Sealing method and device used for improving insulation performance of annular force transducer

A load cell and insulation performance technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve problems such as malfunction, air bubbles infiltrated, sensor insulation performance degradation, etc., to improve insulation performance and prolong service life , the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the present invention, the sealing protection of the annular force sensor is sealed with silicon rubber, and a sealant is provided in the sensor cavity. After the sensor is debugged and assembled, the air bubbles in the sealant are filled and insulated by using the sealing device of the present invention. Medium, improve the sealing effect.

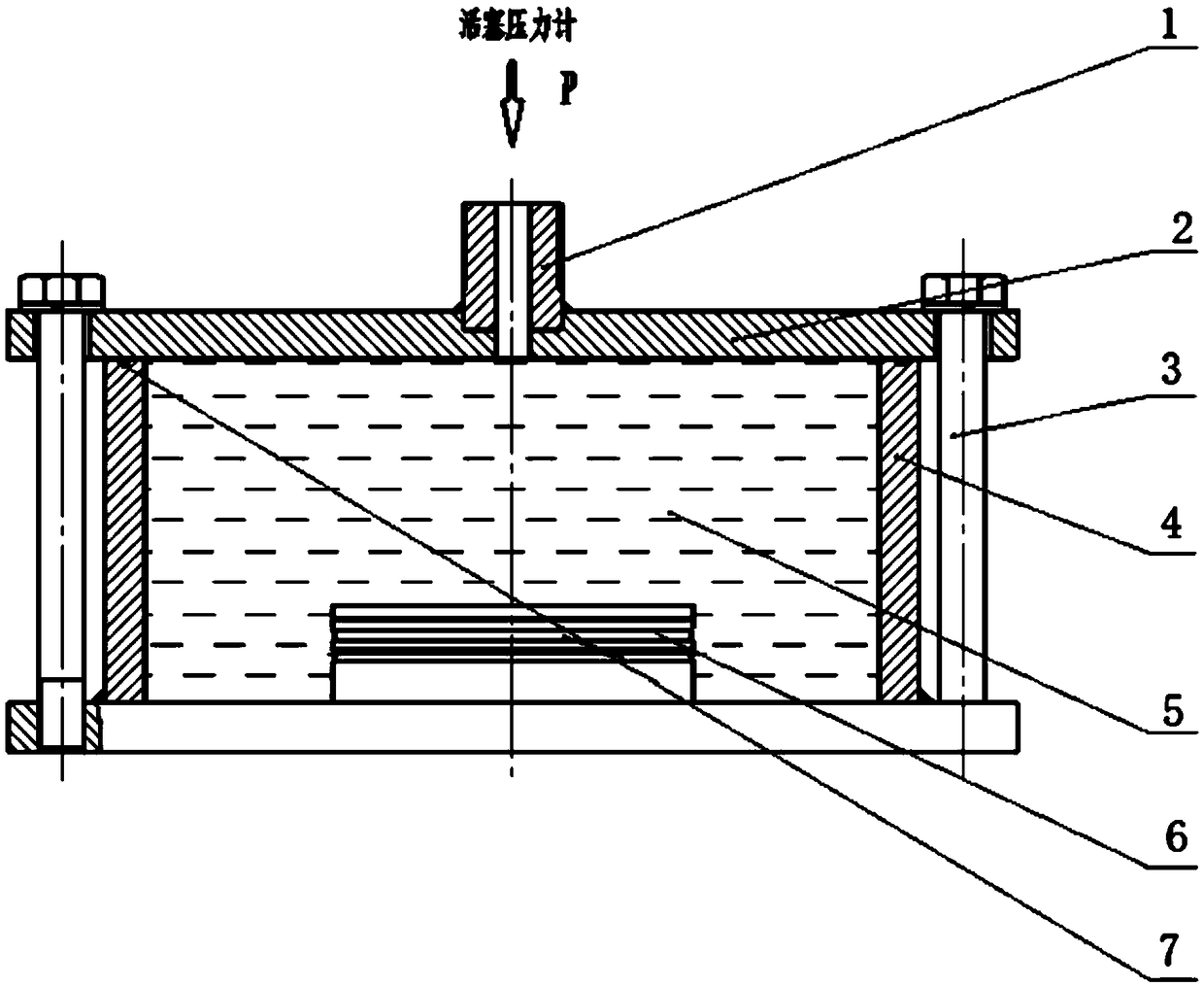

[0024] Such as figure 1 As shown, the present invention is a sealing method for improving the insulation performance of ring-shaped load cells. A number of ring-shaped load cells are put into a pressure vessel filled with liquid insulating medium for sealing, and by applying a pressure greater than the rated working water pressure to the pressure container , so that the liquid insulating medium penetrates into the air bubbles of the silicone rubber of the annular load cell and retains them to form a one-way valve, which blocks the passage of water entering the sensor and completes the air bubble sealing of the silicon rubber. By f

Embodiment 2

[0032] A sensor used to measure the axial force of a rocket engine needs to meet the technical requirements of being underwater at a depth of 250 meters (equivalent to 2.5MPa pressure) and withstanding pressure for 2 hours, and the insulation resistance of the axial force sensor is greater than 1000 megohms.

[0033] By this method and using an oil pressure device, the axial force sensor is placed in a pressure vessel filled with silicone oil, and an oil pressure of 6MPa is applied, and the pressure is kept for 3 hours. The bubbles of the sensor sealant are filled with silicone oil, which plays a protective role. In the subsequent actual measurement of the sensor, the insulation performance met the technical requirements, which met the technical requirements of the rocket engine axial force sensor at a depth of 250 meters underwater, withstand voltage for 2 hours, and the insulation resistance of the sensor was greater than 1000 megohm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap