Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Heat transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat transfer is most efficient by convection, then by conduction; radiation is the least efficient and slowest means of heat transfer. Low efficiency of heat transfer means that vacuums make excellent insulation.

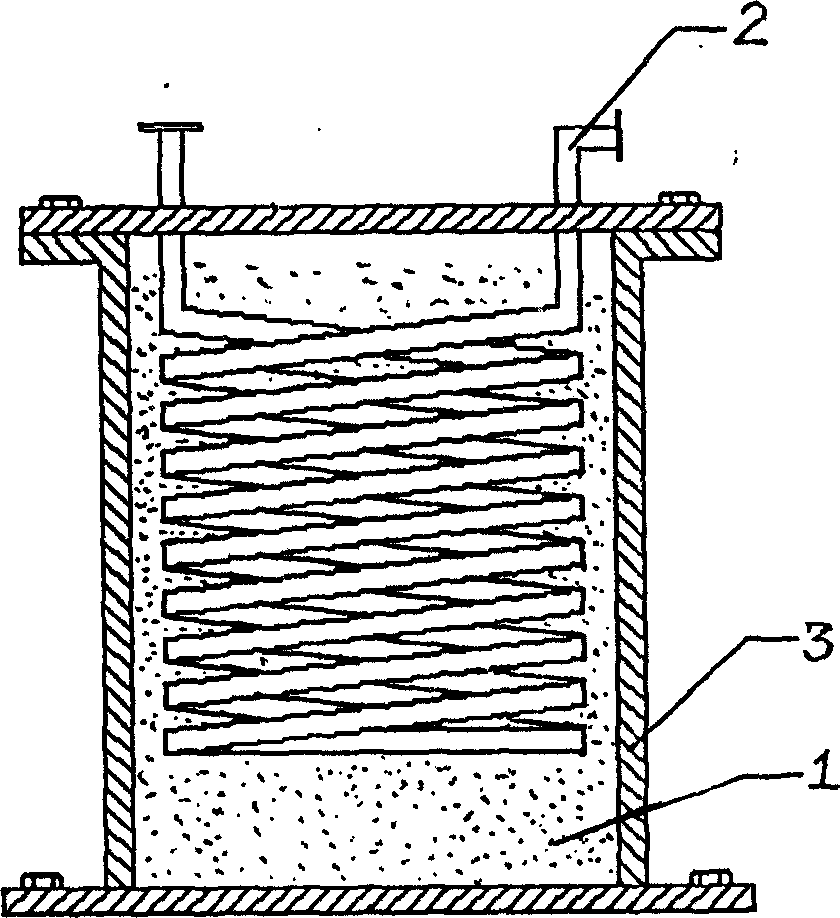

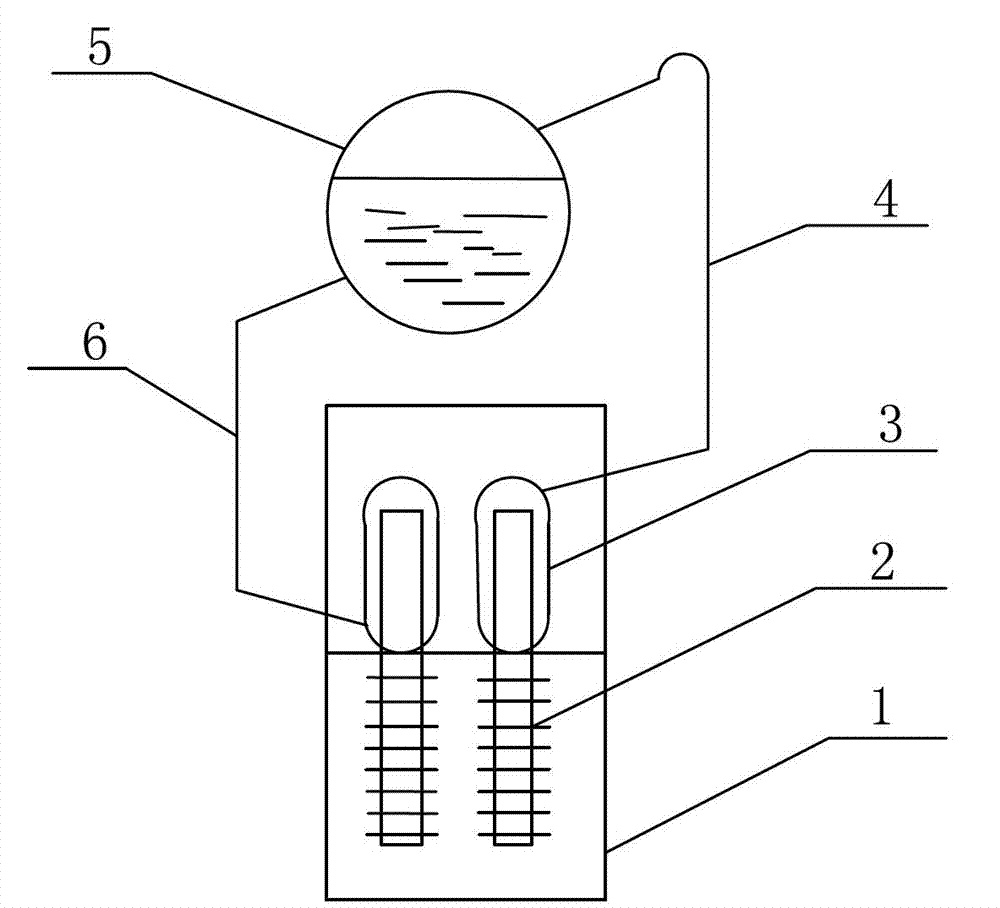

Heat reservoir of heat storage type heat pump air conditioning unit and preparation method for heat storage material thereof

ActiveCN1546927AHeat pumpsHeat storage plantsHeat transfer efficiencyPhase-change material

Owner:武汉长盈通热控技术有限公司

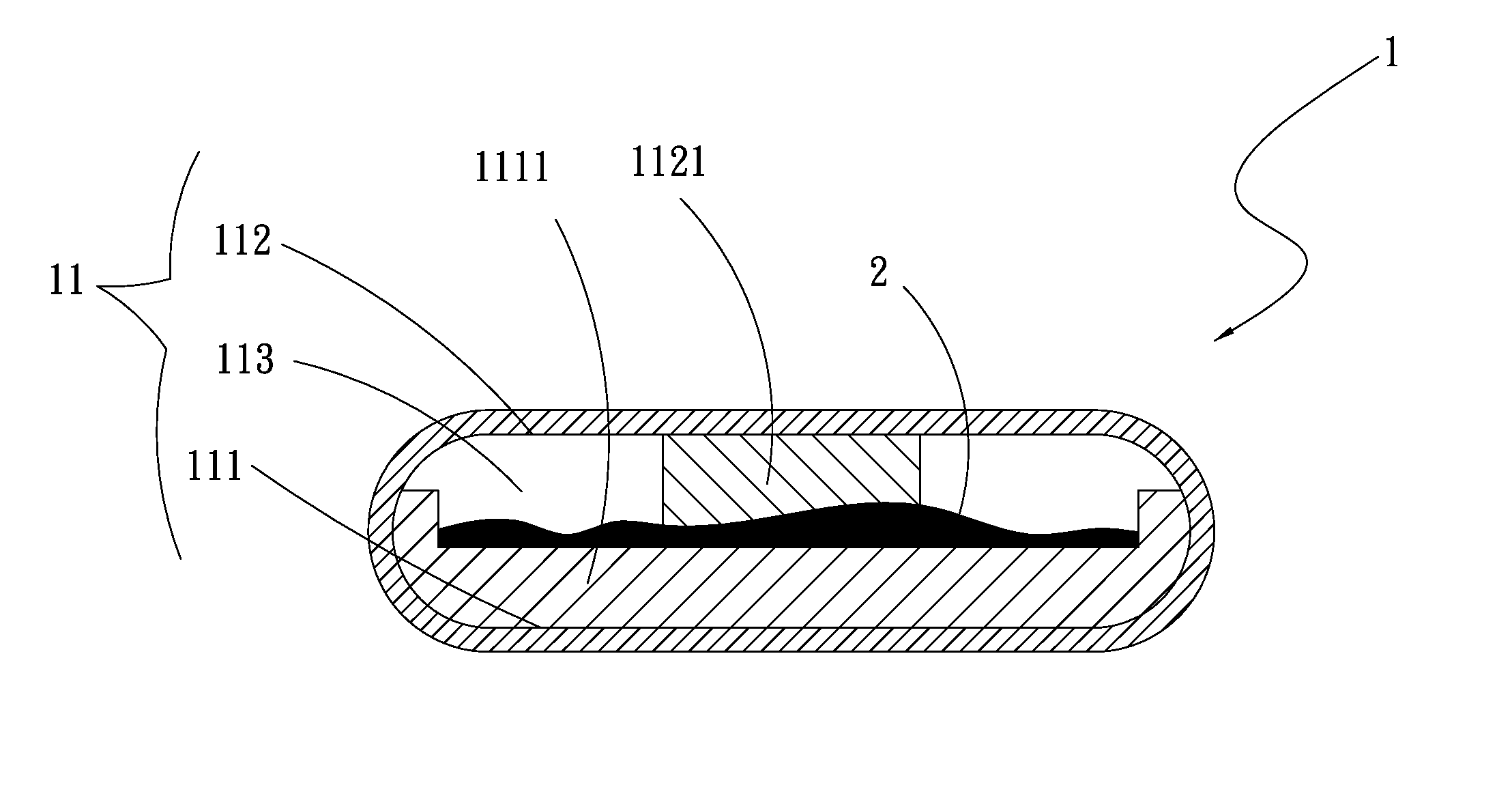

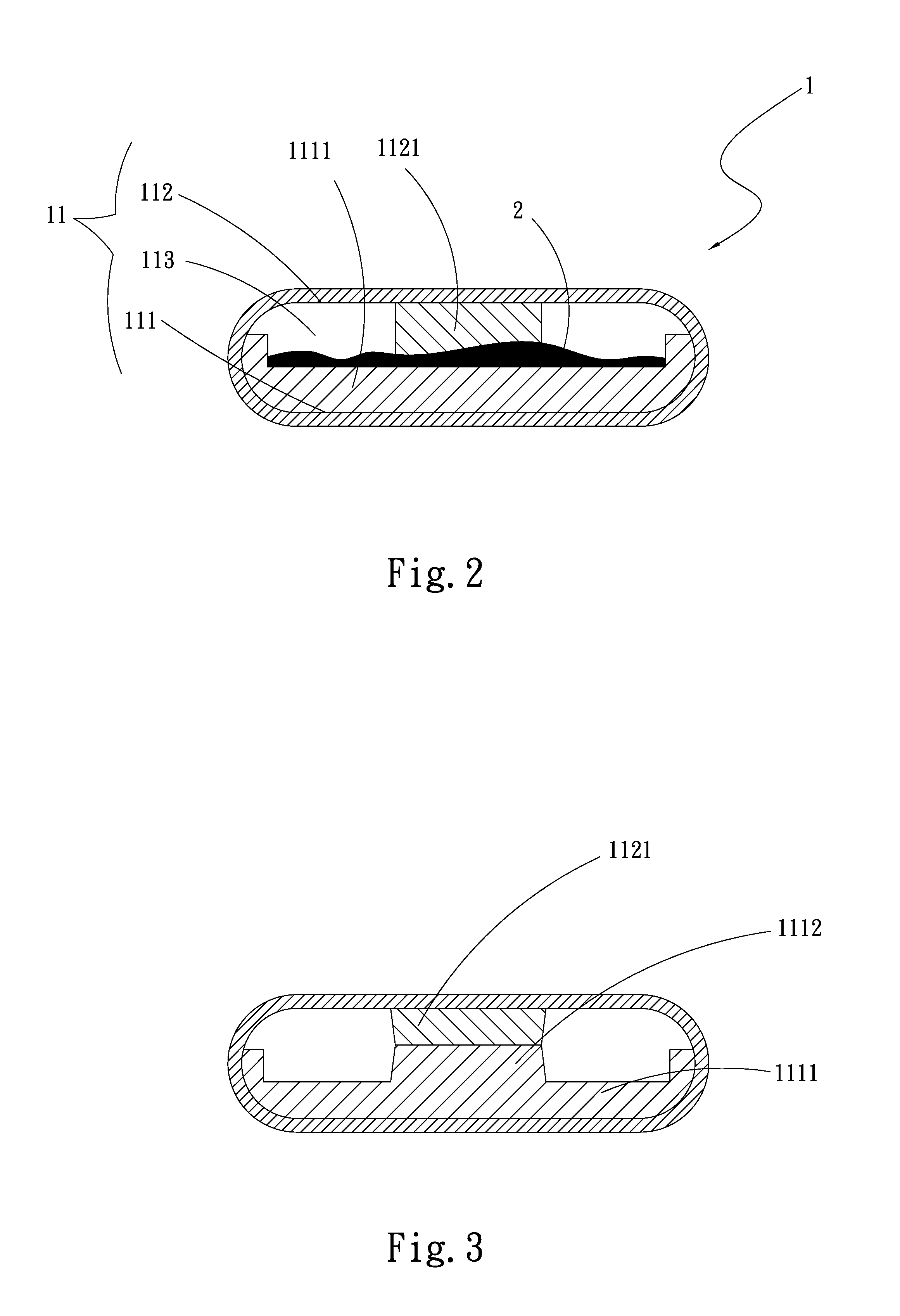

Heat pipe structure

ActiveUS20130213610A1Good heat conduction efficiencyImprove heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidHeat transfer efficiency

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

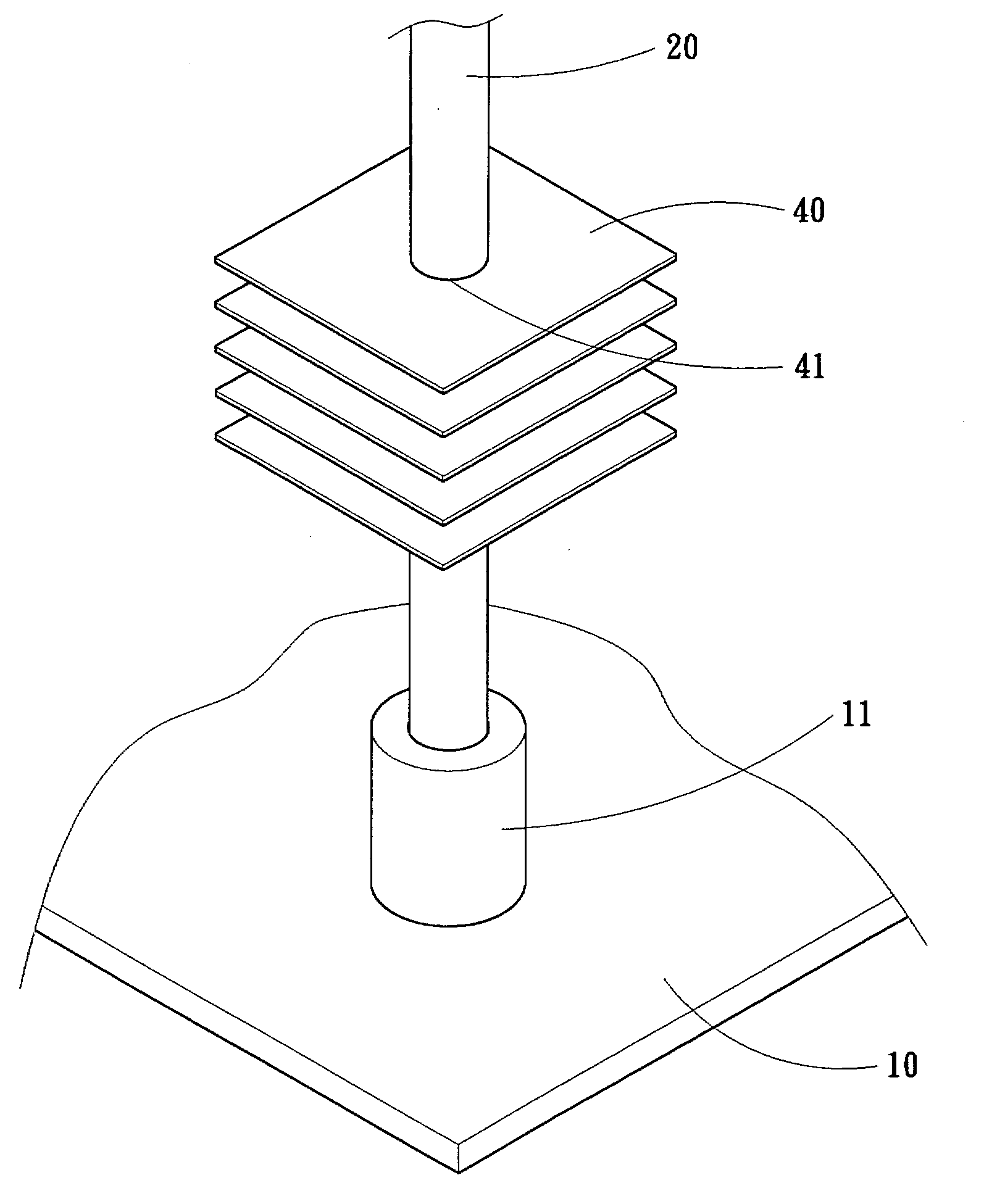

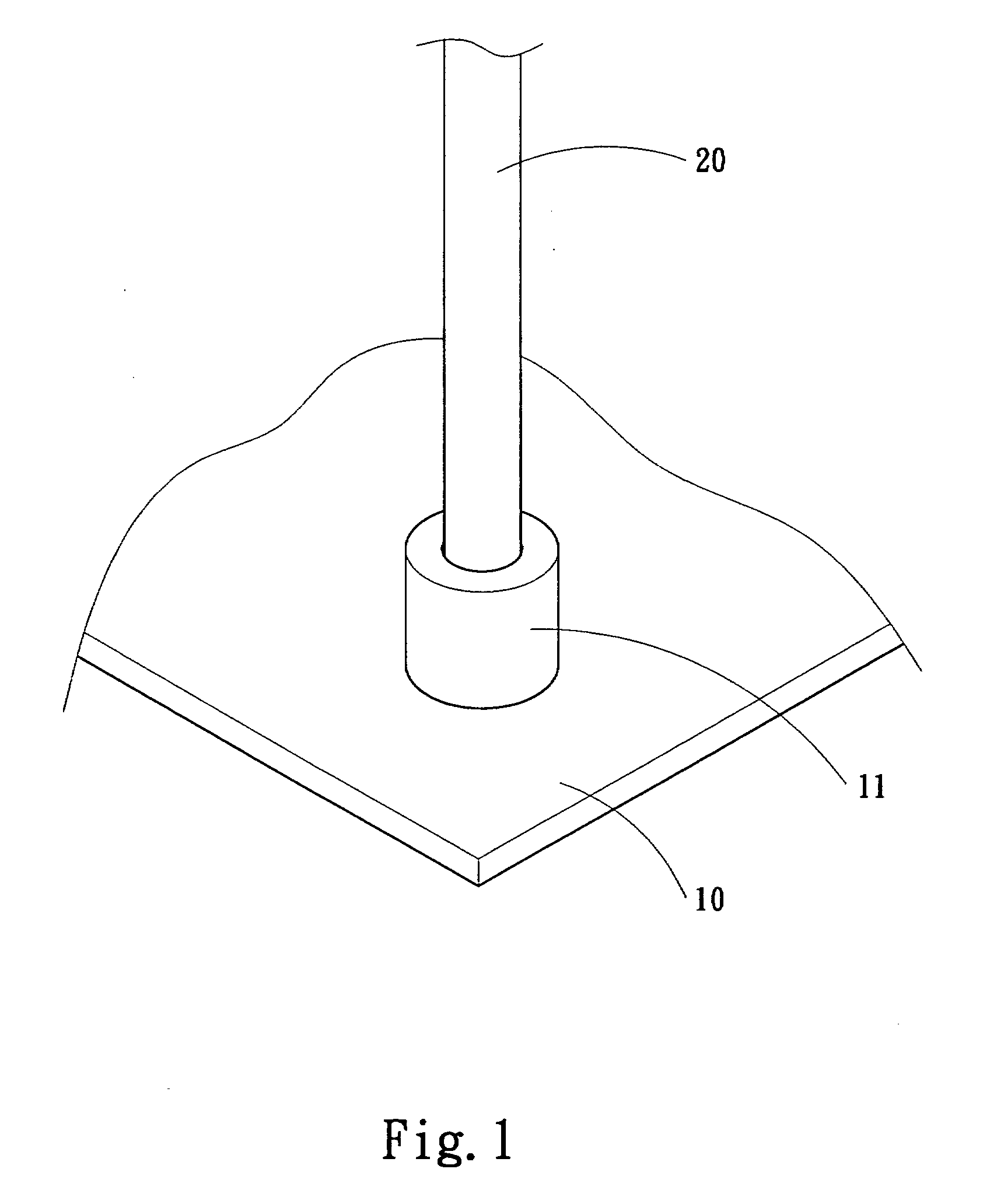

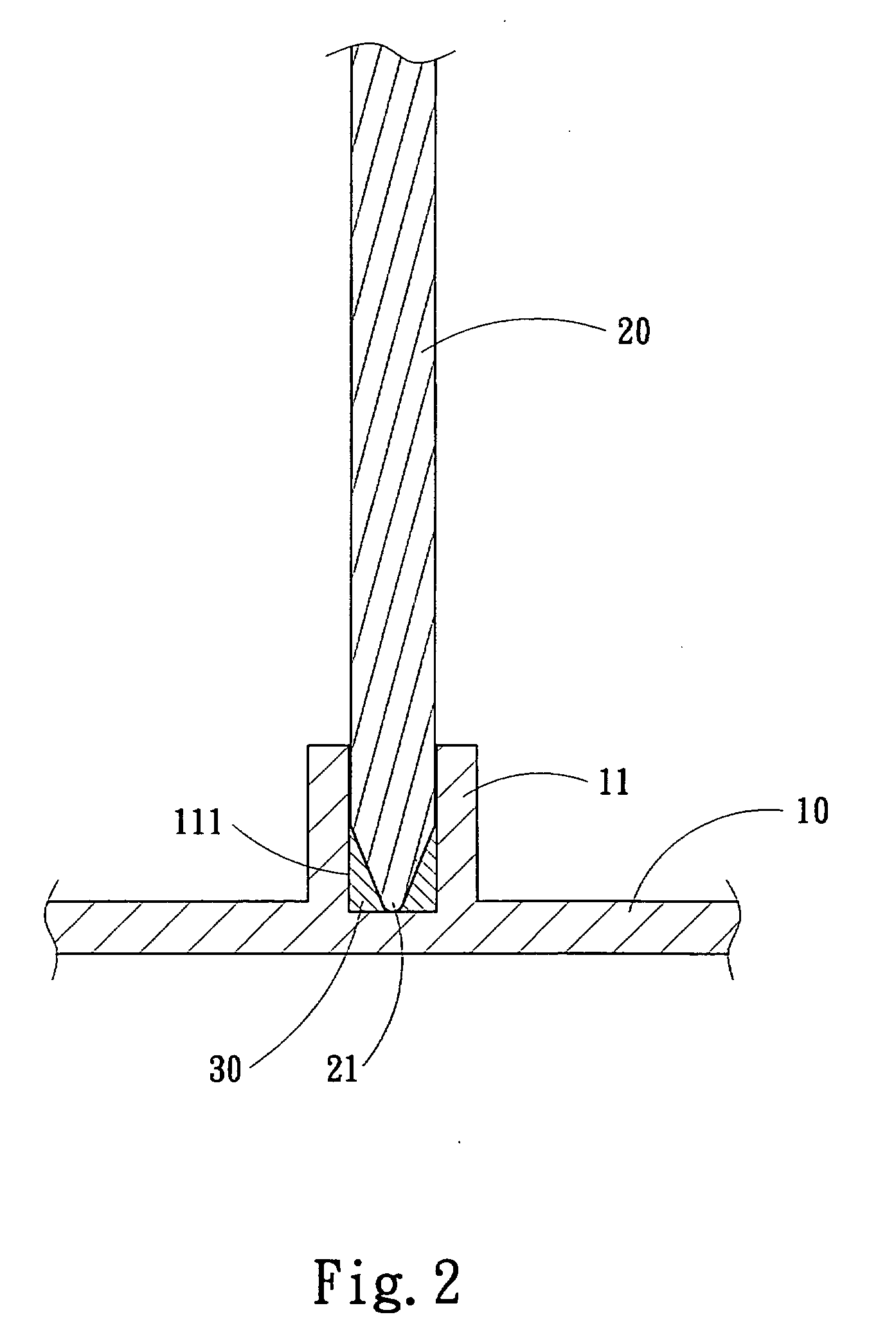

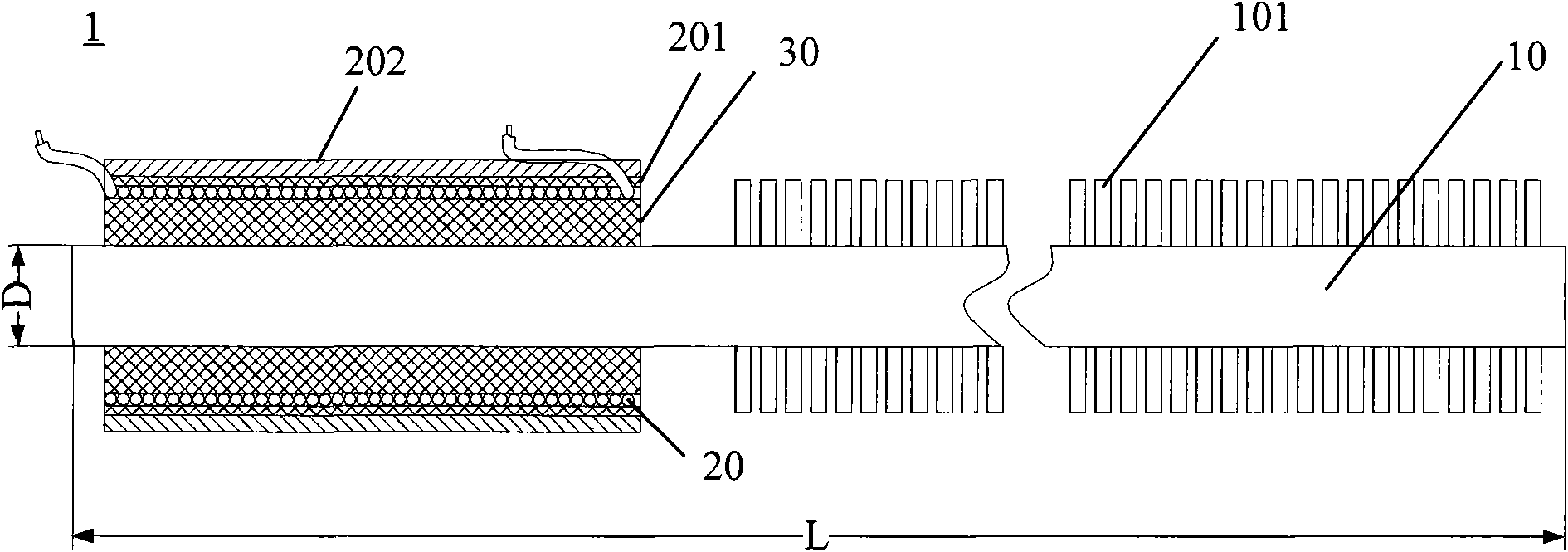

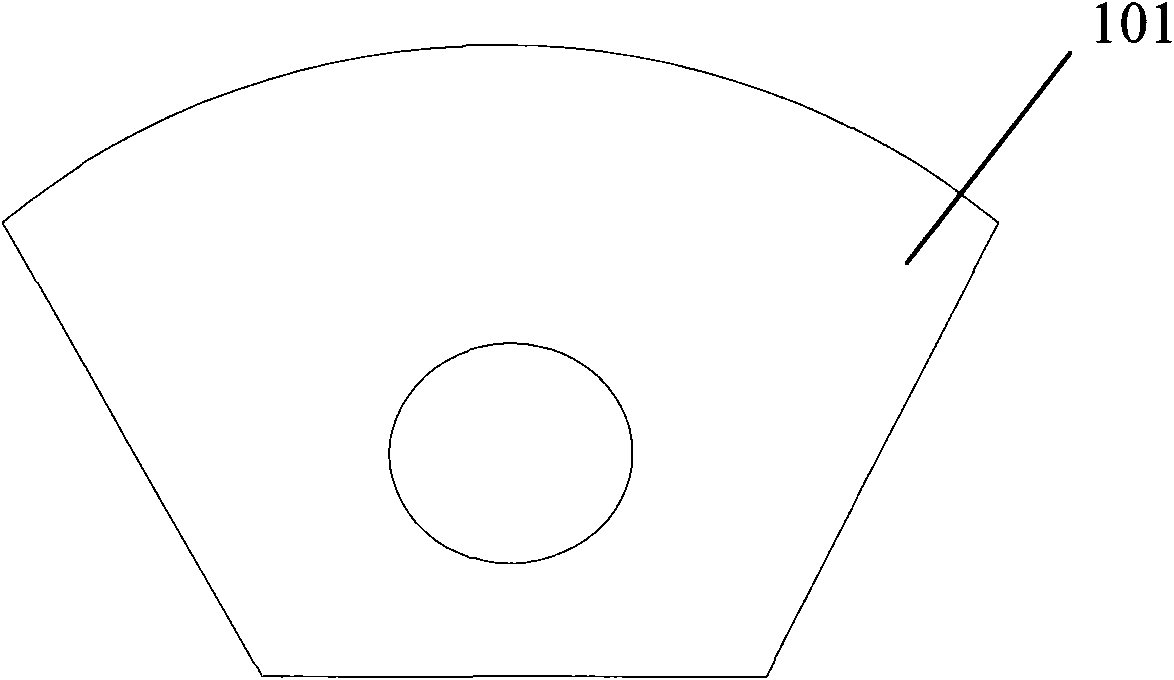

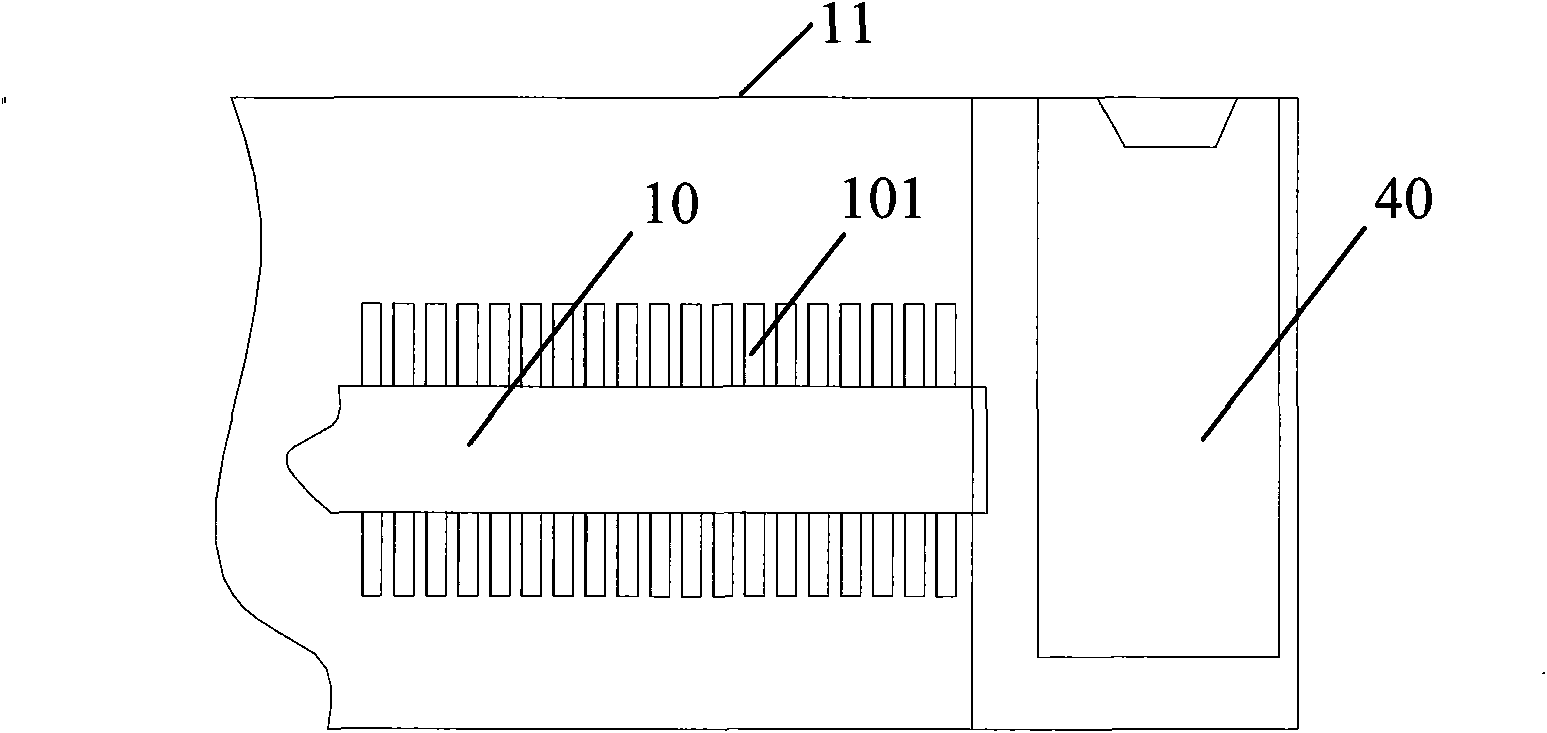

Heat transfer duct fastening structure

InactiveUS20080149307A1Improve cooling efficiencyEfficient heat transferSemiconductor/solid-state device detailsSolid-state devicesHeat transfer efficiencySolder paste

Owner:CHENG HOME ELECTRONICS

Electromagnetic heating warmer

InactiveCN101963371ALighting and heating apparatusElectric heating systemHeat transfer efficiencyEngineering

Owner:卡飒科技(杭州)有限公司

Cracking equipment

PendingCN110578923AIncrease heat transfer areaAvoid direct dischargeIncinerator apparatusCombustionHeat transfer efficiency

Owner:ZHAOYUAN HUICHAO NEW ENERGY TECH CO LTD

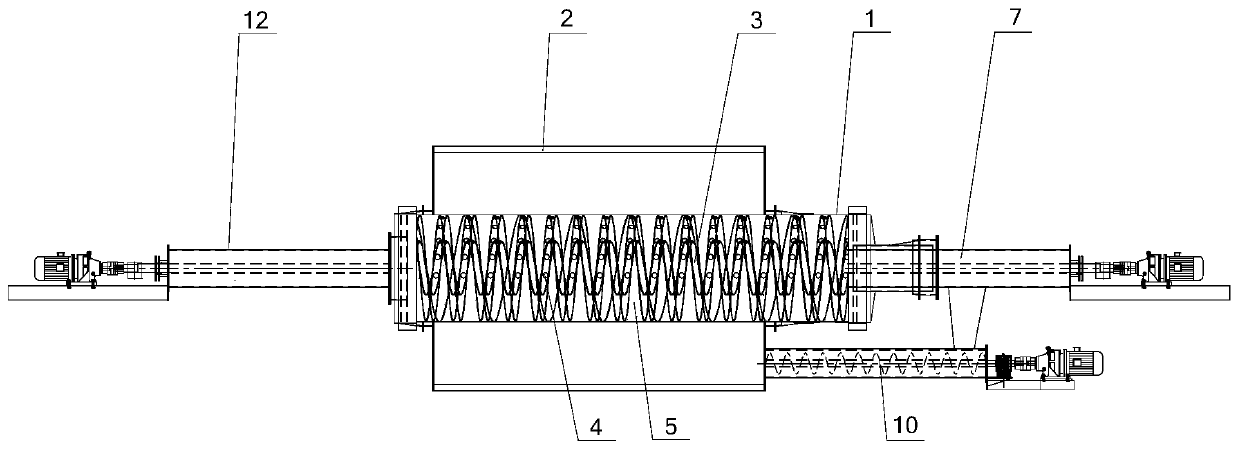

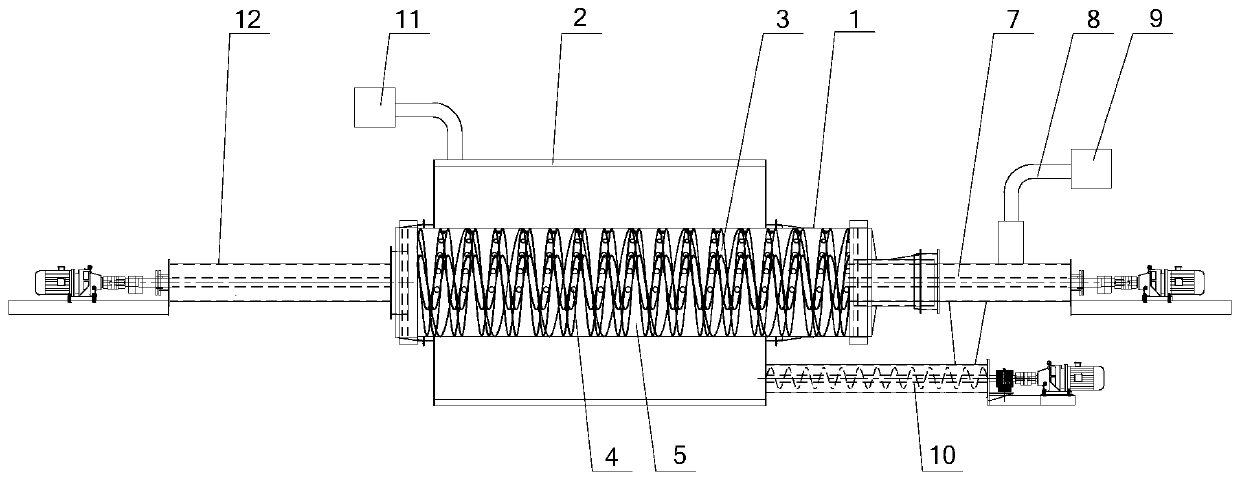

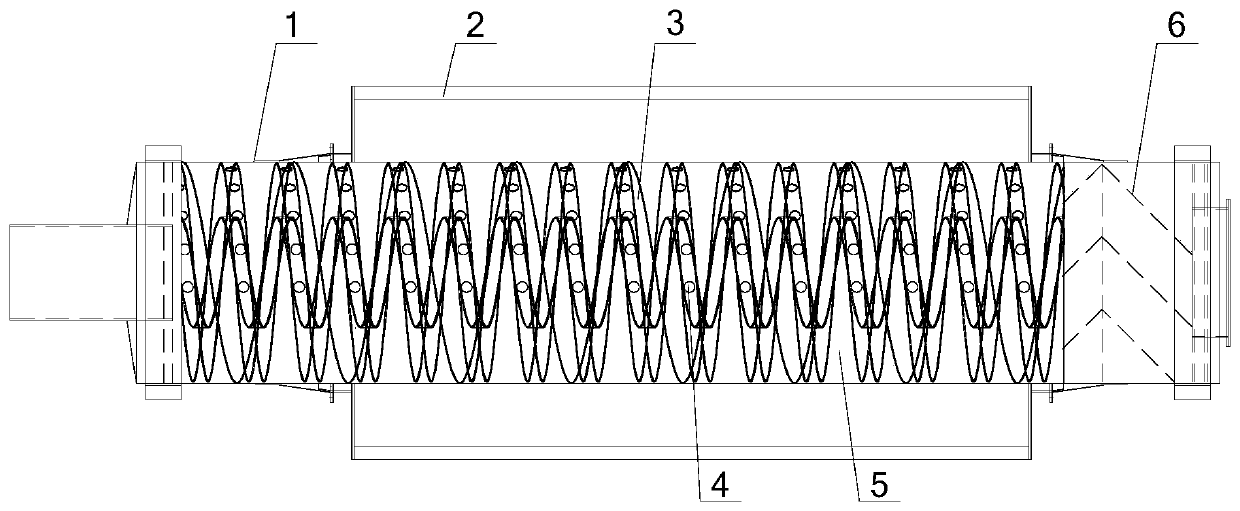

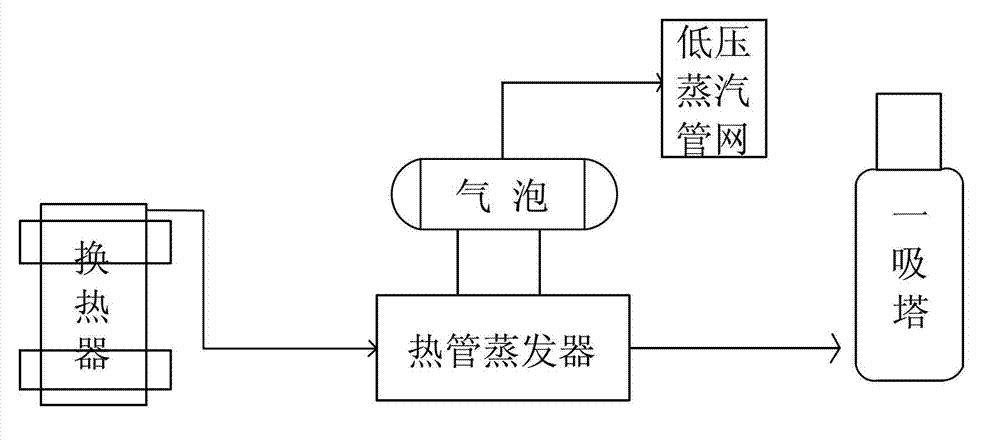

Device for recycling waste heat generated in procedure of acid making and conversion of sulphide ore

Owner:SHANDONG BOFENG LIZHONG CHEM

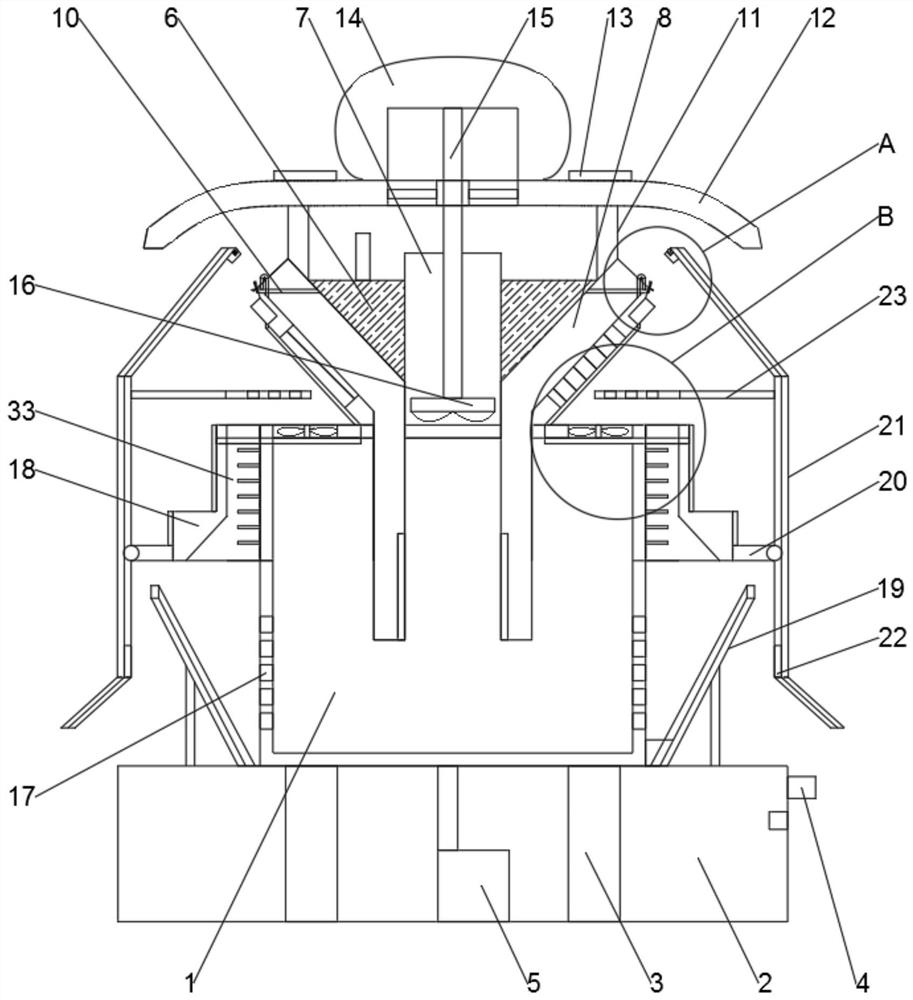

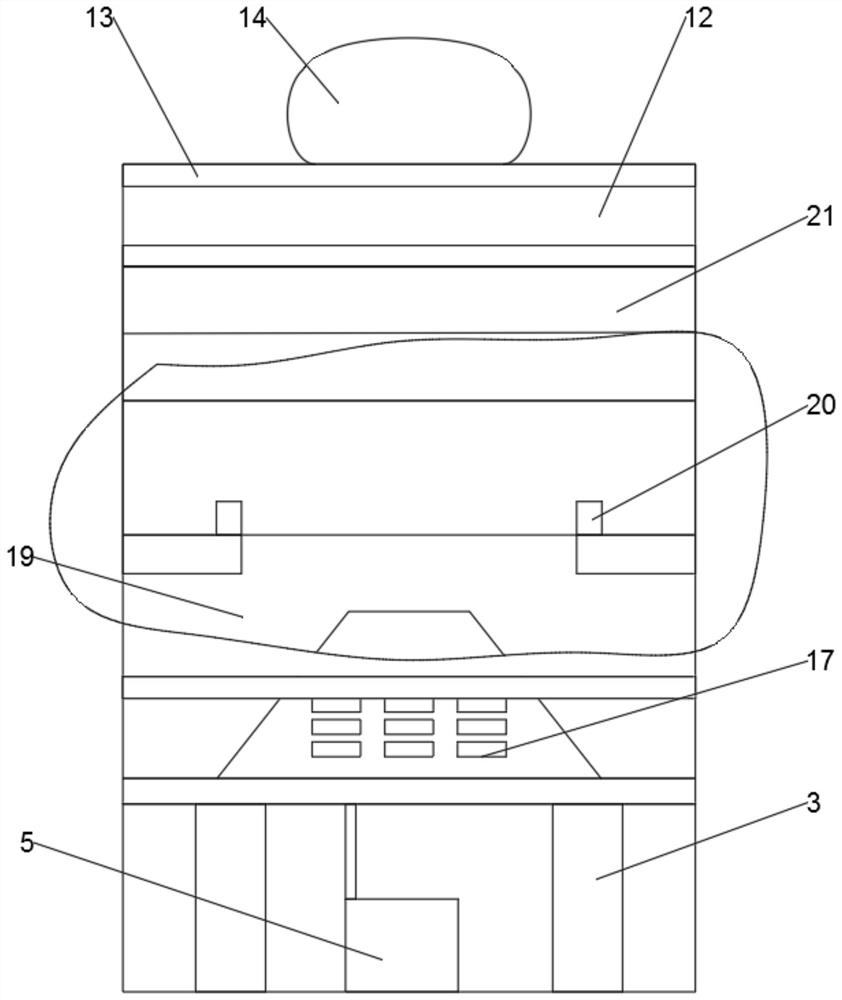

High-heat-dissipation modular transformer substation box body

PendingCN112186567ASubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsHeat transfer efficiencyEngineering

Owner:安徽唐盛电气科技有限公司

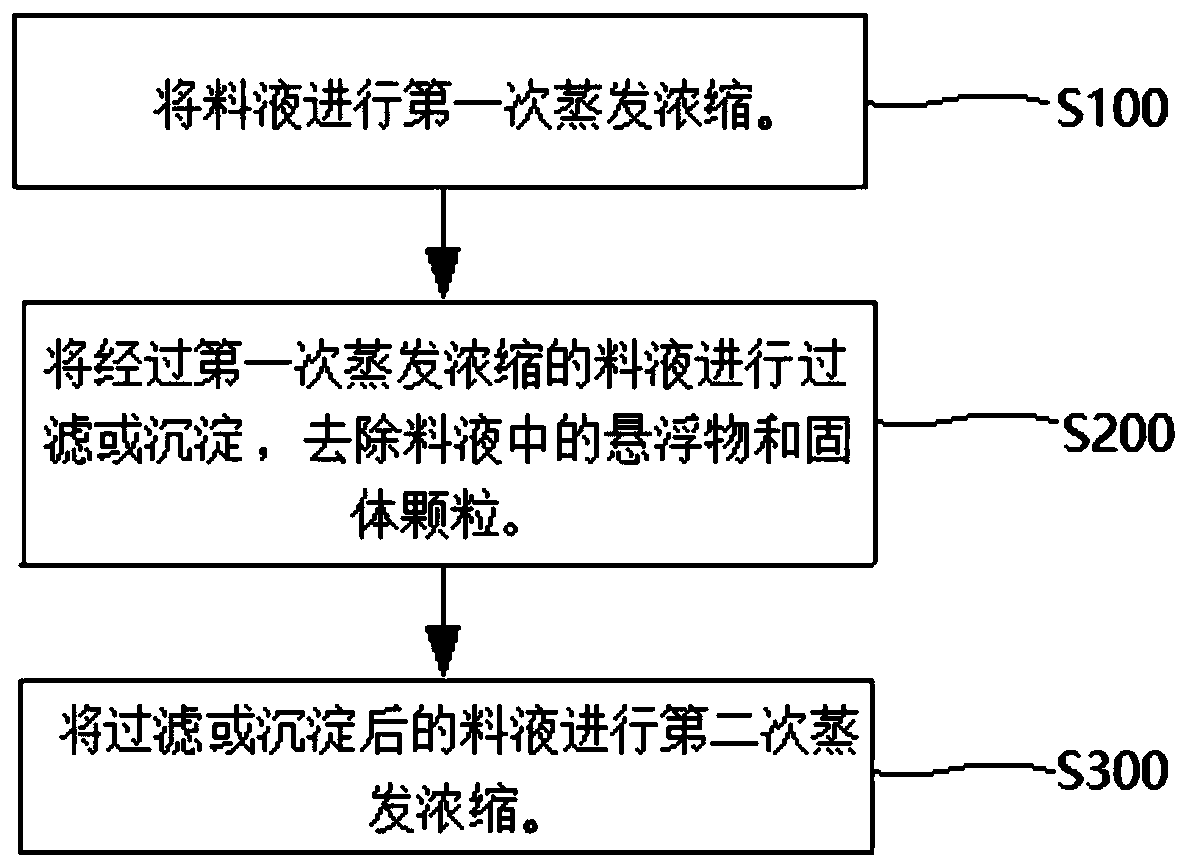

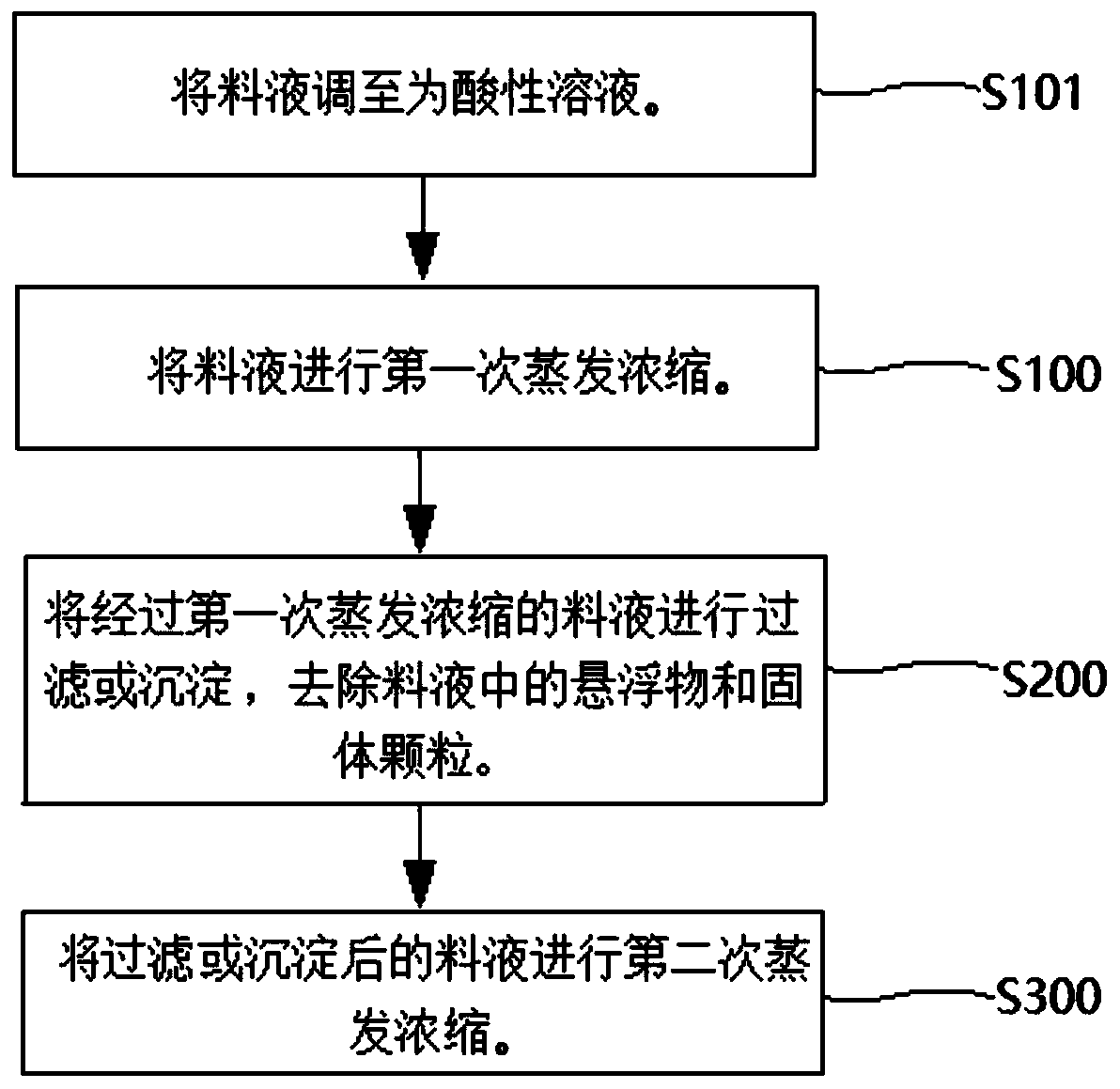

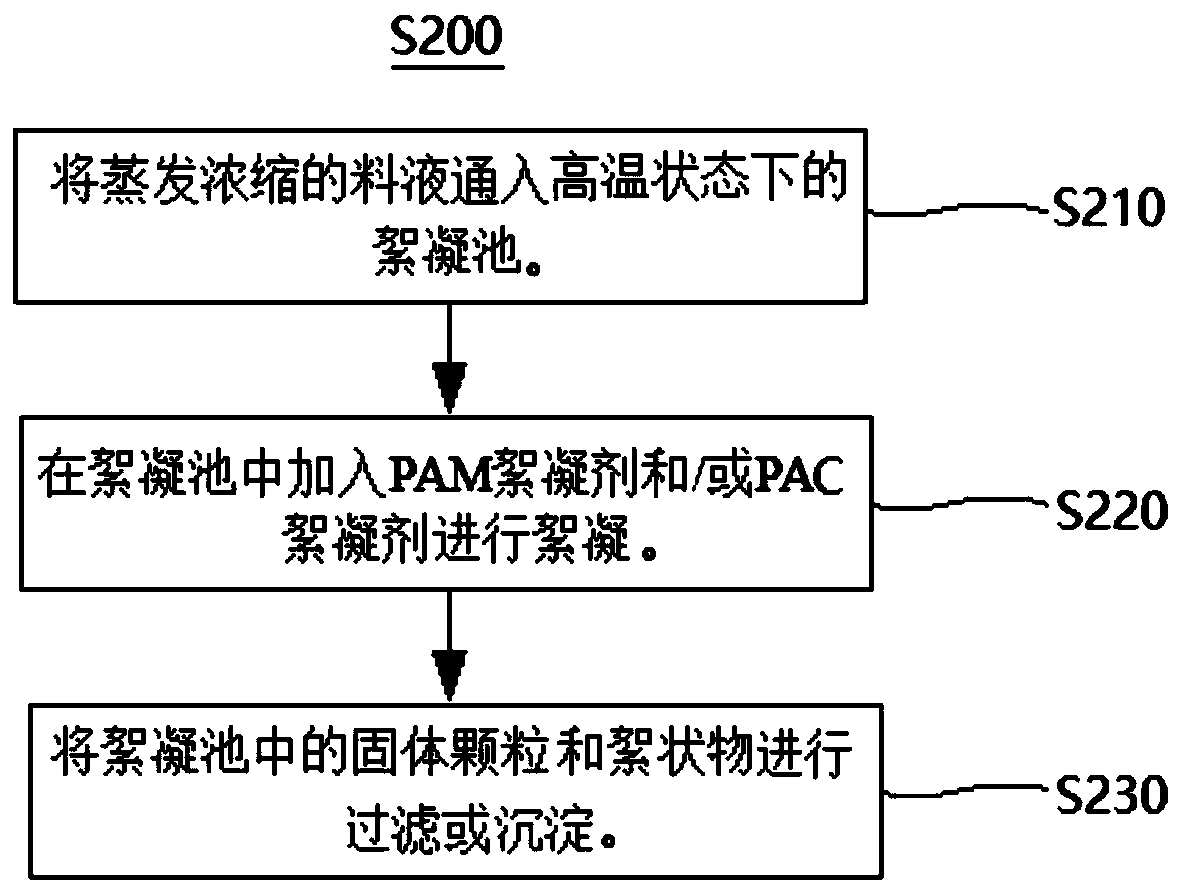

Percolate concentrated solution evaporation and concentration method and system

PendingCN111423047ANo lossAvoid inefficient heat transferTreatment involving filtrationMultistage water/sewage treatmentHeat transfer efficiencySolid particle

The embodiment of the invention provides a percolate concentrated solution evaporation and concentration method and system. The percolate concentrated solution evaporation and concentration method comprises the steps: carrying out primary evaporation and concentration on feed liquid; filtering or precipitating the feed liquid subjected to primary evaporation and concentration to remove suspended matters and solid particles in the feed liquid; and carrying out secondary evaporation and concentration on the filtered or precipitated feed liquid. According to the percolate concentrated solution evaporation and concentration method provided by the invention, the evaporation process of the leachate concentrated solution is divided into two parts; the operation pressure of the equipment is reduced; filtration or precipitation is carried out after the first evaporation and concentration; the reduction of the heat transfer efficiency of equipment caused by inorganic scaling and blockage of organic slime attached to a heat exchanger in the evaporation process of the leachate concentrated solution and unability to function properly are effectively avoided; and the filtering or precipitating process is carried out at high temperature, so that heat loss is avoided, the cleaning period of the equipment is shortened, and meanwhile, the evaporation and concentration continuous efficiency is improved.

Owner:BEIJING TDR ENVIRON TECH CO LTD

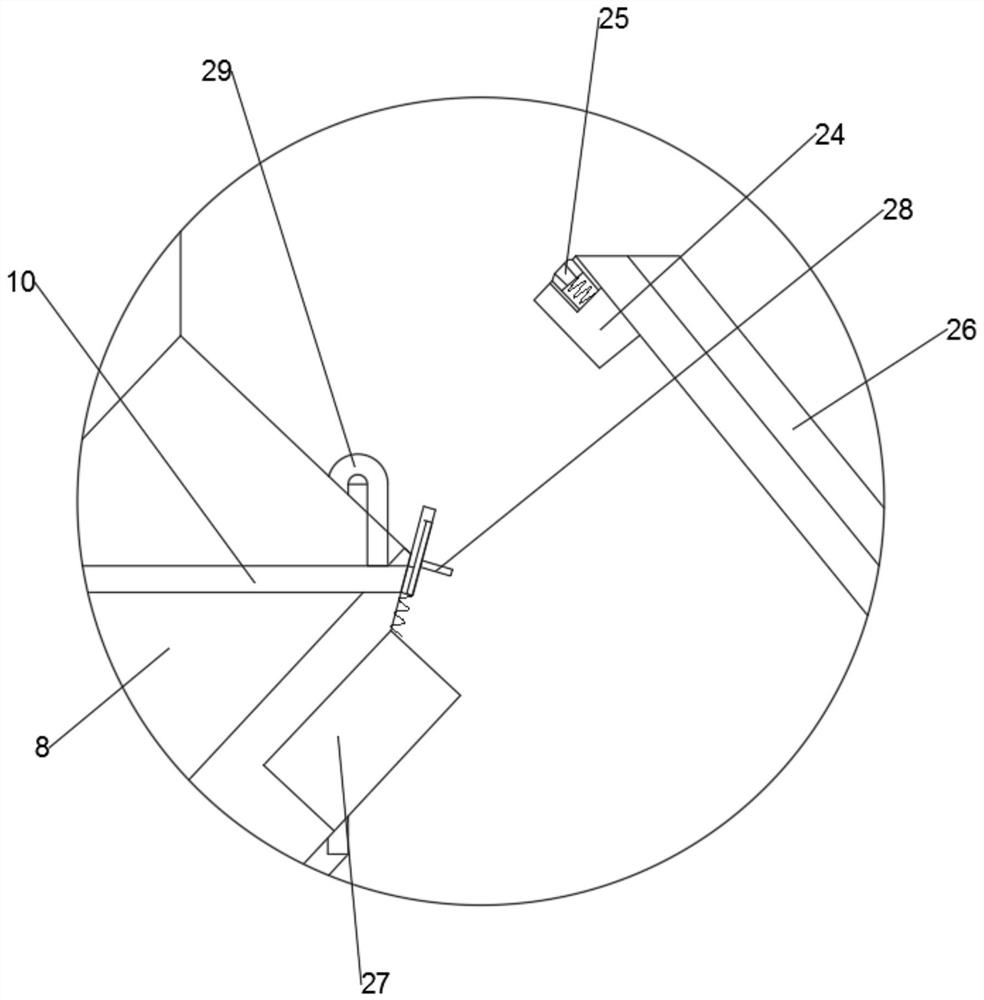

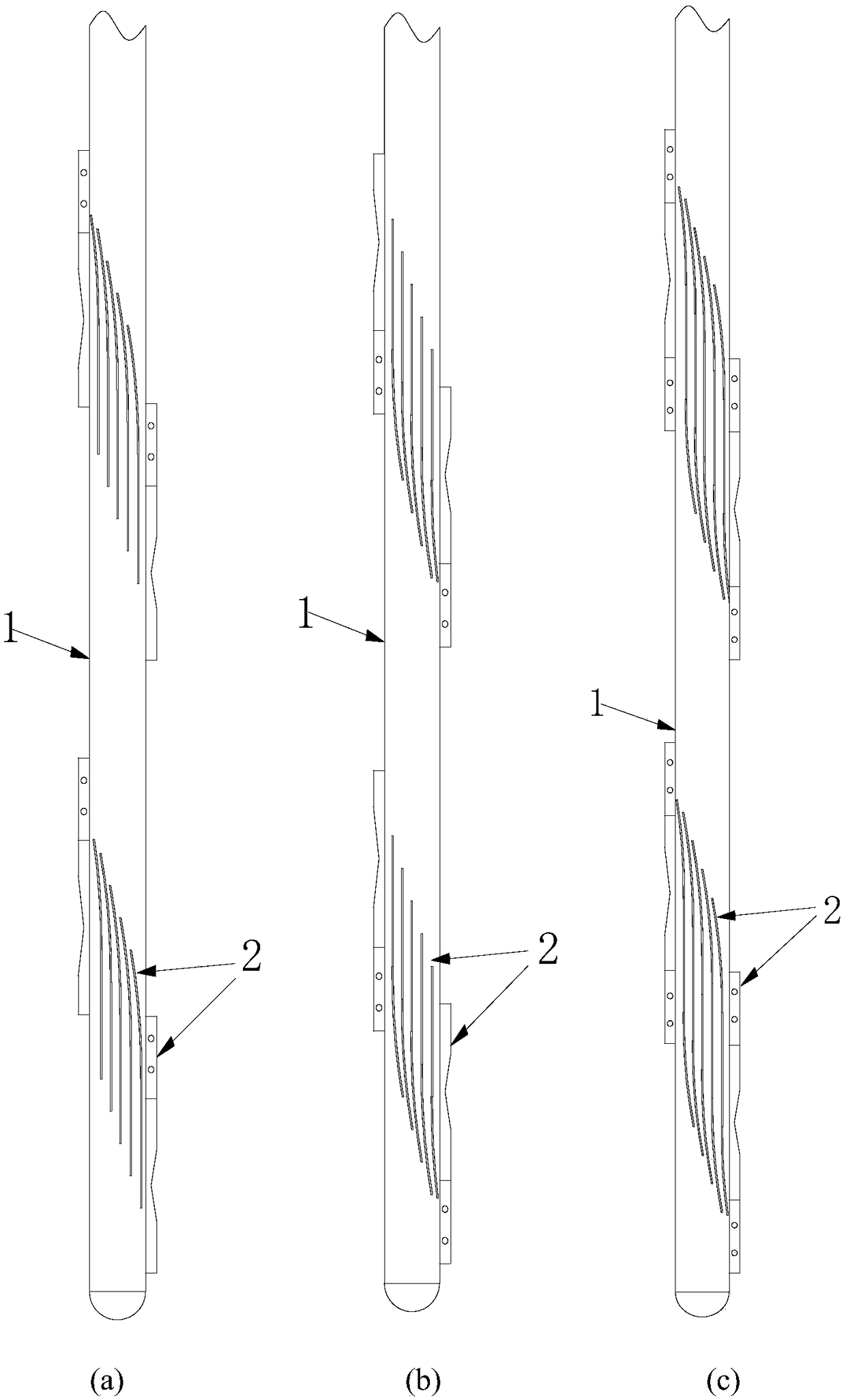

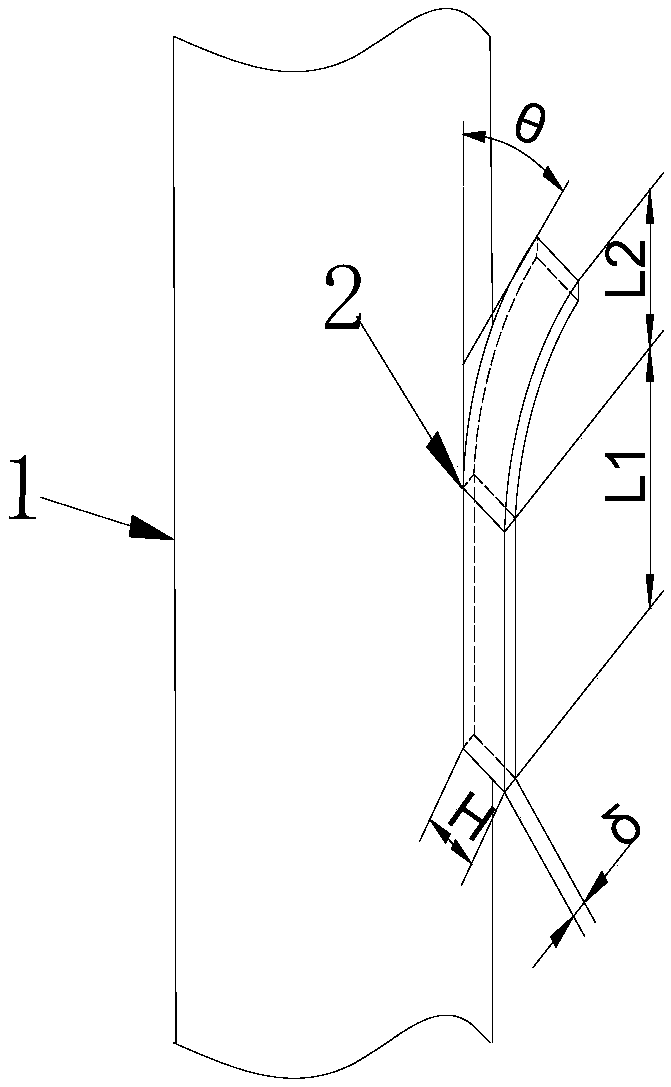

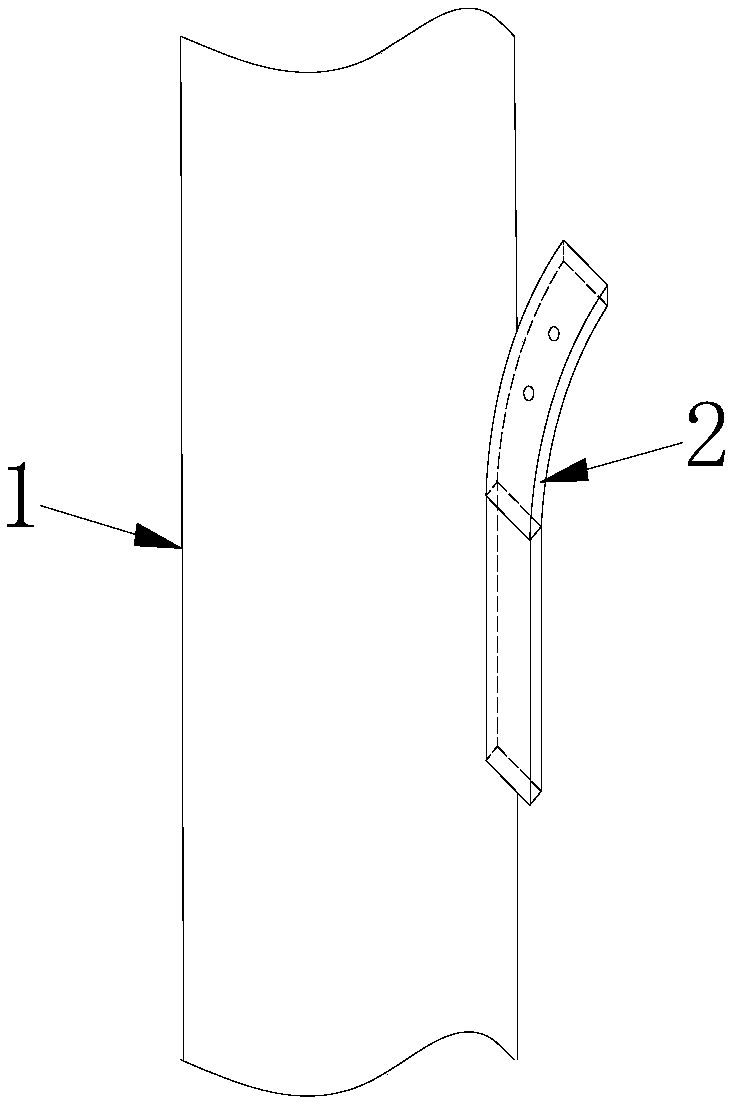

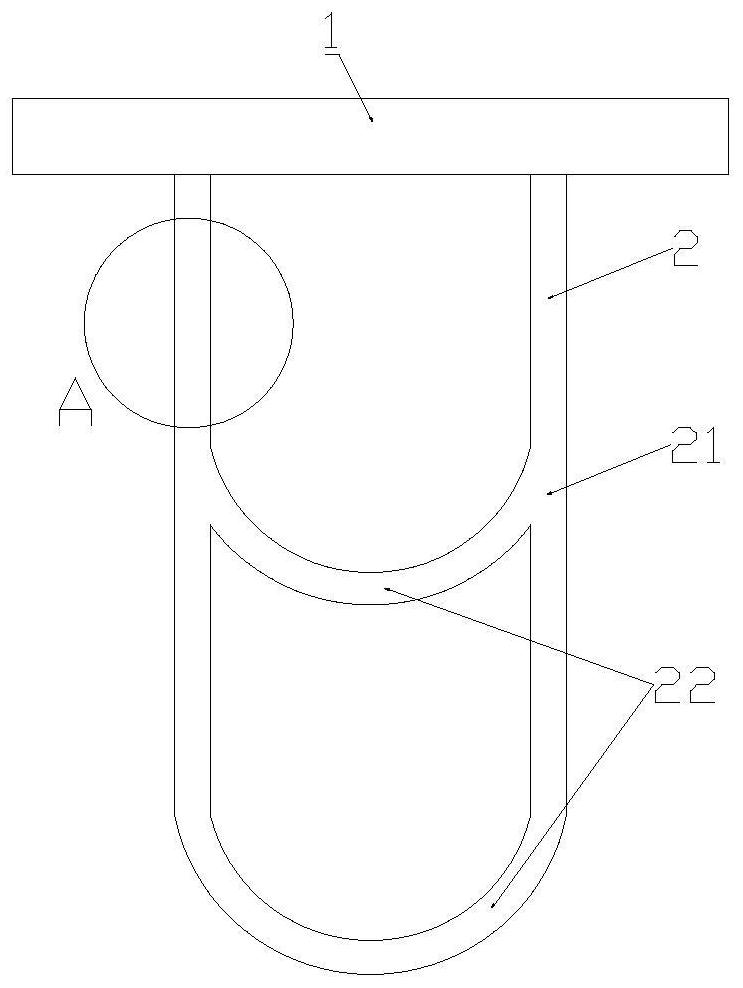

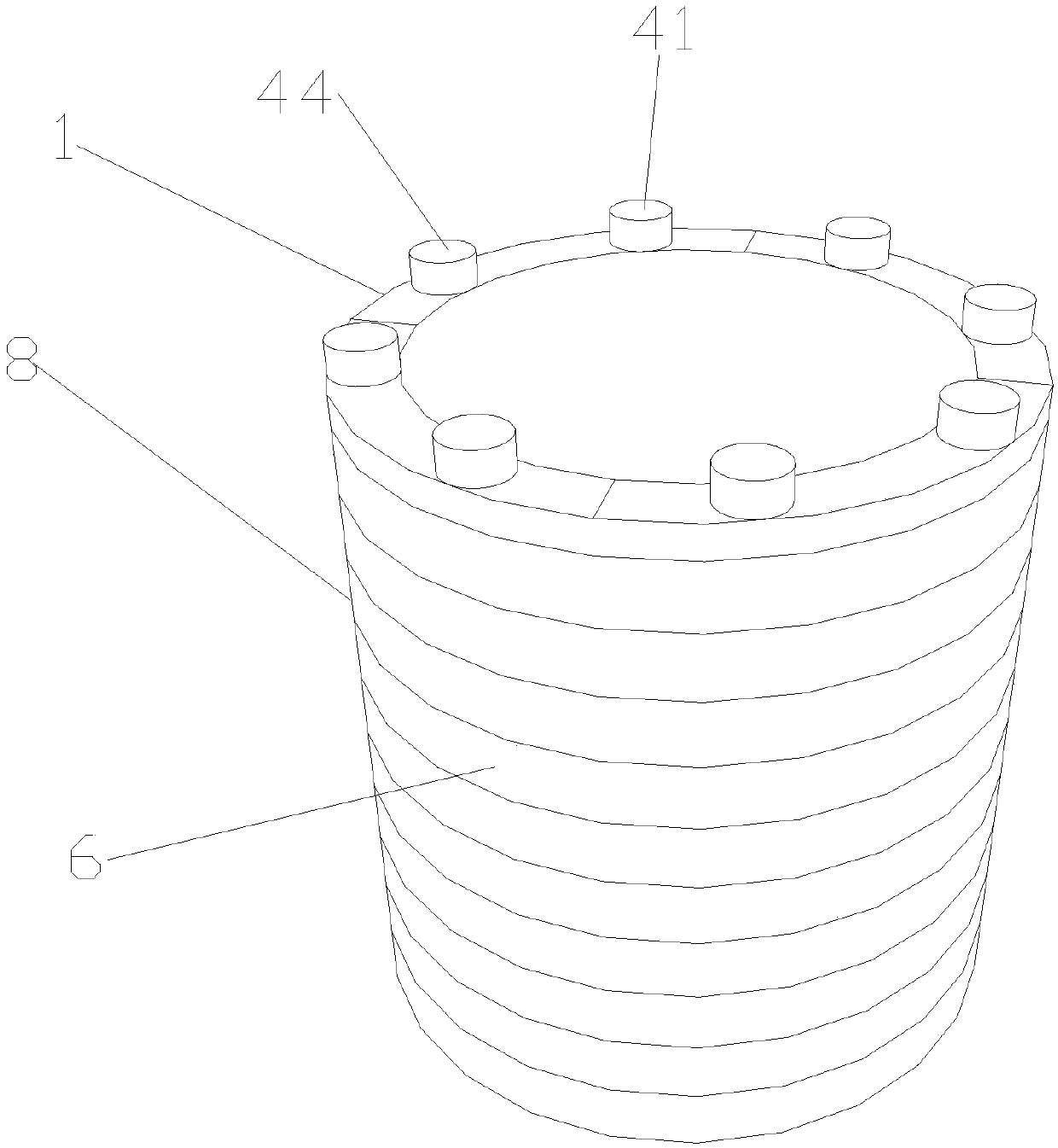

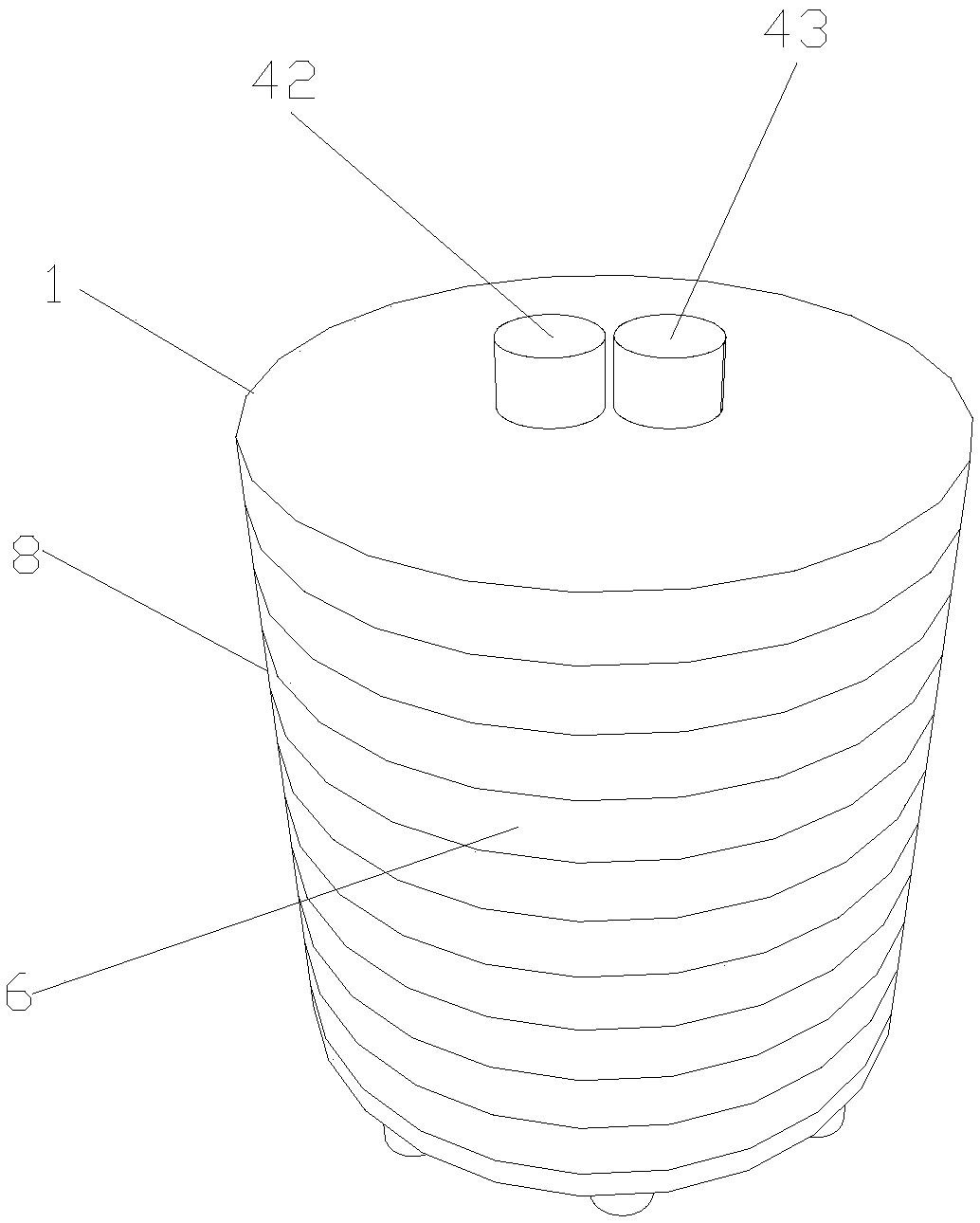

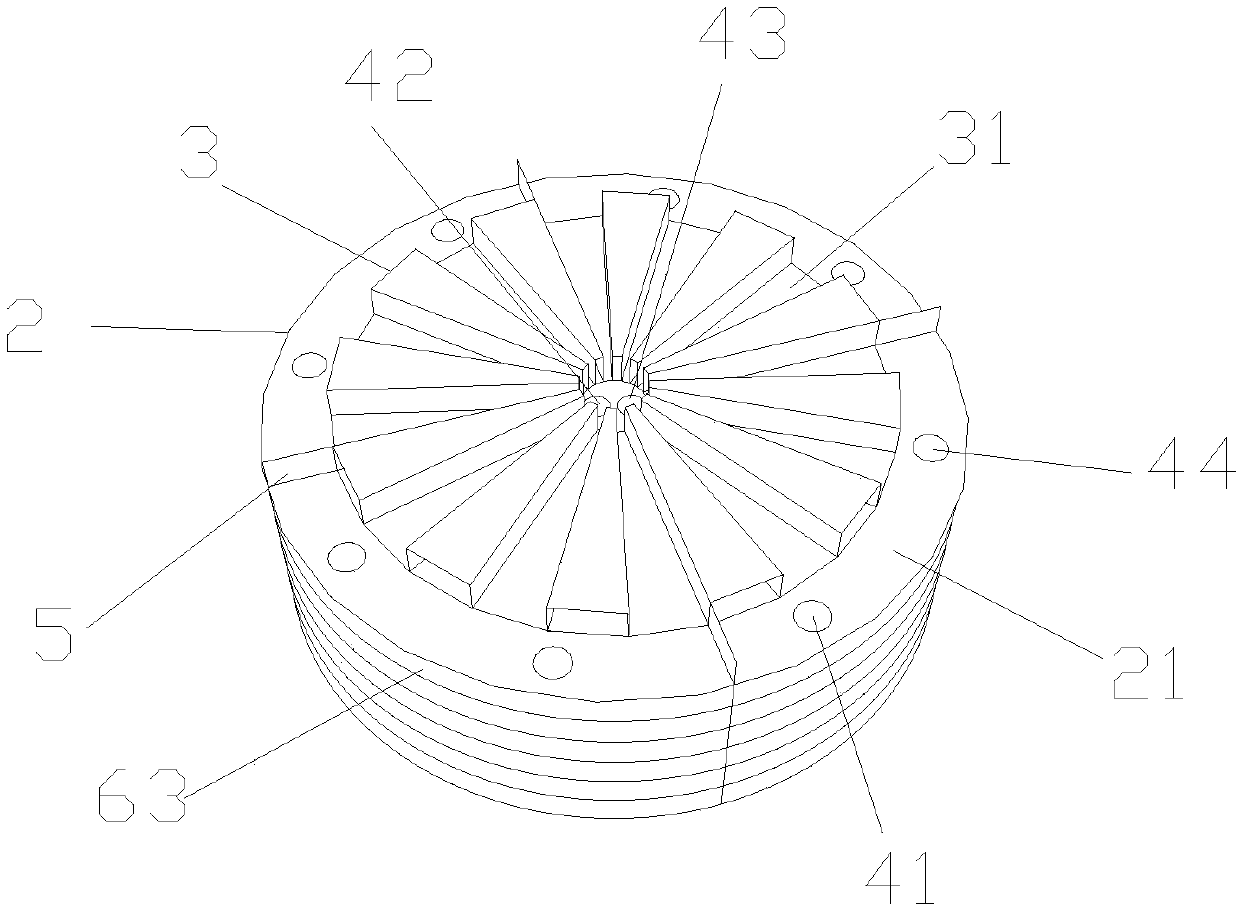

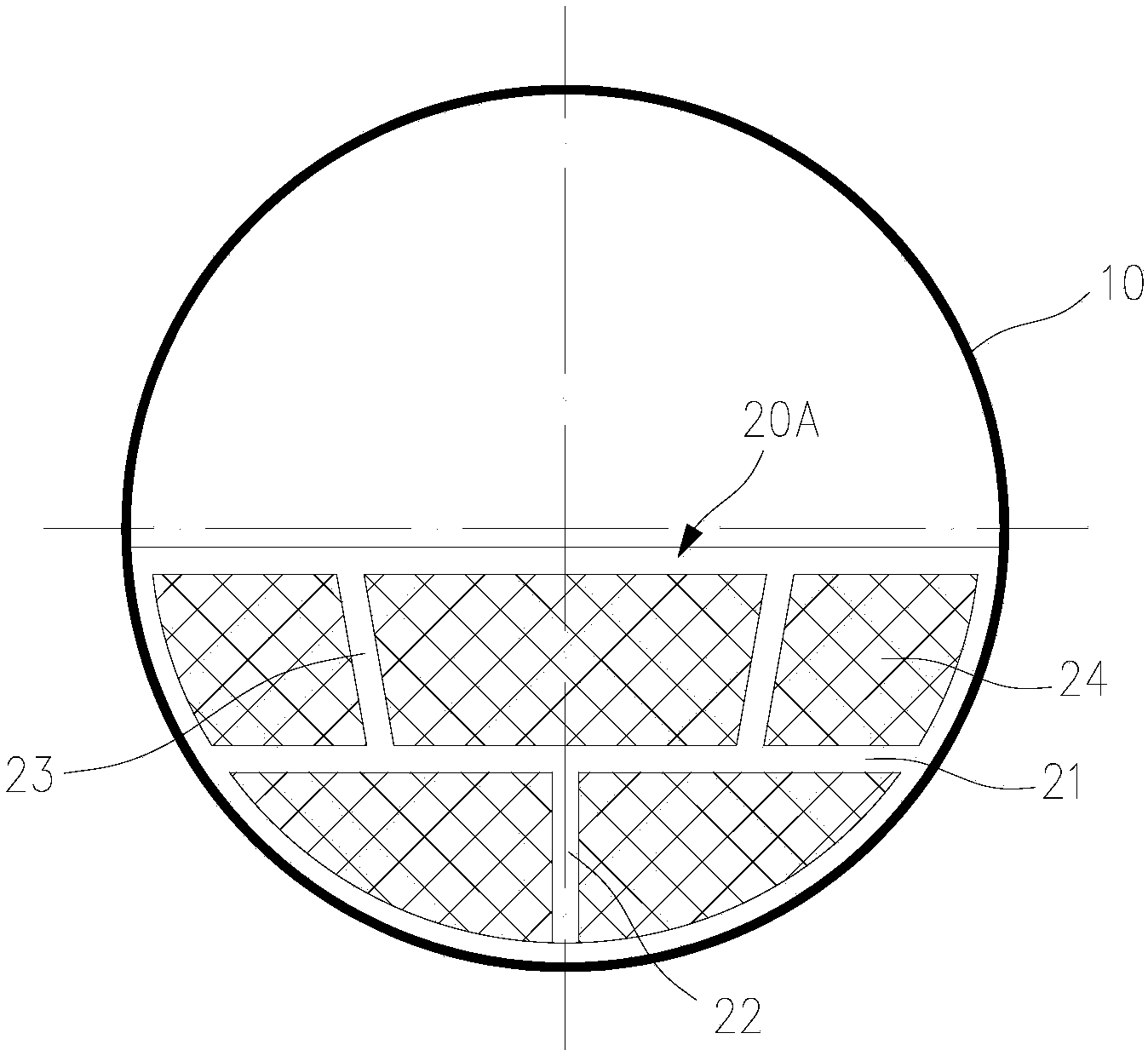

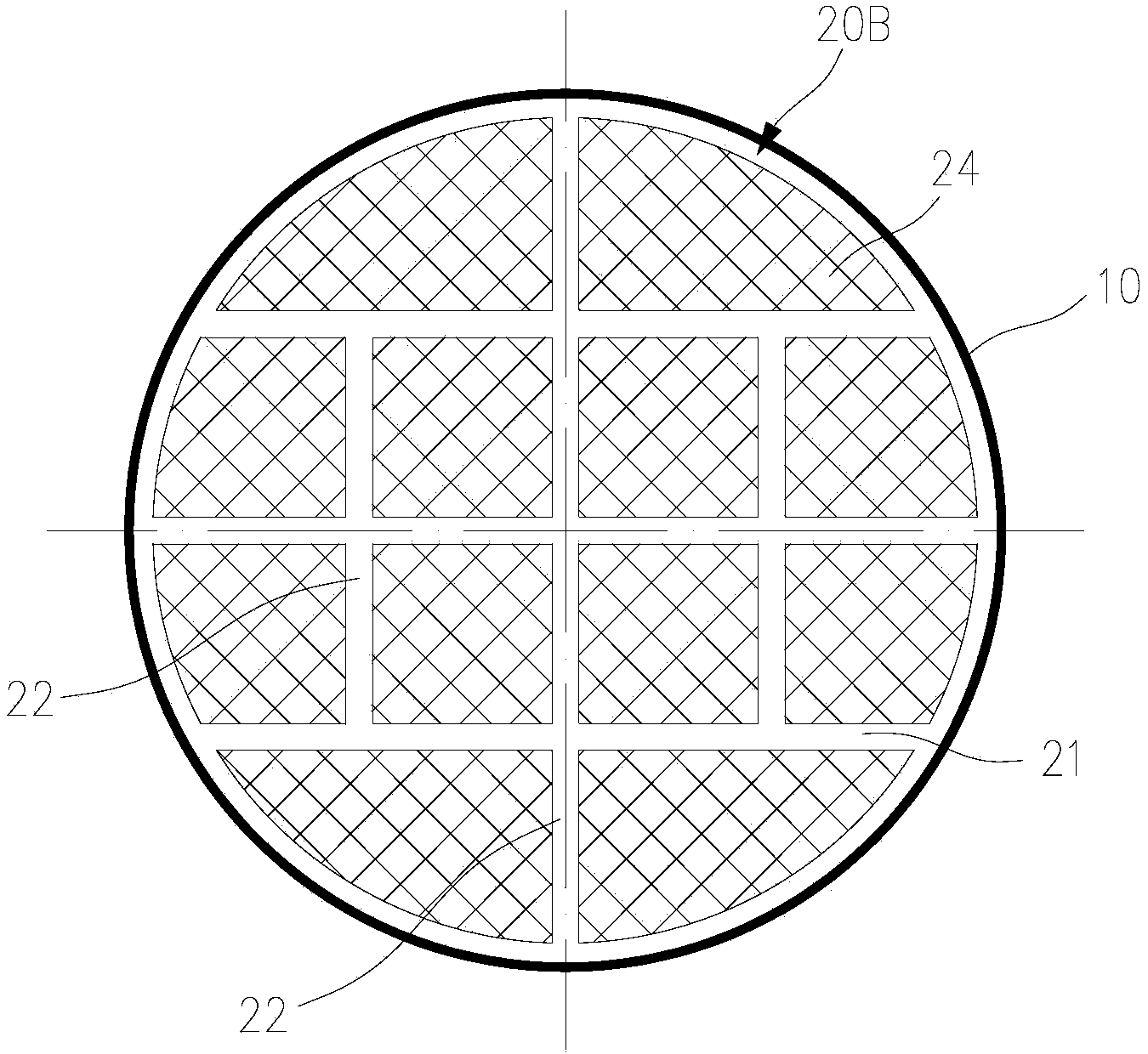

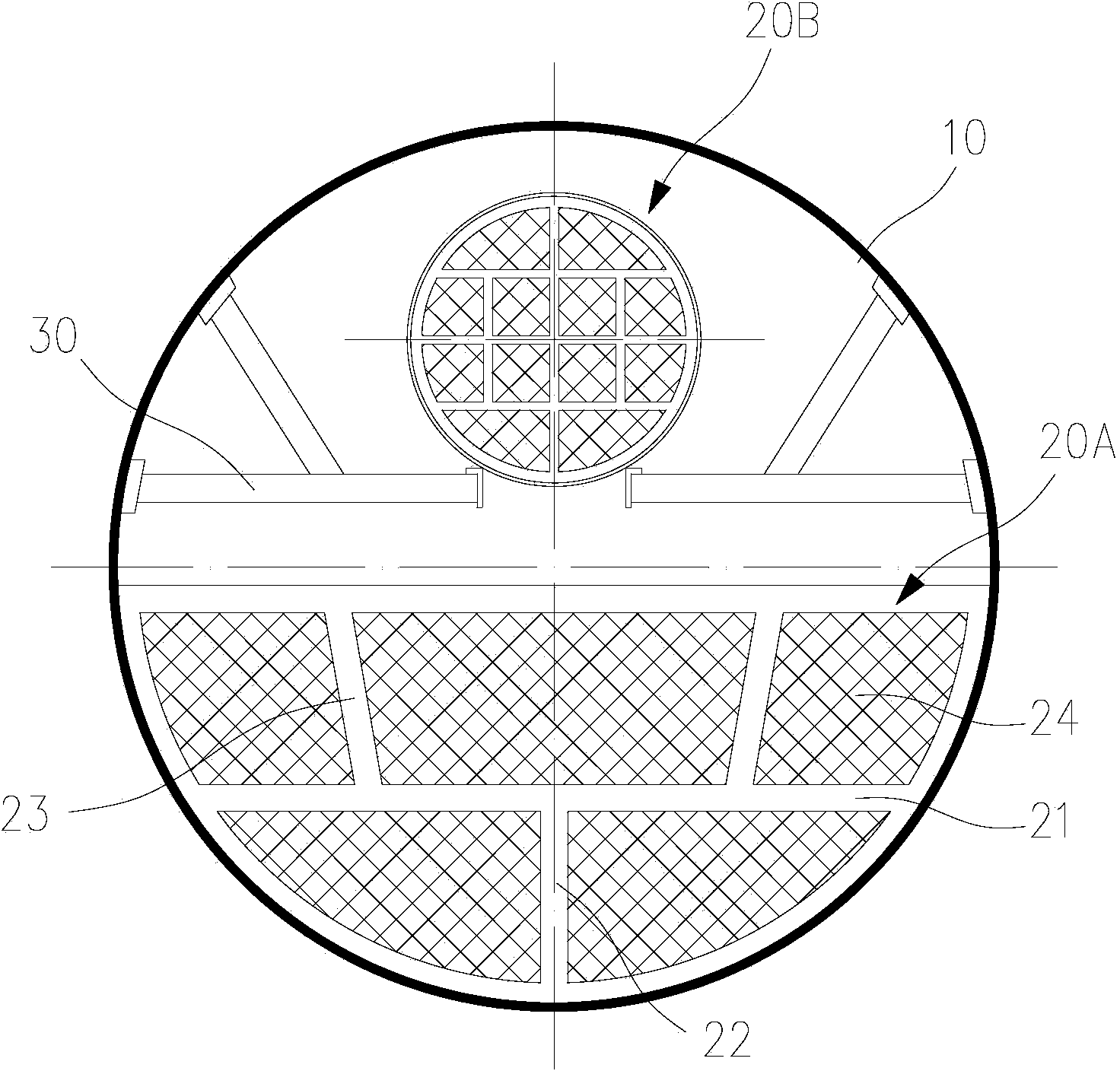

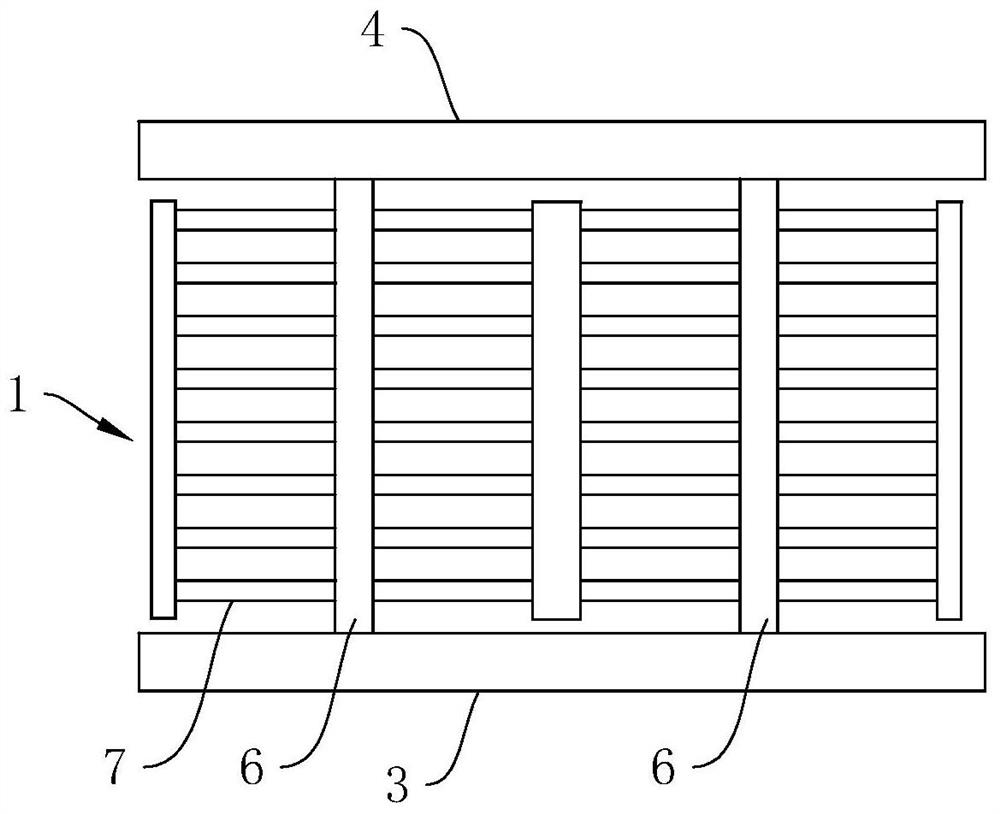

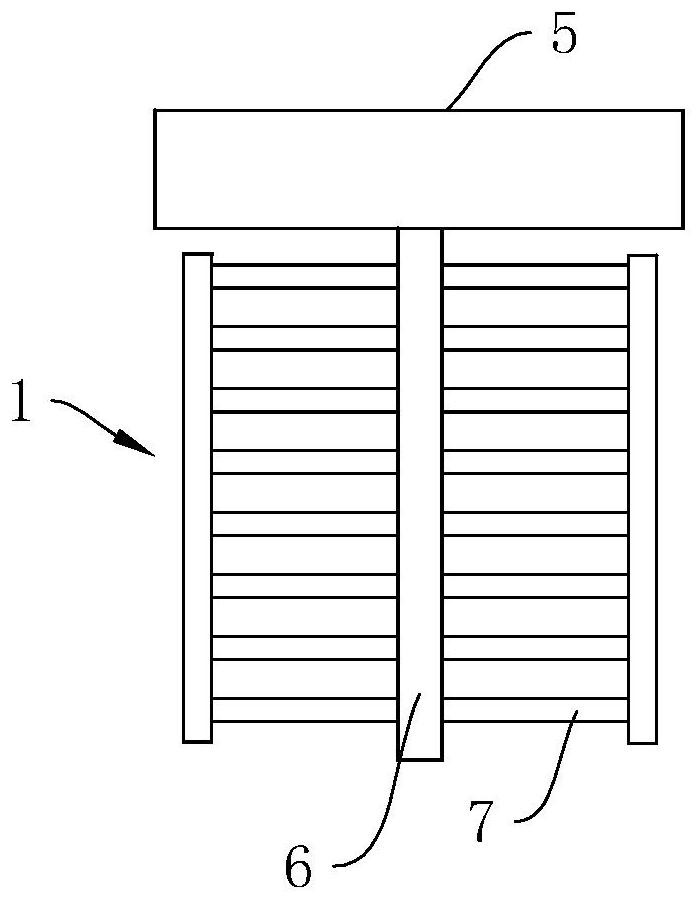

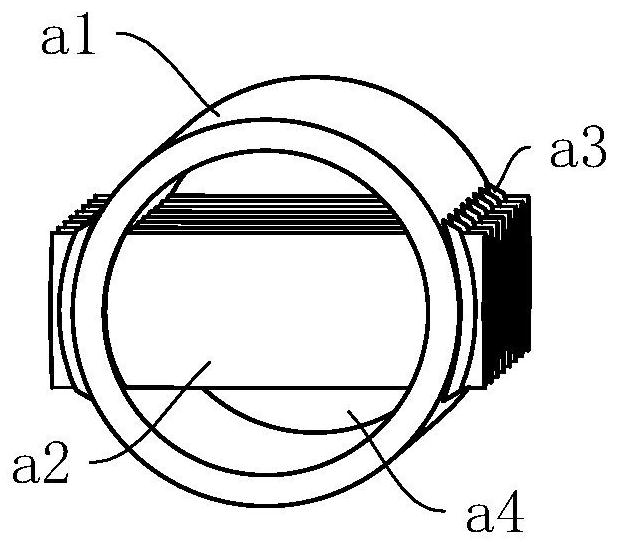

Finned tube fluidized bed heater

ActiveCN108827042AImprove heat transfer efficiencyIncreased turbulenceFluidised bed heat exchangersTubular elementsVertical tubeFluidized bed

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Electric heating tube with high output power and high heat transfer efficiency

PendingCN113038645ASpeed up distributionNovel structural designOhmic-resistance heating detailsHeating element shapesEngineeringHeat transfer efficiency

Owner:江苏奥凯自动化设备技术有限公司

Special plate-fin heat exchanger capable of being conveniently inspected and installed

PendingCN109556435ALaminated elementsStationary plate conduit assembliesHeat transfer efficiencyEngineering

Owner:WUXI BOLIDA HEAT EXCHANGER

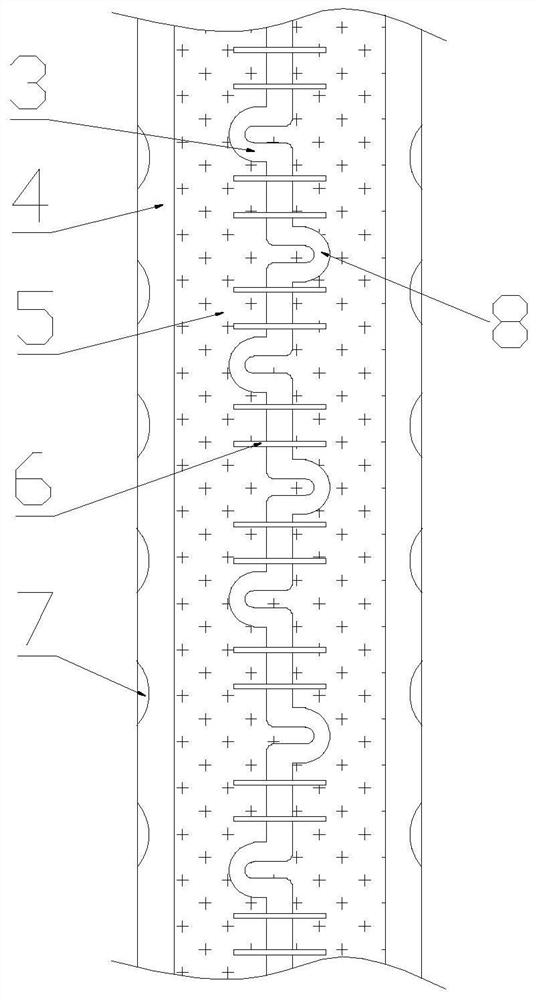

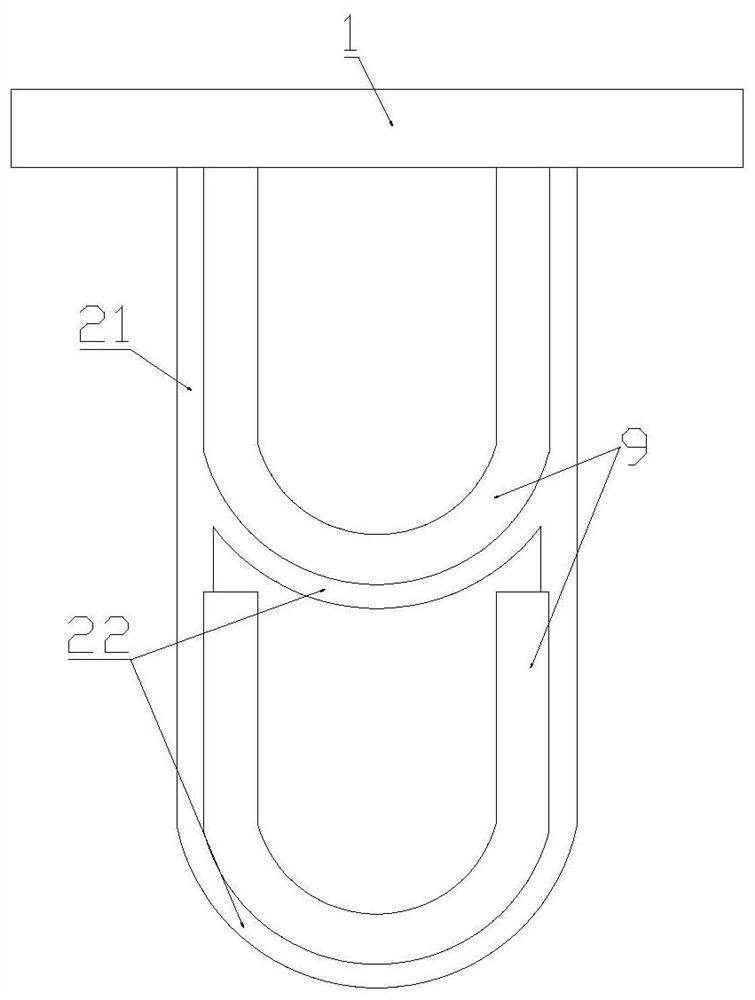

Piping structure suitable for heat exchanger with phase change

ActiveCN104165533AAvoid or even eliminate the problem of "short circuit"Improve mobilityStationary tubular conduit assembliesGas phaseProcess engineering

Owner:HEFEI GENERAL MACHINERY RES INST

Superconducting heat pipe solar water heating system

PendingCN113251673AEnsuring light-to-heat conversion efficiencyIncrease usageSolar heating energySolar heat collectors with working fluidsThermodynamicsHeat transmission

Owner:山东阳光博士太阳能工程有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap