Removal Method and Removal Apparatus for Entrained Air in Coating Fluid

a technology of entrapment air and removal apparatus, which is applied in the direction of liquid degasification, separation processes, instruments, etc., can solve the problems of high cost of photochromic fluid and the problem of large expenditure, and achieve the effect of preventing backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]An embodiment of a removal method for entrained air in a coating fluid according to the present invention will now be described with reference to the accompanying drawings.

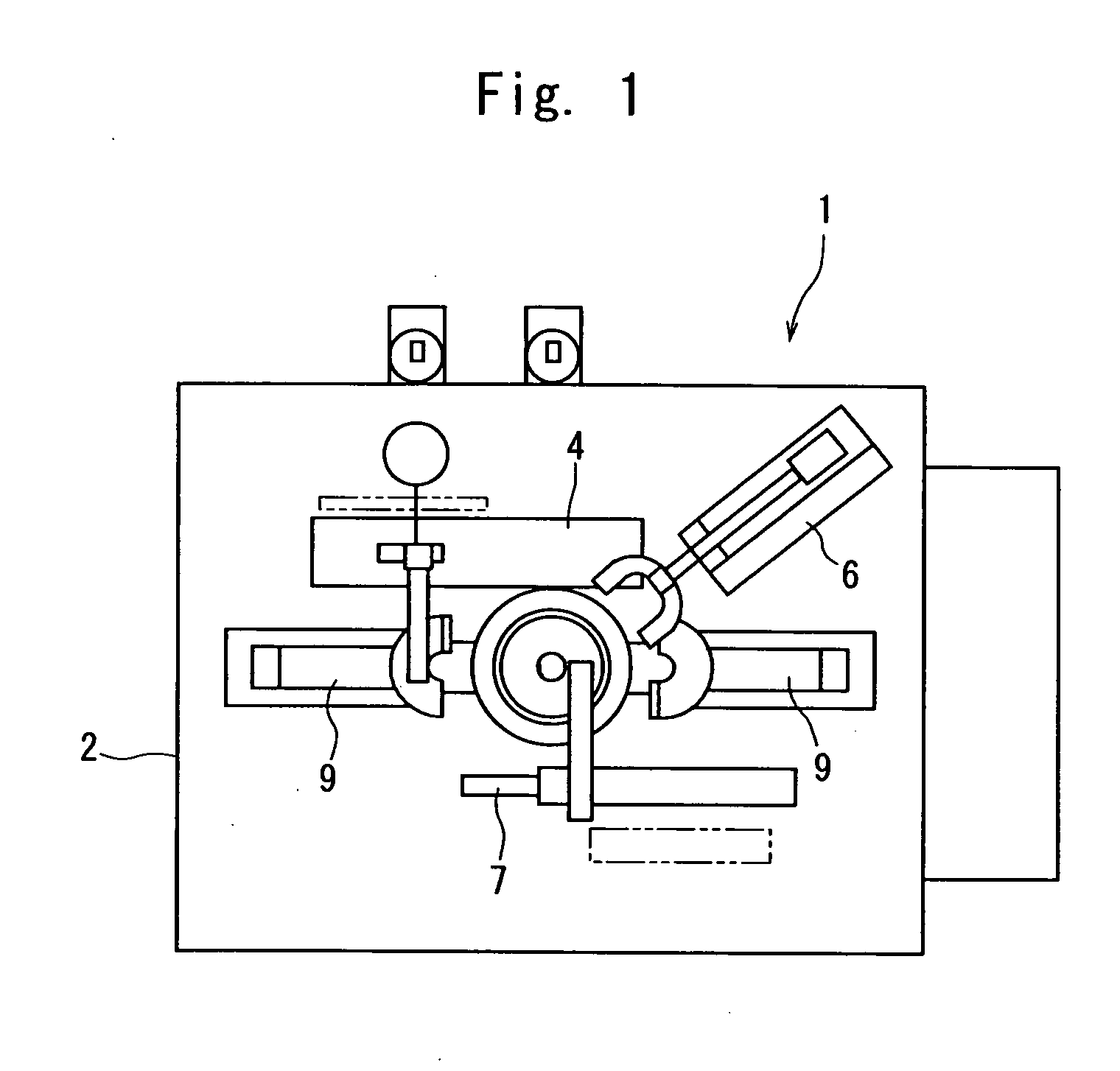

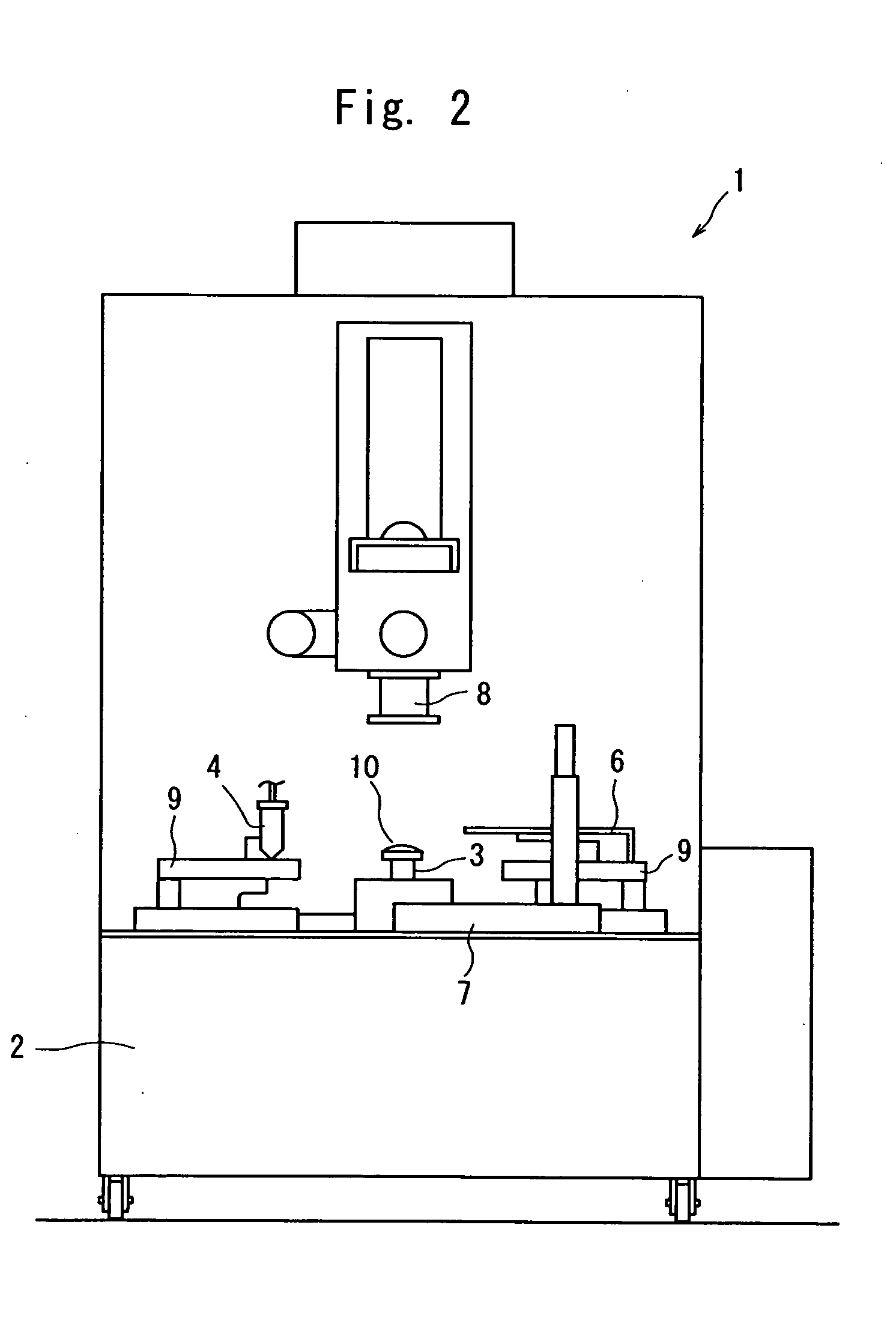

[0042]FIGS. 1 and 2 show a photochromic coating apparatus for coating a photochromic fluid onto a lens under automatic control. The lower side of the photochromic coating apparatus in FIG. 1 is the front side of the apparatus (in the Y-axis direction), and the right-to-left side of the apparatus is in the lateral direction (X-axis direction).

[0043]A photochromic coating apparatus 1 has a lens support device 3, a coating unit support device 4, a lens height measuring sensor 6, a coating film uniformizing device 7, a UV device 8, and a movable fluid receiving device 9 provided on a base stand 2.

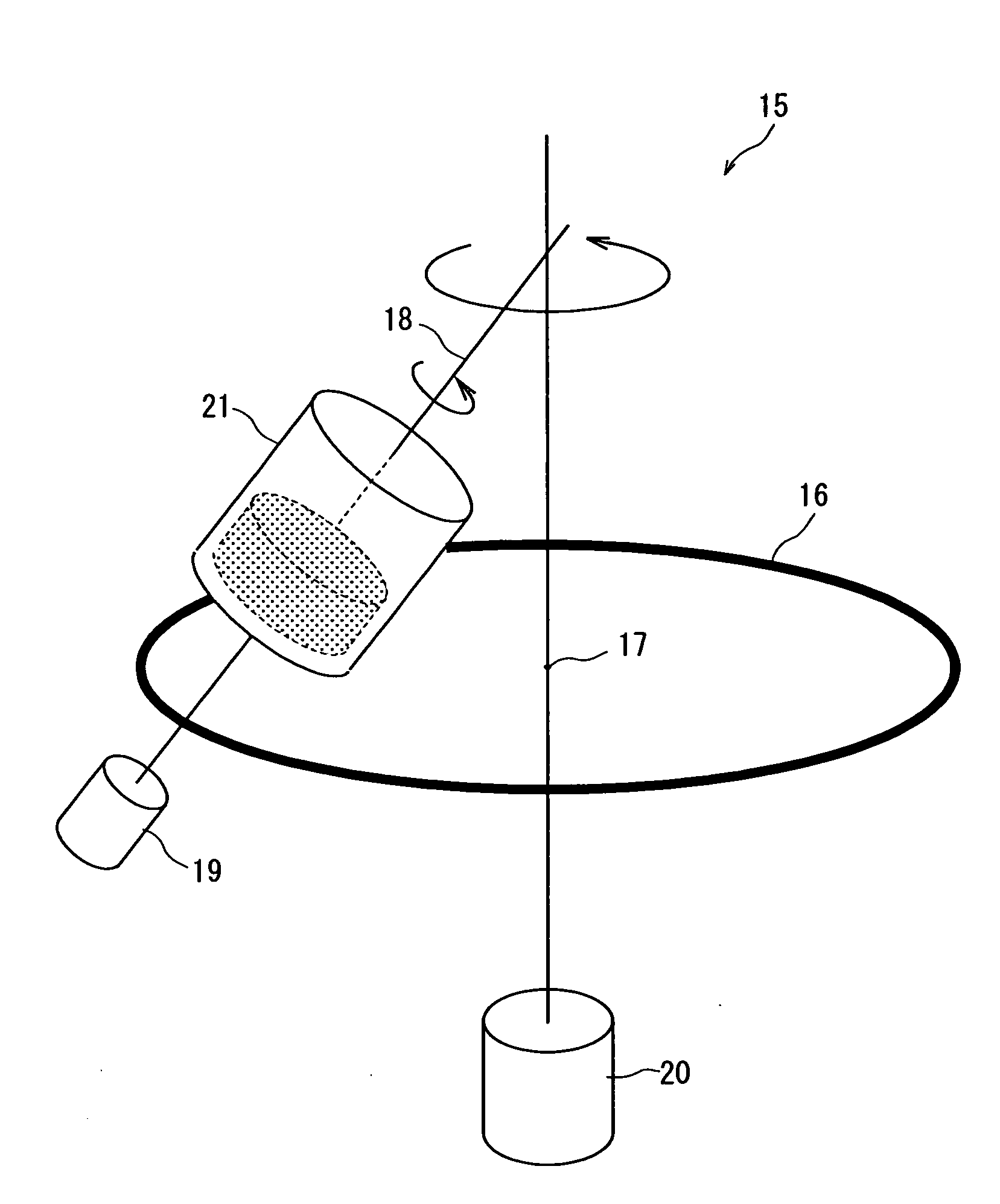

[0044]As shown in FIG. 3, the lens support device 3 is provided in a nearly central portion of the base stand 2, and has a circular pedestal 31 formed to protrude upward from the base stand 2. A guide member 32 is provided

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Photochromic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap