials are composed of the following raw materials in parts by weight: 20 parts of garlic, 40 parts of turmeric, and 30 parts of ginger, and the cross-linking agent is composed of the following raw materials in parts by weight: 30 parts of distilled water, 5 parts of compound essential oil, 5 parts of food-grade glycerin, put the plant raw materials into a pulverizer for crushing, and then sieve and dry after crushing. The drying temperature is 50°C, and the drying time is 40 minutes;

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap