Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Air bubble" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

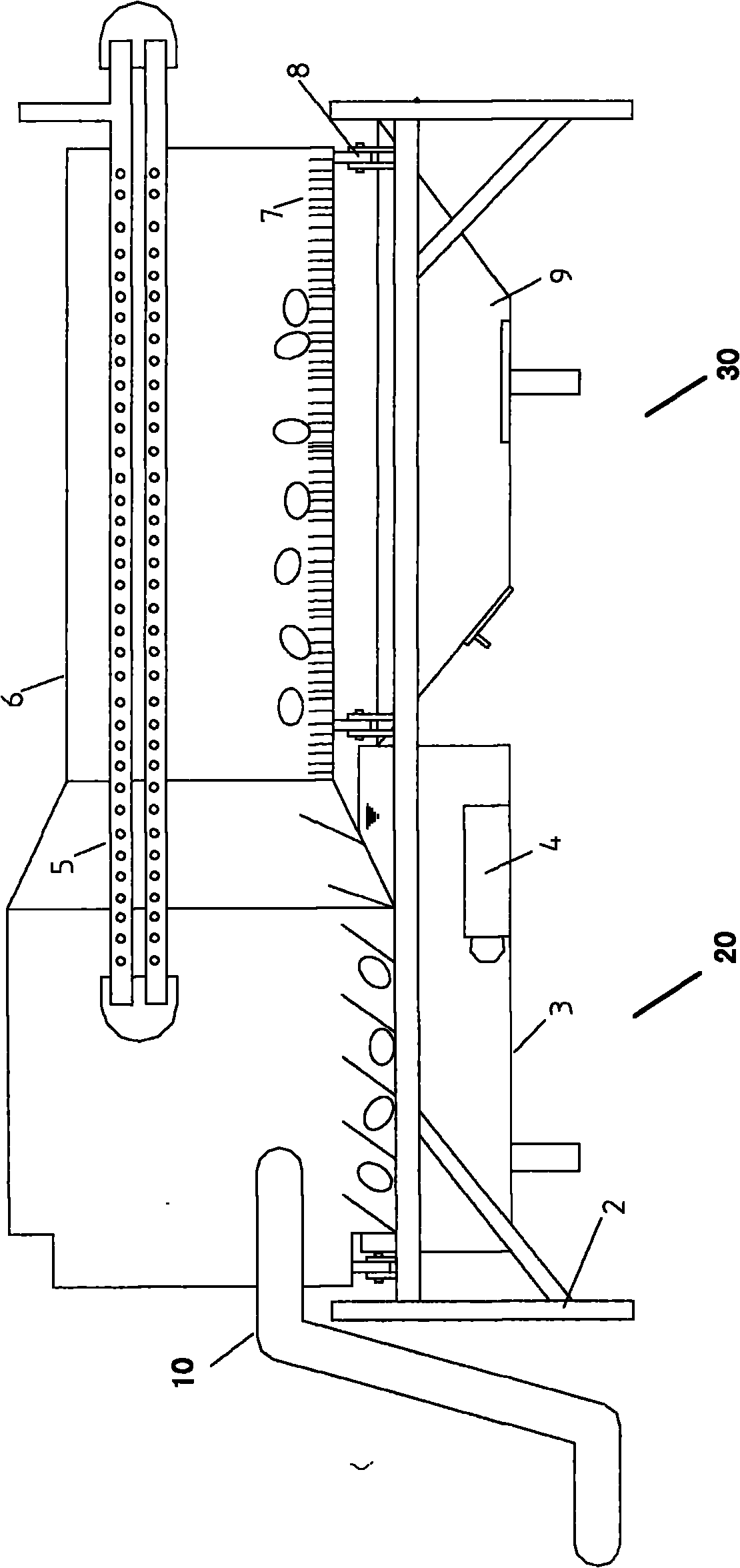

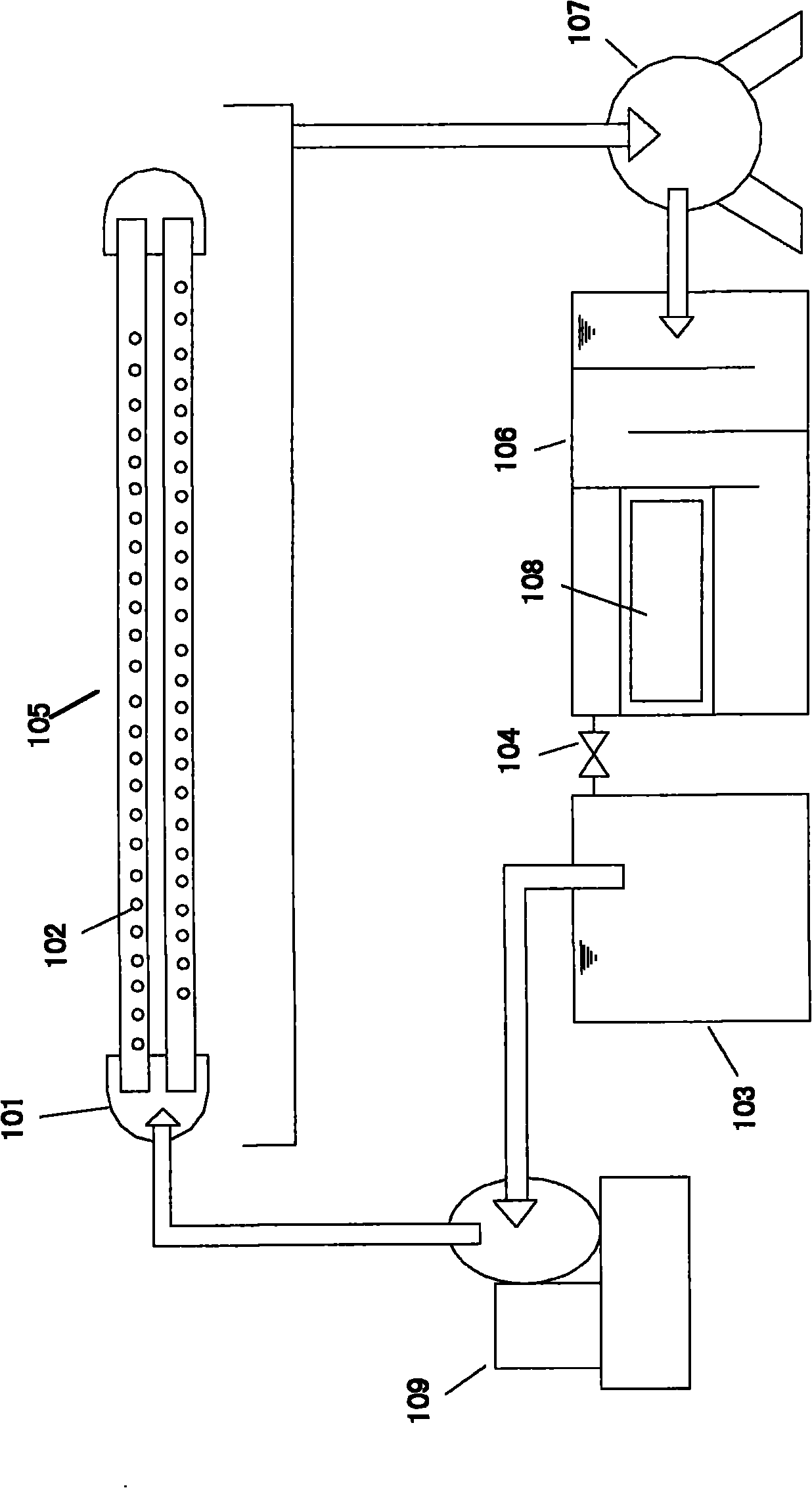

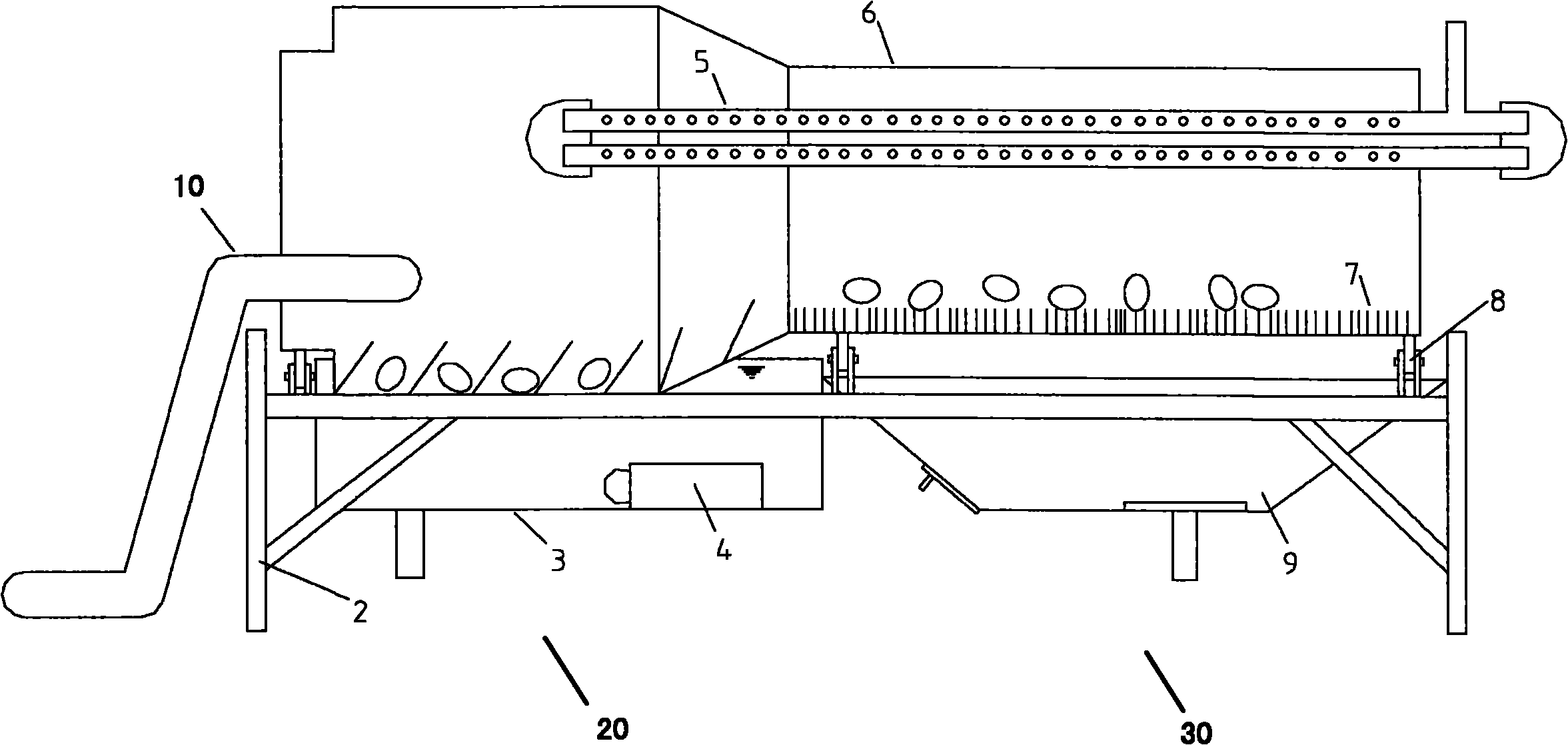

Oyster cleaning device

InactiveCN101766207AChange the cleaning methodIncrease productivityBivalves processingOysterEngineering

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

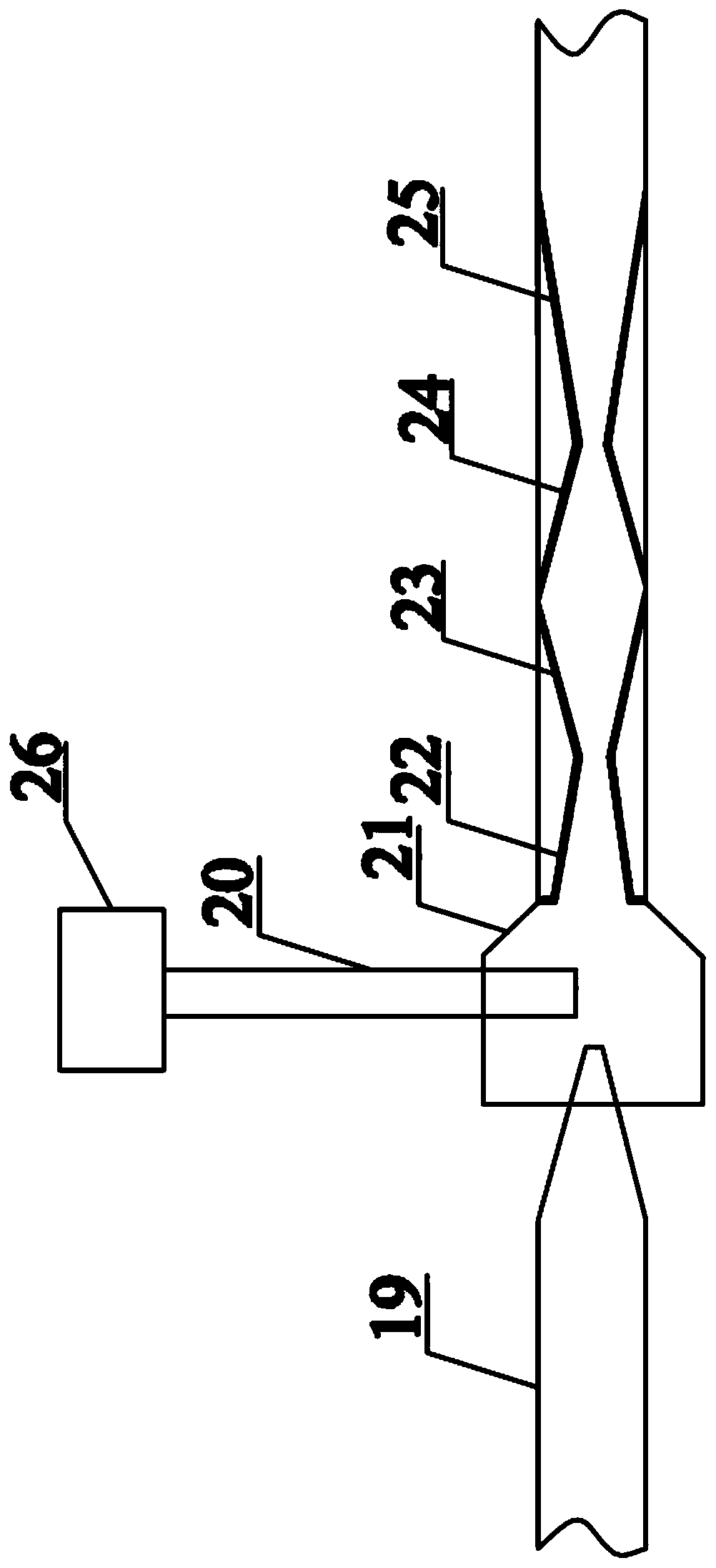

Low-residual safe self-destructing injector

InactiveCN101444649ATo achieve the purpose of locking the push rodInfusion syringesInfusion needlesEngineeringFrustum

The invention relates to a low-residual safe self-destructing injector comprising a hollow syringe, a push rod sliding in the syringe and a rubber plug arranged at the front end of the push rod. The front end of the syringe is provided with a needle seat supported by a support base, an elastic claw is arranged at the inner side of the support base, and the front end of the push rod is provided with a frustum clamped with the elastic claw after injection. The injector is characterized in that a cone base of the frustum is contacted and connected with the top of the rubber plug when the injection is not performed; the rubber plug is interiorly hollow; the push rod is provided with a blocking piece for pushing and blocking the rubber plug; during the injection, the rubber plug is compressed and deforms due to counterforce generated by injection liquid and push force of the blocking piece, and at the same moment, the frustum at the front end of the push rod axially extend forward along the push rod; and after the injection, the frustum can be clamped and combined with the elastic claw. After the adoption of the structure, as the cone base of the frustum is contacted and connected with the top of the rubber plug when the injection is not performed and a higher part of the frustum is short, extracted liquid generates no foam at the top of the rubber plug, gas discharge suffers no blockage and is smooth after the liquid extraction, and little residual of injection liquid is left in the syringe after the injection; and the invention is in particular applicable to injectors such as insulin syringes with small dosage.

Owner:SHANGHAI SOL MILLENNIUM MEDICAL PRODUCTS CO LTD

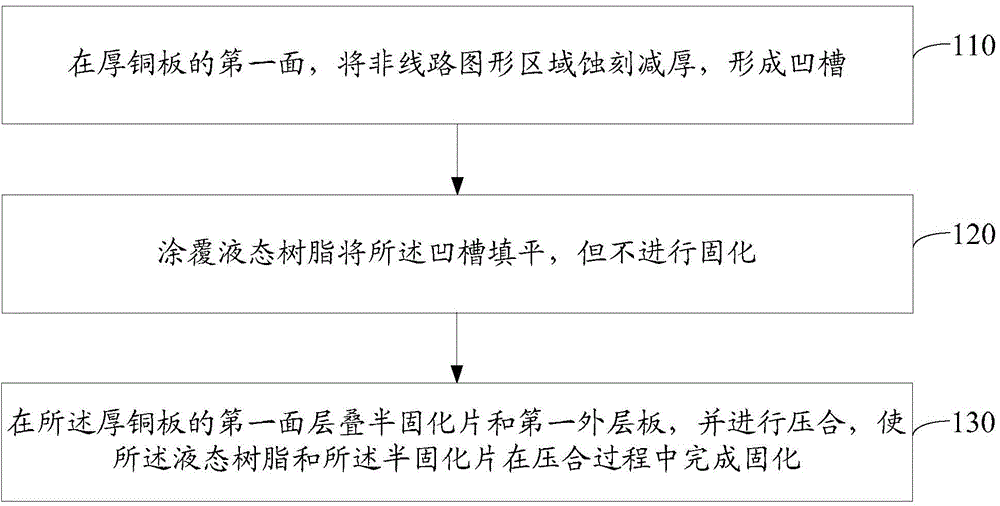

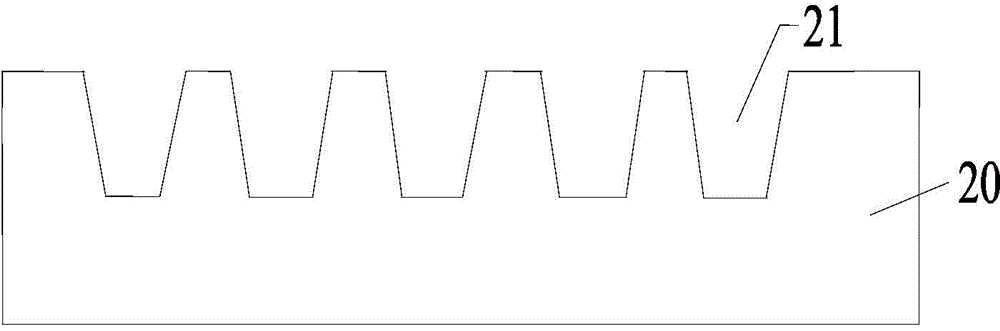

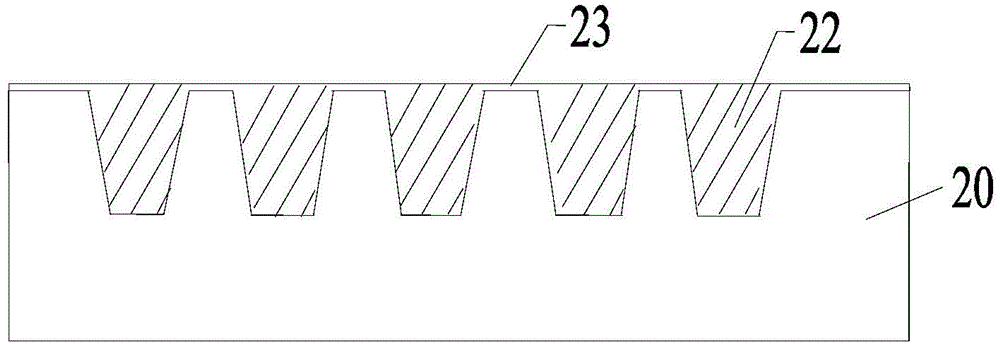

Thick copper circuit board processing method

ActiveCN104918419AImprove bindingAvoid explosionInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentGlass fiberInter layer

Owner:SHENNAN CIRCUITS

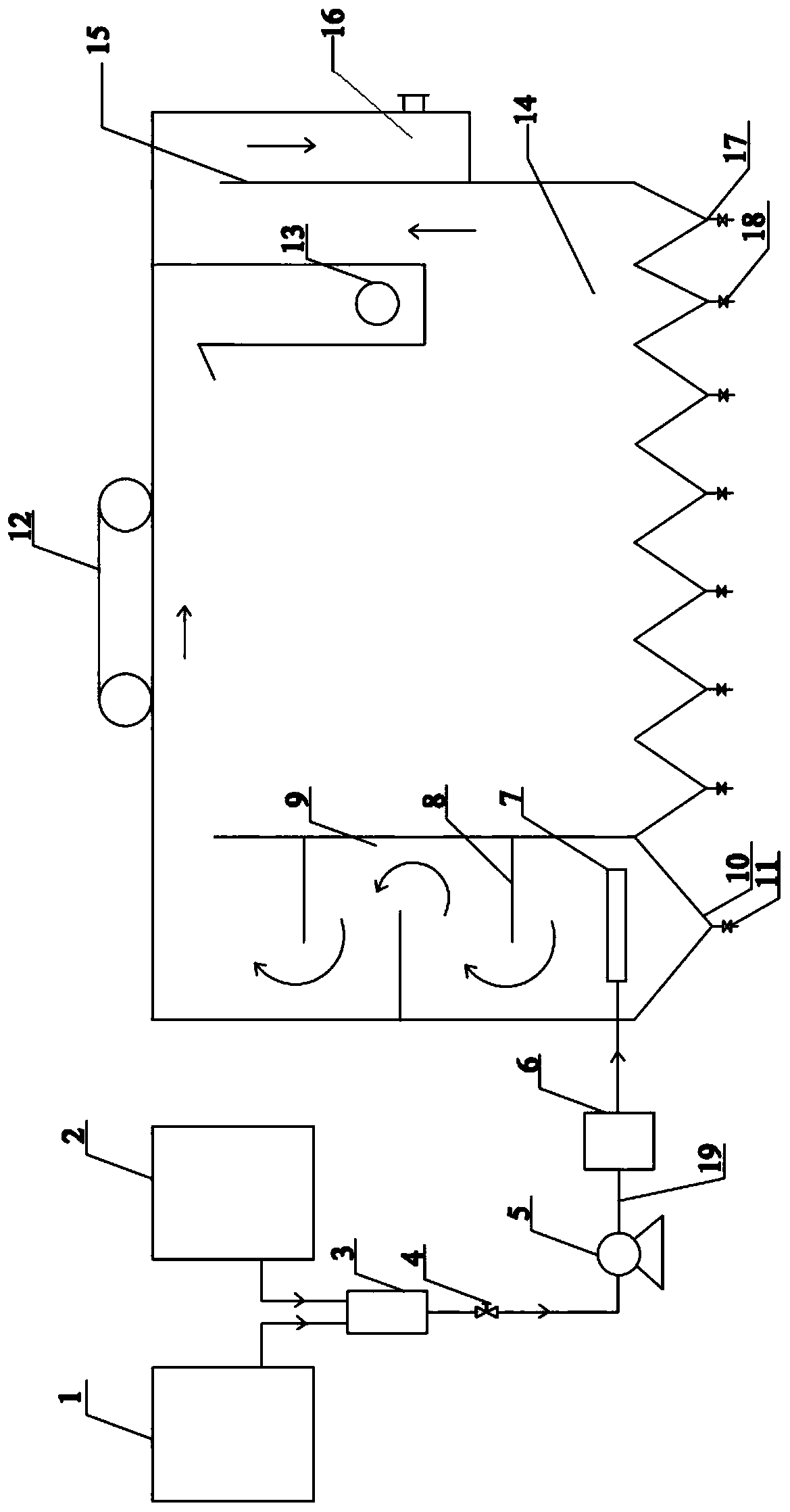

Method and device for detecting automatic sample injection of laboratory liquid

InactiveCN102175622AReduce wasteIncrease positive pressureColor/spectral properties measurementsCuvetteLiquid height

The embodiment of the invention discloses a method and device for detecting the automatic sample injection of a laboratory liquid. The method disclosed by the embodiment of the invention comprises the following steps: controlling a microprocessor to enable a driving pump to enhance the positive pressure or negative pressure of a pipeline by extracting the gas in a connecting pipe and a cuvette; finishing the steps of sampling color comparison, liquid drainage, moistening and cleaning under the condition that no manpower participates in the operation; and regulating and controlling the on-off action of the corresponding valves when each operation is carried out. In the embodiment of the invention, the testing course is simple and rapid; and moreover, the control of the microprocessor is matched with the slow liquid injection and air exhaust action of the driving pump and the accurate monitoring of a liquid height detector for the liquid injection height of the connecting pipe, thereby overcoming the defects of air bubbles and water blockage because of the existing artificial liquid pouring and realizing the purposes of greatly reducing testing errors and reducing reagent water source waste.

Owner:CHANGSHA KAIYUAN INSTR

Production method of welding rod steel H08A

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

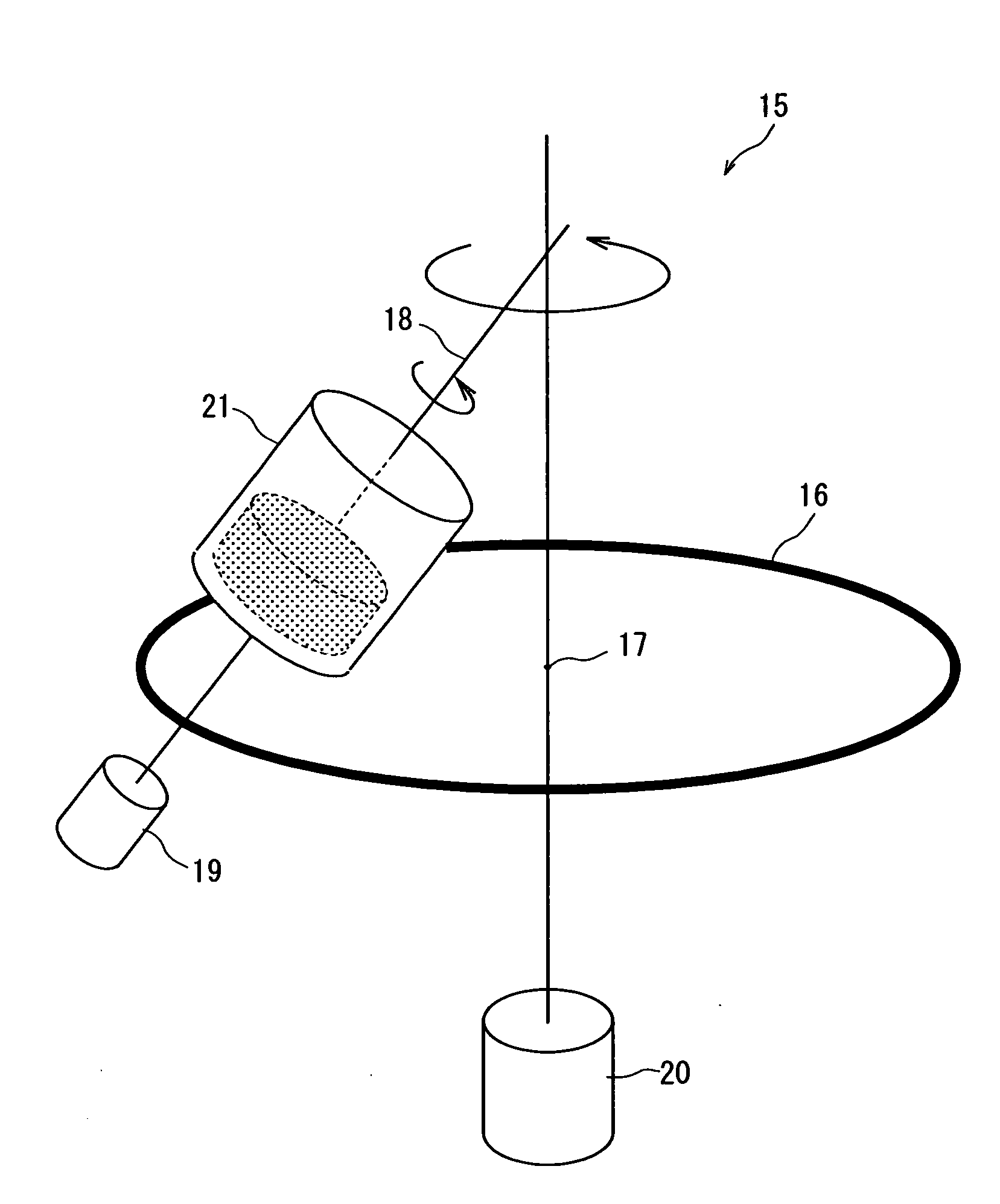

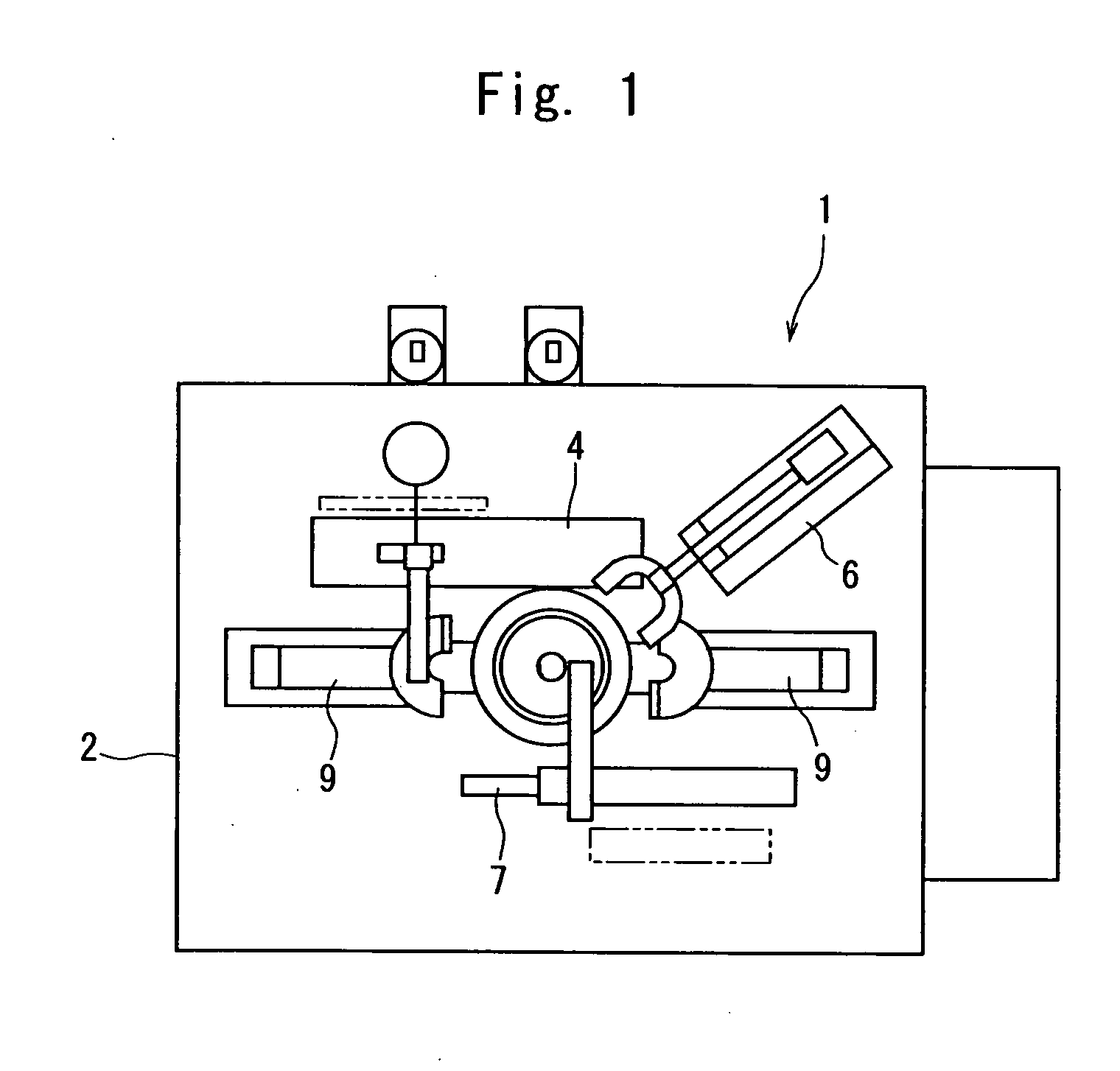

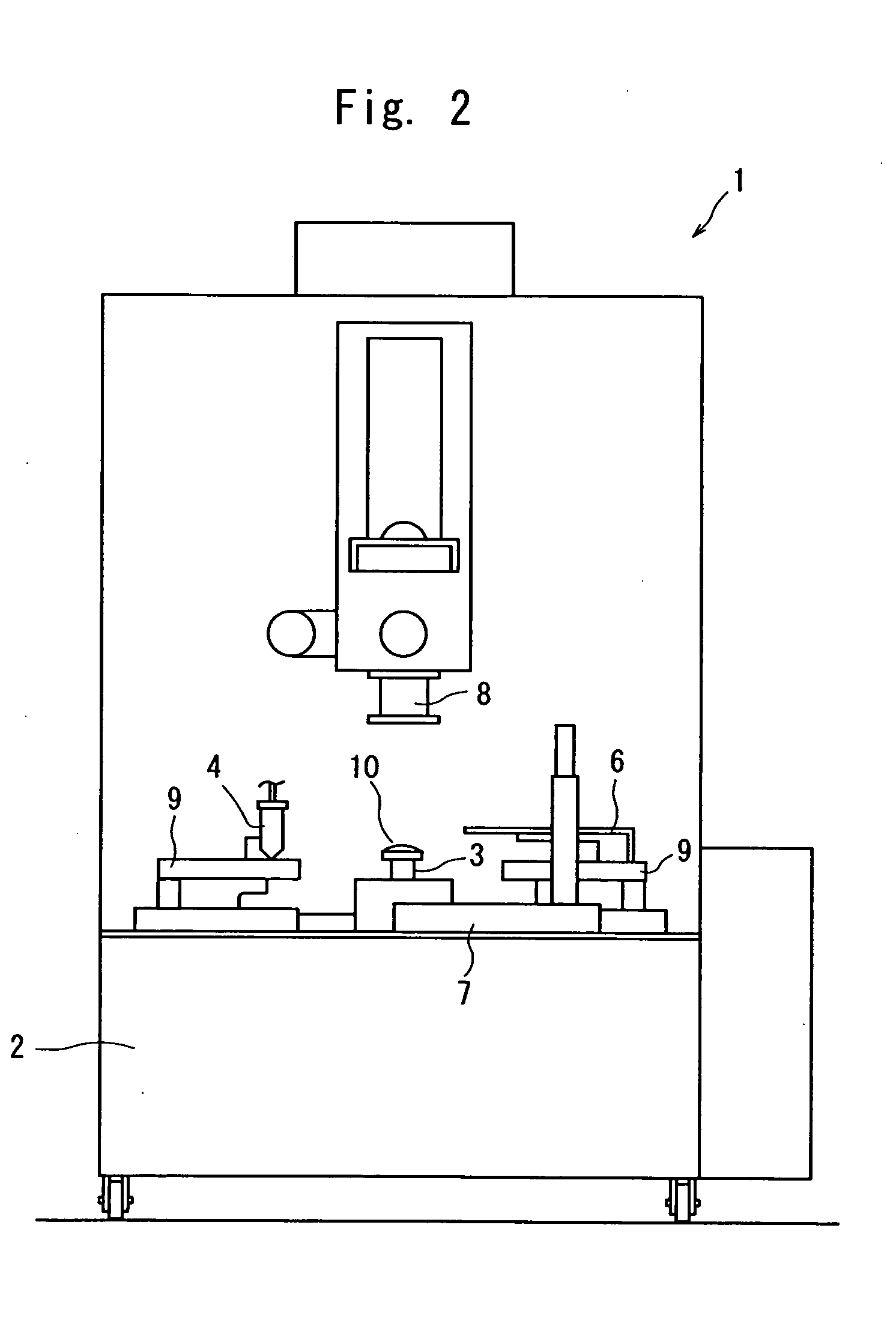

Removal Method and Removal Apparatus for Entrained Air in Coating Fluid

InactiveUS20090229465A1Prevent backflowLiquid degasification regulation/controlSpecial surfacesRotational axisAir entrainment

Owner:TOKUYAMA CORP

Pilot dispensing device, dispensing machine and dispensing method of dispensing machine

ActiveCN103071606AGuaranteed accuracyGuaranteed efficiencyLiquid surface applicatorsCoatingsNumerical controlMechanical engineering

Owner:SHENZHEN DINGJING TECH CO LTD

Process for adopting fair-faced concrete pouring during building construction

The invention discloses a process for adopting fair-faced concrete pouring during building construction. According to the process, concrete mixing is strictly measured according to a mixing ratio, a pump is used for transportation, and a concrete pump should be placed on a solid ground; vibration time of the concrete is mastered, and vibration is not stopped until the surface of the concrete has uniform cement paste represented and does not have obvious sinking and a large number of risen air bubbles; after the concrete is cooled to <+>5 DEG C, and the difference value between the concrete surface temperature and the ambient temperature is greater than 15 DEG C after form removal, coverage and maintenance should be carried out on the surface of the concrete, so that the concrete is cooledslowly; the form removal is carried out on the concrete when the strength of test pieces under the same conditions reaches 3 MPa or 4 MPa, and in-time maintenance should be carried out after the formremoval to reduce the phenomena of chromatic aberration, shrinkage cracks and the like on the surface of the concrete, fair-faced concrete often adopts the method of combining plastic film or flame retardant mat coverage and watering maintenance, watering should be carried out before the form removal and during maintenance respectively to keep wet, and the maintenance time is not less than 7d. Theprocess for adopting fair-faced concrete pouring during the building construction can ensure that the fair-faced concrete meets the requirements after pouring and the service life of the concrete islonger.

Owner:成都美吉房地产营销策划有限公司

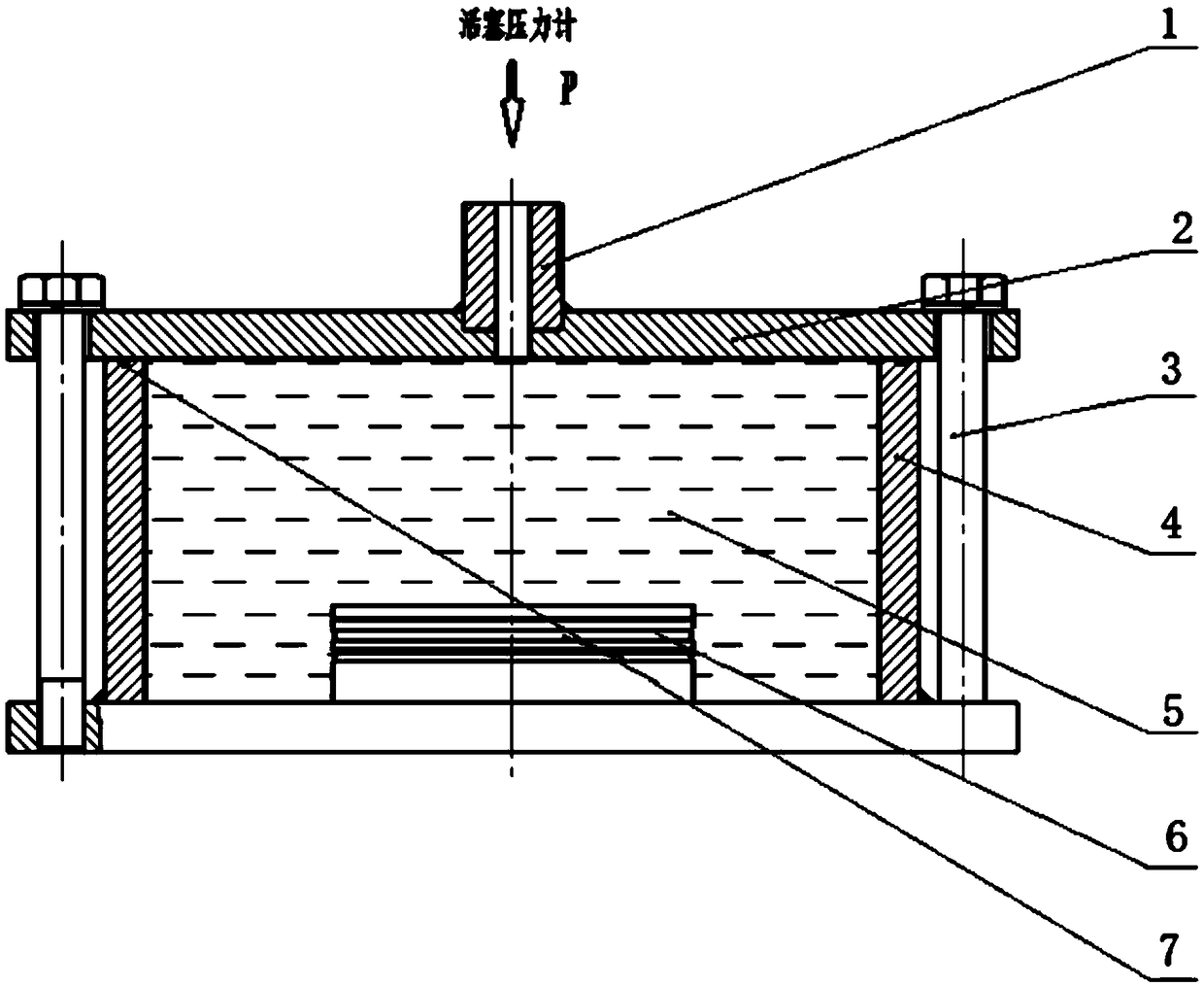

Sealing method and device used for improving insulation performance of annular force transducer

PendingCN109185458AImprove insulation performanceQuality improvementEngine sealsLiquid stateTransducer

Owner:秦川机床集团宝鸡仪表有限公司

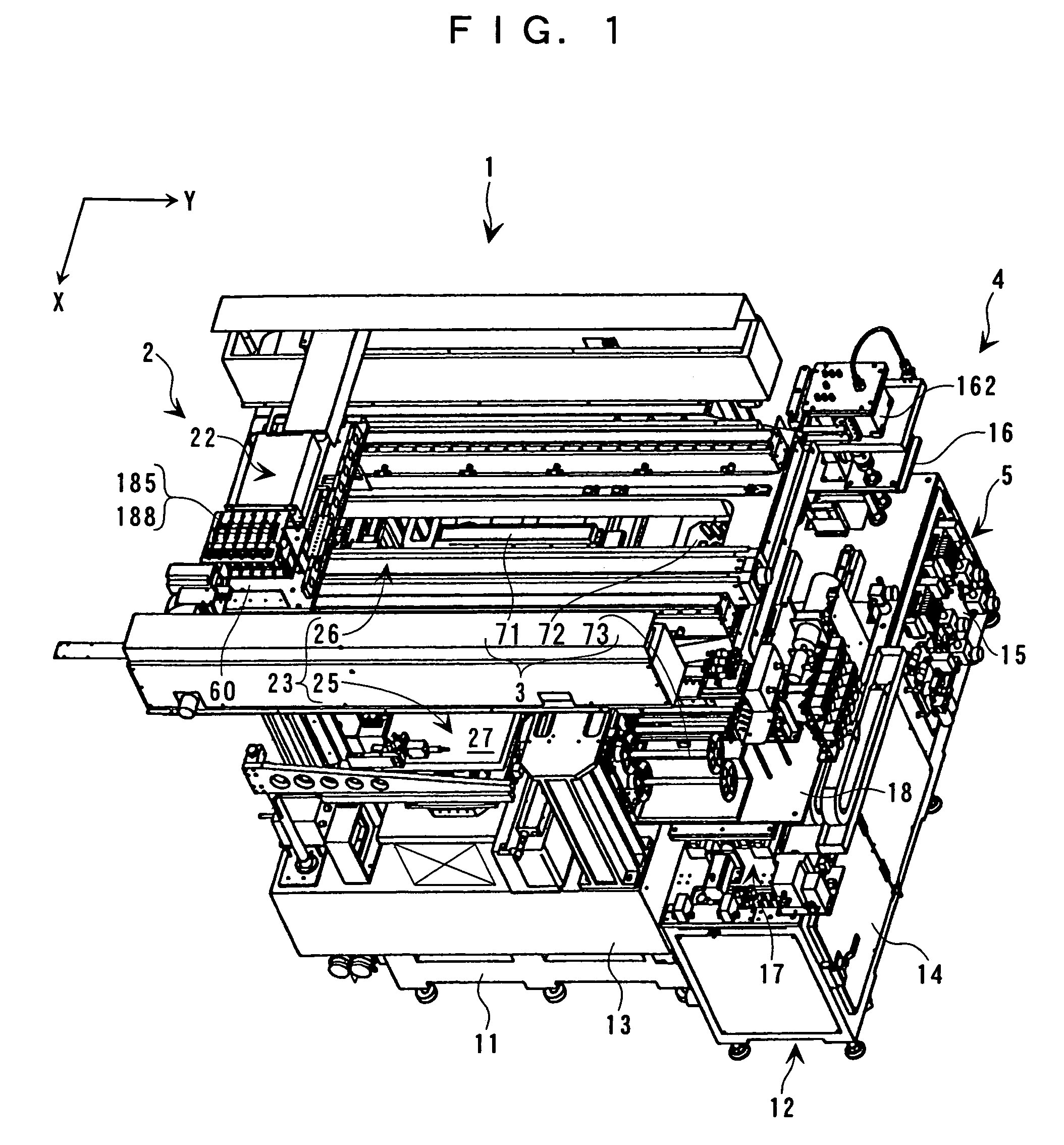

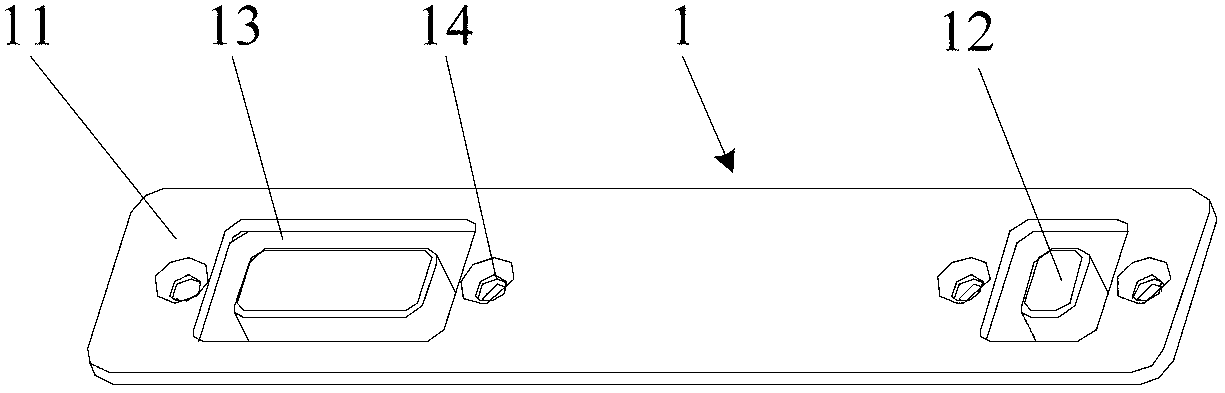

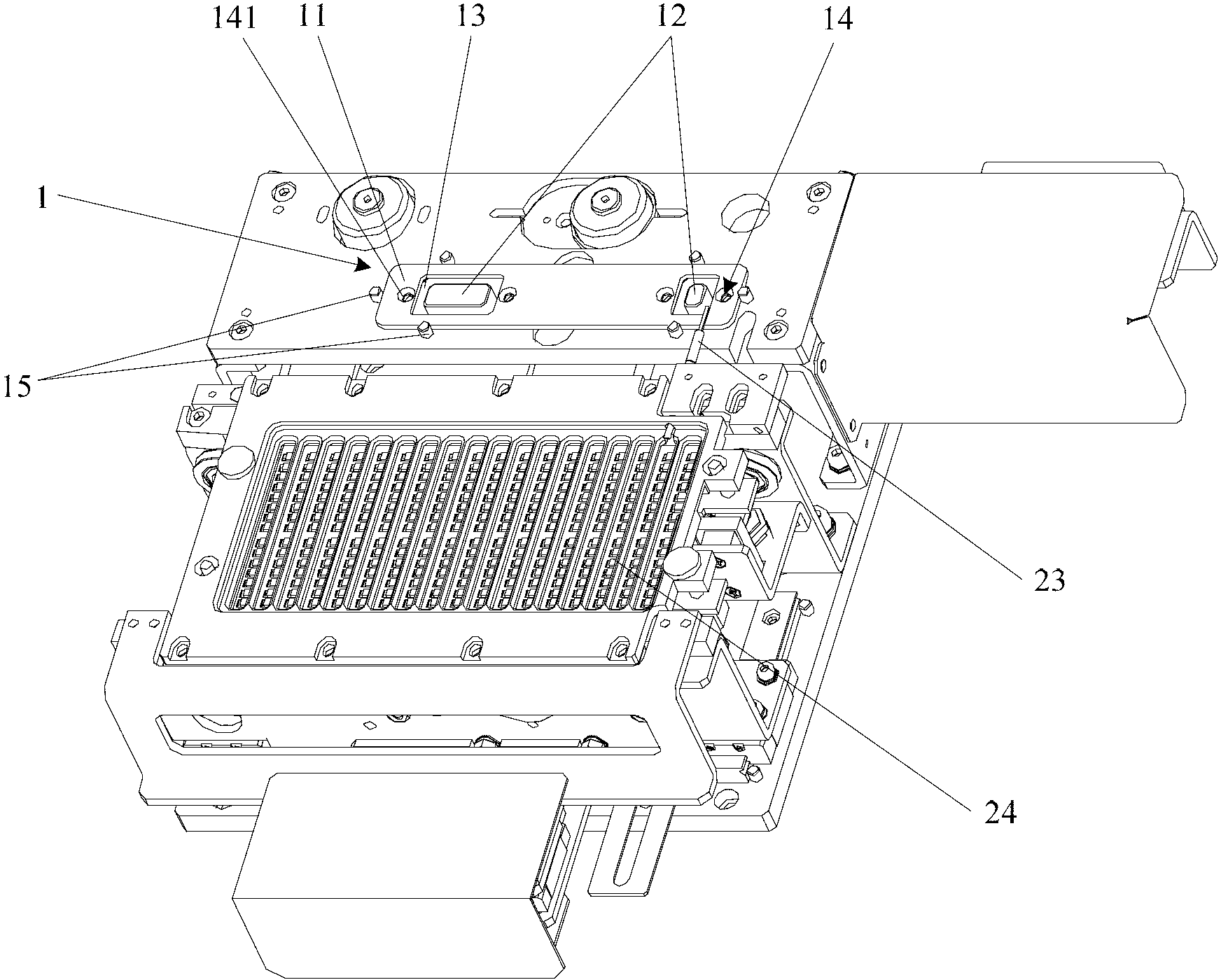

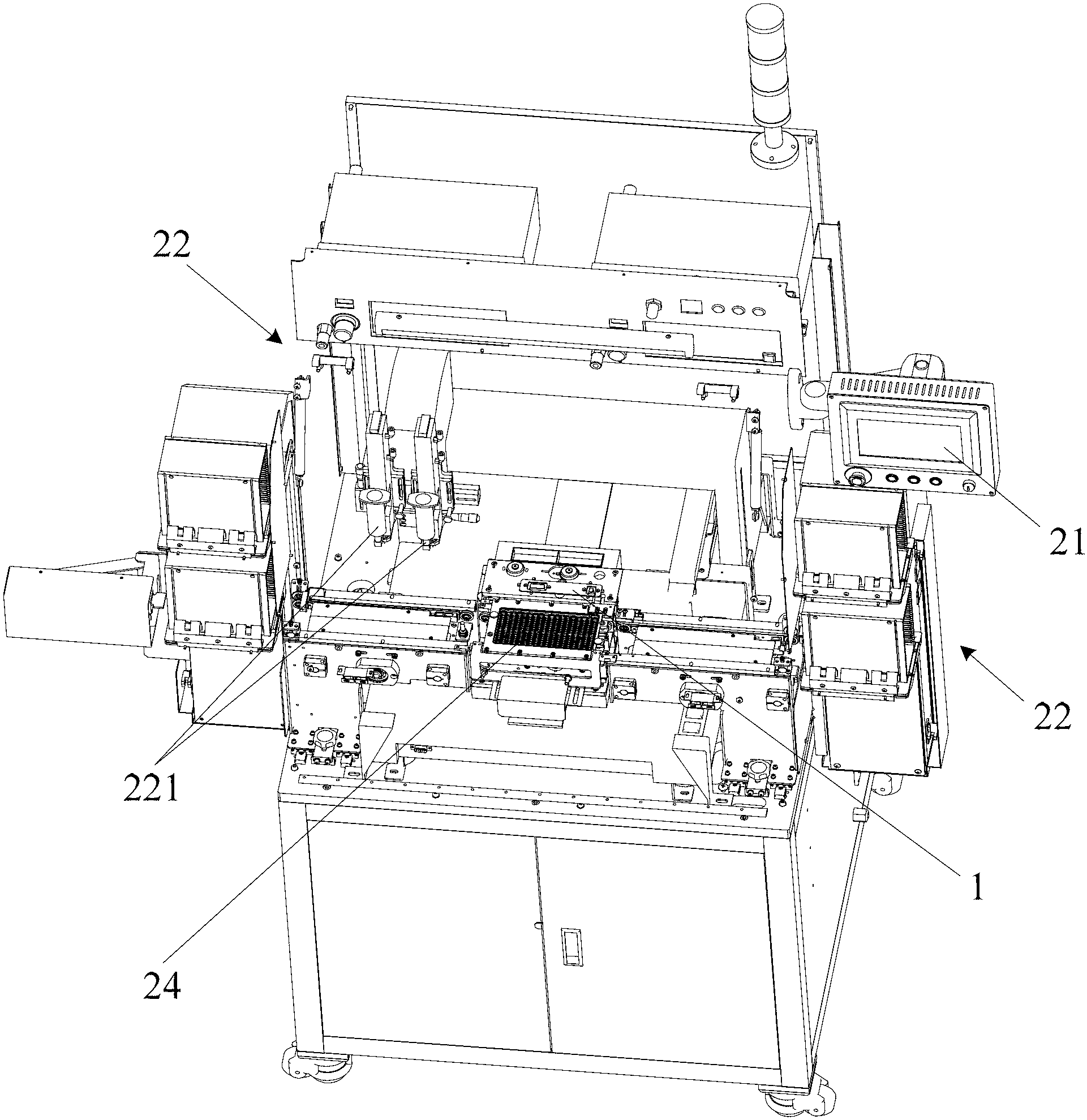

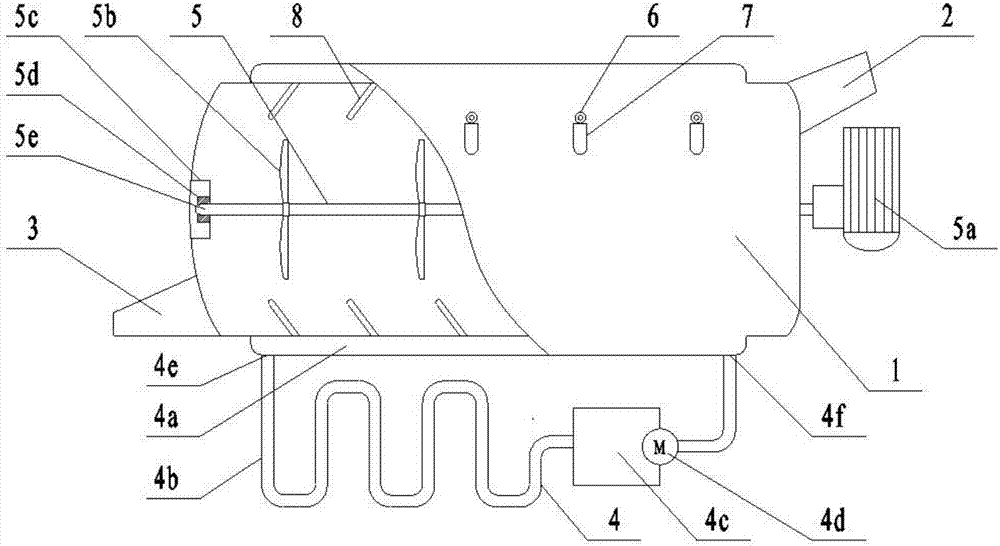

Laminating machine

ActiveCN102152596AAvoid it happening againImprove yield rateLamination ancillary operationsLaminationReciprocating motionAir bubble

The invention relates to a laminating machine comprising an upper air suction platform capable of rotating on a bench and a lower air suction platform capable of horizontally moving. An isolation device which can move along with the lower air suction platform is arranged on one side of the lower air suction platform, and the isolation device comprises an isolation strip spanning above the lower air suction platform and a movement mechanism capable of carrying out linear reciprocating motion, wherein the isolation strip is fixedly arranged on one side of the movement mechanism and is capable of moving along the lower air suction platform back and forth under the drive of the movement mechanism. The laminating machine can reduce the reject ratio because of bubbles generated at the time of adhering products, enhance the operation quality, and reduce the production cost. The laminating machine is suitable for adhering of varisized products.

Owner:SUZHOU NEW TOUCH TECH

Metal surface micro-patterning method

ActiveCN109175708AAvoid rapid degradationImprove heat dissipationLaser beam welding apparatusMicro nanoLiquid medium

The invention discloses a metal surface micro-patterning method. A transparent liquid medium not reacted with metal is adopted as protecting liquid; and in particular, when sodium hydroxide solution is adopted, the quick degradation of magnesium in water is prevented, and the machining of a magnesium alloy material by femtosecond laser filamentation in water is realized. When a flowing liquid filmis adopted, the heat dissipation condition of the periphery of a machined part can be prominently improved; and meanwhile, bubbles generated in machining are taken away to prevent accumulation of chips, so that the self-cleaning in the machining process is realized. In addition, compared with high-energy femtosecond laser filamentation in air, on the basis of guaranteeing the machining quality ofa metal surface micro-nano structure, the machining precision can be prominently improved to reach about 10 microns, and meanwhile, the production equipment cost is reduced. More importantly, an active oxidation atmosphere formed by femtosecond laser in the air is prevented, and oxides in machined products are prominently reduced, so that the metal surface and the microcosmic substance forms in machined grooves are not changed to the greatest extent.

Owner:BEIHANG UNIV

Extrusion equipment for producing multi-color master batches

The invention discloses extrusion equipment for producing multi-color master batches. The extrusion equipment comprises an extrusion equipment assembly, and the extrusion equipment assembly comprisesan internal mixing device, a material control device, a reserved transition device, an extrusion die head and a transmission extrusion mechanism. The internal mixing device, the material control device, the reserved transition device and the extrusion die head form a communication barrel body. During use, various raw materials can be mixed and stirred during discharging, so that the raw materialscan be uniformly stirred, the quality of a master batch finished product is further improved, the problem of powder blockage is avoided by adopting a stepless discharging manner, the powder can be discharged more uniformly, firstly, by adopting a stirring manner of a stirring shaft, the raw materials can be uniformly preheated, the phenomenon that hard particles exist in the master batches after the master batches are produced due to non-uniform heating of the raw materials caused by a heating blind area of the powder is avoided, gas in the master batches can be reduced in the secondary process, and the problem that air bubbles exist in the master batches is avoided.

Owner:ANHUI JIHONG MATERIAL TECH

Air floatation sewage treatment device and method based on superoxide nano micro-bubbles

ActiveCN109928539ANo occurrenceAscending velocity decreasesMultistage water/sewage treatmentSustainable biological treatmentParticulatesSlag

Owner:JIANGSU FANGYANG WATER

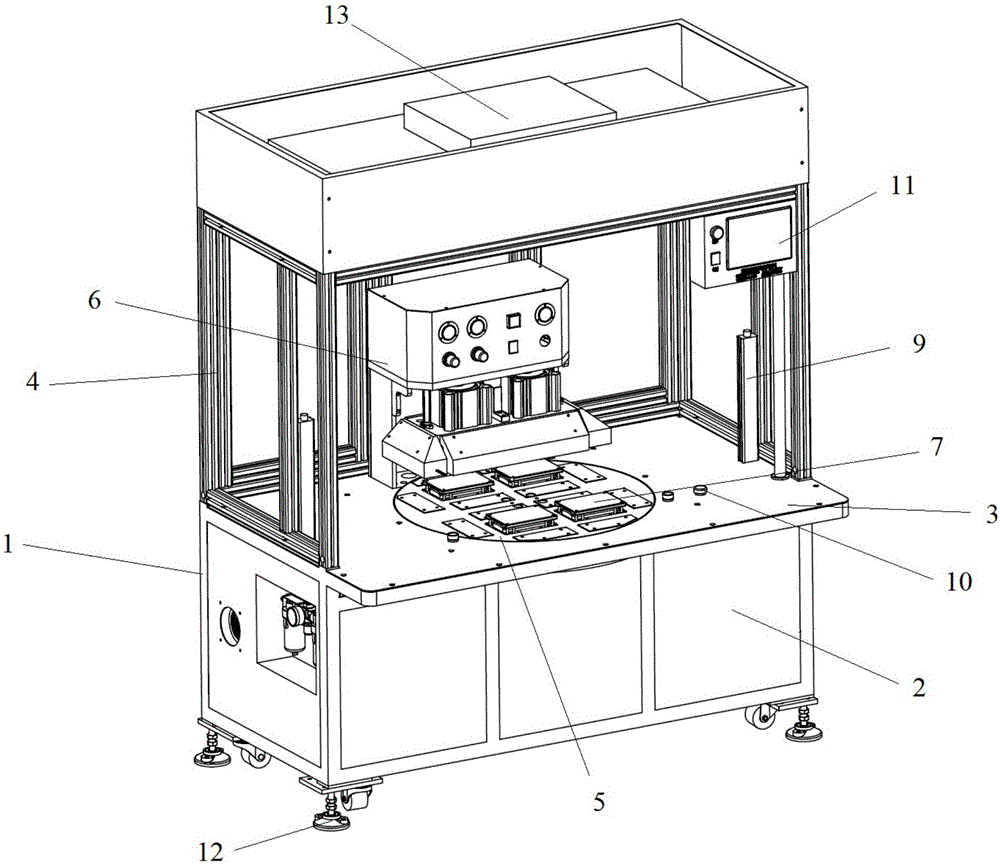

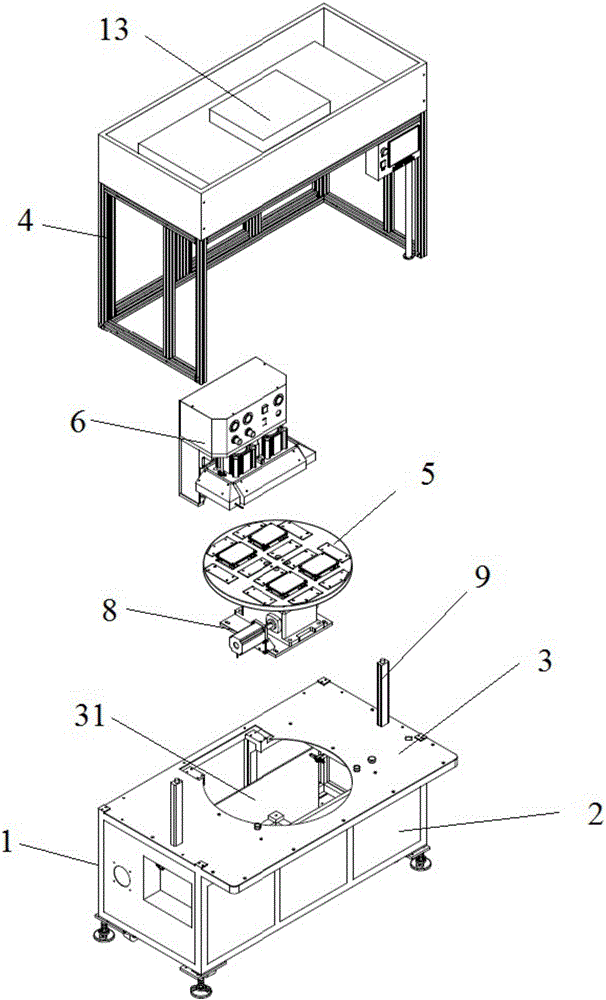

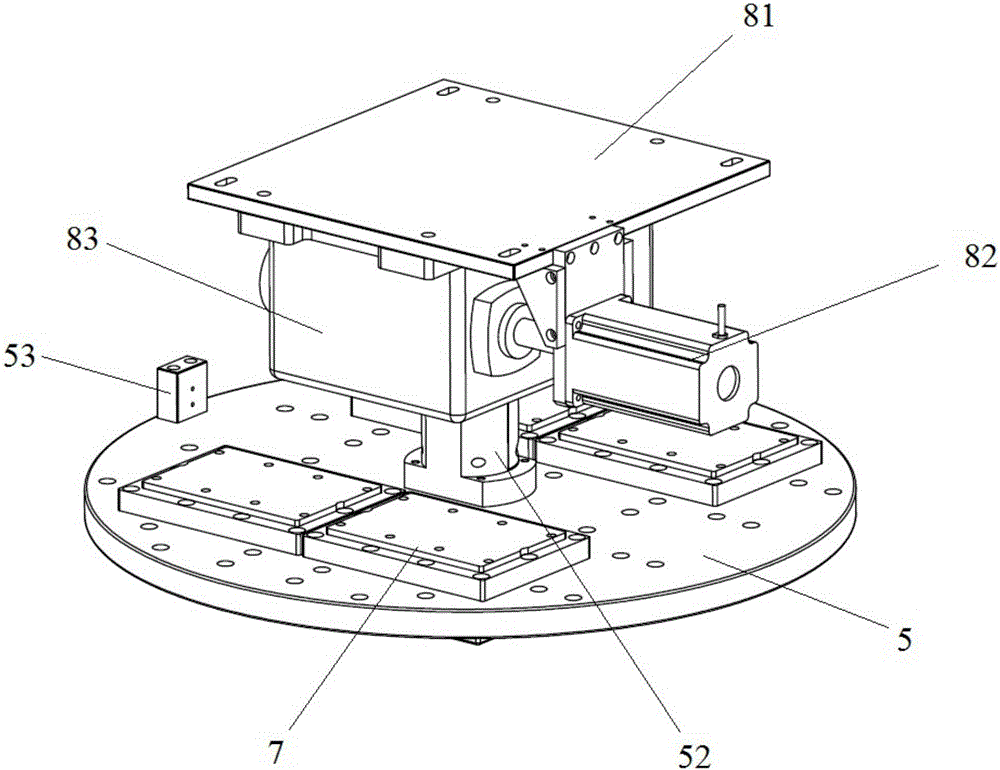

Curved surface fitting equipment and fitting method of curved surface fitting equipment

ActiveCN106827765AImprove fitting accuracyAvoid fitLaminationLamination apparatusAutomatic controlElectrical control

Owner:SHENZHEN CHENG XI ELECTROMECHANICAL EQUIP

Fire extinguishing air bubble film doped with powdery fire extinguishing medium and manufacturing method thereof

ActiveCN111716854AImprove high temperature resistanceStrong toughnessWrappersFlexible coversFilm baseProcess engineering

The invention discloses a fire extinguishing air bubble film doped with a powdery fire extinguishing medium and a manufacturing method thereof. The fire extinguishing air bubble film comprises a double-layer air bubble film base material and buffer air bubbles which are distributed in the double-layer air bubble film base material and are filled with the powdery fire extinguishing medium, whereinthe air bubble film base material consists of polyethylene serving as a base material and auxiliary materials according to a weight ratio. Compared with the prior art, the fire extinguishing air bubble film doped with the powdery fire extinguishing medium and the manufacturing method thereof in the invention have the following advantages: various kinds of polyethylene can be used as the base material for preparing the air bubble film; by adding a certain proportion of a flame retardant in the mixing process and filling buffering air bubbles with a large amount of the powdery fire extinguishingmedium by using a proper method, the overall high temperature resistance of the bubble film can be improved on the premise of not changing original performance, and flame retardant and fire extinguishing effects are obvious. Meanwhile, through the manufacturing method, the bubble film prepared through the method is high in toughness and not prone to damage, processing process is simple, the produced film has market competitiveness, and better benefits can be brought.

Owner:CIVIL AVIATION UNIV OF CHINA

Crystallization kettle with screening function

PendingCN107186910AReduce labor costsThe principle is simpleRotary stirring mixersTransportation and packagingEngineeringBuoyancy

Owner:南通协鑫热熔胶有限公司

Chemical abrasive device and glass substrate

Owner:NISHIYAMA STAINLESS CHEMICAL KK

Horizontal winding packaging machine

InactiveCN106428704AReduce manufacturing costVersatileBinding material applicationEngineeringConductor Coil

The invention discloses a horizontal winding packaging machine. The horizontal winding packaging machine comprises a rack, an objective table system, a movement positioning system and a rotational winding system. The packaging machine adopts the horizontal winding packaging thought, after an object is put onto the lifting objective table system, the movement positioning system fixes the object to be packaged, the fixed object to be packaged is horizontally moved to the center of the rotational winding system, and then, the rotational winding system is rotated to wind plastic bubble paper around the object and package the object; and after packaging is completed, the movement positioning system is used for pulling the object back to the objective table system, by means of rotation of the objective table system, winding in the second direction is carried out, and therefore the whole packaging process is completed. The device is simple in structure, low in manufacturing cost and capable of quickly achieving winding and package sealing, has complete functions, conducts packaging quickly and can solve the problem of manpower shortage during the packaging busy period.

Owner:CHONGQING UNIV

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap