Electric vehicle wheel assembly capable of recycling road surface excitation energy

A technology for wheel components and excitation energy, which is applied to wheels, vehicle parts, engine components, etc., can solve problems such as increased work intensity, waste of resources and energy, damage to wheel parts, etc., to reduce work intensity, reduce oil loss, prevent The effect of reflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

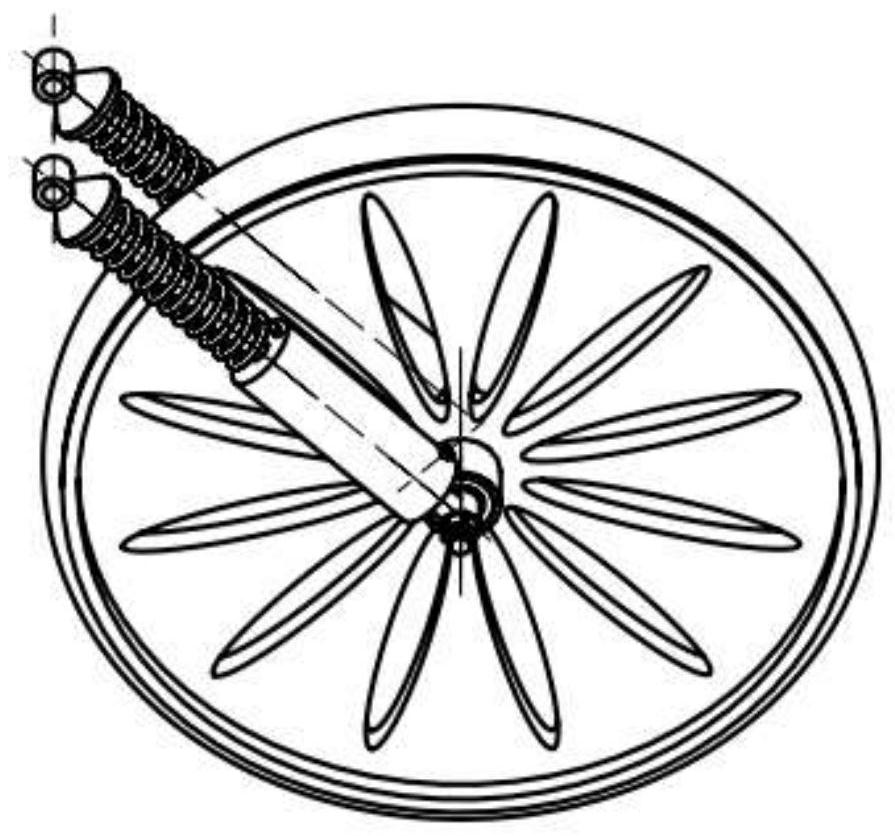

[0030] From figure 1 , figure 2 , Figure 9 It can be seen that a kind of electric vehicle wheel assembly of the present invention can reclaim road surface excitation energy, it comprises wheel 14, transmission part, two front and rear damping parts; The front and rear shock-absorbing components are located at the front and rear ends of the wheel 14; the shock-absorbing component is provided with a lubricating oil passage I, and the transmission part is provided with a lubricating oil passage II, and the two are connected.

[0031] The working principle of the electric vehicle wheel assembly of the present invention is: when the electric vehicle is running on an uneven road surface, the excitation energy of the uneven road surface causes the lubricating oil in the shock absorbing part to reach the transmission part through the lubricating oil passage I and the lubricating oil passage II, Lubricate the bearings in the transmission components. Therefore, the electric vehicle...

Embodiment 2

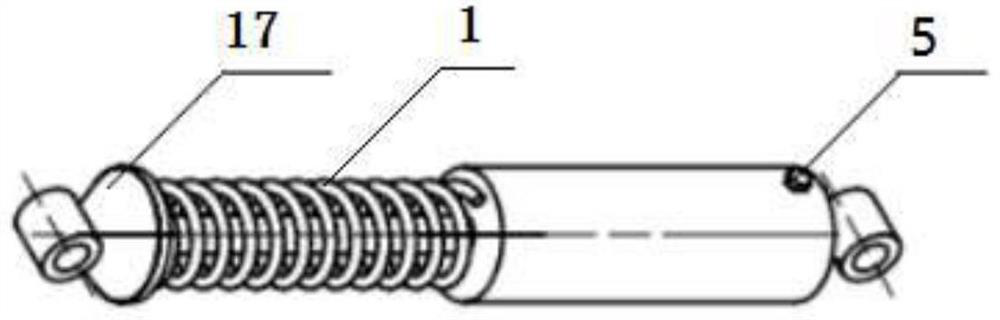

[0033] From figure 1 , figure 2 , image 3 , Figure 4 It can be seen that the electric vehicle wheel assembly of the present invention: each damping component includes a spring 1, a hydraulic cylinder 3, a piston 4, a piston rod 15, a check valve 2, and a shaft sleeve 16; The piston 4 is set in the hydraulic cylinder 3, the check valve 2 is connected to the bottom of the hydraulic cylinder 3, and the sleeve 16 is fixed on the lower part of the check valve 2; the oil inlet of the check valve 2 is connected to the bottom of the hydraulic cylinder 3 The oil outlet of the one-way valve 2 and the oil outlet of the one-way valve 2 are connected to the radial oil hole of the shaft sleeve 16; the hydraulic cylinder 3, the one-way valve 2, and the radial oil hole of the shaft sleeve 16 constitute the lubricating oil circuit of the shock-absorbing component I.

[0034] From figure 1 , figure 2 , image 3 It can be seen that each shock absorbing part also includes a gland 17, t...

Embodiment 3

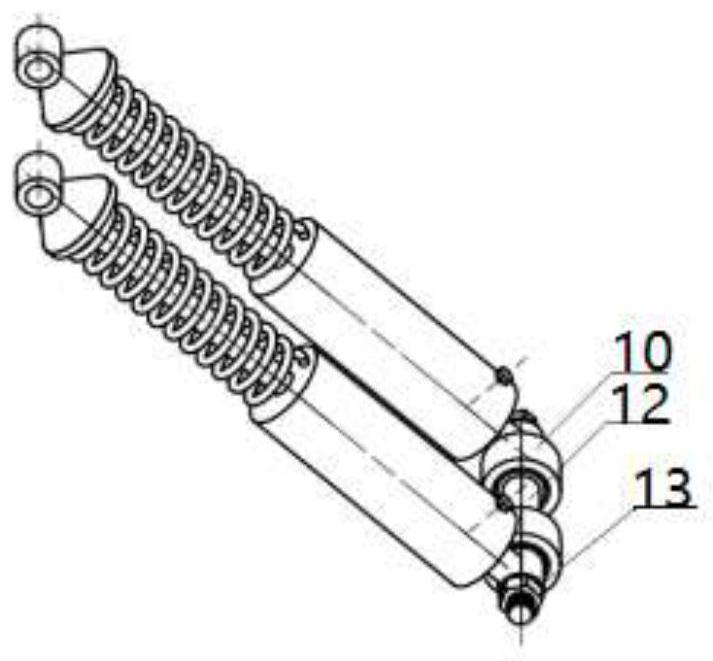

[0040] From figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 , Figure 8 It can be seen that the electric vehicle wheel assembly of the present invention: the transmission part includes the wheel shaft 6, the bushing 12, two front and rear ball bearings 10, and a nut 13; the wheel shaft 6 passes through the front and rear two bushings 16 and is locked by the nut 13, Two front and rear ball bearings 10 are arranged in the radial direction of both the wheel shaft 6 and the wheel 14, and the bushing 12 is sleeved on the middle section of the wheel shaft 6 to axially position the ball bearings 10; The axle lubricating oil passage and the ball bearing 10 are provided with a bearing oil inlet 11, the wheel axle lubricating oil passage and the bearing oil inlet 11 form the lubricating oil passage II on the transmission part, and the oil inlet holes of the wheel axle lubricating oil passage are respectively connected to the front and rear The radial oil holes of the shaft...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap