Special plate-fin heat exchanger capable of being conveniently inspected and installed

A plate-fin heat exchanger and fin technology, which is applied in the field of plate-fin heat exchangers, can solve the problems of constant flow channel width, slow thermal fluid speed, and low heat transfer efficiency, and solve the problem of installation size Check the effect of job complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

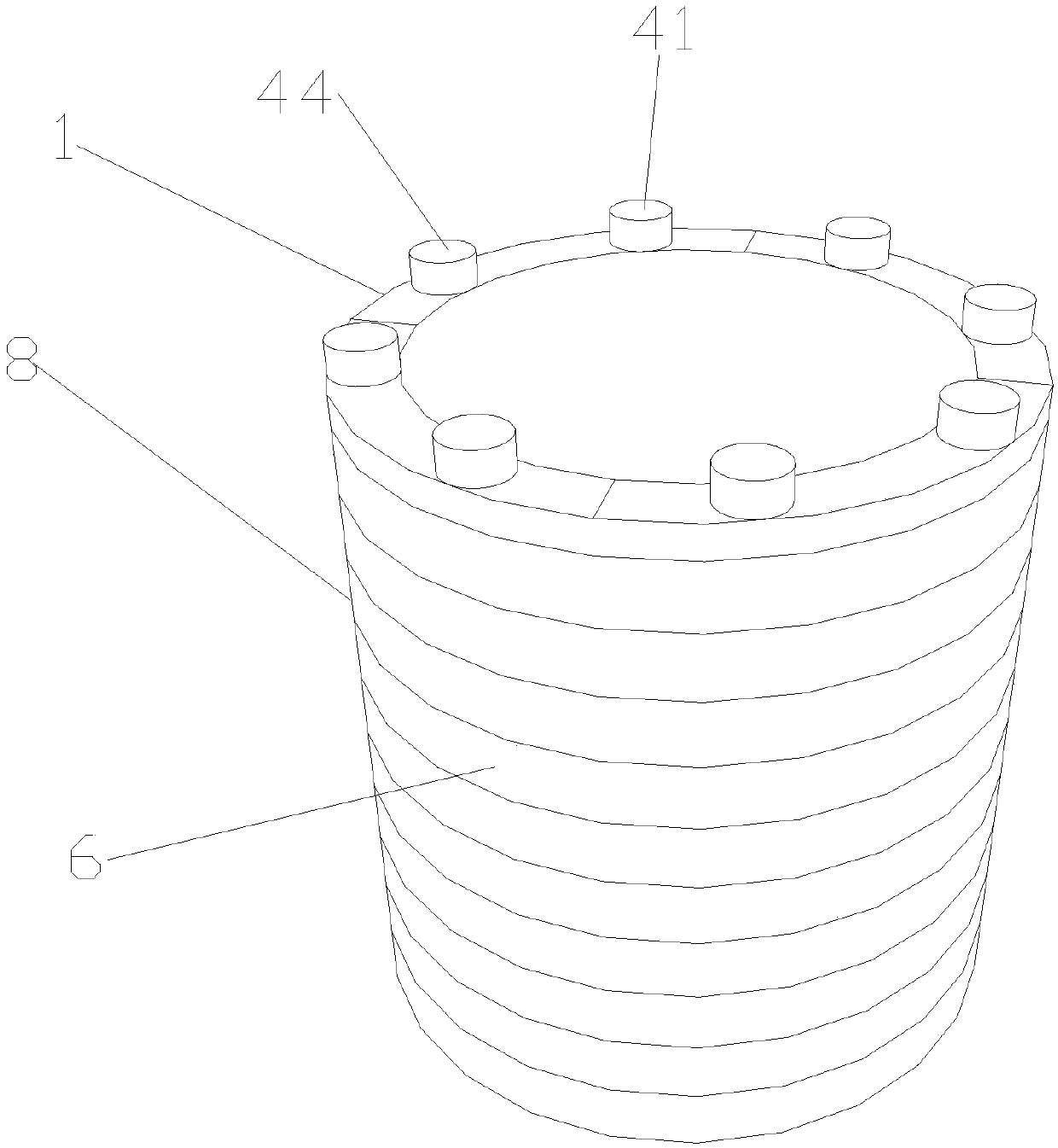

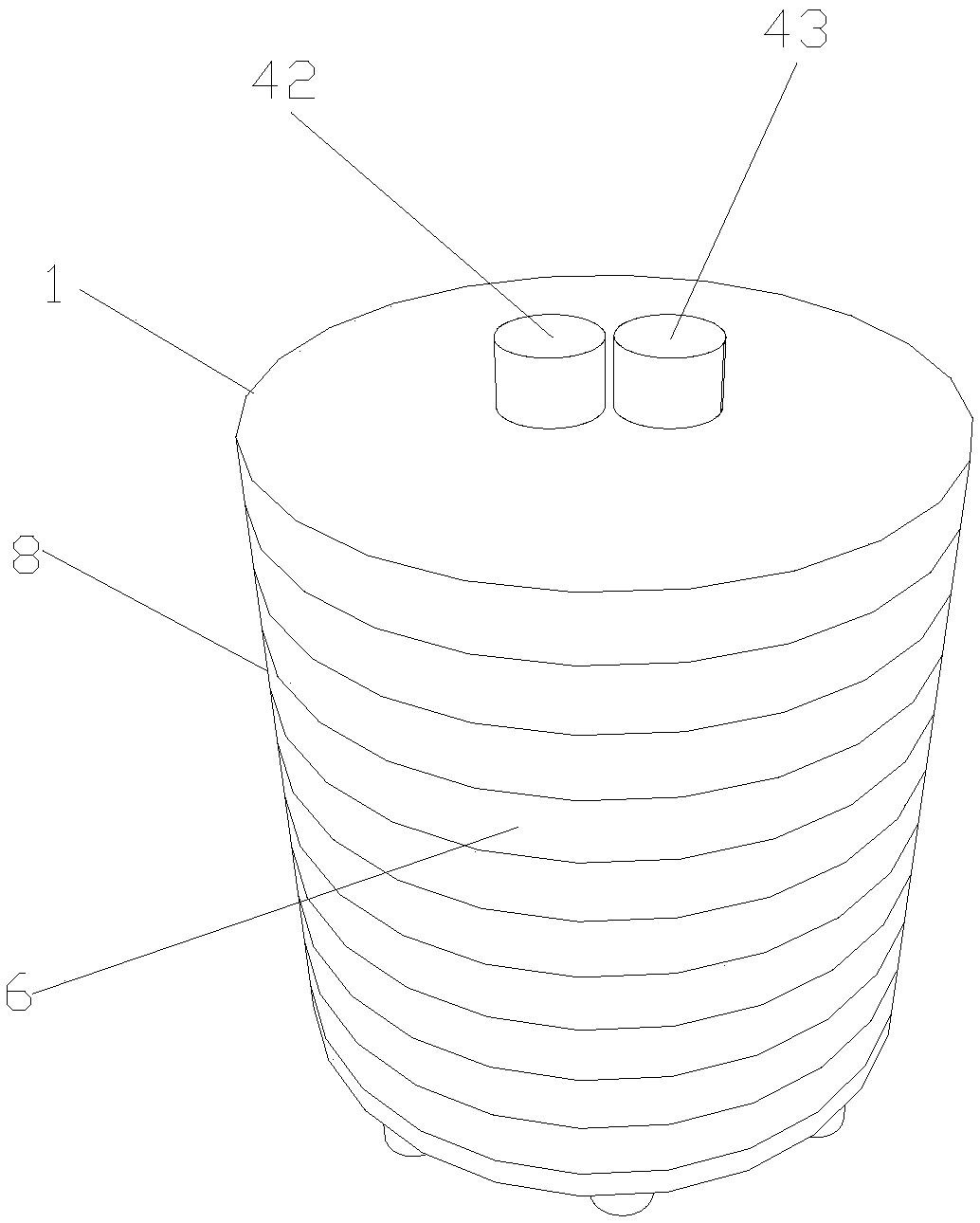

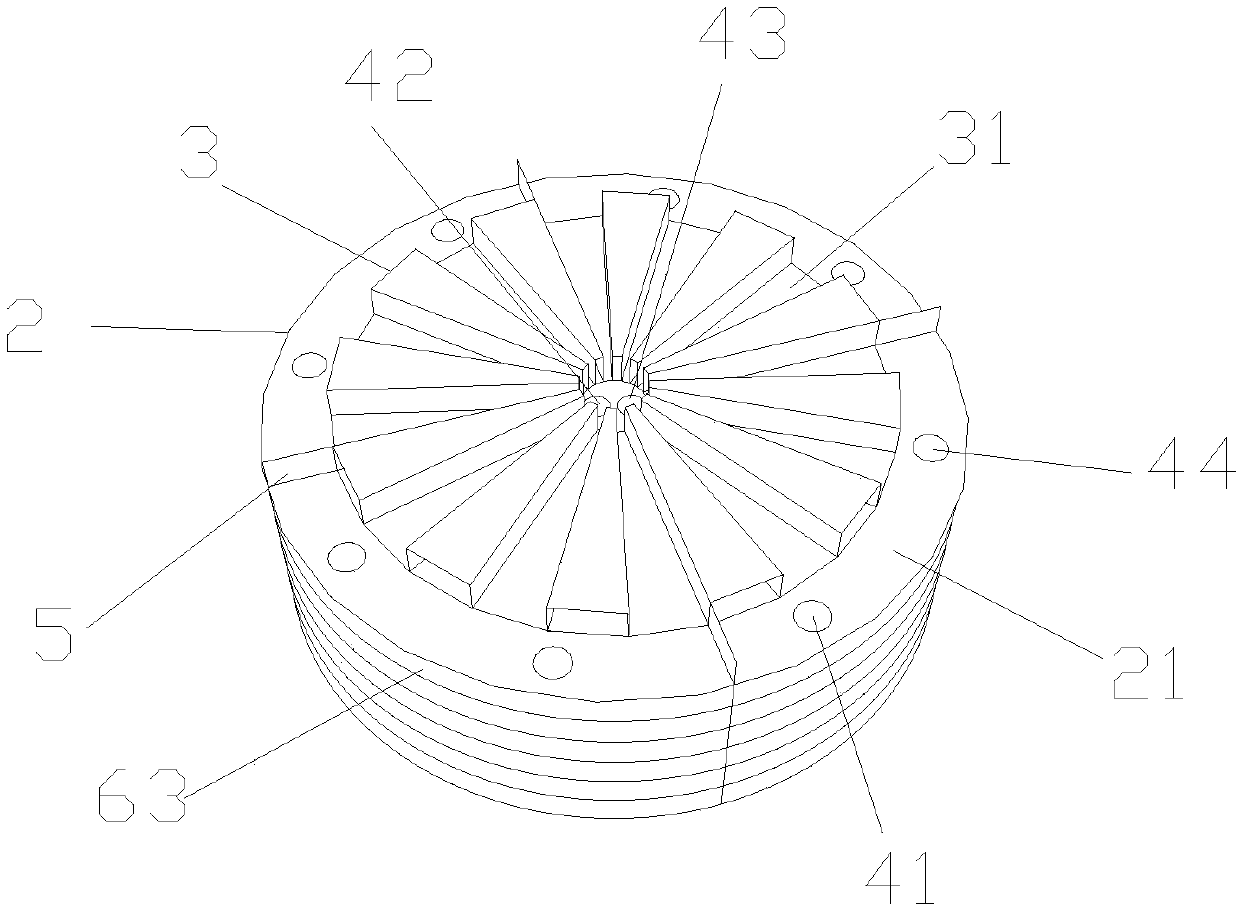

[0027] Such as Figure 1 to Figure 7 As shown, a plate-fin heat exchanger that is convenient for special inspection and installation provided by Embodiment 1 of the present invention includes a core body 1; the core body 1 includes a channel 6 for fluid circulation; channel 6 includes a hot channel for heating fluid circulation 61 and the cold channel 62 for the circulation of cold fluid; the hot channel 61 and the cold channel 62 are arranged at intervals from top to bottom; a partition 2 is arranged between the hot channel 61 and the cold channel 62; the channel 6 is annular; the channel 6 is set There are fins 3; the fins 3 divide the passage 6 into several fin passages 31; the fin passages 31 are arranged radially along the passage 6; One end of the center of circle increases gradually; It also includes hot fluid inlet 41, hot fluid outlet 42, cold fluid inlet 43 and cold fluid outlet 44; hot fluid inlet 41 communicates with the wide end of the fin channel 31 of hot channel 6

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap