Heating U-shaped tower tube multi-phase-flow boosting turbine motor high-efficiency circulation power generation device

A cycle power generation and multi-phase flow technology, which is applied to steam engine devices, machines/engines, mechanical equipment, etc., can solve the problem that the energy conversion rate cannot reach the optimal state, the ratio of steam flow rate to speed is not uniform, and the utilization rate of steam energy is not uniform, etc. problem, to achieve the effect of high drive energy mechanical shaft power conversion efficiency, large drive energy, and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

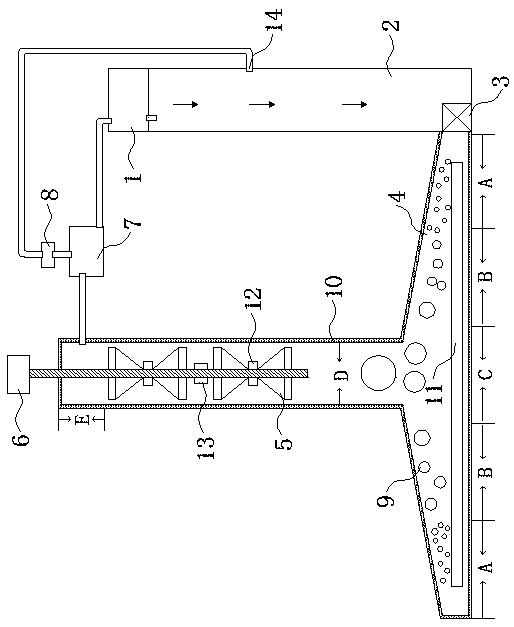

[0014] Such as figure 1 As shown, the heating U-shaped tower tube multiphase flow booster turbine high-efficiency cycle power generation device of the present invention is composed of a cooler 1, a cooling tower tube 2, a liquid supply booster 3, a heating tower tube 4, and a multi-stage multi-stage turbine unit 5. A generator 6, a gas-liquid separator 7 and an exhaust converter 8 are formed. The cooler 1 is connected to the cooling tower pipe 2, and low-temperature water is injected into the cooling tower pipe 2. The cooling tower pipe 2 is provided with a gas inlet 14, Inject dissolved gas into the cooling tower tube 2 through the gas inlet 14 to dissolve and form saturated dissolved gas water. The heating tower tube 4 is composed of a chassis 9 and a vertical tower tube 10. The heating chassis 9 is a flat plate to increase the heat exchange area and heat exchange efficiency. , in order to make full use of low-energy density and large-capacity clean energy (solar energy, geo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap