Compressive underground engineering pipe

An underground engineering and pipe body technology, applied in the field of engineering pipes, can solve the problems of no classification and storage function, unsatisfactory compression and impact resistance, poor corrosion resistance, etc., to achieve convenient classification and storage, novel structural design, and improved impact resistance The effect of capacity and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

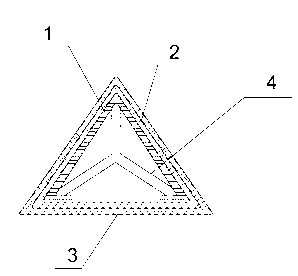

[0012] As an embodiment of the present invention, see figure 1 , The present invention includes a pipe body 1, the cross section of the pipe body 1 is an equilateral triangle, the outer wall of the pipe body 1 is provided with a reinforcing layer 2 and an anti-corrosion layer 3 sequentially from the inside to the outside. The tubes are glued together, and the tube body 1 is provided with a "herringbone" shaped partition 4, which divides the tube body 1 into three independent chambers. The top corner of the pipe body 1 is chamfered.

[0013] The section of the pipe body 1 is an equilateral triangle, which directly improves the overall resistance and pressure resistance. The reinforcement layer 2 can further improve the overall strength, and the anticorrosion layer 3 can improve the corrosion resistance. The pipe body 1 is provided with a partition 4, Convenient for classified storage.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap