Electric heating tube with high output power and high heat transfer efficiency

A high output power, electric heating tube technology, applied in the field of heating tubes, can solve the problems of low heat exchange efficiency and slow heating of the heating medium, and achieve the effects of increasing the heat dissipation area, increasing the current rate, and enhancing the heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

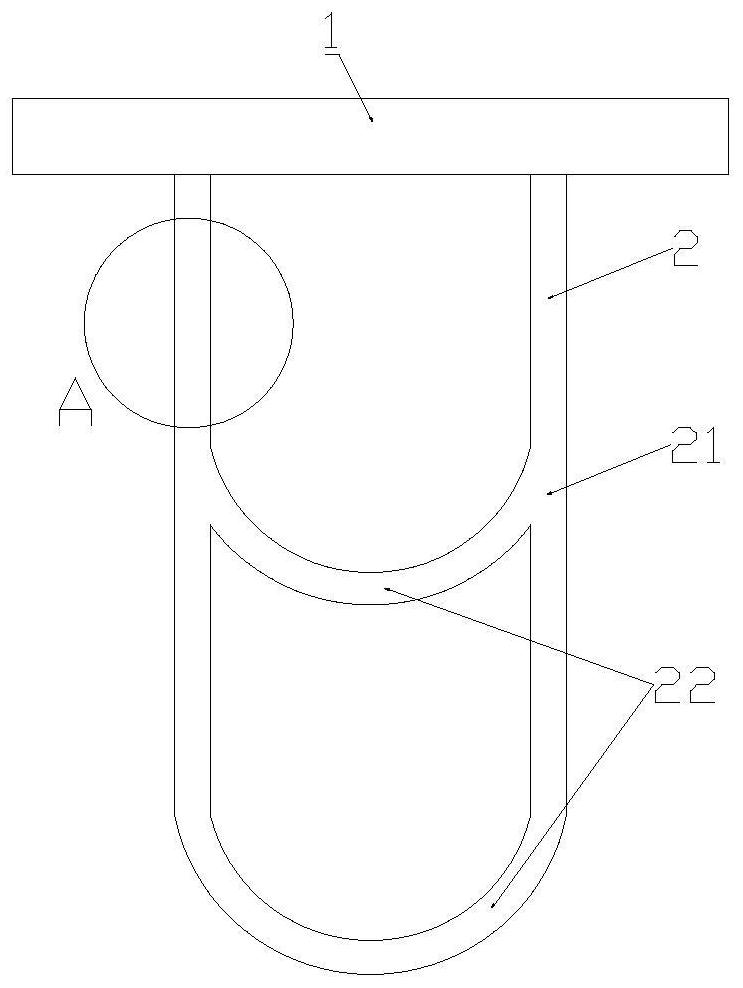

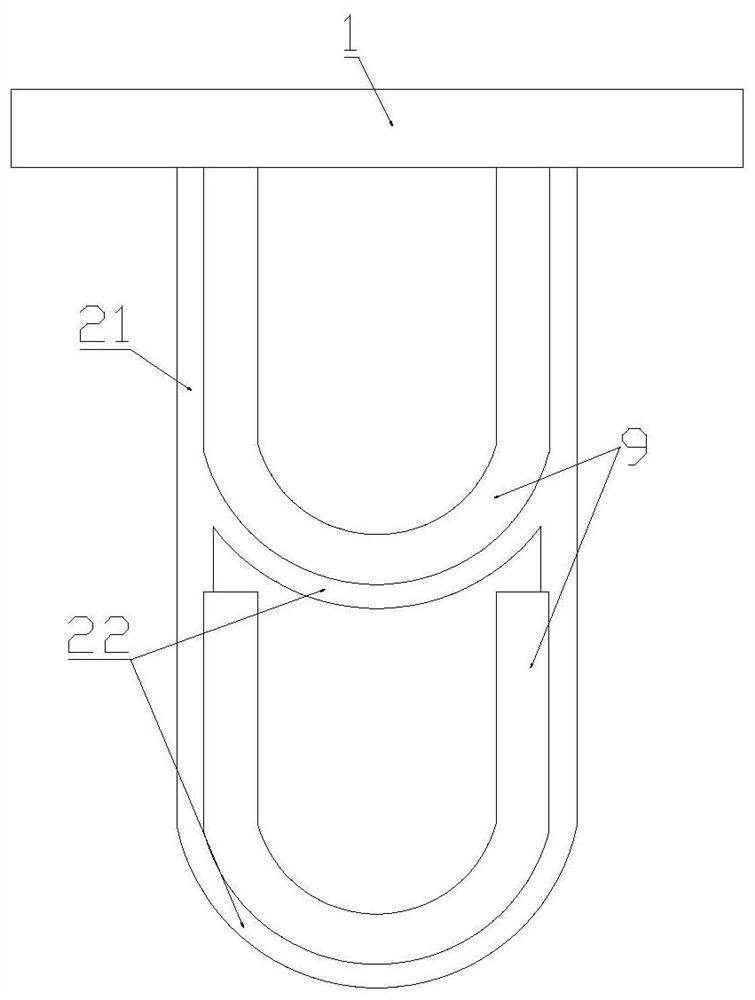

[0028] The heating mechanism 2 is provided with a metal heat radiating plate 9 in the inner portion of the straight heating tube 21 and the curved heating tube 22, and the metal heat radiating plate 9 is a curved structure. Since the direct heating tube 21 and the inner heat of the curved heating tube 22 are more concentrated. Therefore, the uniformity is low, so that the inner temperature of the heating tube is high, one aspect, uniform heating is made to the heating body, and the electric heating tube is damaged due to the concentration of heat, and the electric heating tube is lowered.

Embodiment 2

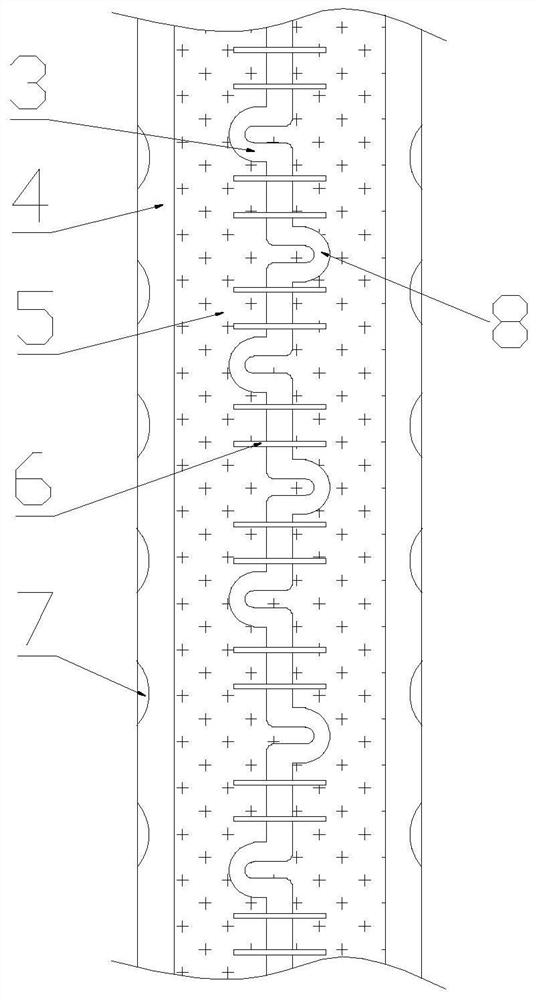

[0030] The distribution of uniform intervals on the metal heat dissipation plate 9 has a plurality of heat sink 10, the heat sink 10 is a curved structure, and the heat dissipation area of the metal heat dissipation plate 9 can increase the heat dissipation efficiency.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap